TimCx

Members-

Posts

30 -

Joined

-

Last visited

Everything posted by TimCx

-

Balancing Query - Replacement MVHR

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

This balancing is getting very complex in my house ! I have 2 small rooms which are essentially plant rooms, one has the indoor part of the ASHP and underfloor heating manifold and the other some plumbing related to solar thermal and a second underfloor manifold, however both of these rooms have extract valves in them. I am also struggling to get the extracts rates right for the kitchen and the system remains unbalanced as the total extract rates are higher than I can achieve for the inlets. As the 2 plant rooms are not really utility rooms and are small (approx. 2.5 m2 each) and normally don't have people in them can I close both of these valves and not include them in the calculations? -

Balancing Query - Replacement MVHR

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Excellent thanks you mentioned lock nuts made me realise I wasn't sure how they are meant to lock, my vents have nuts but they were not locked, most only had 1 but I have now put 2 on each, how should they be locked? Are they to just stop the vent being wound in too far or should they be locked either side of the threaded bit? -

Balancing Query - Replacement MVHR

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks Jack, mine is not that clever, I wish it was it would be a lot easier. -

Balancing Query - Replacement MVHR

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Regarding terminals being 'fully open' mine are round screw in things with no markings, I have removed all the screw-in bits to clean them. Am I better off starting with the covers off or should I just connect them as far out as they will go, I am not sure if this would make any difference . I hope to complete the balancing by Sunday., wish me luck ;-) I thought I had read somewhere that the required flows for each room e.g. 13ls (45m3) for kitchen could be done on boost and that the normal running could be at a lower rate but I can't find where I read that. From your info I think I need to ensure that the required rates are available on the normal setting and that boost should be higher? Thanks -

Balancing Query - Replacement MVHR

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Does anyone have any ideas on this, I have been searching elsewhere but I haven't found anything useful especially about the Kitchen situation. Thanks -

I am working through balancing my system now that my replacement MVHR is installed, it replaced a failed system from an defunct manufacturer so I was not able to change the ducting other than near the new unit. I have done some initial tests before doing the proper balancing but I hit a couple of issues and hopefully someone can offer some advice: 1) The default setting on the new MVHR (Vent Axia Kinetic Advance S) gave very poor rates, I have now increased these and I am getting better rates without trying to properly balance it yet. The unit it correctly sized for my house but the ducting may be less than ideal. In order to get the flow rates required I may need to run the boost setting at somewhere near 75%. Is the normal or does it indicate a problem? 2) We have a cooker hood in the kitchen, I am not sure how to take that into account with extraction from the kitchen, there is also a vent in the kitchen. Can I keep the vent at a lowish rate and rely on the cooker hood to meet the required kitchen extract figure? Thanks

-

Fused Spur for MVHR with Boost

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks again Andy, yes I noticed that in the circuit but on the old unit the boost switches were connected to the unit live and the black wire so if any was switched then the black wire was live. There are 7 boost switches and they were wired in parallel to a common point near the unit. I think I will leave the boost wiring for the electrician as I wont be using it initially. The isolation switch will be next to the unit and visible -

Fused Spur for MVHR with Boost

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

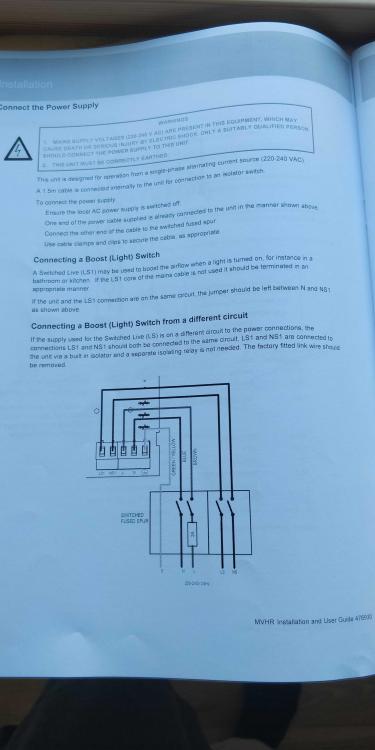

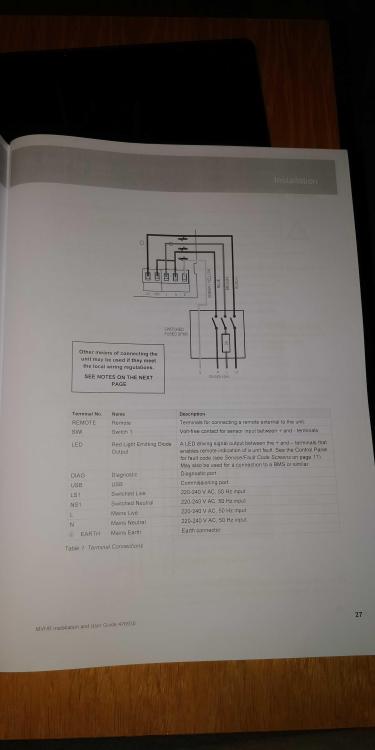

Hi Andy Thanks for your reply its very helpful, the other means relates to energising the boost line when not using the MVHS supply to power it. I have added a scan of that page to this comment Yes they do state 3amp fuse is required and I will ensure thats done. Thinking about it a bit more as the boost line is energised from the MVHR supply then a 2 pole isolator to isolate the supply from the CU will also isolate the boost line anyway so I should not need a separate isolator for the boost line? I also found a statement in the 'Warnings and Safety Information section' of the manual that says 'The unit should be provided with a local double pole fused spur fitted with a 3A fuse having contact separation of at least 3mm....' -

I am about to wire my new MVHR, the attached lead is 4 core with L, N and Earth and an additional black cable that if energised (at 240v) will switch on the boast function. The boost wiring is connected to switches outside the wet rooms, these were (in the old system) connected to the live from the unit and if any switch was closed then the black wire with be at 240v and will initiate boost, I wont be using this boost initially want to be able to add it later. What is the correct way of wiring the unit for isolation, the unit wiring diagram looks as though it should be connected to a 3 pole fuse spur but I have not been able to find one (see attached) All wiring will be checked and signed of by a qualified electrician.

-

Flexi Duct - Help Connecting to Spigots !!

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Wow thanks again, can I ask what you mean by 'insulating tape' is that the electrical type tape or something else? -

Flexi Duct - Help Connecting to Spigots !!

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Excellent thanks and yes it is the wired type, I was going to add a Jubilee or worm drive clip to keep it in place and possibly some aluminium foil tape as well, but are they needed as it will be pretty tight? -

I am nearly ready to install my new MVHR unit and I think I have everything ready to go. My pipework is nominally 125mm. I have just tried a test fit of some Flexi Duct to the spigots on the MVHR unit, it seems hard to get it onto the spigot. Is there a trick to using this stuff? Any tips appreciated. Thanks

-

Just in case its of use to anyone in the future, I checked with Soudal about using Soudalduct with plastic ventilation pipe, I said I wanted to check because it only mentions metal ducting, the technical advisor said that was its primary use but its fine for plastic as well.

-

Rigid plastic ventilation ducts - what type of duct sealant (if any)

TimCx replied to TimCx's topic in Ventilation

Thanks all, I have done a but more research and managed to speak to someone who has fitted this stuff before, his preference was Soudaduct. As the Soudal state that is for metal duct I phoned their technical help line to ask if its OK for plastic and they said yes its fine, so I think I will use that. -

Carbon dioxide levels in a MVHR home

TimCx replied to Seeoda's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Am I right in thinking that RH is Relative Humidity in this context? -

Rigid plastic ventilation ducts - what type of duct sealant (if any)

TimCx replied to TimCx's topic in Ventilation

Do you know what sort of glue was used? -

Rigid plastic ventilation ducts - what type of duct sealant (if any)

TimCx replied to TimCx's topic in Ventilation

Interesting I was assuming that any sealant used would be flexible and and not an adhesive. Do you know what sort of glue was used? -

I have done some searching and not found a definitive answer hence this post. I am using 125mm rigid plastic ducting close to my new MVHR (replacement for a failed MVHR unit installed from 11 years ago). The joints on my the old rigid plastic duct are taped together with Aluminium tape but they have no sealant. People here mention using ducting sealant but this does not seem to be used everywhere. Furthermore I have seen 'Soudalduct' being used but that seems to be designed for use with metal ducting and makes no mention of being used with plastic, I have also seen 'Domus DDSEAL' mentioned and that is marketed as for use with plastic ducts but it mostly seems to be used by electricians. So my questions are: 1) Should I use a duct sealant with rigid plastic duct (in addition to the aluminium tape) ? 2) if yes then what duct sealant should I use. Thanks

-

Hi. I'm a complete beginner confused self-builder!!!

TimCx replied to Jack757's topic in Introduce Yourself

We built a timber framed highly insulated house about 10 years ago, all I can advise is try and see as many building of different construction types as you can, we went round several new builds in the area and spoke to the developers about what they were doing and we also approached some self builders, most were very happy to help, at that time in Norfolk there was an excellent open house scheme for people interested in design and energy efficiency where self builders and related business has open days. -

Borrowing MVHR balancing kit from buildhub

TimCx replied to joe90's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Hi Jack thanks but I cant see the link I get 'Sorry, we can't show this content because you do not have permission to see it.' I guess I need to do something? -

Borrowing MVHR balancing kit from buildhub

TimCx replied to joe90's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Is the forum balancing tool still available? If so I would like to borrow or rent it? can anyone help? PS if not has anyone found a source to rent one? -

Carbon dioxide levels in a MVHR home

TimCx replied to Seeoda's topic in Mechanical Ventilation with Heat Recovery (MVHR)

What CO2 monitors are you guys using? I was thinking if getting one but I am struggling to find any that are good, most of the YouTube reviews seem to be for cheap Chinese units and I would like something that is likely to be accurate. -

Thanks Jack, I was suspicious that the ali flex stuff wasn't great. Interesting that you picked up on the condensation drain, the old unit did not have one and I think that has a lot to do with it failing as its electronics were flooded, the new one will have one. These is some scope for limited insulation and boxing but although its in the garage (which is outside the thermal envelope) the garage rarely gets very cold normally 10C or more even on a cold winters day, this probably due to heat from 2 freezers a fridge and a load of solar equipment.

-

Hi now that I have decided on a new unit to replaced the old failed one, (as explained in my earlier 'Replacement MVHR central Unit - Confused !' thread in this forum.) I am looking at how to connect the new unit as it is a lot bigger than the old one. The new unit is a 'Vent Axia Kinetic Advance S' I have attached some photos of my ducting where it joins the MVHR in the garage. These show the old failed unit which is approx. (WHD) 560x500x260 the new unit will be approx. 660x760x443. I am planning to put the new unit on the wall and slightly to the right of the where the old one was. The 2 ducts on the right are the to/from outside, and the others are to/from dwelling. Previously the ducting was connected to the spigots using the thing aluminium flexible ducting and it sat below the ducting. It may not be clear from the photos but the to/from dwelling ducting comes through the wall just above the old unit and the from dwelling (marked III) is a 'T' joined to the leftmost of the Square ducting which drops down from the top. I have a couple of questions about terminating the new unit: Is it OK to use the thin aluminium flexible duct to connect to the spigots? or is there a better way I will need probably some flexibilty to line up with the new unit. I am planning to shorten the vertical rectangular duct and re-join it to the round but to give more room to wall mount the new unit. Can anyone advice how best to join the to/from dwelling to the new unit causing as little airflow restriction as possible The From Dwelling will have to be a take 2 bits of ducting into a single spigot. The ducting above the old unit was all boxed in, if I re-box it for the new unit should it be insulated? I understand that there is (or was) a loan balancing tool available from this site, can someone tell me what the process is to borrow/rent it? Thanks

-

Replacement MVHR central Unit - Confused !

TimCx replied to TimCx's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks for the info. I have now calculated the floor area and m3 for all rooms, my hallways and stairs do not have any vents but they account for about 25m2 of floorspace and about 75m3 of volume, I saw a comment somewhere that these areas are not included in calculations, does that mean they should be removed from all calculations or are they required in for example the 0.3ls m2 minimum for floor areas?