benben5555

Members-

Posts

102 -

Joined

-

Last visited

Everything posted by benben5555

-

Hi guys, We are fitting a granite hearth and a limestone fire chamber. I understand its a good idea to leave expansion gaps between the different pieces. The limestone back is in two pieces and the hearth is in two pieces. What have other people done with the gaps? I was planning on a 2/3mm gap between the pieces, but would prefer to seal with a high temperature sealant. Is this a good idea? Also fitting a limestone fire surround. Similar question, ive seen these with dry gaps between the legs and the header, but is there an alternative? I was thinking to maybe put a 2/3mm metal packer in between the pieces and then grout the gap to get a neater finish. Any thoughts, or ideally photos welcome. Thanks

-

When the stove is fitted I'd like to have it closer than 200mm to the surface of the wall yes

-

We are fitting a stove with a 200mm distance to combustibles at the rear. It's a timber framed house and the room in question is not plastered yet. The wall currently has 50mm PIR over the studs then an air membrane and 25mm timber battens on top. The fitter came out and was concerned about the heat from the stove melting the air membrane so suggested a twin wall metal heat shield. This is expensive and requires ventilation at the top and bottom which doesn't really work as we are planning a fake chimney breast with alcove units either side. Also I don't really want to move the stove too far forward from an aesthetic point of view. Are there any alternatives? Like some kind of insulation board? I could remove the 25mm battens. Then my only concern would be the distance to the main studs in the wall and not melting the air membrane. Thanks

-

Hi Guys, We have a bit of an issues with the level threshold that is required at the front door. The front door comes out into a small (kind off) courtyard. So to get a level threshold, and keeping appropriate falls etc, is difficult. I asked Building Control for an exemption but they said no. Has anyone installed a wooden ramp, with a non-slip surface, property sturdy and correct falls / landings etc, and got building control to sign off? We are rapidly running out of money and I'd like to do this and then obviously remove it once sign off is obtained. Thanks

-

Airtightness progress, this is a lot of work...

benben5555 replied to Post and beam's topic in Heat Insulation

What is the purpose of the airtight box? -

Hi all, Any recommendations for T&G wall paneling suitable for a bathroom. I've seen a few and some end up with that 'fluffy' mdf appearance. Looking for something of good quality that will allow a nice finish without having to sand excessively. Thanks

-

Hi, Let me know if not allowed. I've got some left over 75mm radial ductwork. 1 x 16m and 2 x 5m approx Anyone in the Midlands near Nottingham need any - £40

-

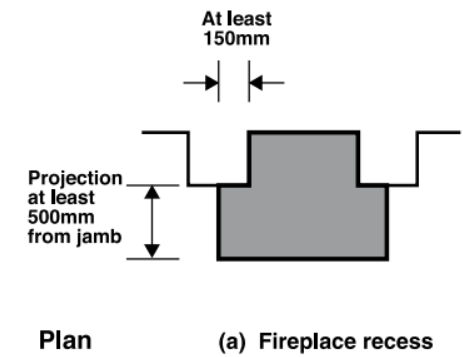

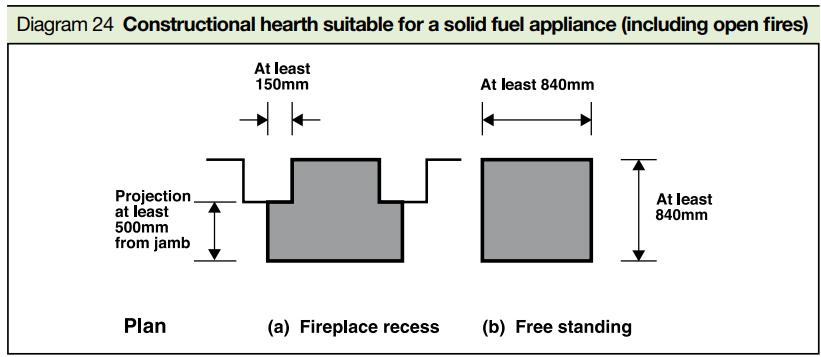

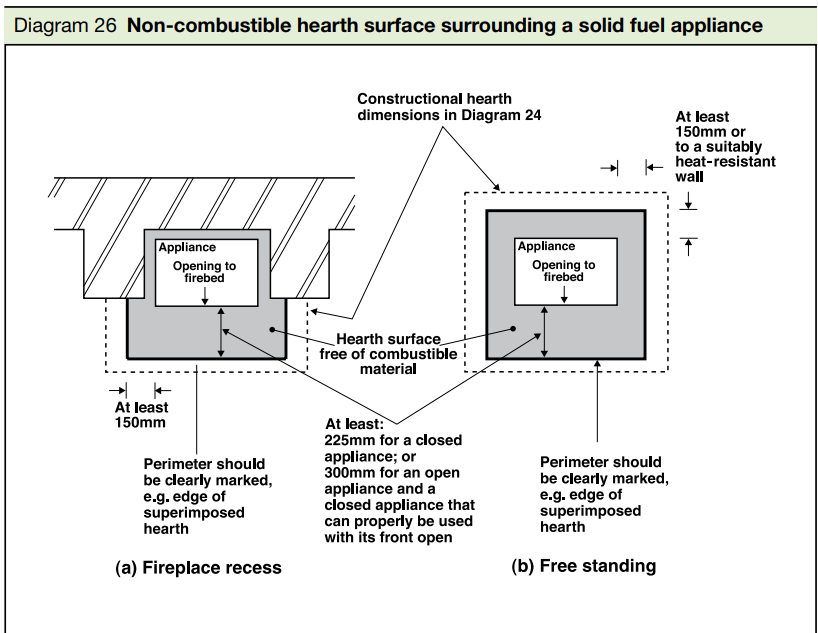

Depth of Hearth in front of Wood Burning Stove

benben5555 replied to benben5555's topic in Stoves, Fires & Fireplaces

Get it now, I'd missed that bit, thanks -

Depth of Hearth in front of Wood Burning Stove

benben5555 replied to benben5555's topic in Stoves, Fires & Fireplaces

-

I've had a quote from Octopus for 16 panels (7.04kw) on a SW facing roof (50 degree pitch). The quote appears good value at £7,300 with a GivEnergy 5.2kWh battery. They have given the option to have a Enphase IQ Battery 5kw battery, but the price goes up to £10,089. I have no knowledge of either of these brands and the price difference suggests that the cheaper one is a bit of a no brainer (comes with 12 year guarantee). Any thoughts on this in terms of price and battery brand. There is also an option for a 10kw battery, but again the price goes up to £8,740 & £11,290 for the different brands. We have / will have a 7kw ASHP. I'm also getting a quote from Wickes and may try a couple of local providers, but instinct tells me no one will beat the Octopus price.

-

Pre-Filter for Log Burner Smells

benben5555 replied to benben5555's topic in Mechanical Ventilation with Heat Recovery (MVHR)

How have you found it? I've gone full circle and come back to thinking that the Blauberg is the best solution. Did you notice any extra noise due to the increased resistance from the filter? -

Pre-Filter for Log Burner Smells

benben5555 replied to benben5555's topic in Mechanical Ventilation with Heat Recovery (MVHR)

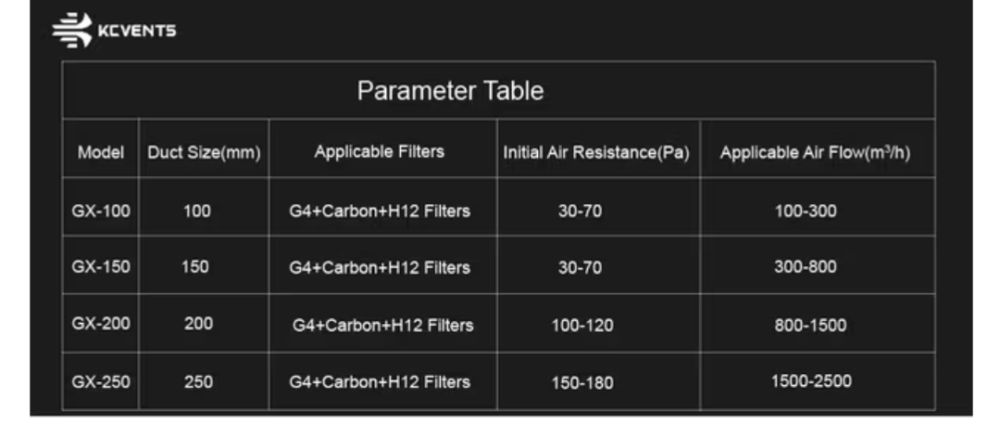

Thank you! This I think is what I've been searching for! Which size did you use and where is it mounted? Between intake and MVHR unit? Or before the manifold? -

Pre-Filter for Log Burner Smells

benben5555 replied to benben5555's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I did see that one on AliExpress, but initially wrote it off thinking it may be suspect quality. It lists the pressure drops and airflow, but I don't understand if these would be an issue -

Pre-Filter for Log Burner Smells

benben5555 replied to benben5555's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I did look around for that but couldn't find it anywhere -

Hi Chaps, I've been installing my Vent Axia MVHR system the last few days (designed by BPC), its got the basic filter installed which I'm planning on changing to a F7 type. I'd like to add a pre-filter and a carbon filter. I've not got the time to make my own so would really like an off the shelf product. I saw the Blauberg Clean Box which has a set of 3 filters, but is expensive and the filters are extortionate. I'm also not sure about the added air resistance. Any ideas on a simple solution? I don't mind spending a few quid as long as I can get the filters subsequently for a reasonable price. Thanks

-

Hi, We've got a timber frame house under construction. The garage is attached to the house but has a bedroom above. I'm going to insulate the garage walls to keep it slightly warmer in there, there will be no heating, but our water cylinder will be in there. There will be insulation in the garage ceiling to insulate the floor of the room above. I'm planning on using an airtight paint on the floor of the room above. Do I also need to put an air membrane on the inside of the garage? I was planning on doing this, but now I'm not sure if it is necessary. Thanks

-

Hi, Not sure if this exists but I'm looking for an air tight wall vent for our planned log burner. I'd like to have something that I can open when the stove is in use and then close off to an air tight standard when its not in use. The stove will have direct ventilation but I understand that when you open the door smoke can spill out if you don't have enough air supply in the room (house is airtight with MVHR). Thanks

- 1 reply

-

- 1

-

-

Sorry yes, I meant service void

-

Hi, what timber have people used for their cavity battens. Roof battens (25x50) would seem to do the job, but I don't know if a untreated timber would be better. I can't seem to find much untreated wood of a suitable size. Thanks

-

Hi Guys, Any tips for which is best to install first? I feel that it would make sense to fit the terminals first and then cut the membrane around and push up over. What is the best way to seal the membrane after? Grommets?

-

Fixing Centrers for Plasterboard (Timber Frame)

benben5555 replied to benben5555's topic in Plastering & Rendering

Lots of insulation, very airtight! That's the plan anyway. I feel on top of that part, just didn't really consider the plasterboard fixings. I've been in the loft of loads of big estate new builds for my job and never seen a noggin. Pretty sure they just fix everything at 600mm centers -

Fixing Centrers for Plasterboard (Timber Frame)

benben5555 replied to benben5555's topic in Plastering & Rendering

Looks like the easiest option might be to fit a 25x50mm counter batten at 400mm centers then. Would save cutting a huge amount of individual noggins. Plus I've already bought 12.5mm boards so can't really change to 15mm now. -

Hi, We are moving on to plasterboarding with our build. The timberframers built everything at 600mm centers with no noggins. What have people done in terms of their plasterboard fixing centers? Take the ceilings as an example, one board would touch 3 joists. I could then fix every 300mm down each joist (longways) but there would still be 600mm gaps widthways. Do you noggin across the ends of each board and put another fixing in between each joist making the widthways fixings 300mm centers (at the ends anyway)? Any maybe one noggin in the middle? Just for our first floor this would be 350 noggins!

-

Heat Loss Calculation for ASHP - Air Changes

benben5555 replied to benben5555's topic in Other Heating Systems

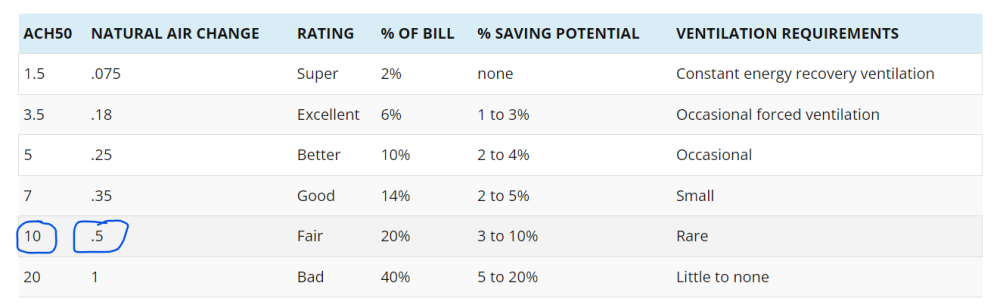

I found this conversion table on an Australian website. If the heat loss calc is using natural ventilation rates, 0.5 is the equivalent of 10ACH which is crazy and must be really affecting the calculations. The bathrooms at utility were calculated at 1.5 which would be the equivalent of 30ACH!