MMcGill

Members-

Posts

24 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

MMcGill's Achievements

Member (3/5)

8

Reputation

-

Thanks - new build so new Octopus meter so fine from that perspective

-

14kwh heat pump for me - 13.6kwh solar over three phases… bit I’m still trying to figure is; if solar is outputting 12 kWh and the three phases are drawing; 1 - 8kwh (where the heat pump is) 2 - 2 kWh 3 - 0 kwh I would hope that we’d us 10 of the 12kwh available, however, this is the bit i don’t know, if the solar is on the phases evenly ie 4kwh each will I instead have to rely on the meter to recognise the balance of incoming and export; so using the above; 1 - Using full 4 in but draws 4 from the grid 2 - Uses 2 exports 2 3 - exports 4 so the meter recognises the above so nets it to 2kwh export. or is there something in between to ensure the full 12 of solar is used before pulling anything from the grid?

-

Hey all - my ASHP supplier has installed a single phase ASHP rather than the three phase I ordered and is trying to convince me it won't matter - The house has three phases available. Now I get that the electrician can balance across the phases so from a supply no problem, but I also have a 13kwh of solar with a three phase inverter, his view is again no problem as the conumer unit will put power to whatever phase is calling for it... Is this right, I',m not in the detail of this one and worried that the ASHP will only be able to make use of one phase worth of solar? Any pointers to reading material / your views would be helpful!

-

-

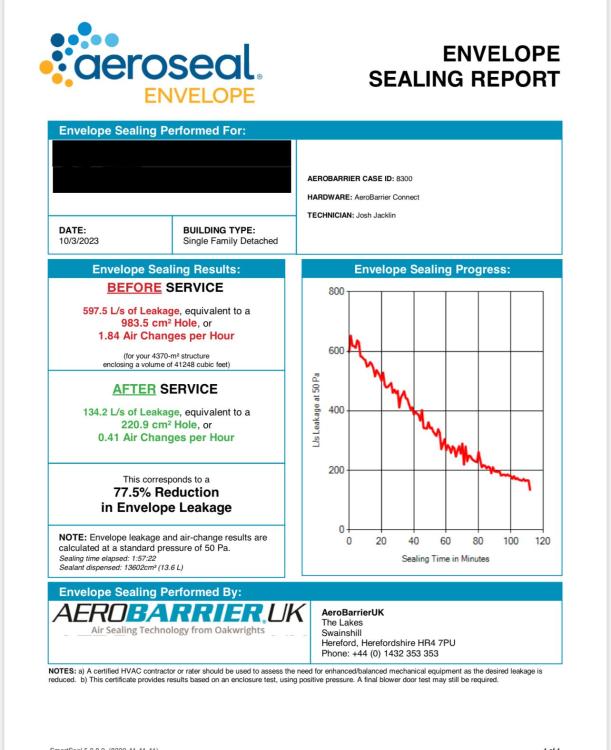

Hi all - I know this is very late after these original posts but it seemed the right thread - I'd been debating Aerobarrier https://www.aerobarrieruk.co.uk for some time, I really wanted to build a house that's as efficient as possible but was stuck with a traditional build (brick and block)... My builder knew this and supported me with air tight roof membranes, parge coat, and air tight tapes to all windows and doors but I didn't think this would get me as far as I wanted - the passive 0.6ach I spent quite a bit of time on the phone with the folk at Aerobarrier who were really patient with me as I asked them lots of questions to deal with my internal debates, but eventually took the plunge - the cost wasn't crazy so I had convinced myself to give it a go... The Aerobarrier team spoke with my builder a few weeks before to run through all the work he had completed and they had agreed that the best stage to do this work was pre-plaster so my builder was a little concerned at what the initial test result would come out at! The team spent most of the day on site, initially checking the completed work, and then using an air heater to warm the house (which helps with the sealant), the kit consists of several 'stations' set up around the house which is a computer controlled mist that comes through nozzles on tripods which contains the sealant. The initial test on the house came out at 1.84ach which we were fairly happy with, the team then kick the process off and I watched the house fill with the sealant, which runs for about 2 hours, as it's going you can start to see the numbers drop as very small holes are plugged, after a while a member of the team entered the house to spot larger holes (you can see where a lot of sealant is attracted to the holes as it forms a white mass) and manually sealed these leaving the process to continue to run... And... The result for me was an amazing 0.41ach at the end of the day and this is pre plaster and floor tiles which I hope will at least keep me at this level - A very happy end result for me. I thought I'd share my experience with you all as I know this is newish to the UK - I'll be waiting for my final post build air test now and making sure no new holes are made in the envelope! I've included a couple of pictures which may help give a view of what I've explained about, happy to take any questions....

-

Thanks will get in contact with them - what’s your view on how hard wearing / long lasting this is as a floor solution?

-

Hey all - looking for a bit of advice, we're getting to the stage of our new build where I need to think flooring, we're UFH throughout and have a large kitchen/diner/snug area that flows through to a boot room and utility room. I've been looking at various floor types one of which was polished cement which now seems to flow more towards micro cement as an option which looks like it gives more options on final finish, hard wearing and not susceptible to cracking... However I'm struggling to find many posts on the forum of users that have gone down this route or suppliers where we're based (between York and Harrogate) where we can physically see this in operation. Any help, advice or pointers gratefully received!

-

Maybe - think I’ll do a parge coat and air test at first fix, see where I am and decide the ..

-

Just had a quote for a 4000sqft house for this which was quite reasonable… very tempted but would like to find people on here who have already had it done..

-

First floor UFH on Beam and Block - Insulation issue.

MMcGill replied to MMcGill's topic in Underfloor Heating

First floor UFH with no insulation under it - not seen any issues then? Had heard that it could cause issues in the ground floor effectively heating from below and above at once… -

First floor UFH on Beam and Block - Insulation issue.

MMcGill replied to MMcGill's topic in Underfloor Heating

Thanks - block and beam on first floor is already on, agree it was probably overkill but not a detriment so happy enough… -

First floor UFH on Beam and Block - Insulation issue.

MMcGill replied to MMcGill's topic in Underfloor Heating

The block and beam is defo a bit overkill but really wanted to isolate each floor and absolutely hate squeaky floors so will never have to deal with that! This is my forever home so wanted to get the fabric as high quality as possible. Air tight aiming for 1 or less and the insulation is pretty good throughout so hopefully we’ll end up with a very efficient home. thanks for the comments - my concerns have dropped somewhat! -

First floor UFH on Beam and Block - Insulation issue.

MMcGill replied to MMcGill's topic in Underfloor Heating

I’m only at 50 to 60mm screed already, from what I’ve read the be edits of the insulation is to prevent the first floor UFH unintentionally heating the ground floor as well along it harder to control on that floor - think you’re saying don’t worry about it though? -

Hi - we're using beam and block on all three floors of our new build and are looking to install UFH on all three levels. Ground floor no issue - K103 being installed and allowed for, but it now comes to light that the architect didn't specify insulation on the floor build up for first and second floors (yes I'm annoyed and should have spotted this - but too late now). So I'm looking for your advice, as I see it I have three options; 1 - Lose headroom on these floors to allow for insulation - I'd clearly rather not lose headroom 2 - Insulate the void under the beam and block on first and second floor - this void will be used for MVHR ducts, wiring and downlighter where required, thought is that we could fill around the ducts leaving enough room for everything else. 3 - Move to radiators on first and second floor. No ideal option as I see it but probably attracted most to option 2 as the best compromise - what would you do? Any thoughts appreciated. For reference insulation is as follows; Floor - Kingspan 110mm K103 = 0.11U Walls - Kingspan K106 115mm with 10mm void (current spec would then give a void of 20mm) = 0.14U Roof - 150mm K107 to full fill and 57.5mm K118 used under = 0.11U Windows - All triple glazed so assuming 0.8U