Beelbeebub

Members-

Posts

1224 -

Joined

-

Last visited

-

Days Won

6

Beelbeebub last won the day on January 23

Beelbeebub had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Beelbeebub's Achievements

Advanced Member (5/5)

276

Reputation

-

Has anyone gone through the process of upping their export limit? I have an 8kw inverter limited to 3.68kw. I suspect my G99 was done (by the installer) on the fast track, hence my 3.68kw limit. I want to reapply to get it upped as they have done some work on my local network (and to compensate for the lower export rates). I've been going round in circles as everything on the website (national grid) is either the g98/G99 fast track - which assumes you are notifying of a sub 3.68kw system or the G99 full route which assumes the system isn't yet up. There doesn't seem to be a button or form for "here is my existing permission for this system, can I up the limits please" Anyone got any pointers?

-

what i should not have done when installing solar

Beelbeebub replied to scottishjohn's topic in Photovoltaics (PV)

Mine is based on the decidedly old school economy 7 tariff that's been around forever and will prob still be around for some time to come given the number of people on all electric heating with no heatpump eg all electric flats. My batteries were sized to cover 90% of my days. As the export rate falls I'll have to get smarter about only filling the battery as much as I need but for now (this winter) fill up at night on 14p electric seems to be the best strategy. -

what i should not have done when installing solar

Beelbeebub replied to scottishjohn's topic in Photovoltaics (PV)

Useful. What is your heating system? Storage heaters? Direct electric panels? Heatpump? I'm currently using my batteries (15kwh) to store E7 electricity and that runs my (gas heated) house pretty much all day on low cost elec - the exception is days when we do alot of washing and there is not much sun, then we end up using a few hours at peak rate. Overall using 95% cheap rate elec. Am on standard octopus outgoing which was more or less thr same as import (14p cheap rate import, 15p all day export). Unfortunately the export will drop to 12p, but it's not a big deal. You may be able to get more use from your batteries by switching tariffs and tactics. -

Earth Neutral bond for hybrid inverter (again)

Beelbeebub replied to jimseng's topic in Photovoltaics (PV)

I'll try and dig out my wiring diagram but here's the box Incoming tails from grid come in, the SPD and it's breaker are connected there. The love and neutral the head via the SolaX RCD and the live via the MCB out to the solax. They also go into the "grid" input of each changeover switch. The output of each changeover switch then goes to each CU. The eps love and neutral come back from the unit and connect to tge other input of the changeover switch (the live via the eps breaker) Currently CU2 is connected to the grid, the inverter can power it but it will go down in the event of a power cut. CU1 is fed via the EPS and stays up in the event of a power cut. (not shown are some Henley blocks below to split the connections) -

Earth Neutral bond for hybrid inverter (again)

Beelbeebub replied to jimseng's topic in Photovoltaics (PV)

It's the edge case really - kettle, toaster, microwave (not uncommon at certain times) get us over 6kw with house baseload. Chuck in a couple of hob rings and a HP (it'd a bug house so would be a fairly hefty one) and we could exceed 8kw. That said, the point of the changeover box is we can easily run everything off the eps if we find exceeding 8kw isn't an issue. As it happens we currently have a fault which was tripping out the Rcbo to the inverter. It effectively gives us a mini power cut. Not a problem as we run on battery backup, but in the current weather we'll eventually run out of battery and then have an actual power cut. So I just flicked the changeover to grid mode and now it"s fine, although we don't have automatic changeover if there was a real power cut. I did look at givnergy and a couple of other makes that use a seperate changeover box. For various reasons like lead time, cost, local installers etc I ended up going with a Solax DC coupled system and they use the EPS model, which is basically an integrated changeover system. All the mucking about with two consumer units etc (thr house already had 2 consumer units so it wasnt any extra work) was just me hedging my bets abouy future loads. It didn't cost much, IIRC the pair of changeover switches were about £75 and the bigger box to house them was £50 more or so. It did make installation a little easier as it provided a convenient junction box for thr various meter tails. -

Earth Neutral bond for hybrid inverter (again)

Beelbeebub replied to jimseng's topic in Photovoltaics (PV)

My solution was a bit complicated. My solax has a "eps" output that stays live in the event of grid failure whilst the grid feed is disconnected (all internal) As it's an 8kw inverter it will be fine for most loads except if we have a HP or induction hob. So I have 2 consumer units. One for lighting, sockets etc and the other for heavy loads like the induction hob and (potential) HP. The "heavy" consumer unit is fed from the grid so will go down in the event of a power cut. The light consumer unit is fed from thr "eps" that stays up. So in the event of a power cut the induction hob and HP will go down but everything else stays up. The final bit is both consumer units are fed via manual changeover switches. This means I can choose to feed both, one or none from the eps (or grid). If the power cut loops like a long one I can choose to connect the heavy consumer to the eps feed and just be careful.with simultaneous loading. Alternatively, if there is some issue with the inverter unit I can isolate it from the grid and run my house as normal whilst it's fixed. -

Octopus Export rates (Outgoing) are reducing

Beelbeebub replied to JohnMo's topic in Photovoltaics (PV)

Inevitable, but a bit annoying as thr current (15p outgoing) rate almost exactly matches the E7 rate (13.8p) effectively making charging and exporting the same which makes organising charging times easy. I just charged at night and exported in the day. I'll probaly stay on outgoing but go back to fixed rate. -

Earth Neutral bond for hybrid inverter (again)

Beelbeebub replied to jimseng's topic in Photovoltaics (PV)

I'm pretty sure uk regs say double pole breaker. I think the issue is if the cable is severed then the neutral can become line and someone outside working could get a shock between the neutral and local earth. Your electrican should know all this and sort it out The single pole seems to the Australian regs. -

Interesting couple of days with the new heat pump.

Beelbeebub replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

With that level of heat retention your best bet is to maintain the slab at a fairly constant temp, prob 20C or thereabouts. Basically as it is. You probably could try take advantage if cheaper overnight electricity to charge the slab up. Your cop will suffer a little bit but your flow temps will still be pretty low so it won't matter. -

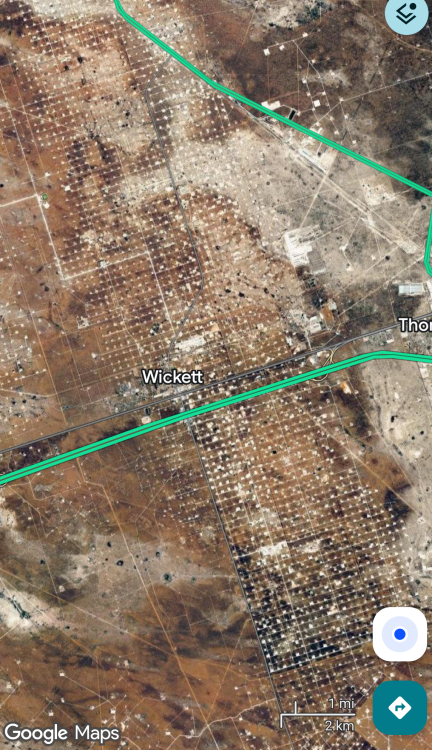

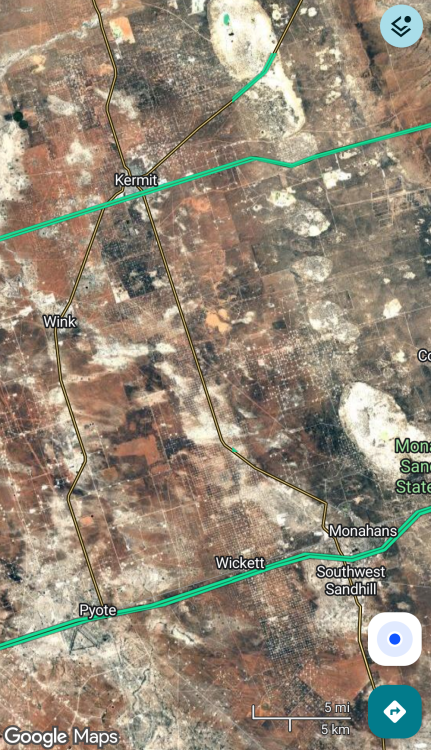

Fracking has been mentioned a few times in this and other threads. Aside from the arguments around there simply not being enough gas left in UK rocks to economically frack, I thought it would be useful to see what fracking actual looks like. Here is a Google maps image of the area around the town of Wickett, Texas. The two itself is the slightly grey patch under the word "Wickett". Those regular white dots in a grid pattern.... They're the fracking wells, both active and abandoned. As you can see, they extend for miles. In fact if you zoom out you can just see it continues. The area.covered in just this one field is hundreds of square miles, it's the size of several English counties. You don't have to be a rabid environmentalist to see this would not be possible in the UK even if there was the gas down there in the first place.

-

Some interesting diagrams. First from UK gov https://assets.publishing.service.gov.uk/media/6887aa04be2291b14d11b01d/Energy_Flow_Chart_TWh_2024.pdf And Lawrence Livermore labs. Some notes - the UK gov is 2024, LLL is 2017. The LLL diagram use Peta Joules whilst UK uses TWh Conversion is 1,000 Pj is 278Twh The reason I included the LLL diagram is that it shows wasted energy (heat) And the crucial bit is the useful energy for the UK is around 2,800Pj or 775Twh. A lot of people concentrate on the left side of the diagram, primary energy which is somewhere around the 2,000Twh of fossil fuels at the moment (the diagrams don't match up exactly so that is a round number) That is around 20x our current renewables - so people rightly say "hang on a minute, we have to build another 20x wind turbines, solar parks etc.? That seems alot....." But renewables don't have as much inefficency so we should be looking at the 7-800Twh useful work. For example transport uses ~650Twh of delivered energy (primarily petrol/diesel) but only around 140Twh is actually used - the rest is heat. So if we could double our current renewables (+100Twh) we could replace about 2/3 of the petrol and diesel we use. Domestic heating uses around 275Twh useful. If we used heatpumps with an achievable 2.75 SCoP we could replace the vast majority of domestic heating with another 100Twh of renewables. So we could replace 2/3 of our petro/diesel and almost all of our gas heating by 3x our current capacity - not impossible.

-

Absolutely, but in that scenario your maximum earning is saving your entire electricity consumption. Some people bank on making even more by exporting lots to the grid. Currently this works But if you are investing assuming you can export lots to earn even more you could be left flat footed. Ultimately about grid scale battery storage to reduce the need for more transmission capacity. Say Scotland. At certain times there is way more local power than they can use or export to the south because the transmission lines are at capacity If Scotland could store that excess and then release it when the wind isn't blowing, either to power themselves *or* to continue to export at the maximum the existing lines can take, there would be less pressure on upgrading the line. This could be achieved with battery farms, but it has been pointed out 50kw+ car battery could output 2kw for 24hrs. 5,000 cars could provide 10MW for 24hrs Kia UK sold 7,000 EVs in one quarter. Potentially 40MW of "generation" (or absorption) availible every quarter from Kia alone. Maybe they could use all the EV's the conspiracy nutters think are parked up somewhere in the UK after being pre-registered to inflate thr sales figures. 😁

-

The special tarrifs (cosy, go etc) might vanish. I suspect economy 7 is going to stick around for quite some time. The 15p fixed export will surely have to go sometime. I also suspect that the "agile" ie half hourly variable tariff types will become more common - I believe Spain has them as the norm. So when making the financial case for batteries don't rely on export remaking 15p. Don't rely on using your special 7p overnight car charge or cosy charging times. Do think about storing enough electricity to run through the night or at he very least the 4pm to 7pm peak Home batteries have the potential to really help the grid by massively reducing the peaks and dips and allowing less infrastructure upgrades or more efficient use of existing infrastructure. Potentially V2G could really help. Again, home batteries, rooftop solar and electrification of transport are often seen through the "Net zero" and "green" lenses, but they are also vital to energy security and cost reduction.

-

That was what I was toying with.

-

Carbon capture via trees only works if we don't burn the trees afterwards. Locking the timber up in building materials is good but ultimately the destiny of most wood is to burn or rot. Think of how many tons of trees used to cover the UK 300 years ago, and how much of that timber is still around in buildings, ships and furniture.... Not much.