Search the Community

Showing results for tags 'gate'.

-

First post... just realised my 'handle' makes me sound like I'm a from a solicitor's practice... sorry not the case so hold off on those legal queries :-) . Am in the very early stages of our self build project and just researching. (We have found a plot but are currently going through the conveyancing process so fingers crossed.) After initially becoming completely overwhelmed (witness the state of my office!)... am now trying to 'chunk' things up into bite size pieces... sounds easy right? Security fencing... I only require a modest amount (20-25m or so) and from my initial research it seems a no-brainer to purchase some second hand... I can see Ebay has a wide selection and you can get a (Heras style) panel, clip and foot for about £20 each. (I don't anticipate a speedy build and want my costs defined as far as poss.) Question I have for the more experienced out there is would I need a gate to get in/off site or do peeps usually just move the fencing out of the supports. Also... does this stuff stay-up pretty well in a bit of wind. I've seen support mechanisms out there but think this may be going over the top and additionally will take up more space and provide something else to trip over. Thanks in advance for any shared experience in this area.

-

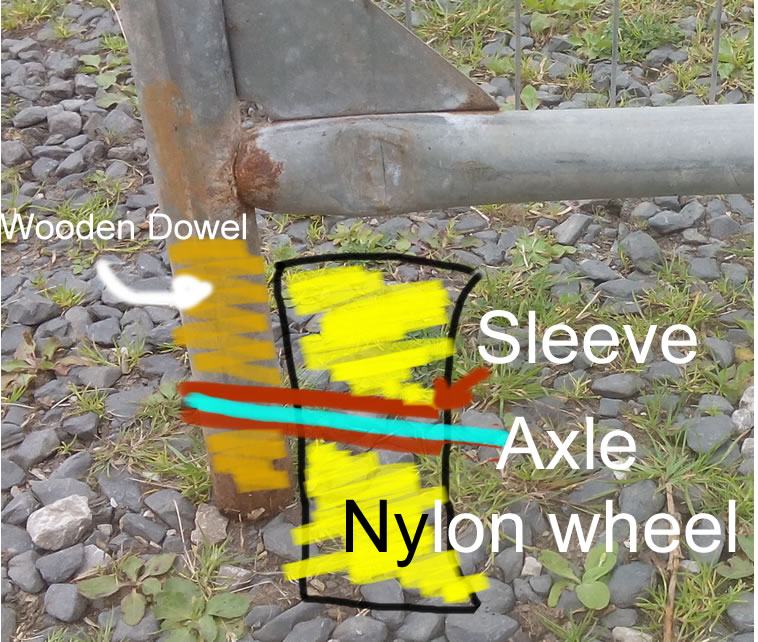

Just before I cobble this revolutionary (geddit?) idea together, I thought I'd run this past you all; I need a double HERAS gate that @MrsRA can use with ease. The second hand ones available here are somewhere between sh1te and not good and cost a good deal too much for my liking. I have a couple of full size HERAS panels spare ...... So, how about this arrangement? A wooden dowel is put inside the vertical of the HERAS panel and drilled to accept a 12mm threaded rod and a thin sleeve encases the threaded rod, AKA - axle. I'm likely to need this 'gate' for a good while. That makes me wonder whether I should double up on the nylon wheels: one outside the panel and one 'inside'. Both wheels will be running on the surface you see in the photo - semi compacted shale chips. A bit of me says put some wheelbarrow wheels on the outside (too big to run under the bottom of the panel) of the HERAS panel instead. Easier for Debbie to push. Worse, the outer edges of the panels would be (about) 6 inches apart. What do you think?