Shaun McD

Members-

Posts

98 -

Joined

-

Last visited

Everything posted by Shaun McD

-

Thanks for this, would you mind sharing what your wall, floor and ceiling U values are? And what sort of temps are you at in each room? My better half must have been an eskimo in a previous life as she has current house at 22-23 in living area, and is happy to sleep in bedroom at 21

-

I am finding that most companies want a deposit before they will design

-

Thanks @JohnMo, I will look at loopcad over weekend and see how it goes. For sure caught between playing it safe with pipe centers and zones V larger spaced open loops. I would have thought I would struggle with loop length on a single manifold but maybe will look about having it in a kitchen unit if I can make the lengths work

-

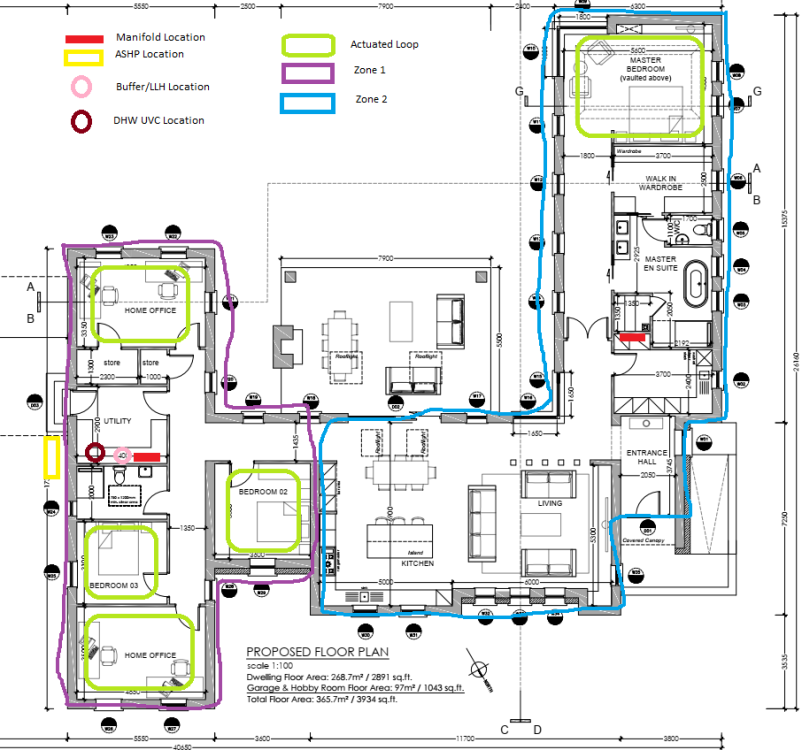

Learning as I go here having read lots of great content! Below is my first pass at a high level UFH layout for our new build. House is a single storey, and the area off the kitchen/dining to the south is covered flat roof, so will act as a brise soliel for the central living area. House will be on a kore insulated foundation, TF at 0.15 wall u value and looking around 4875w total heat loss at -10 based on @Jeremy Harris fantastic spreadsheet. Rough maths of around 18 W/m2 on hopefully a very very rare worst day. My broad assumptions/reasonings on design; Due to size and orientation of house, two manifolds looks to be obvious, one central within each larger zone. Each of the two zones will have heat redistribution available within the zone to distribute solar gain around the slab - controls within HA I plan to have actuated loops to allow for heat limit - again controls within HA I am guessing I will need to use a buffer/llh but not got that deep into that understanding/calculations yet. Pipe spacing of 150mm (maybe less if negates need for buffer/llh) to allow for lower flow temps. ASHP will determine when there is heat demand based on temp of return - i.e. neither zone can call for heat independently. Be aiming for a ASHP in the region of 6-8kw output (dependent on brand - assuming no issue as they can modulate), 300-500l DHW and around 5.5KW worth of south(ish) facing PV on the central living area pitched roof. Hoping for input on; A general keep me honest if design makes sense and has potential to be efficient and setup to allow low flow temps? What am I missing or not accounting for? Does the zone proportions make sense, especially considering the redistribution of heat plan? I am conflicted if I should add kitchen area to zone 2 to better proportion the area of solar gain V low impact solar gain? Other option is to split the kitchen/living area and have half on each zone? Any issue with the distance between manifolds and if the system will have sufficient flow to satisfy both? How best to go about decision on buffer/llh, 2 port, 4 port, coil in etc. My understanding is that in an ideal scenario, the best buffer/llh is NO buffer/llh but it seems to be the more cautious approach here to put one in and potentially sacrifice a very small COP hit to prevent any risk of under sizing of ASHP or promoting cycling & defrosting.

-

Hi all, I am open to a DIY ASHP install on our new build, but have been speaking to local HP installers to try get prices to make sure its worth saving the money on! Basically EVERY installer is pushing hard on GSHP, stating that the lifespan of ASHP will result in needing to replace the machine long before I see any saving by opting for ASHP v GSHP. I am based on Donegal, and house will be a few miles from the Atlantic, and the them of "Salt Air" is repeated time and time again. My cynical mind is thinking that its most likely an upselling scenario, where the installer can make a nicer premium on an install which needs ground loop or borehole, but naturally there is doubt.... Is there any evidence out there to support a reduced life span on ASHP less than say 12-15 years due to the site location?

-

I am hoping this approach of wrapping most of the 110mm risers in a 200x200 shutter or foam will give space to cut down and reduce below FFL and just have the right size waste rising from FFL in the correct position. Mine is a single story house so im guessing only the toilet wastes can be confidently put in without leaving for some wiggle room. In real world terms, how much more complicated is this when it's an external block skin? Taking pipes, wires etc out before insulation and with access to both internal and external faces of the frame is ideal, but if there is blockwork built, what is the best way to go about taking out something bigger than a small conduit?

-

Ha, little black dress was always over rated! I wouldnt consider myself a complete novice so would be interested to know pros and cons of each. I would like to aim for 300l+ of dhw storage, so im guessing that will rule out the split systems with build in cylinders, and not sure if the remaining options are good ones or not. It seems like it makes sense to have the heat transfer happen inside the building envelope, but I would worry that adding on any challenges in dealing with refrigerant may be a pain. Although maybe its all pretty straight forward and could get that filling and pressurising of it done by a pro and still save a lot of money over paying a full system installer?

-

I was referring to monoblock indeed, and I assume it same idea to take in gas pipes if I was going for a split? In general, is one more DIY friendly than the other?

-

Fantastic, thank you! Feel much more comfortable with this approach! Another quick question if you would be so kind, I am hoping to take on the ASHP install, with the external unit outside the utility, where the 300l cylinder will be located. Would you typically take the pipes from the HP through wall (shortest route) or take it under the ring beam and up through the slab?

-

Boxing these out with a 200x200 shutter of either EPS or just shuttering seems like a solid approach. Do you shutter from top of EPS all the way up or from the steel up? Im guessing you would try and have it from EPS as encasing even the bottom inch or two of the pipe would make it pretty tough to move

-

I just sent my TF company a question on this yesterday, where I would want wastes within the stud, would they plan to notch or how would they handle. I think if the wall in question turns out to be load bearing then I would chicken out and leave the pipe outside of the frame. Thanks for note on DPM, makes sense. Nice trick to use foam to make the pipe bigger so it has some movement! Do you use anything fancy to ensure the pipes are in the correct place? The guy from Kore mentioned that they are seeing some installers using GPS but I am hoping I could get away with some levels and plenty of maths?

-

Sounds like a good idea, would love to hear how it works out! I like the look of the reducer shared by @JackofAll as it would mean you could line up the edge of the 110mm pipe with the internal face of the service cavity, and rotate the reducer to have the waste pipe sit inside the service cavity. Would be working to fine tolerances so would need to be very exact with placement of 110mm pipes which is something I need to solve

-

Thanks @SuperJohnG I am guessing you could cut them down flush with the slab is needed? Dependent on the correct reducer fitting

-

Sounds good, would appreciate if you could let me know what the thinking is!

-

Thanks for this @JackofAll Why is the radon barrier between the first and second layer of EPS as opposed to underneath all? I guess it must wrap down under the external EPS300, so why not have it underneath all? Thanks for the confirmation @Nickfromwales How do you usually go about ensuring these are in the correct spot? They must need a high level of accuracy?

-

Thanks @MikeSharp01 was the pipe in the sump a 110mm too? Was it same for sanitary wastes? 110mm upstanding through the slab?

-

Hi all, We are looking likely to go with a Kore insulated slab and hoping someone can give some clarity on wastes and shower trays etc. What is common practice for non toilet sized waste pipes? Do we put in 4 inch wastes and connect 40mm wastes into these? Thinking sinks, washing machine, MHRV drain, dryer drain etc etc. Specifically for a bath waste, do we just leave a 4 inch waste under the bath and the bath waste will get put into it? Showers - if a tray then do we again just leave a 4 inch waste and leave a recess into the slab to connect the trap? If walk in - same thing? Any other considerations for wastes? Thanks all! Shaun

-

Thanks @TerryE good note on 110mm v 50mm, makes sense. We are planning on ASHP so thanks for that call out too!

-

Got my quote from Kore today and as if I wasn't conflicted enough already, the quote is not massively off what I would have been expecting the floor insulation + screed to cost alone. Site is not that uneven, so struggling to see how it will not work out cheaper doing an insulated slab. Trying to put together a list of items that would need to decided up front if we go that route, please let me know if i'm missing any, or any you think I should consider/add; UFH layout and manifold positions DHW and DCW feeds (assuming I would cut into insulation as in the video in this thread) Incoming water feed from garage (We are in a region with not infrequent water outages, in current house we have a 1000l tank in garage which services all cold feeds except kitchen sink and downstairs toilet, and this system works well. Also allows us to have our pump in the garage so no noise concerns) Incoming mains water feed for kitchen sink and toilet. Trunk for incoming power from garage (meter box will be installed on detached garage wall). Thinking 50mm duct - red Trunk for incoming phone/internet from garage (again box will be on garage wall) - 50mm duct - red Service duct to garage (allows networking to/from garage, externals, gates etc.) - 50 duct - black Spare service duct to garage (future proofing for any expansion of PV etc. route cables to garage and have a path into house which can be sealed on both ends easily, and not have to drill into house) - 50mm duct - red Toilet wastes Sink/shower wastes - how are these normally handled? Do people leave in a dedicated 4 inch waste for each? Anything I am missing?

-

bumping up for input

-

Insulated Slab Installers Northwest Ireland/ Northern Ireland

Shaun McD replied to Shaun McD's topic in Foundations

Thanks, would you mind sharing contact details? TBH the last few days have me questioning this again now, if it will be more expensive to install an insulated found, and if it is pretty straight forward to get to similar level of thermal performance with a strip, and be cheaper, then think strip will win out, but be good to talk to a few installers still to get a more concrete idea on price -

Insulated Slab Installers Northwest Ireland/ Northern Ireland

Shaun McD replied to Shaun McD's topic in Foundations

Great to know, had no idea about this, makes perfect sense but was always thinking it would be a PIR job. Thank you all for the input! On a slightly related note, has anyone used these door thresholds to make life simpler? https://passivesills.com/door-threshold/ -

Insulated Slab Installers Northwest Ireland/ Northern Ireland

Shaun McD replied to Shaun McD's topic in Foundations

Ok so is just a thickness thing? Use 300mm eps instead of 150mm pir? Cost wise is eps cheaper to get the same u value? -

Insulated Slab Installers Northwest Ireland/ Northern Ireland

Shaun McD replied to Shaun McD's topic in Foundations

Sorry if this is a very naive question but is eps different than the normal foil backed boards by Kingspan etc? Is it just that you need a greater depth of eps than pir/put (if that's what they are called) to achieve the same u value? -

Yeah, I need to understand their order of operations, ideally membrane on ceiling but wall cavity open for first fix would be ideal I think