ADringer

Members-

Posts

31 -

Joined

-

Last visited

Everything posted by ADringer

-

Hi all, As I'm sure everyone else is doing, I'm looking at using my ASHP to cool down my house! I don't have an issue with downstairs - it's a slab and will just run at 12C for periods of time which should avoid the dew point on the wooden floor. My main issue is around upstairs. It's a sand/cement mix with carpet on top. Is it worth cooling or will I not feel it through carpet? And will I have to worry about condensation more with carpet? Thanks!

-

Hi all, We had our UFH (75mm screed with engineered wood + ASHP) installed this time last year and turned it on slowly when we first started using it. Now it's coming round to turning it on again, I was wondering if we need to turn it on again slowly each year or is this only needed the very first time? I've tried googling but can only find information about the very first time. For context, I'm on Intelligent Octopus tariff. When it's between 10-15C I was just running the ASHP at 40C for 3 hours overnight and this was enough to keep it warm for the day. Would going straight to 40C for that duration be ok or is that a shock for the slab? I assume the wood wouldn't be an issue as it will take a while to for the slab to warm up before getting through to the wood. Thanks!

-

How to control an Ecodan with UFH manifolds?

ADringer replied to ADringer's topic in Air Source Heat Pumps (ASHP)

Regarding @MortarThePoint suggestion - that makes sense about having it run constantly, but how do you control the pumps on the manifolds? These should only run when the heat pump is generating heat. @joth What are you using for the logic controller to only do it when a percentage of rooms need heating? I think this is what I'm missing -

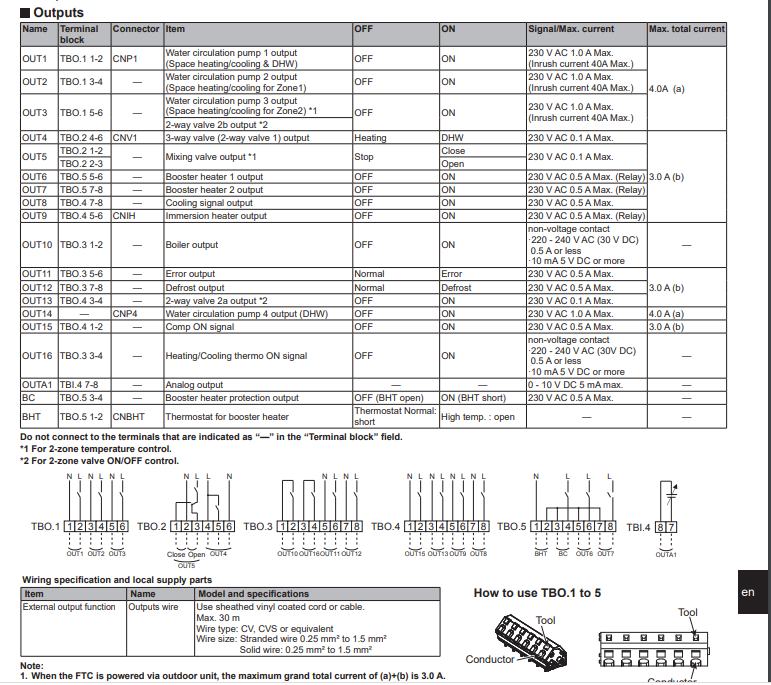

Hi, I currently have a Ecodan and a manifold. This was originally wired up so that if a room stat calls for heat then this will trigger the circulation pump on the manifold and the heat pump itself. I don't want to do this, as this could result in only one room running at a time and so poor performance, and I would like to control it remotely via MELCloud. Basically, I want to reverse this - when the heat pump turns on, turn on the manifold pumps. Looking at the wiring diagram, there are outputs on the Ecodan board (OUT1,2,3) which I believe I can hook the pumps up to so that the Ecodan is the master. Has anyone else wired it up like this?

-

Insulating ducting in the loft

ADringer replied to ADringer's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Yeah that's the sort of product I was looking at (linked in my post), but Screwfix is almost double the price! Would it be an issue having a 102mm wrap around a 90mm pipe? Would the air pocket make any difference? -

Hi all, Just had my MVHR installed in the unheated loft and was planning on running the ducting underneath the loft insulation. This isn't actually feasible as I underestimated how much ducting there was and how much space there is for the loft insulation! So I'm looking at alternatives, and I'm thinking the easiest thing to do would be to get something like this: https://www.bpcventilation.com/insulated-flex-duct. Would this be ok? Manufacturer instructions says I need 25mm wool insulation so this should hopefully be ok. The only thing I wasn't sure of was my ducting is 90mm, whereas that lagging is 100mm - does having this extra 10mm gap make any difference in performance? Thanks

-

Am I able to turn a UFH manifold pump on wirelessly?

ADringer replied to ADringer's topic in Underfloor Heating

Ah ok thanks, good to know there are products for this! Yeah I have a central thermostat that turns it on. But don't want the rooms to control it as could get one room running at a time and short cycling. Plus for things like Octopus Agile I'd like to control it from one place - otherwise I'll have to go round each room thermostat every time it changes. Thanks -

Hi, I might be imagining things that don't exist, but thought I'd ask! I've got an ASHP (Ecodan) and I've just had UFH installed in addition. Currently the pumps on the manifolds turn on when the rooms call for heat, but this is completely disconnected from when the ASHP is actually running. From looking at the manual for the Ecodan, I could be able to wire up the manifold pump to one of the outputs on the ASHP. I'd use the rooms as temperature limiters so the loops are pretty much always open. That way when the Ecodan turns on it will also turn on the manifold pump and they will run in unison. My issue is that one of the manifolds is upstairs and will be pretty tricky getting a wire from the ASHP to upstairs. Are there any products I can use to stop/start the pump on the upstairs manifold wirelessly when the ASHP sends an output? Thanks Alex

-

We've have wet UFH installed and just started to run it now the screed is dry enough. I've set all the flow rates for the zones according to the design, but when I come back after a short time two of them have dropped back to 0. I can open the flow gauge further and get it back up, but then drops again shortly. What does this mean? Air in the system? A leak on the loop? Thanks.

-

How to control an Ecodan with UFH manifolds?

ADringer replied to ADringer's topic in Air Source Heat Pumps (ASHP)

Ok, so by this do you mean drop the flow temp down so it's low enough that it's always running as heat loss equals heat input? Thereby avoiding my whole control issue as everything is always on? is it fine to leave the manifold pump to always be running? is setback on the flow temp? If so, not sure how to do that on the ecodan without manually changing it every time on the local controller. -

How to control an Ecodan with UFH manifolds?

ADringer posted a topic in Air Source Heat Pumps (ASHP)

Hi all, I've had a Ecodan for a year now and originally it was set up with just rads on a single loop. This was easy to control as I had the Mitsubishi wireless controller (PAR-WT50R-E) which turned on the HP when triggered by temperature. I'm just at the end of a house renovation and have now got UFH upstairs and down. Both floors have their own manifolds with pump, and each loop has it's own thermostat. My issue is that the wireless controller and room thermostat works independently from each other - a room could call for heating but the wireless controller doesn't so no heat, or the controller turns on but if no rooms ask for heat then it's a waste of energy, and potentially lots of short cycling if the heat has no where to go. I'm wondering how people have wired theirs up? My plumber and electrician haven't worked with ASHPs before so haven't really been able to give any guidance on this. I can think of two possible ways (I'm not a plumber/electrician, so what I'm suggesting is probably completely wrong!): Essentially ignore the room thermostats (have each loop permently open) and have the wireless controller as the main thing to turn on the HP. But how does the pump on the manifold turn on when required? I don't want the manifold pump to run continously if there is no heat. Have the room thermostats used as a 'max' value so that it's pretty much always open. This way the HP is running continuously at a low flow temp. When people say they run the ASHP 24/7, do they actually mean the whole time? As I think it would it this case if the room thermostats aren't wired to turn off the HP. The main thing I'm having trouble understanding is how to get the pumps on both the manifolds and Ecodan to run when there is a call for heat - is there an obvious wiring solution that I'm missing? -

We've joined up the garage to our house now into a single heated space, so although they were external walls, they're not anymore. Does this count as internal now? Wasn't sure if it made any difference as some of the wall is only internal to single storey.

-

That's what I thought, it's just our building regs drawing says for external walls.

-

Hi all, Question about edge insulation - do you fit it on all edges or just external walls? And if it's external, does that include party walls? Thanks Alex

-

Hi @Redbeard, thanks for the response. I noticed you used a thickness of 1.2m 8n your calculations whereas I have 1.0m - does you statement still stand saying that all other elements will get me to 0.18, or was that only for 1.2m? Just saw your follow up message! I'm going tomorrow to double check everything but pretty sure there's nothing else there

-

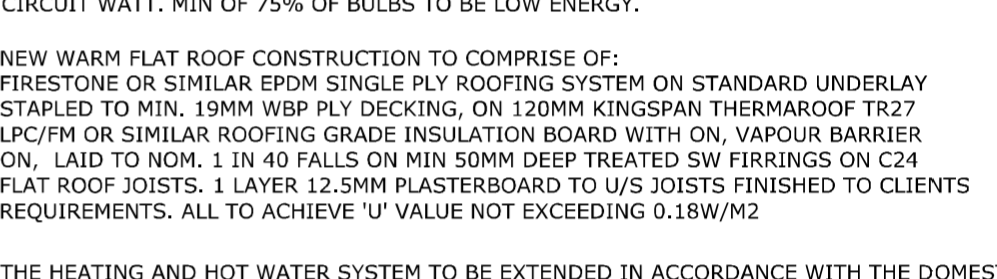

Hi all, Currently having an extension done and the building reg drawings state: Not the target U value of 0.18. I've noticed they've gone for 100mm Xtratherm which has a U value of slightly above 0.2 - is this correct? If so, when looking at U values do I also need to take into account other layers such as the EPDM or is it just the insulation? And if not, should I be getting them to top it up? The roof is finished so would have to be done from below. Thanks

-

Yes got UFH. It was part of the wunda design and we did get the insulation delivered as part of the wunda order. Cool, I'll be having that chat this morning!

-

Hi all, My screed went down last Friday and I just realised that no edge insulation was put down first. I assume this is very important? Should I get the builders to dig out the edges to put it in whilst it's still drying? Thanks

-

Hi all, In the middle of a renovation and our flooring is currently 100mm PIR boards sat on some freshly laid cement. The screed is due to go down tomorrow but just popped by the house to find a pipe leaking a lot of water! I've turned the water supply off but I think it might have been running for a bit. I can hear a lot of squelching when walking over the boards. I'm thinking that it would be a bad idea to screed tomorrow as this will trap a lot of water underneath - am I correct in this thinking? It doesn't sound right that we screed over water logged boards. Just want to be prepared when chatting to the builders tomorrow!

-

Yeah don't quote me on that, sparky is coming in soon, that's just from what I've seen. Cool, we'll do that, thanks for your help

-

Cables are going underneath the insulation, not in the actual heated space, if that changes anything? So effectively sitting on the ceiling of below. Yeah might get them to put wool down rather than push up every board from below. At least that will get the plates to point up 👍

-

Should probably also say this is first floor! Downstairs has 150mm

-

Ah ok, I misread your last post! Tbh we can't fit much more insulation between the joists if we are to put cabling in as well, best we can do with a retrofit. I'll measure the gap when I'm at the house tomorrow, but from your previous message would it be along the lines of: greater than 20/25mm do insulation+ wool, otherwise just wool?