hrc

Members-

Posts

18 -

Joined

-

Last visited

Everything posted by hrc

-

Design was changed twice: we live in a "block" (ribbon) of 6 houses all with very long gardens and the character of the area is just these 6 houses with long gardens ..... I'm fairly sure that in a couple of years this will probably go thru' That was the only point we (my planning consultant and I) couldn't overcome, everything else was dealt with - highways for road access, services for access, garden sizes, turning circles, car parking, etc As the kids have gone and we're in a 5 bed we need to downsize so, once again thanks Henry

-

Hello and thank you to all for a very informative and friendly forum, I have truly learnt a LOT. Not really bye as I will continue to read and learn from you guys. After almost 2 years our final appeal has been rejected on a purely subjective "not in keeping with the character of the area" even tho' it won't be seen so how...... Anyway, we will now look for another opportunity and I hope I'll be able to join you again Henry

-

Of course, so back to my original question, does anyone see any problems with the proposal

-

Hi Dave, I'm also self employed but have been working with a couple of young builders for a few years. They just need some watching and 'larning'. Now reading your blog over at ebuild, and mine looks similar so I'll have loads to ask ? My guess is for a timber frame at about 140mm but obviously will need SE to verify H

-

That's the whole site - the house is 8 x 8 floor and a half plus a 4 x 5 ground floor 'nib' I'd been advised by my planning consultant (we've been refused already - so this is second try) not to dig out as they may look on this as too much engineering so everything is related back to original GL H Edit - Not Gutex infil - Earthwool (Gutex on the brain!)

-

@ProDave Yes, I'm leaning that way at the moment - probably something like 140mm timber (Gutex infil) and 160mm Gutex overlay, but have asked MBC and Kingspan - I'm a sparks and have worked with a builder for the last four/five years so thinking that a low tech system would be the way to go with them and watch them like a hawk!! @PeterW Site is approx 17 x 17 with the overall slope being about 500mm - haven't had any surveys analysis done as yet - waiting until approval (lives in hope!) H

-

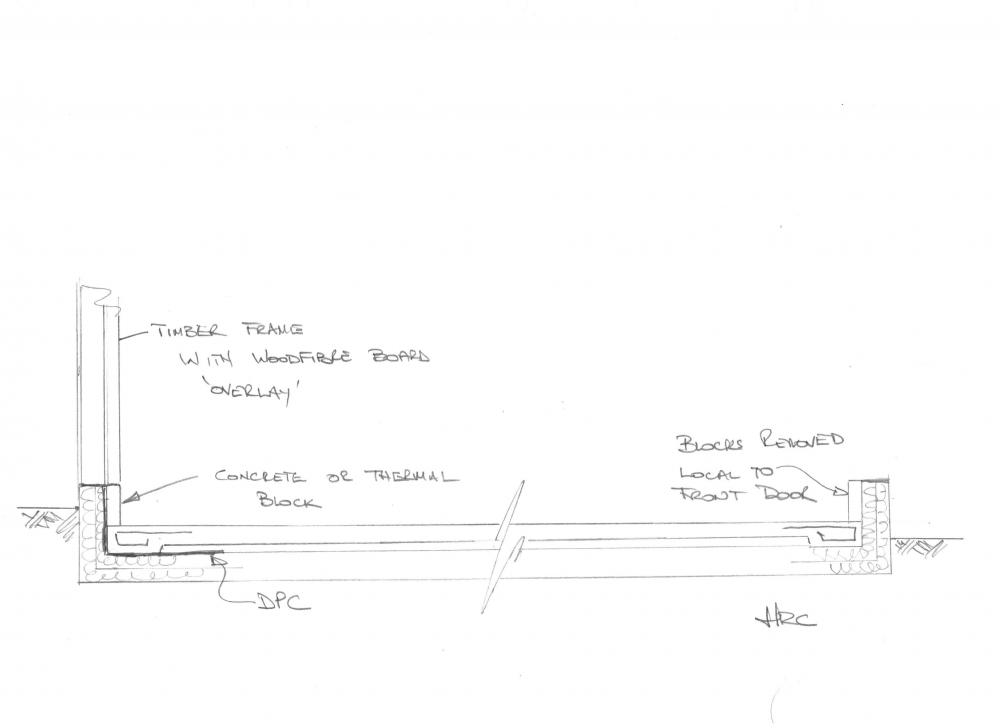

Hi all, thanks in advance. While I'm waiting for the "result", I thought I'd run this idea past the forum, My site has a slope back to front of about 250mm and my thinking is to cast a standard passive slab (Viking/MBC/Kore) except that I would lay a concrete or thermal block, advice please, (cut to size for the slope) along the perimeter of the slab, and extend the EPS insulation up to that level on the outside. Apart from the problem to sort out with steps out to the rear garden, the front should be okay as the ground level will be 'correct' and I can remove the blocks locally - can anyone see anything I've missed in terms of cold bridges/structural etc Many thanks Henry

-

Generally the VD is not a problem over 5m (which is why that's the usual max reel length) - don't forget that's 12v at both ends

-

Yes, they normally have a flying lead on one end, just need wiring into the driver (secondary) 12v - your 230v into primary

-

Are both these openings required opinions please

hrc replied to janedevon's topic in Windows & Glazing

Saw these at Biscester - don't have any technical details, but looked at least possible to do something with H http://www.newwavedoors.co.uk/easy-to-use.html?id=30 -

Hi, on the ebuild site Peter and others mentioned getting hold of SPON price books, which do you recommend? Buying them all would be £6 -700! I think somewhere there was mention of even using an older version? H

-

Jeremy, I know you've said this before but in practice how level and how straight/flat :+/-0? 1? 2? Over what sort of distance (if I get my planning) I'll have 12.1m I've worked on site (sparky) so if it can easily be done I need to get my builder trained. I take it from your comments that MBC DO get them level/straigh?t

-

If the combination of a level concrete foundation and a straight timber soleplate is difficult to achieve a perfect fit would it not be possible to lay a neoprene or EPDM strip, say 3mm thick to take out any imperfections?

-

I am about to raise this with Bentleys (and a couple of other points). I was considering the EPS external insulation (ala passive slab) would be higher externally and thus give some support to the external woodfibre, which would 'overfly' all the wall/eaves joints and prevent cold bridging. The external cladding, depends on planning approval, would then 'join' with a rendered protection at low/ground level which would protect the EPS H

-

Agreed that the systems that appear on youtube videos (that first attracted me) seemed to be the answer on a relatively shallow pitch, on, say, a metal roof. These were no longer available. There seems to be a lot of progress in obtaining 'high' yields from thin film with the best now reaching 19-20% efficiencies, better low angle and better shading performances. They appear to be used a lot in commercial applications especially in PV farms, unfortunately this does not appear to be coming thru to the 'domestic' market Oh well, maybe when I finally get to build ..... In the meantime the alternative seems to be the in-roof systems

-

Hi all, Due to planning I've had to submit for a dormer bungalow which has a standard 35deg slate/tile roof front but a 7deg roof (full width) to the rear. I found a couple of 'old' systems of adhesive thin film PV panels about 5m long - just my span - great! No longer available I see there is a lot of research and progress with thin film but the only systems I can find all seem to be commercial. The technology appeals because i'm on a virtually flat roof and the thin film appears to be very forgiving of shading and low angles, Has anyone any info of suppliers (not installers) or used them or anything? H

-

Hi, I'm in the process of deciding build methods and have asked for budgets from Kingspan (Bentleys) and MBC. I'm now looking at 'stick built' on-site: you say above that you could have blown in cellulose from the inside after fitting the cladding, I presume that this then needs to have all the holes sealed to get back to the airtightness, I was looking at 140mm SIPs with 160mm (2 x 80mm) Gutex woodfibre boards - on the premise that with an external layer of OSB I could screw in anywhere and not miss!