MarkW1979

Members-

Posts

50 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

MarkW1979's Achievements

Member (3/5)

3

Reputation

-

Thanks guys, lightning fast response as usual! All the best

-

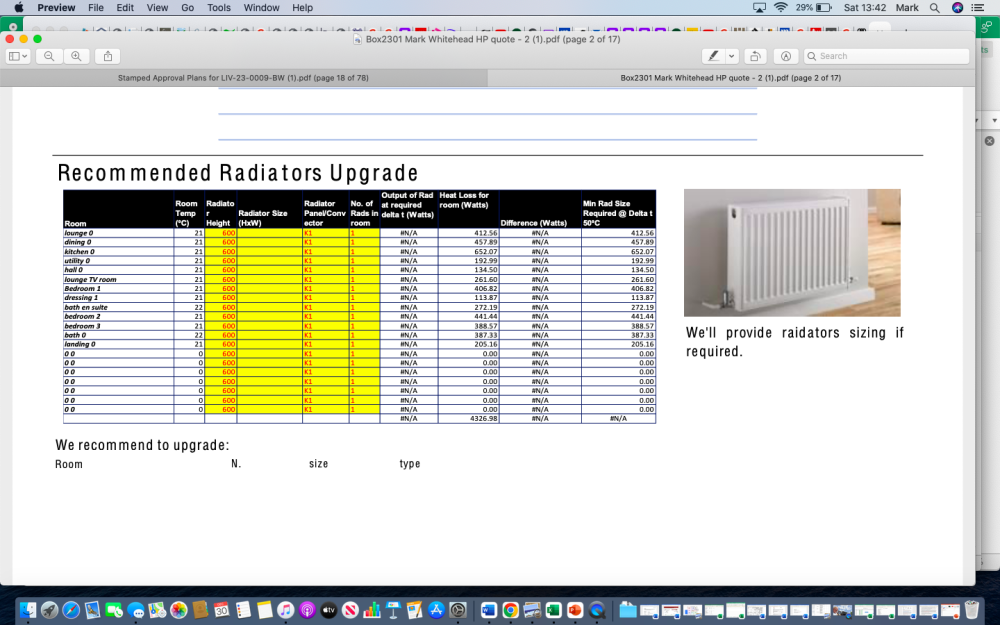

Hi all, and a happy to New Year when it comes. My plumber needs to know the sizes of radiators I am using and as usual I have left planning it to the last minute and thought interpreting the information I have from the heat pump installer would be straightforward (it may be that I am just overcomplicating things as usual!). The heat pump installer has provided the heat loss calcs for the rooms. I am only having rads in the bedrooms: 1,2 & 3. The radiators I am finding online seem to only need to be fairly small to match the wattage calcs as recorded below (at Delta 50) - I had expected them to be required to be much larger (i.e. oversized for a HP). Am I missing something? Should I be looking at achieving the stipulated wattages at Delta 30? Thanks in advance!

-

Thanks guys, but I will be using the renderboard - I was really trying to work out how the flashing works i.e. does it go against the renderboard or underneath it against the kit...

-

-

Too late for a lintel - the porch is already connected to the kit (which I'm guessing why it's done in the first place because it's easier for the kit builder...

-

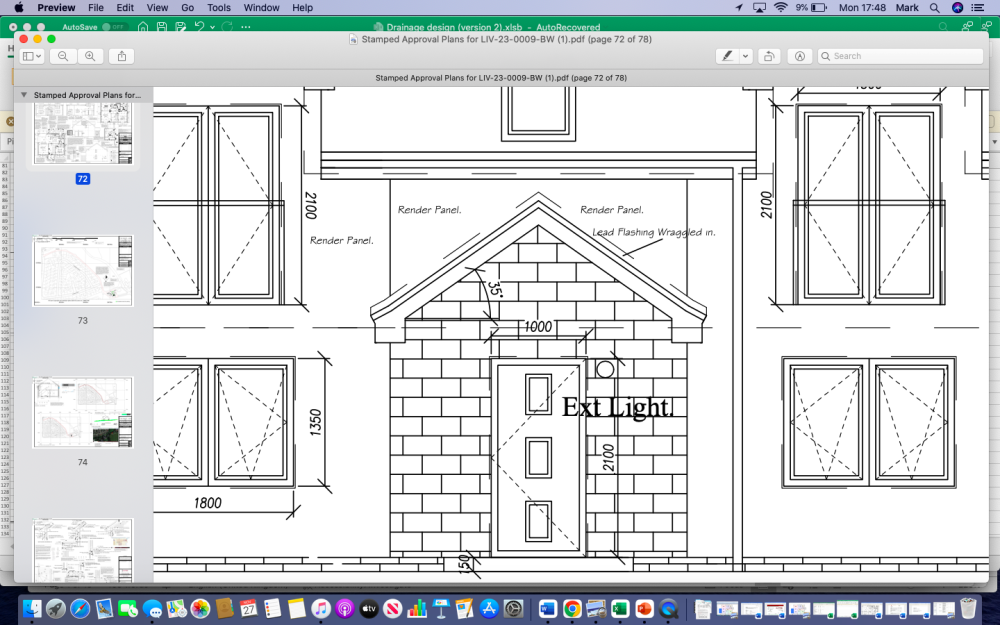

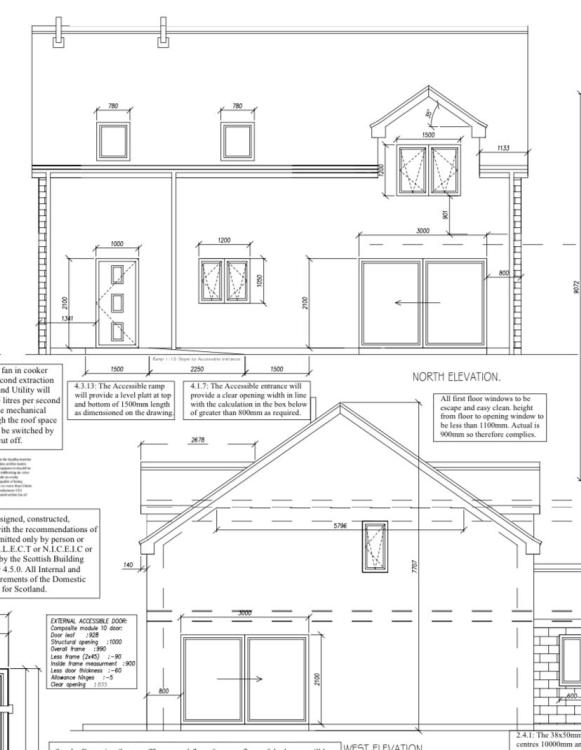

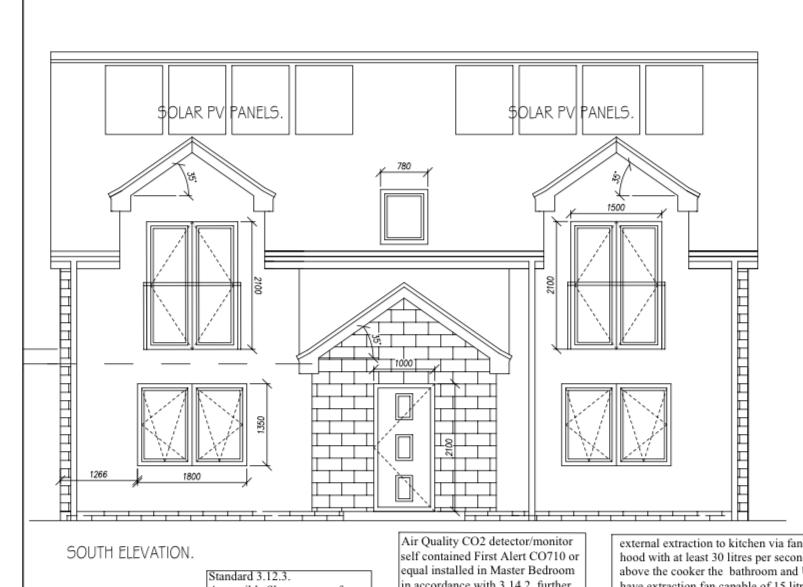

Hi, I would very much appreciate some help with the following!: My timber kit porch has been designed with a render board panel above it (it is 1.75 storey timber frame with blockwork/render cladding - apart from the area above the porch). The detail in the plans is poor (and don't make sense to me) and I have had about 3 differing versions on how it gets done. It obviously has to get framed out out to 138mm + 12mm renderboard to bring out to the blockwork at 150mm (100mm block + 50mm cavity) but does anyone have experience of how this has been done regarding the roofwork? Does the flashing go to the renderboard when built out or back to the timberframe and renderboard goes over it? Plans say lead flashing wraggled in but can you wraggle into renderboard (I thought "wraggling" would be only possible in blockwork unless I have the wrong understanding of what wraggling means!). Thanks in advance, Mark

-

-

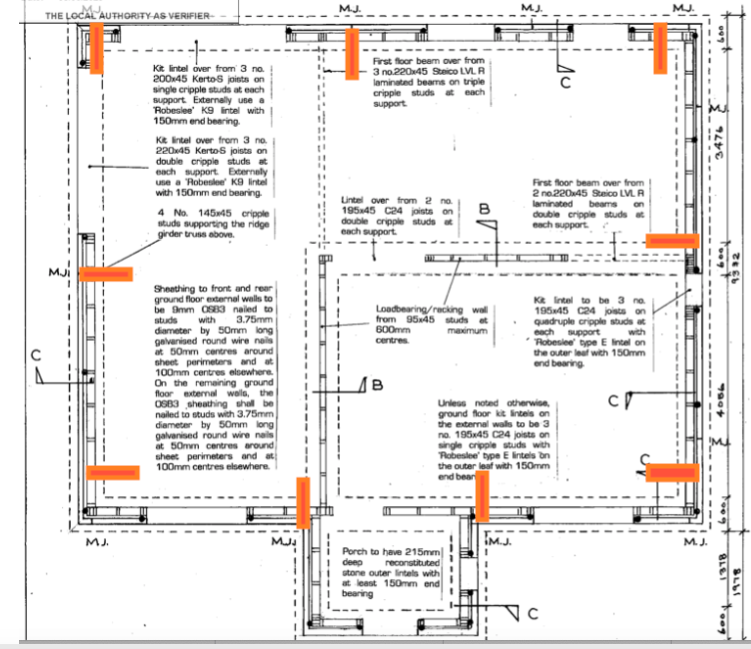

Hi George, Many thanks. The engineer has done the drawings but the brickie has come on site and basically said that what has indicated is a bit excessive and plans to rationalise from 11 to 9. The 9 proposed (in orange on the drawing) seems to make more sense to me but I am just trying to understand the rationale for the SEs drawing. Cheers, Mark

-

A quick question I hope someone could help me with re: movement joints in blockwork. Guidance suggests that in structures constructed of cement based materials (concrete blocks, artificial stone, concrete bricks, cement render and the like) then movement joints should be provided at 6m intervals and within 3m of corners, however re: the corners - does this mean within 3 metre in each axis from the corner, or just one per corner if that makes sense? (i.e. the difference between the 2 pictures - movement joint in blue): Many thanks!

-

Expansion joint locations

MarkW1979 replied to Barryscotland's topic in Bricklaying, Blockwork & Mortar

Hi Barry, Maybe we have the same Structural Engineer. I'm in a similar position - exactly the same wording on approved building warrant plans - how did you get on with your approach? Cheers, Mark -

Thanks guys - i spoke to my brickie who says use a K9 (100mm x 215mm). The Structural Engineer has been useless from start to finish...

-

Perhaps someone could just keep me right on quick lintel related question just to set my mind at rest. The Structural Engineer (who unfortunately I don't place to much faith in anymore!) has specified the following lintels for the outer skin of the 1.75 storey timber kit which will be 100mm blockwork: Unless noted otherwise on the drawings, lintels in blockwork cladding to be ‘Robeslee’ prestressed concrete lintels type E (100 x 100mm deep) with 150mm end bearing. I have a couple of patio doors 3m in length so a 3300mm lintel. 100mm x 100mm doesn't seem a lot to me, but maybe I'm overthinking things?! Many thanks, Mark

-

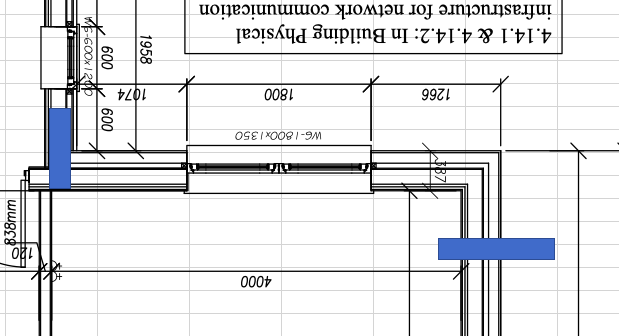

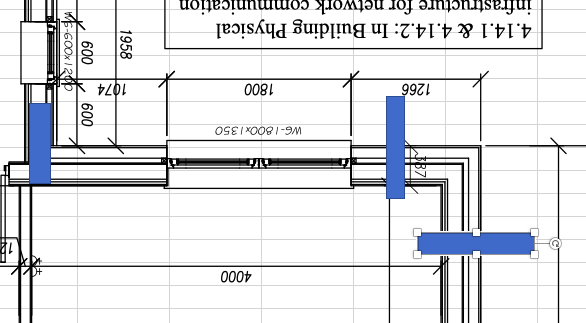

I have decided to install an ASHP over a boiler (mainly due to grant still being available) but have overlooked the fact that I might need ducting in the slab (and am not far away from this stage). The ASHP installers are very slow to respond and I'm very impatient at the moment! I would be grateful if someone could confirm my basic understanding. The ducting is for the flow and return pipes to the system and possibly also the electric cable to power the unit? Diameter needs to be suitable to house these items obviously - around 50mm (and ideally insulated). The bends need to allow for the bend radius of the plastic pipe (i.e. no right angles in any axis). My manifold for UFH is in the utility room downstairs (not all that far from where the ashp will be situated) and my hot water tank will be upstairs. I'm assuming I need to install the ducting in the slab to get me to the utility where I tee off flow/return to the manifold (consumer unit will also be here for power) and flow/return will also continue up through the ceiling void and across to the cupboard housing the tank? Simplified obviously, but is that basically what I am aiming for? Many thanks, Mark

-

Screed before or after timber kit erected (and DPM question)

MarkW1979 replied to MarkW1979's topic in Foundations

Thanks RedOctober, I'll certainly be referring to your blog in the coming weeks. Did your dpm go below your slab then? Cheers, Mark