Bruce

Members-

Posts

37 -

Joined

-

Last visited

Personal Information

-

Location

Reading

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Bruce's Achievements

Member (3/5)

0

Reputation

-

How to attached studwall with cavity with no ceiling connection

Bruce replied to Bruce's topic in Heat Insulation

They are quite assertive that they cannot give tips/tricks or recommend anything really, just confirm or deny design suggestions due to liability reasons. I really think that with a bit of dpc and those sloped brackets that they will be happy so we are goign with that for now. -

How to attached studwall with cavity with no ceiling connection

Bruce replied to Bruce's topic in Heat Insulation

Sorry but I don't understand the question? Are you telling me it has to be SS? The reason I have looked at the one pictured was that I don't see how to use those ties when the brick wall is already in place. But maybe they can be bent and drilled out to work? BCO didn't seem to like the idea of any timber touching the external wall (on the "external" side of the VCL), but yea it looks like the window board is going to have to be part of the stud wall structure/fixture. -

How to attached studwall with cavity with no ceiling connection

Bruce replied to Bruce's topic in Heat Insulation

BCO have clairfied that they expect any wall ties to have sufficient slope towards the external wall or have a drip in them. We intend to use the below type combined with DPC which hopefully gets their approval. -

How to attached studwall with cavity with no ceiling connection

Bruce replied to Bruce's topic in Heat Insulation

That souunds like a good sollution. I was somehow fixated on using a timber batten as a bracket which aboviusly they where not happy with. Your sollution with a steel bracket I didn't even think of. -

How to attached studwall with cavity with no ceiling connection

Bruce replied to Bruce's topic in Heat Insulation

To avoid leading any pentrating water/moisture that comes through the brick to the timber frame as per BCO demands. -

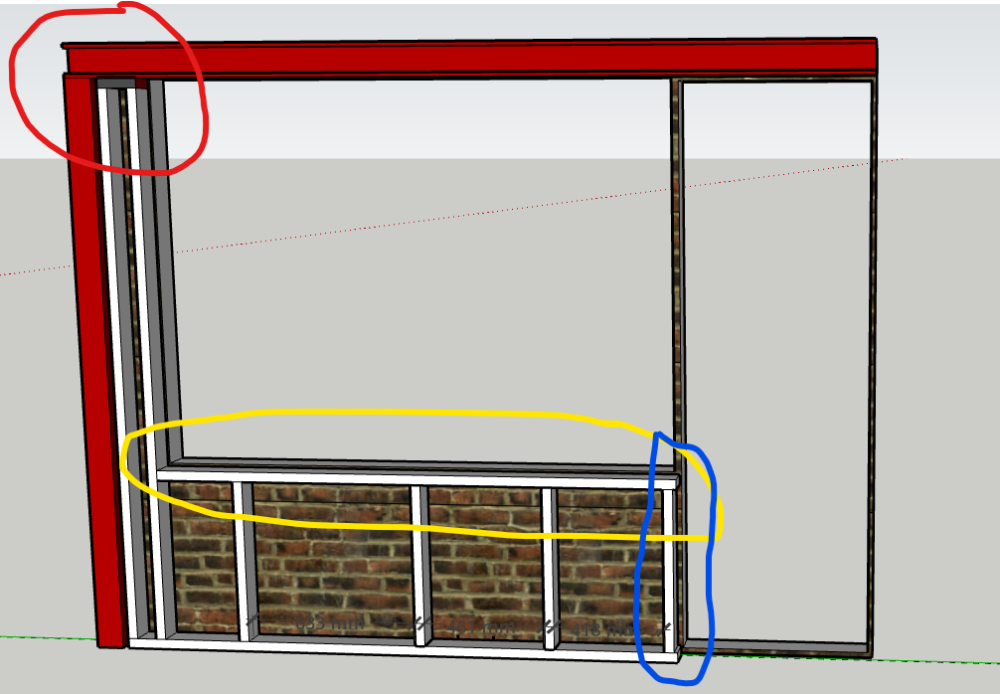

We are currenly insulating and external wall with a timberframe and a cavity to the studwall, the goal is to not to attach the fram to the brick att all if possible. The crux is that the wall is under a window and then it ends at a door so no ceiling nor no side connection. Does anyone have an idea on how to build this without making it super wobly? I guess we need to attach it somehow to the wall but I'm not sure how to do that and make it BC compliant. To the left and above the window we have steel that we can potentiall connect to. Is there any spacers that can do the job or can the window board just do it all? Though that doesn't stop the wall from movin away from the brick wall.

-

Waterproofing window sill with too little incline

Bruce replied to Bruce's topic in Waterproofing & Sealants

I forgot to take a picture but I measured the slope to about 3°, so definitely on " too flat" side. -

Detail of IWI on single skin / half brick wall for picky building control

Bruce replied to Bruce's topic in Heat Insulation

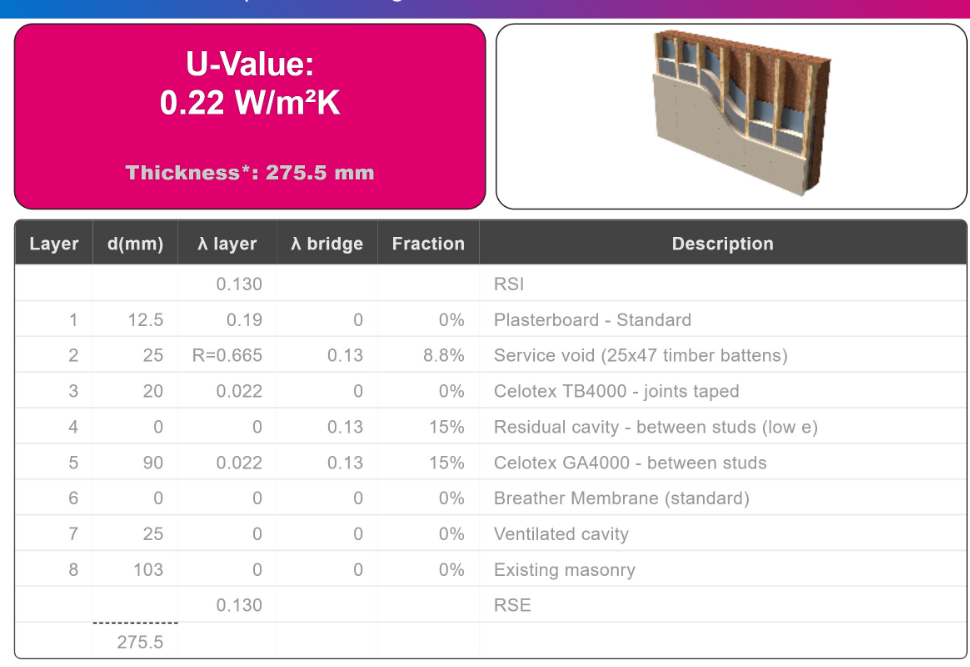

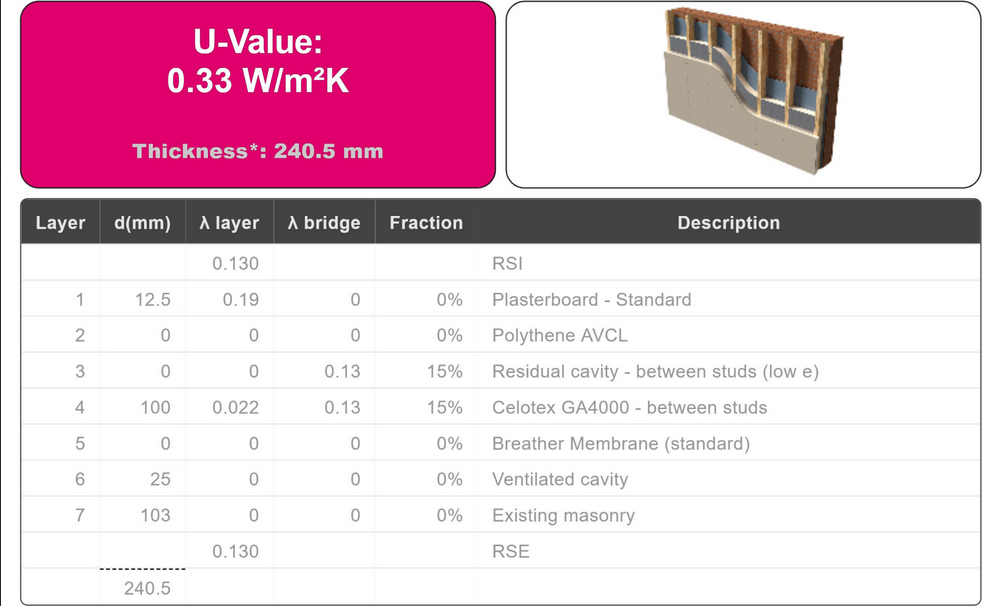

DPM then 75mm PIR and joists with 18mm floor boards with UFH system on top (22mm). Not really, it would look really awkward with the rest of the external wall on that side. We have submitted to the BCO now with the timber wall solution from Celotex with the following layers + a VCL between the service void and 90mm studs instead of relying on taped PIR joints. What I'm thinking is that perhaps the service void could be turned 90deg (i.e. lying down) to reduce cold bridges and even make it easier for cables as they will run horizontally rather than vertically. I bet there are good reasons not to do it, but it seems reasonable when thinking about the thermal bridges. -

Waterproofing window sill with too little incline

Bruce replied to Bruce's topic in Waterproofing & Sealants

Thank, I will take a picture with my smallest level and post it. Not to be lasy but rather asking for experience, do you have a link to the EWIstore that you used? TIA -

Waterproofing window sill with too little incline

Bruce replied to Bruce's topic in Waterproofing & Sealants

It's the tiles that they complain about. -

Waterproofing window sill with too little incline

Bruce replied to Bruce's topic in Waterproofing & Sealants

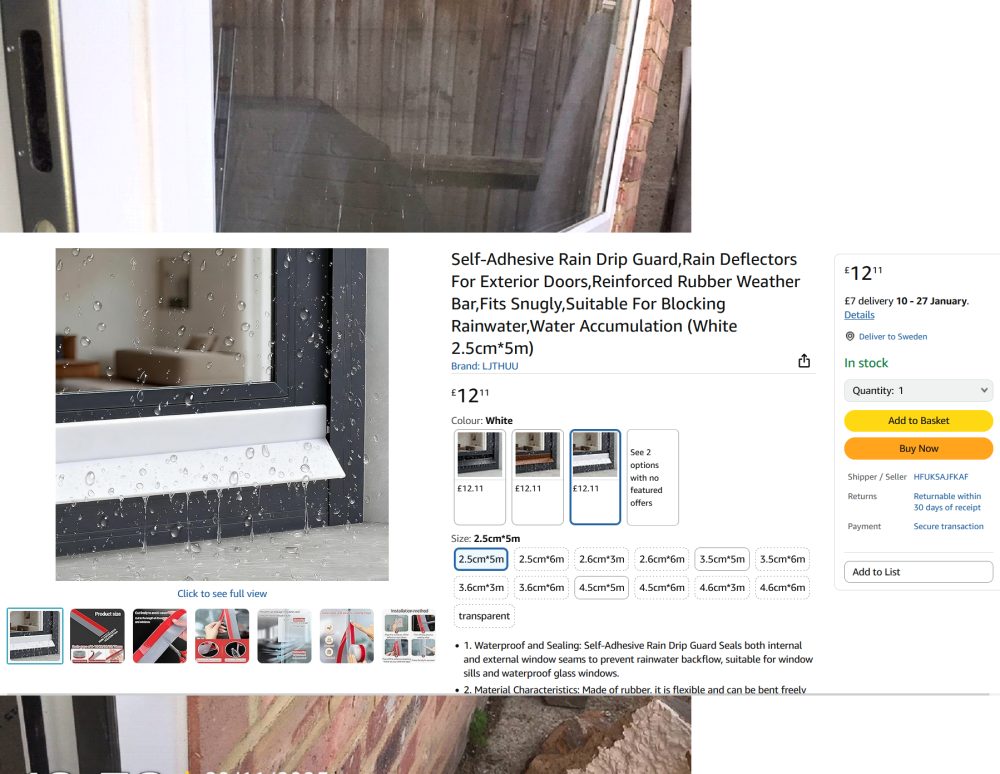

I like the look of that but not sure if it helps with the incline of the sill if just mounted on top of it? -

Our BCO is not happy with the incline of our window sill and say it might lead to water ingress. They alluded that the sill should not need redoing but they were not allowed to tell us how. So I'm after any ideas that we can use/submit on how to retrofit a simple solution to this problem. I'm thinking maybe suggesting something like the below pictured diverter but wanted to see if someone else has done something clever before me? We have had this window like this since August, without any selaent under it (life got in the way) and it has never leaked.

-

Detail of IWI on single skin / half brick wall for picky building control

Bruce replied to Bruce's topic in Heat Insulation

Roof is already converted, 170mm Celotex. Windwow is double glazed and door tripple. We are going to suggest as change to the following celotex soolution + another 25mm insulated service void behind the plasterboard which adds a tad more insulation. We are excempt of the u-value due to the limited floor space so don't worry about the non compliant u-value. -

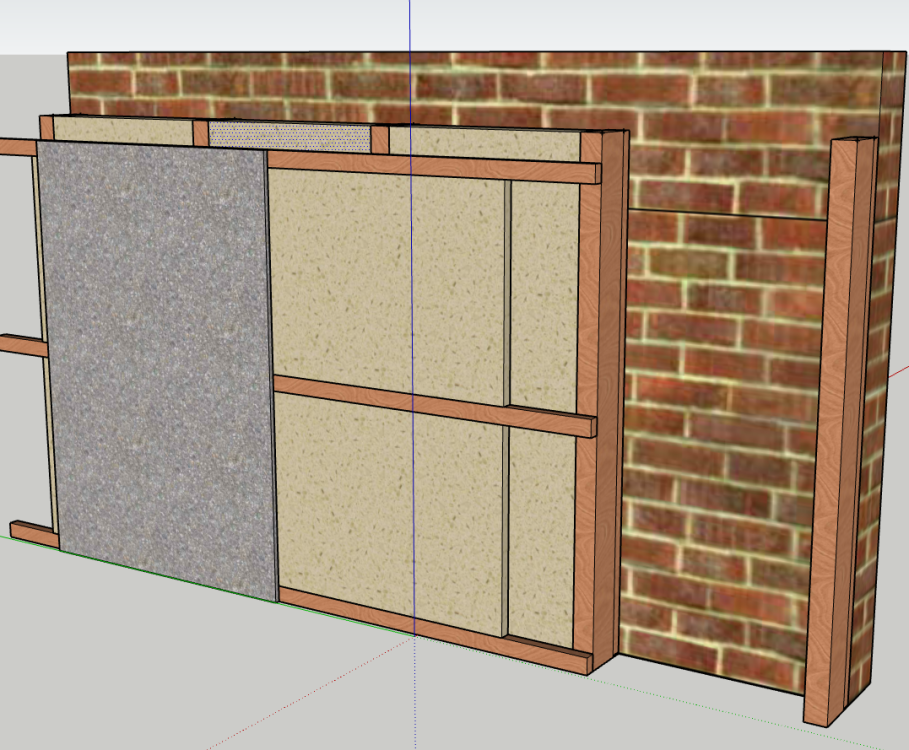

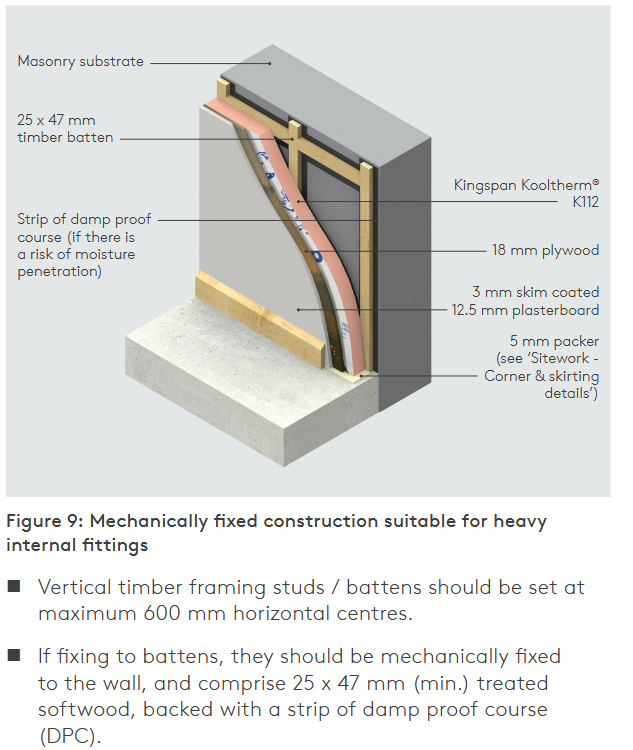

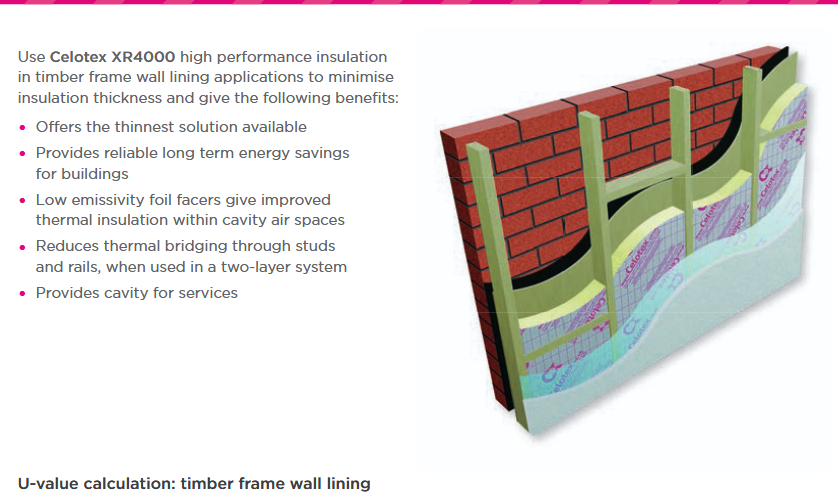

We are insulating our conservatory to bring it into the heated envelope of the house and was going to use the SWIP system but our building control won't approve of it as SWIP have their BBA certification done on a double brick wall rather than just one brick. It is also rather expensive with not great insulating performance but I was prepared to take that hit but I just feel deflated by the retraction of approval from the BC. So I am abandoning the idea of having a vapour open insulation and will go with a more traditional PIR insulated wall. But to make them happy, I need to submit a detail of what we are going to do. What I want is something similar to the one below from Kingspan but I want it to be PIR manufacturer agnostic or from a manufacturer that doesn't charge £350 for two sheets of insulation. I really like how simple it looks. Has anyone done this with Celotex GA4000, how do I do that and make BC happy? Alternatively, we could do the stud system based on below Celotex system (but this one seem outdated and cannot find an updated version). But using a timber stud wall like that, how do you create the distances needed to create the cavity, just blocks on treated timber? Any help appreciated.

-

Joe, we are finally on our way with the garage. Slab poured yesterday and the garage should be delivered in about 4 weeks. Did the Fixall adhesive solve the water ingress issue for you? I'm looking into what ashesive to put under my plast boards and want to it it right from the start. Sounds like you have no succes the with the PU/foam strips.