-

Posts

40 -

Joined

-

Last visited

Personal Information

-

Location

East midlands

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

JackOfNoTrades's Achievements

Member (3/5)

5

Reputation

-

Sorry, this should have read that the middle of the chimney is the middle of the party line.

-

Nope - that chimney is right in the middle of the building and evenly straddles the property line.

-

Thanks everyone. This really helped. I wasn't missing anything and my confusion at their approach was justified. Thanks all for helping confirm I'm not going mad.

-

Hi roofing afficiandos, I've just had the roof replaced (pretty much one of the only things I haven't done myself as my roofing skills max out at flatroof EPDM on the outbuildings). The scaffolding came down a few hours ago and this is what the bonding gutter looks like. Our neighbour (who is very laid back and never once complained about anything in the years we have been neighbours) pointed this out before I saw it and asked me when the roofers can come back and fix it. The roofer is standing by this job by saying "There is a bonding gutter Between the roofs there as to be a gap". Can I check if I'm wrong in thinking this is an unusually wide, messy and offcentre bonding gutter? Life is busy and I need to know which battles to choose, having already had to fight a few. Thanks for your thoughts everyone! It's appreciated.

-

Yeah, I understand what they've done from the diagram . It's the *why* they've done it that way that's getting me. And the fact that there's seemingly no ventilation but they claim there is.

-

Sorry. That's confusing of me. One of them is on the inside side of the wall, but the reason I was adding that bit was to make it clear it's a continuous sheet and not between the timbers.

-

Just thought... Here is their diagram in case it helps

-

Hi all Can I pick your brains? I was looking at alternative cladding options for a timber frame conservatory wall and found a diagram of Dunster House's Addroom wall. It makes no sense to me ... so I'm trying to make it make sense just so I can learn something from the process. The wall is ... - 10mm wood polymer composite external cladding - 25mm PIR - continuous outside of frame - 75mm timber frame - 25mm PIR - continuous on inside side of frame - 10mm fermacell fibreboard interior wall They also say "The walls have a 70mm cavity to increase airflow and ventilation" I know this is a conservatory alternative not a traditional building, but it seems to fly in the face of what I know about timber build. To help me get my head around it, could anyone throw in their two cents on the following? - Would there not be a condensation point in the middle of all this? - How is it working without an air gap behind the cladding? - What do they mean by "70mm airgap for ventilation", when it seems from the diagram that the only airgap is in the timber frame itself ... and that's presumably sealed by the PIR? Thanks for your ideas everyone. Jack

-

Timber frame allowing for close proximity to neighbours….

JackOfNoTrades replied to G and J's topic in Timber Frame

Sheets directly on the osb. But then battens and fibre cement cladding over. -

Timber frame allowing for close proximity to neighbours….

JackOfNoTrades replied to G and J's topic in Timber Frame

This is precisely what I'm doing. The wall facing the boundary has fibre cement board cladding, and I'm having treated larch elsewhere. Double check your SE is happy with this too. I wanted to replace my external OSB3 with cement board sheathing, but have been told I need to add it in addition to the OSB as they couldn't find the details on the cement board to do accurate racking calcs. -

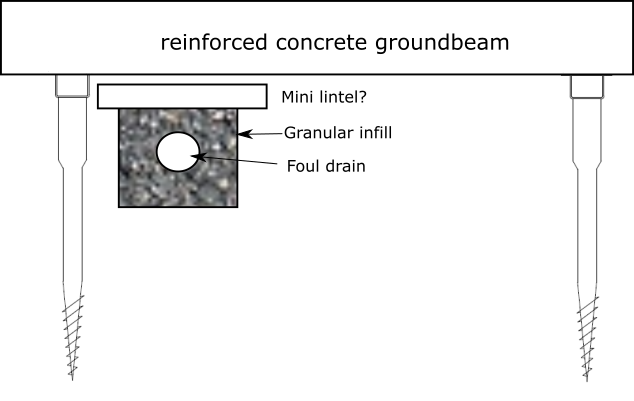

Piled foundations and private drain question

JackOfNoTrades replied to JackOfNoTrades's topic in Foundations

Thanks for the reply Conor, I guess what I'm struggling with is ... isn't the reinforced ground beam a huge lintel in this context? Given that the lintel above the granular infill will be in the same direction as the ground beam, does it actually protect the drain? -

Piled foundations and private drain question

JackOfNoTrades replied to JackOfNoTrades's topic in Foundations

Afraid that's not possible due to where it leaves the property. That would be the dream though 🙂 -

Hi all For a number of reasons, I've had to opt for foundations of a reinforced ground beam supported by screw piles. There is a private foul drain running underneath the new extension and as it stands the drain will go under the ring beam, between two of the screw piles. I'm obviously planning on surrounding the pipes with pea shingle as it's going under the building, but I'm trying to work out if I need to provide any other protection above the plastic drain. If this was a traditional trench foundation I'd obviously have a lintel, but I can't find anything clear on the regs with ground beam and screw piles. The pipe will end up being around 200mm - 300mm from the bottom of the reinforced ring beam. But the screw piles will go a few metres below the drain. As far as I can tell it, the things I can do to support the pipe are: 1. Add flexible joints to the pipe either side of the ring beam. 2. Add another concrete slab/lintel above the pea shingle. (As in Approved Doc H for shallow laid pipes - although there might not be enough room for this between the screw piles as Doc H states minimum bearing of 300mm each side, plus 100 granular.) 3. Nothing - the ring beam acts as a lintel sat on top of screw piles that go below the depth of the drain. Any thoughts on the above would be really appreciated. Thanks all!

-

Hi all, I am investigating mini piling and ground beam options as I'm having a few issues with my soil, hedges and trees, neighbour's extension location and the miniscule depth of my existing brick footings. I came across Shire's Quickbase foundations and wondered if anyone has seen them in action? It seems to be a concrete free pile and beam offering. Helical screws, then a plastic prefab beam which gets filled with a grout onsite to make it rigid and a proprietary floor slab on top. All installed in a day. They seem to be mostly used for conservatories, but also some single story extensions. As I'm doing a timber build and timber clad extension they might work. Has anyone seen them in the wild? Any thoughts on the longevity of something like this? Thanks in advance for any thoughts

-

Builder's upstand vs proprietary

JackOfNoTrades replied to JackOfNoTrades's topic in Skylights & Roof Windows

Actually just seen that they have a video of this application on their youtube channel. Seems remarkably quick. Did you have any pushback from your BCO about the Euroclass E fire rating on your roof? Or is it so small a percentage of the build that they are OK? Fair point. I think I have a few other areas in the build that might need the BCO's good will ... so I want to demonstrate I'm comfortably within their expectations everywhere I can.