doyled

Members-

Posts

7 -

Joined

-

Last visited

doyled's Achievements

New Member (2/5)

0

Reputation

-

Wondered on views on copper vs plastic for the following situation. I'm wanting to put in some pipework to prepare the house ready for a future ASHP installation. The ASHP and cylinder would be placed at the front of the property in the lower ground floor with a run of 7 metres or so back to the water riser at the back. I believe there would thus be 3 pipes required - 1 x DHW, 1 x heating flow and 1 x heating return. The pipework would be in the lower ground floor kitchen, running front-back in the ceiling void. Putting in the pipework now is useful as the ceiling plasterboard is down due to refurbishment. Makes great sense to run the pipework now so it's hidden away later. My ASHP engineer said to put in 22mm copper for all 3 pipes, insulated with 19mm Armaflex. My builder has issues with that, saying that as copper is only in 3m lengths there would be several joins and he has concerns for future servicing with it being in the ceiling. He also says that as there are other obstructions in the void (the ceiling is suspended from battens attached to the joists but there are some obstructions) that having "PVC barrier pipe" instead would make more sense and enable him to negotiate around potential obstacles in the void if needed. He's said 22mm plastic is the same as 22mm copper but having looked online (https://heatpumps.co.uk/pressure+flow/simulator.html) I know that the internal bore would be reduced with plastic, plus with smoothness issues. I'm feeling rather piggy in the middle - my view is that if the ASHP engineer says we should run 22mm copper then that is what we should run. If not then I think we'd need to run 28/32mm plastic instead to make up for the reduced bore. I'm not convinced that plastic is the right choice. Unfortunately the only contact I have at the ASHP provider is the sales person who is difficult to get in contact with. The engineer came to site but my builder was not there at the same time. I don't want to have to keep trying to go between the two. If copper is the best option then I'll direct that to be used. Thanks, David.

-

So it looks like a World Heat cylinder can be used with immersion heaters with a cut out up to 95 degrees can be used, though I suspect running below that would be best..... I checked my bath again and the dimensions do indicate it would be around 250 litres of water to take it to the level I normally fill it to, but I like it super full when I get in. Looking at an online calculator https://www.onlineconversion.com/mixing_water.htm and putting in the following figures gives a final temperature of 40 degrees. 100 litres @ 85 degrees C 150 litres @ 10 degrees C So I suspect this might be quite tight for comfort.... likely need another 15-20 litres of hot capacity perhaps. Thanks for all the input.

-

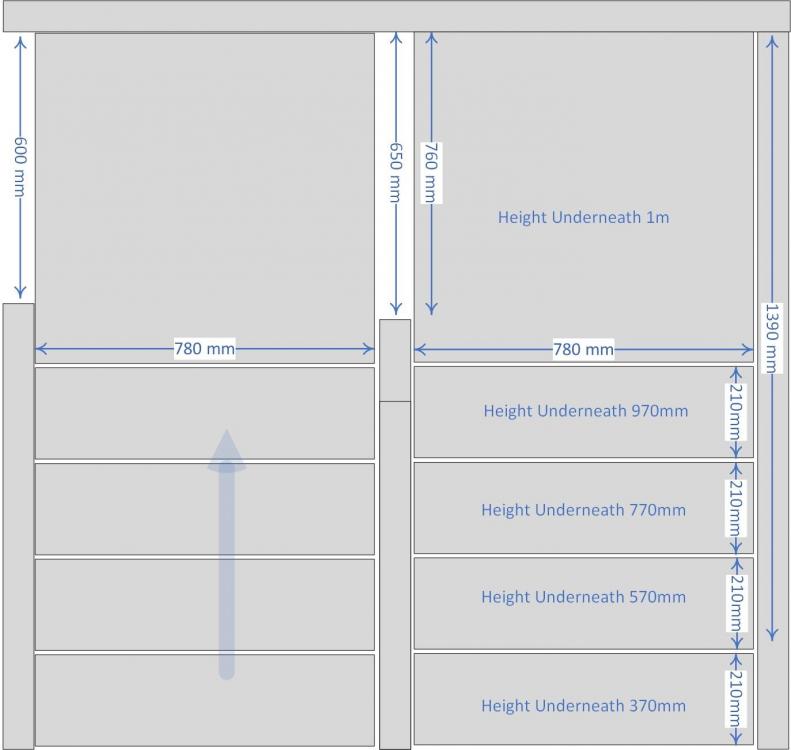

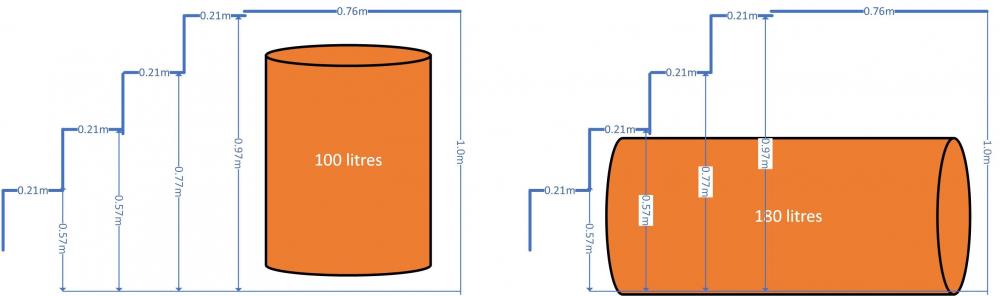

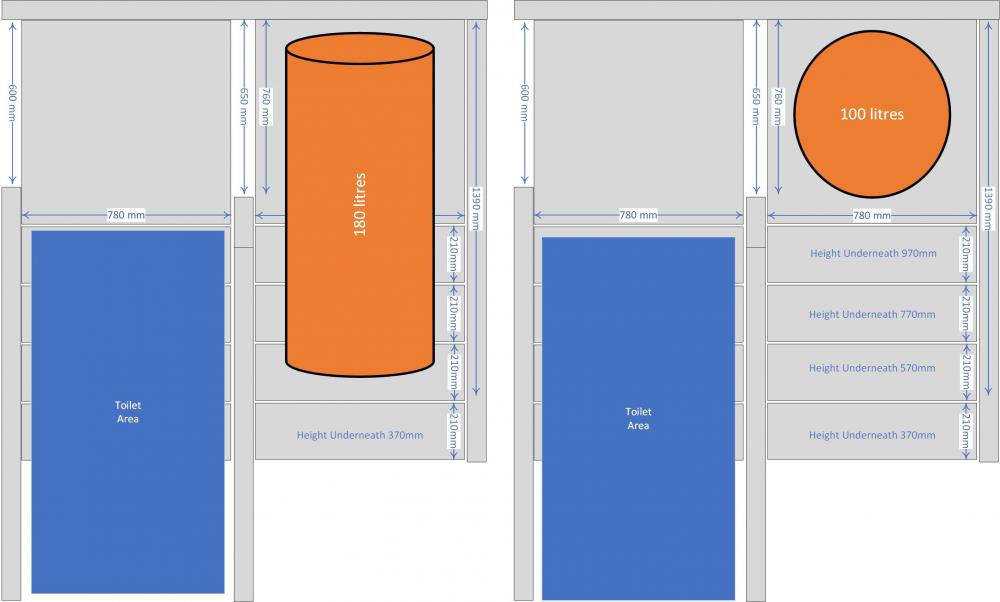

This is an example layout as provided by the installer from another customer. It was to show me that there would be a number of others physical items to accomodate than just the cylinder itself. So not my cupboard I'm afraid....! The only siting location I realistically have is under the landing area / lower set of stairs down to my kitchen. I'd love to have a big cupboard elsewhere in the house with an existing cylinder and paraphernalia but I just don't. Here is the current plan view of this area. I need to have a new downstairs toilet so this will be fashioned out of the existing understairs cupboard area by extending the walls out. This then leaves the area under the landing and the area under the stairs from the landing to the kitchen for storage. I wanted to use some of that space for a cylinder and piping. Here's an example of the layout I was hoping for, using either a horizontal tank or vertical tank. I looked at World Heat Cylinders to get some dimensions and see what might be able to fit, then modelled this to the understairs area available. These are of course very tight fits! But would make good use of difficult to use storage areas. My builder is removing the lower set of stairs and the landing area so access should be ok for install. If the expansion vessels can be accomodated somewhere close to the cylinder this may also be a potential option, as there is another storage area by the water riser. Based on the advice above from joth I think I'm now keen on a 100 litre vertical cylinder, which looks to be an easier option to install together with expansion vessels and avoids stratification issues with a horizontal. I expect that this may seem like absolute fantasy to achieve, but this is the only way I can realistically change from combi gas to ASHP - either by locating the cylinder here or by using a separate Sunamp for DHW which could be accomodated in a small upstairs cupboard that is too small for a cylinder.

-

This is a great suggestion, thank you. So simple I feel stupid for not even thinking about this. I was looking at some online calculations around a typical split of hot/cold water temperature. Looking at a 250 litre bath gives 40 degrees final mixed temp with a mix of 100 litres hot water at 85 degrees and 150 litres cold at say 10 degrees. I have a combi gas boiler at present. I was wanting to go for a Midea ASHP for DHW and heating. Using immersion and/or bumping up the ASHP temporarily feels like a far more sustainable option then buying additional kit that will just sit there unused for much of the time. I'm hoping to add solar heat / PV at a later time so would look to get a twin coil cylinder with immersion to give options for future.

-

This is what the installer sent me. I'm pretty baffled also. My issue is that I can - at a squeeze - I can put in a large tank but these extra elements are a killer. I just don't have a large spare cupboard to host all this.

-

Am keen to install a heat pump however siting a cylinder and buffer tanks is a problem - lack of physical space. The best I can look at is a 100 litre (vertical) or 150 litre (horizontal) cylinder. With a 150 litre horizontal cylinder I'm really pushing space constraints except if I can put the 3x buffer cylinders in another cupboard by the water riser about 4 metres away from where I want the cylinder. My question is whether anyone has ever used a Sunamp as a backup to a normal cylinder? There are just 2 of us in the house and our normal water consumption requirements should be able to be serviced from a 100 litre approx vertical cylinder, but I appreciate this just won't be enough for other occasions such as having a bath. I'm awaiting my installer (Evergreen) to do a site visit to discuss siting options, however I am wondering if there's a way to pipe in a small Sunamp as a backup for those odd times when more than 100 litres of hot water is required - so most of the time the cylinder would refill with cold water but for odd occasions for heavy hot water demand it could be plumbed to pull hot water from the Sunamp instead, which would then be recharged after. Is this even a viable option though.....? Thanks, David.

-

Hi All, New here and following reading some good threads on ASHP and Sunamp I wanted to detail my situation and see what people would advise. I am based in South London and in a 4 storey Victorian townhouse. I'm keen to reduce my use of fossil fuels and have been working with a company (Evergreen) to take up the GHG voucher scheme and switch to using an ASHP. I\m trying something interesting (and ironic) by looking to place the ASHP in the location of the old 'coal hole' that would be used to store coal when that was the only energy source. These are bunkers under the front steps but separate to the house structure, which kept moisture away from the main building. My existing steps have blown Yorkstone and are a patchwork quilt of bad concrete additions over the years. I'd get new steps fabricated from steel and then have a contractor dress them with masonry/tiles etc to resemble the existing steps to retain look. The ASHP would then be connected into the kitchen and could then directly feed new underfloor insulation (100mm piping gap I hope) and the main heating circult together with upgraded radiators. From the attached image the ASHP (A Midea single fan 12kW unit - MHC-V12) would be in red, with the new exposed coal hole area under the green line. This would enable good airflow for the unit. The issue is around cylinder location. My OH is not keen on being cold and our current compact combi boiler works well. As we are looking to develop the kitchen to get better layout and more storage the prospect of having to give up storage for a 250 litre cylinder has not gone down at all well. I've then considered whether I could use a horizontal cylinder under the steps down into the kitchen (pictured) and a 210 litre unit would fit snugly under them, however I have been advised online that a horizontal cylinder is not compatible with ASHP's and has lower 'stratification' than a vertical cylinder, affecting it's efficiency. So likely a non-starter there either. So I was recommended to look at Sunamp. I have seen them before and didn't realise they could be 'charged' with water from an ASHP. A 250 litre equivalent model is a little over 1m high and would fit nicely under the kitchen steps area and has various piping options. As there is just 2 of us in the house presently we could even go for a smaller capacity Sunamp unit and change to a bigger unit over time if we chose. On an Agile/overnight tariff the ASHP could charge the Sunamp (or use electricity on some models) to give us DHW in the morning and keep some for later in day if required etc. I have some questions though: 1) The installer has calculated a flow temperature of 45 degrees for a MCS SCOP of 4.1 for heating and 1.75 for hot water. The Sunamp's however seem to require 58 degrees or so (I believe) so would likely require more like 65 degrees or so from the ASHP. Does an ASHP have ability to 'flex' the temperature output to a higher temperature if required for purpose such as a Sunamp? 2) Sunamp seem to have tie-in's to Daikin and Samsung, but would their ASHP compatble units (the UniQ HW +iLTHP models) work with any ASHP that meets the input temperature requirement? 2) Another option could be to have a smaller capacity vertical tank like 120 litres or so, plus a Sunamp for 'backup' DHW e.g for a bath. 120 litres would be fine for 2 people I think (2 x showers per day). Is this a possible option at all? To run a Sunamp and a cylinder in series? The key issue I am overcoming is storage. Though the house has a large square footage the actual usable storage is quite limited. Sacrificing more internal storage for a large cylinder is the issue I'm trying to negate. Any and all advice gratefully received! Including telling me I'm doing the wrong thing etc.... Thanks, David.