Joshua Graham

Members-

Posts

27 -

Joined

-

Last visited

Everything posted by Joshua Graham

-

Is it fine even below ground level? Should I tooth in some kind of lintel? And box around it under the ground to stop earth and water entering the subfloor?

-

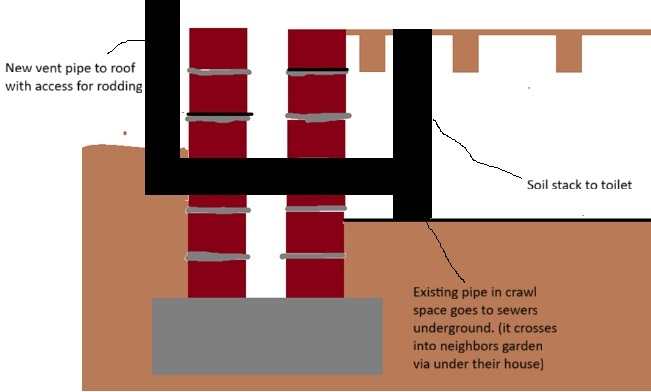

Hello, As the title suggests, I want to bore a hole for the soil stack of my home. I wanted to know if that would be a safe thing to in terms of water ingress as it is below the ground outside. If not what can I do to make it safe? Should I put expanding foam around the pipe to not allow water in or should the pipe be excavated around and drained at the bottom? Unfortunately its not an option to redo the pipe underground myself as it goes under neighbours house, joys of council houses! Please see the illustration I have attached. Thanks

-

Sizing radiators for rooms

Joshua Graham replied to Joshua Graham's topic in Central Heating (Radiators)

Ok, I will have to take a look at the manual see what the case is. -

Sizing radiators for rooms

Joshua Graham replied to Joshua Graham's topic in Central Heating (Radiators)

I am very confused, some sources say 2.5 times the BTU (I would imagine watts would work also) for ASHP but this just sounds a bit loosey-goosey advice and could lead to cold rooms. Is this advice sound? It doesn't seem to take into account that I would like to run the system at lower temperatures. -

Sizing radiators for rooms

Joshua Graham replied to Joshua Graham's topic in Central Heating (Radiators)

Gosh, I have to admit, I feel more confused then before. Thanks everyone for the input. I am probably going to have to have a serious sit-down and look into this, or if there are suggestions on who to hire to help with this? -

Sizing radiators for rooms

Joshua Graham replied to Joshua Graham's topic in Central Heating (Radiators)

That is great thanks. I have replaced the micro bore with a manifold system and 15mm pex pipe. There is a tank if that is what you mean by a buffer (sorry for my ignorance!) built into the valiant internal unit. Should i install an expansion vessel on the radiator loop also? Thanks for your reply, I will lookup the calculation tool. -

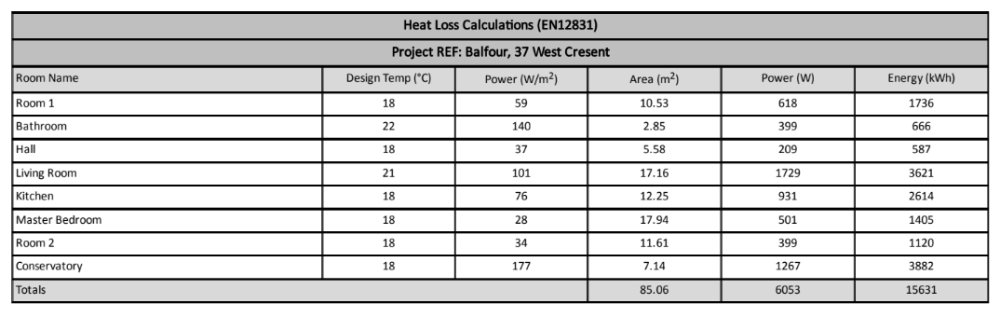

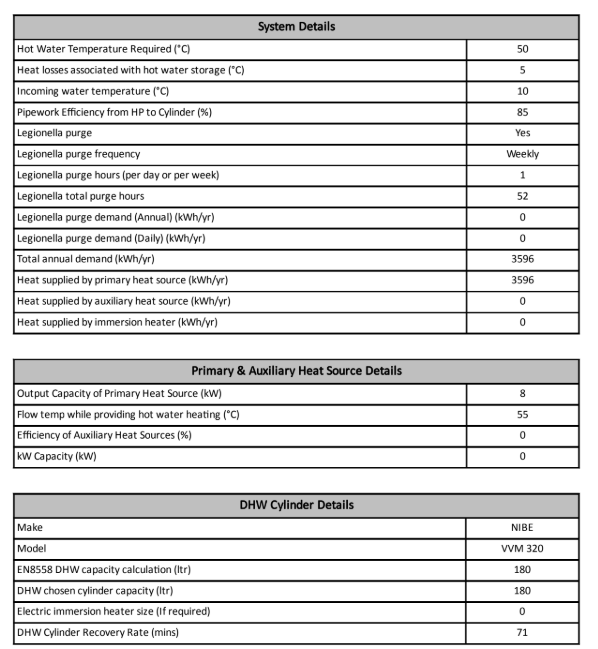

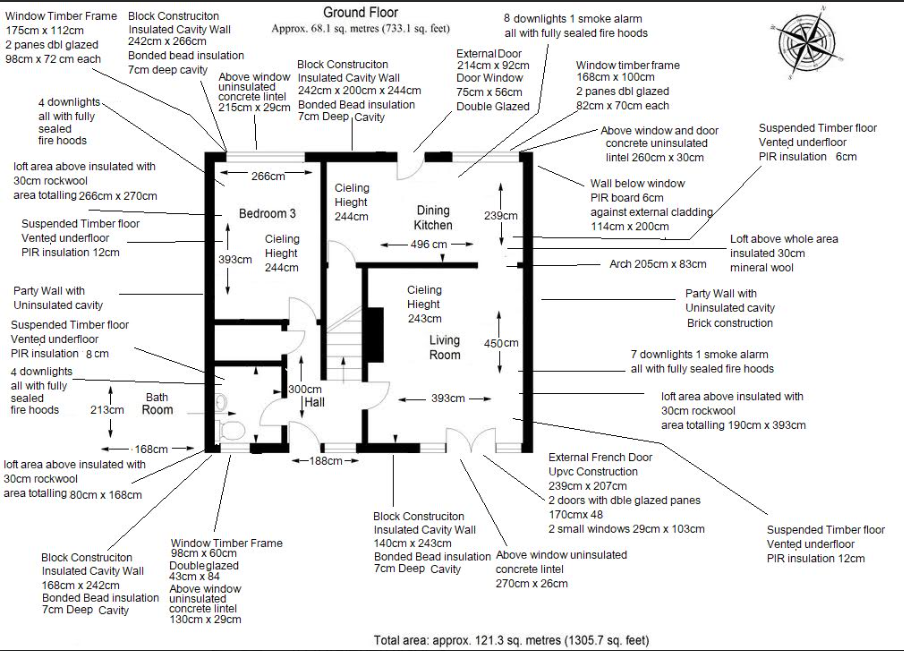

Hi, I had an installer fit an ASHP to my existing heating system. They advised i should upgrade my radiators at the time as it was about 30 years old and micro bore etc. I was a bit strapped for cash at the time of installation so I had no choice but to refuse and come back at a later date to fit new radiator system. As a result I have left my self unsure as to how to scale the radiators for the rooms and what BTU they need to be. I was hoping to run the ASHP as low as possible around 35-40 degrees to reduce long term strain on the system, so have no issue over sizing the radiators. How would I calculate the sizes? I was left with these documents and I am unsure if they are what I need to calculate this out. Also attached is a detailed floor plan of the area needing heated in case that helps. Thanks in advance for any replies, help and support offered. Mike

-

DPM in subfloor

Joshua Graham replied to Joshua Graham's topic in General Self Build & DIY Discussion

Mike, thanks for the reply. Yes i have already done a bit of air tightening of the floor using a dpm between the floor board and joist which was taped to the plaster forming a somewhat decent air barrier. I also have 100mm PIR board between joists. Should mention another reason i would do it is to make maintenance easier and cleaner as i may need to under there a few more times and possibly again in the future also. For that alone it is worth it to me, I would also like to know if covering the area with a dpm would cause issues. It is only one room and a small room 1.8x 1.9 bathroom. -

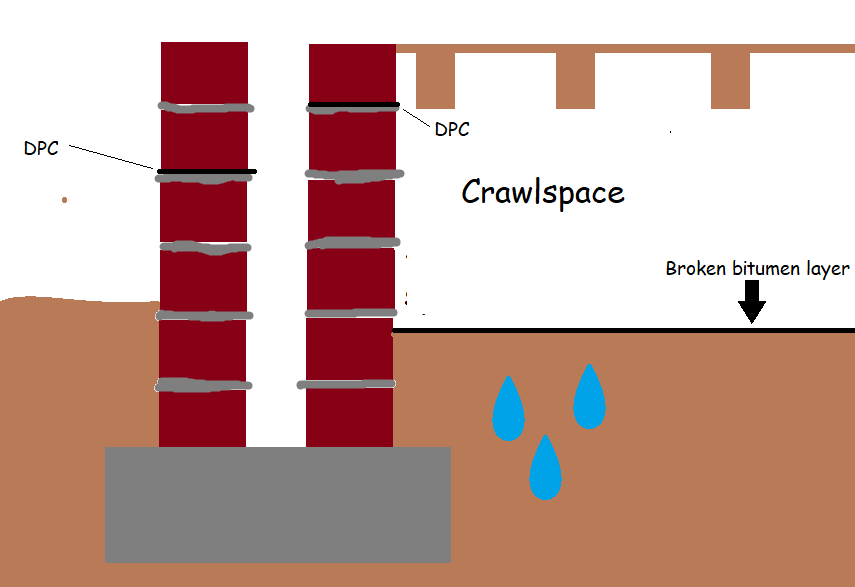

Hello, I have been doing plumbing under my floor which has required me to crawl in the under floor a lot. In there, there is some old bitumen on top of the sand. I believe its there to stop moisture coming in through the ground. Problem is, it is all broken up as black jack gets fragile over time so is no longer serving its purpose. The ground is cool damp to the touch even after being left for a couple years. There are definitely no leaks causing it, it is likely there from a previous leak that has been addressed. I wanted to know if it is worth running a DPM over the top as i have a good bit spare of heavy gauge DPM. I was thinking running some weed fabric to protect it from punctures as there is rubble dotted about and maybe the odd screw, then run the DPM on top of it and finally adhere the DPM to the walls below the DPC by a few bricks using expanding foam. Would this be worth it? Would it help keep it dry under there and would it be OK to do so? Any advice is greatly appreciated, thank you. See my diagram below if needed.

-

Why does this male brass bush leak?

Joshua Graham replied to Joshua Graham's topic in General Self Build & DIY Discussion

Thanks for the answer. -

Why does this male brass bush leak?

Joshua Graham replied to Joshua Graham's topic in General Self Build & DIY Discussion

Can I use ptfe anf the paste together? Also thank you for the reply. -

So the female section is a shower controls and like the male section is brass construction. I have applied 5 revolution of clockwise PTFE tape. Tried tightening it more, but still it leaks.. Why? What have I got wrong? I will upload pictures tomorrow as the pictures i took today do not work. Anyway thanks in advance to any plumbers who help.

-

Review/criticism of low profile underfloor heating plan.

Joshua Graham replied to Joshua Graham's topic in Underfloor Heating

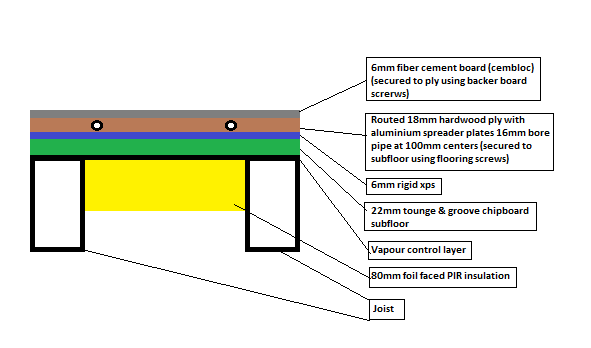

Yes, we did do it about a year ago, which is where the 100mm pipe center came from. But much has changed since then, the property is not airtight, but it is certainly tighter than most and all insulative measures have been carried out. It may be worth another calculation. Do you see any issues with the structure proposed in the diagram (beyond insulation), would this all be functional from a structural perspective? -

Review/criticism of low profile underfloor heating plan.

Joshua Graham replied to Joshua Graham's topic in Underfloor Heating

I should have mentioned, there is also mineral wool below the pir, to the remaining depth of the joist. In terms of high flow rates, that is the whole purpose of using 100mm centers, the pipes should run at a lower temp should they not? what would your recommendation be? -

Hi, As is attached, the image shows a crosssection of the layers in the underfloor heating system I am planning. I have got a company that is giving me a good deal on routing ply for use as an low profile under floor heating system. The system brings the floor up by 30mm; 6mm cement fiber board, 18mm structural ply and 6mm xps insulation. it will be in a living room and kitchen area and is a wet system. I want to know, If anyone sees any immediate issues with it as shown in the diagram, my doubt I have is if the xps will be rigid enough to support such a system but the reason I was thinking this, is to bring it up to 30mm as it brings the floor exactly level with the rest of the house and a little more insulation never hurt, though it is sandwiching the subfloor because a vapor control layer, so maybe it would hurt if water got in... Please let me know if you would do a system like this any differently, I already have the ply, pipes, spreader plates as surplus from a pervious job, so I am planning to work them in no matter what.

-

Basically, i actually lowered the ground. at the brick (its about 300mm above ground), but behind the brick is a joist which blocks airflow a bit, cutting holes in the joist is not an option. Periscopic vents are possible but would be a massive hassle and mean removing a small amount of brick work. so my idea was to remove the brick (cover the hole with fine mesh) to allow more air in. Just want better movement of air.

-

Hi, I was wondering if it is possible to increas ventilation in my underfloor by removing the airbricks as they got clogged with debris over time. I'd basically have a hole with some mesh and a small cowl to protect it from rain splashing in. More air would get in, but would it damage the structure to remove an airbrick without replacing?

-

UFH manifold pump and radiators on first floor

Joshua Graham replied to Joshua Graham's topic in Underfloor Heating

Thanks for that! -

UFH manifold pump and radiators on first floor

Joshua Graham replied to Joshua Graham's topic in Underfloor Heating

Hi John, Yes the radiators are set to run at 35 degrees, basically oversized. I used a couple calculators to work out the btu sizes for the temp. Its also regulated by digital thermostats. I want to avoid using TRVs on my radiators as I prefer the digital thermostats on the walls with a couple extra thermometers around the rooms. A very similar pump, brand and model etc, has a 6.5m delivery head, which from what I have read, represents the max it can push water against gravity. The radiators are about 3.5m max above the pump, would it stand a chance? What else should I consider? -

Hi, I am setting up an underfloor heating circuit with a control unit, thermostats and actuators. On the last 3 ports of the manifold will be rads, 2 are upstairs. Would something like this usually be a problem for ufh pumps? Would I need a bigger pump than the standard types?

-

Thanks for the help, that spreadsheet will come in super handy! Ye the CNC part I was meaning lay 22mm ply atop the existing new 22mm chipboard, this way I can make custom shapes for the loops. The reason I opted out of screed is my floor is suspended and the joists might not take the extra weight or could sag in places, and move which would crack the screed. What are your thoughts?

-

I should have said the floor type is engineered oak, 10mm depth, the system uses a valiant unitower to.