Search the Community

Showing results for tags 'detached garage'.

-

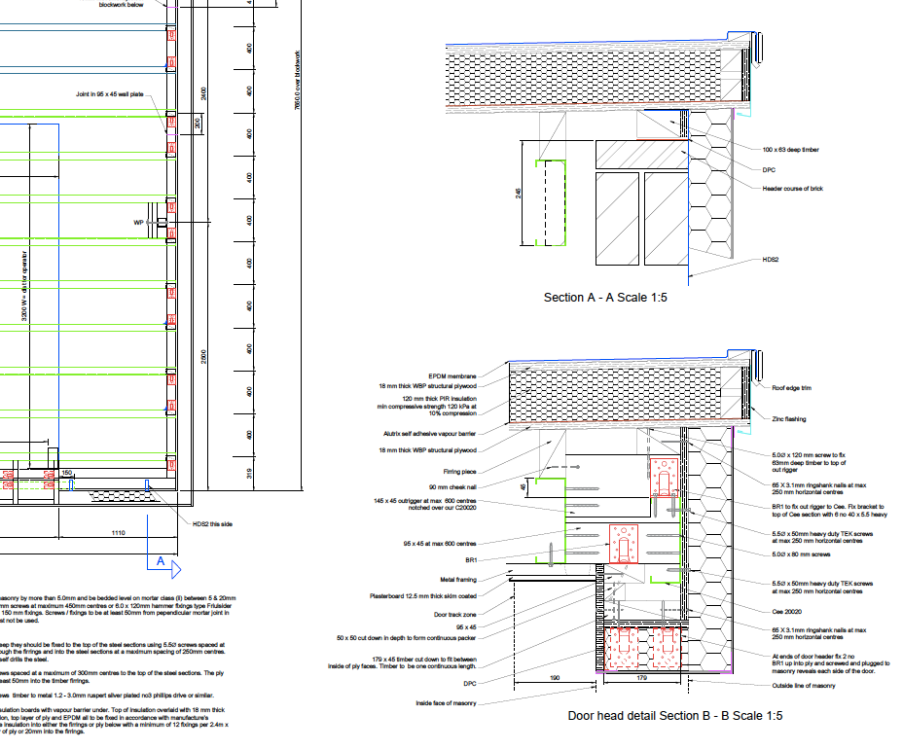

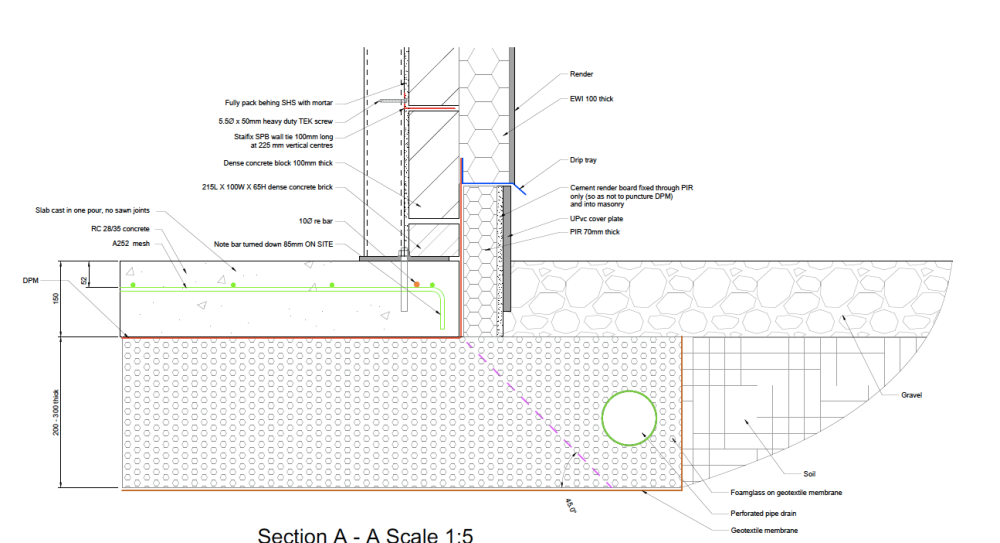

Designing my new build detached garage in SketchUp was easy. Finding someone to convert my fantasy garage into something that Building Control would be happy with was more difficult. I wanted the detached garage to be well insulated, and I may well have got a bit carried away. I wanted to use Geocell Foamglass for the foundation topped off with a concrete slab. I then wanted single skin blockwork clad with external insulation that married up with the Foamglass so that the slab and block work where inside the thermal envelope. I also wanted a warm flat roof. On top of this the garage was to be trapezoidal in plan to make the most of our odd shaped plot and big enough at the front to take a 5m garage door and finally I wanted a thermal break at the door between the slab and the outside world I contacted a local Structural Engineer who came round for a site visit. There more I spoke the more bewildered he looked. He'd never heard of Foamglass, not necessarily an issue but he didn't seem even vaguely interested in finding out more about it and its utilisation. I rapidly came to the conclusion that I couldn't work with him so I pondered my next move and decided to get in touch with a (well known on here) Structural Engineer/Architectural Designer who happens to live at the other end of the country. I wondered if he'd be able to help me out or steer me in the right direction. It turned out that he could. More than that, he took on board all the odd things I wanted to do and worked with me brilliantly. He's an absolute mine of information and had lots of great input with which to finesse my design and he clearly knew what he was talking about which is so reassuring. A site visit wasn't necessary, I provided a site survey and soil survey from the house build and then photos and Google Earth filled in any blanks. I probably drove him nuts, every drawing he sent I added to my SketchUp design because I really wanted (needed) to understand how it was going to go together and didn't want the standard "the builder will know what to do". There was a great deal of detail in the drawings: The upshot of this long story is that working with a Structural Engineer/House Designer who I'd never met and who never visited the site was a great experience and I'm glad I looked further afield than the local offerings and would recommend the same approach to anyone else looking for an SE/Architectural Designer. You’ll find him here:@Gus Potter and if you’re looking for a Structural Engineer/Architectural Designer I would heartily recommend you get in touch 👍🏻

- 27 replies

-

- 4

-

-

-

- detached garage

- structural engineer

-

(and 1 more)

Tagged with:

-

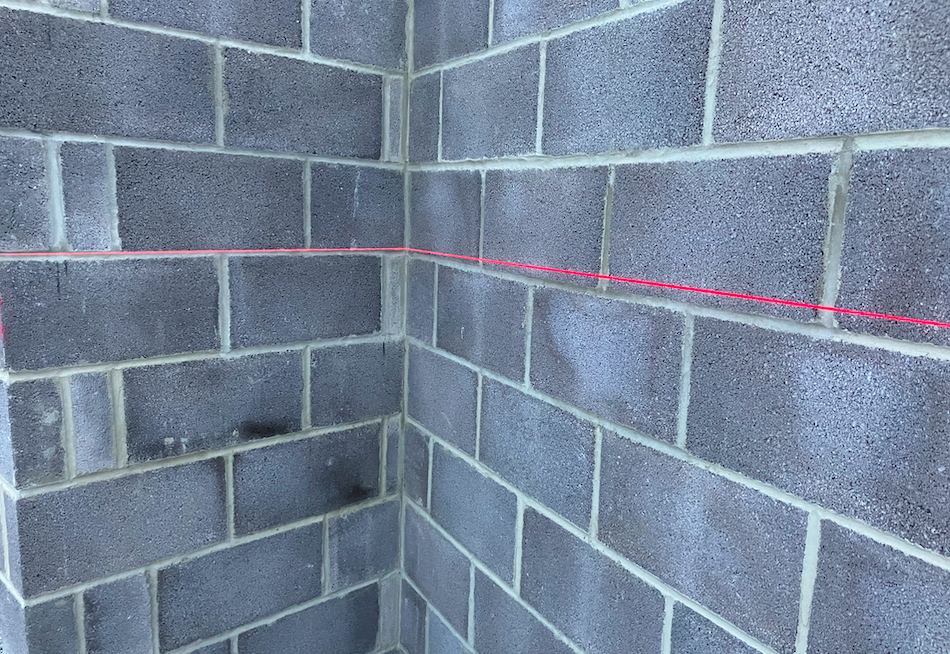

I wanted to build a garage/workshop that would be comfortable to work in year round and also keep the cars, bikes and tools that are stored in there in good condition so I decided I would insulate the slab and eventually settled on Geocell Foam Glass as it looked like it was going to be a pretty straightforward way of achieving an insulated foundation. We dug a hole and took the spoil to a local farmer on a Transit tipper, lined the hole with Geotextile Membrane and then bought the Foam Glass in. Access is a real problem for us so I had it delivered to a nearby builders merchant and then I trailered it in, two 2 ton bags at a time. We pushed the bags over into the hole and spread it about. Foam Glass doesn't really like being spread about, it has a coarse texture that grabs hold of everything, but it is very light and we got there in the end. Once filled to the required level I whacked it down. That was quite a difficult task as well as when I turned the whacker it would lift up the Foam Glass that I'd just whacked down. Again, I got there in the end though and covered the compacted Foam Glass with the membrane. It may actually have been easier to cover the Foam Glass with the membrane and then whacked it. Next time I'll try that (there won't be a next time!) I then built the formwork for the slab, lined it with DPM and set out the steel work following the very comprehensive plan provided by the SE. Concrete was poured and power floated as I was going for a painted floor finish (that changed...) The concrete was covered and left to cure following more comprehensive instructions provided by the SE and that worked well, not one crack has appeared in the circa 7m x 7m slab. The walls were going to be single skin blockwork so wind posts were required. I resin anchored those in place and then awaited the arrival of a highly recommended bricky. If the bricky had known how to use his laser level he would have been dynamite... Unbelievable really. I took the inaccuracies in the block work out with the wall plate so that I had a level starting point for the roof.

- 2 replies

-

- 1

-

-

- insulated slab

- detached garage

-

(and 1 more)

Tagged with: