amavadia

Members-

Posts

90 -

Joined

-

Last visited

Everything posted by amavadia

-

Thanks!

-

Hi all I am building a deck and a pergola on top of it. The deck is 25cm off the ground level. Ive been reading PD and it says structures can be 2.5m tall max when its near the boundary (which it is). Ive also read in other places a 30cm allowance for decking. Question: Is the 2.5m structure height including the decking allowance or can the finished height be 2.75m near the boundary if the decking is 0.25m like in my case? Thanks

-

Anyone have recommendations for a woodstain which will make standard light redwood look like a light oak colour? I have made windowboards out of it and would like to change the finish of them to more closely match my oak doors and mantel. I have Osmo clear matt oil to put on top so just need the stain. If you have done something similar please post a pic of how it turned out ?

-

Morning I have a a large mirror which I recessed into a tiled wall in the bathroom so that it is all level. There is a small 2/3mm gap all around the edge of the mirror between it and the tiles which I am looking for a product to fill in. Mirror supplier said grout or silicone will eat away at the back of the mirror if it gets in contact and suggested just using the same adhesive as used to stick it on. Ideally I wanted a black colour but cant seem to find black mirror adhesive anywhere. Found white and grey. Anyone know of any products I could use for this? Thanks

-

Fixing carpet grippers to smooth latex screed

amavadia replied to amavadia's topic in General Self Build & DIY Discussion

Im fitting myself mate. Done the upstairs rooms and stairs already and this is for the lounge. I got the carpet as a remnant so just need to figure out what to use for this. I might just get some of the green standard Evostik and give the edges a good wet clean first. Had read about doing it in 8" sections so will do that. -

Fixing carpet grippers to smooth latex screed

amavadia replied to amavadia's topic in General Self Build & DIY Discussion

Is that standard evostik the green tube? -

Fixing carpet grippers to smooth latex screed

amavadia replied to amavadia's topic in General Self Build & DIY Discussion

There are just so many grab adhesives out there now! Evostik do an extra strong one too: https://www.toolstation.com/gripfill-xtra/p98918 I saw the super fast gripper @PeterW but reading online seems like fitters use it mainly because it goes off very quick so they can stick the grippers and start fitting in one go. Since I am in no rush I can glue it down one day and then fit another day. Maybe just need to pick one. Any thoughts on priming? -

Hi Need a bit of advice. I used a latex based screed to self level a floor downstairs which I am now looking to carpet. I want to glue the gripper strips rather than nail. Speed is not an issue as I can leave it to dry over night but looking for recommendations on the best adhesive to use. Some people suggest hot glue guns with a certain type of glue, some say just normal grip adhesive. The surface of the floor is smooth rather than rough like concrete and its been open and subject to plaster blobs etc. for some time, so while Ive cleaned it, it still has a bit of residue on it. I was thinking about this stuff: https://www.toolstation.com/griptite/p94608 Just wondering whether maybe I should prime the edges of the floor first? I have half a tub of tiler's primer left (acrylic based), would that be good enough? Thanks

-

So I contacted the vendor and they said the brackets are 'surplus to requirements' and not needed. Strange they would include them then.

-

Thanks for the reply. The unit came with normal L brackets for fixing to the wall which are the same as the brackets which came with all the other base units. Ive used those already. These two only came with the oven unit and are quite thick sturdy. Was wondering whether they are used to fix the oven to the unit in some way or something?

-

Hi so I’ve just finished fitting most my kitchen. The 600 built under unit for the oven came with these brackets. No mention of them on the assembly instructions for the unit or in the main installation guide. Does anyone know what these are for and where they go? Thanks

-

yeah ill pop into Gas Centre tomorrow see if they have any idea

-

yeah the stainless steel thread is the same with 40mm outer diameter. The plastic fitting just adds the appliance nozzle. I tried googling but didn't find a euro 50mm. The sink was sold by a Chinese company. Maybe its an Asian standard size?

-

I bought a kitchen sink off eBay. Really nice but didn’t come with standard size plumbing. The waste trap seems great with a little basket catching any food which you remove with a handle and empty. Seems like a better idea than the standard traps which are annoying to get the food bits out of. Anyway I want to keep the trap part which fits to the actual sink and replace the p trap and pipes that came with it because they seem awful quality. I need an adaptor to change from what seems to be a 45mm diameter on the threaded part at the bottom to a standard 40mm uk connector. I don’t think it is a ‘euro’ size because they are smaller than uk and this one is bigger. any ideas?

-

Thats what I was thinking. I might cut out some of the back panel in the section where the standpipe is and just tape it back onto the back panel. Ive already put a socket under the drawer unit which can be reached by just removing the plinth and theres an isolating switch above counter top level. Water isolation valve is there under the unit too. It is just the standpipe which would have to go actually behind the unit.

-

I am fitting a kitchen at the moment and have a run of units and then a washing machine at the end on the right. I have a waste pipe running low down along the back/bottom of units and was going to put a stand pipe in for the washing machine however the unit adjacent is a drawer unit. The standpipe fits in the service gap behind it but if I put it there, there is no access to it afterwards if there are blockages. What do people normally do in this situation? The back of the drawer unit is just this flimsy board which is slotted into the groove on the sides of the unit which could easily be cut out in the worst scenario but its not easily accessible. Any suggestions? I looked at the size of integrated washing machines and there just doesn't seem enough space to put the standpipe behind it. I already have my standard 600mm worktops so wider worktops is not an option.

-

It says early next week. I imagine this company Plumb-Galaxy have a stock of the warmehaus rads in a UK warehouse where they get delivered from.

-

Thanks very much mate. Very kind. I think its fine now. I just verified the piping and my flow pipe is on the left which matches with their diagram of the inlet being on the left so should be all good! Rad ordered

-

Thanks for the link. all the items on Amazon from them are sold by a company called plumb-galaxy who are the people I got this diagram from and was thinking of buying from. They said as long as it matches the diagram it will be ok. But that is just a customer service team response not really knowing anything technical about the radiators. I also looked for them online. They had a twitter which hasnt been updated since 2018 either! I am just trying to trace my pipes to find out which is flow and return and if i'm not mistaken they are set up in the same configuration as the diagram so might not be an issue. There was a 50% chance it was right!

-

Hi all I am looking at a vertical column radiator for the bathroom. Plumbing is already in place in the wall at the correct width for the bottom valve locations. The diagram indicates the inlet at the bottom left and outlet bottom right with a water block in the middle which makes sense. Question is do these radiators have a one way valve in them or are they symmetrical with just a block? i.e. can you switch the inlet and outlet round so have inlet on the bottom right and outlet bottom left instead as long as both valves are at the bottom?

-

Ah so maybe not so easy to make it accessible then. The unit to the left is a drawer unit so would have to make the back panel removable. Its a thin board which slots into the grooves on the back of the flatpack unit at the moment.

-

Its an old photo before I connected the pipe. The stub above the 2 water pipes is where the boss is. A new boss would be a max of 10/15cm closer to the floor I think. Part of the problem is the length of the run being about 6m from the stack to where the washing machine is so I lose a fair bit on the gradient because I put a decent drop on to get a good flow (again not knowing about the standpipe issue which would come up later!) Does anyone know what the minimum distance from the horizontal waste pipe to the top of a standpipe that you can get away with is?

-

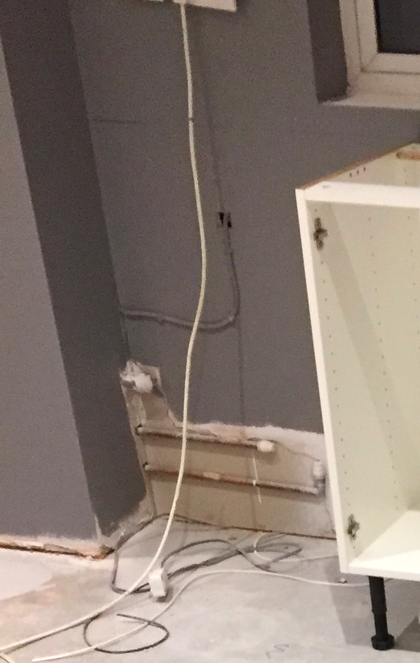

Not the best pic but this was a while ago. Waste pipe is connected and goes round the kitchen from the top outlet. Hot and cold attached and fitted round the kitchen on the bottom two now too. Its fully closed in. The waste pipe is about 35cm off the ground. The bottom 10cm are taken up by the clay socket for the soil stack, the hot water pipe is the next one up but it comes down from upstairs where the boiler is, on the left of the soil stack and then round the back of the stack and out the box section's right side so to move that up would need opening up the other side of that box to cut and re-solder the water pipe. I like the look of the waterless traps but would still like to understand what the potential issues are here which people are concerned about using anything other than a standpipe arrangement? Also it is going to be an integrated washing machine so would have to check there is enough space behind it for the fitting. If depth isn't an issue it would definitely be accessible. Do these things not drain fast enough? Do you need to let air in? Does the washing machine pipe need a peak of a certain amount before coming down and connecting to them? I am a novice and doing this all myself. If I had done a washing machine before I would have known about the boss height for e.g. but all a learning experience I guess... just a frustrating one. ?

-

Unfortunately the soil stack isn’t accessible anymore and been plastered in. Also there are water pipes coming out under the waste pipe so not really much opportunity to relocate it lower. I could lower it slightly by loosing some of the gradient but would still be about half way up the unit I think. Usually under sink waste traps have appliance inlets which have a direct connection where washing machines can connect rather than a standpipe arrangement. Is there a particular reason it wouldn’t work at the end of the run?

-

Hi all bit of advice please... putting in a new L shaped kitchen and the washing machine will be at the end of the long run of units. About 5m away from the soil stack the waste is going into. The sink and dishwasher will feed into the waste pipe earlier about 1.5m from the stack. It’s already taken out of the stack too high at about 40cm, and then as there is a gradient to allow water to flow, by the time it gets to the washing machine location it’s too high for a standpipe. I was thinking of putting an air admittance and then a running ubend like below and then an appliance inlet, the kind you find on a waste fitting under the kitchen sink. https://www.toolstation.com/running-trap-76mm-seal/p63996?store=EF&utm_source=googleshopping&utm_medium=feed&utm_campaign=googleshoppingfeed&gclid=CjwKCAiAxKv_BRBdEiwAyd40N47zgB-l74Ot0j0kGtuLqG-RlFeDKsCy8qK_gPmszuXZykDUM3gOnBoCoIcQAvD_BwE Would this be ok or are there better options?

.thumb.jpg.09d464a37facc67925374419cb50ec1f.jpg)