NeilScotland

Members-

Posts

79 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

NeilScotland's Achievements

Member (3/5)

13

Reputation

-

Hi All, im fitting a deck in my garden. I’m using hardwood beams (Azobe, 4.5 x 7cm). I have some stainless steel torx head fasteners. They just snap. Even with pre drilling. So I tried just a general purpose cross head screw - also snapped (and with pre-drilling)….. it seems to be when it gets towards the center of the beam (approx 1cm in). I also tried using my drill to drive the screws vs impact driver. Same result. so - I think I just have the wrong screws. Can anyone recommend some stainless steel screws that would work well here? thanks. Neil

-

Skirting boards on a step - advice /best practice?

NeilScotland replied to NeilScotland's topic in General Joinery

Ok. Many thanks for the replies. have mitre bond on my list. ? -

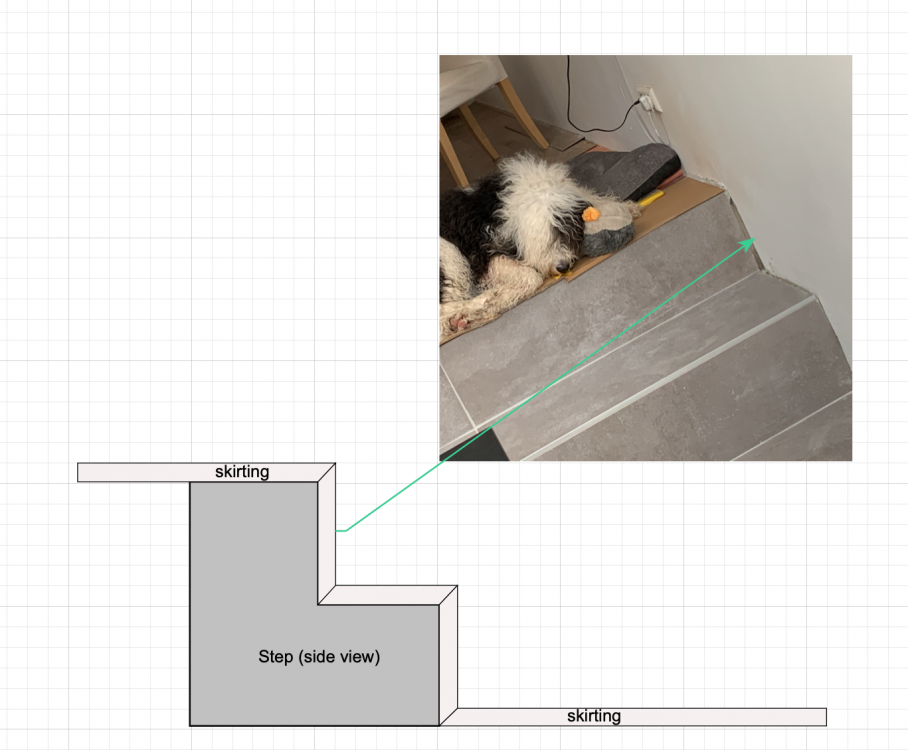

hi all, I have a step - and I'm looking for advice /example son the best way to skirt the side of this step. I'm using 100mm MDF board. Below is a photo (excuse the dog, she's everywhere I turn!) Also, the way I was intending to do the joins (mitre). An example of the board (in situ) I am using Keen to hear your thoughts, many thanks, Neil

-

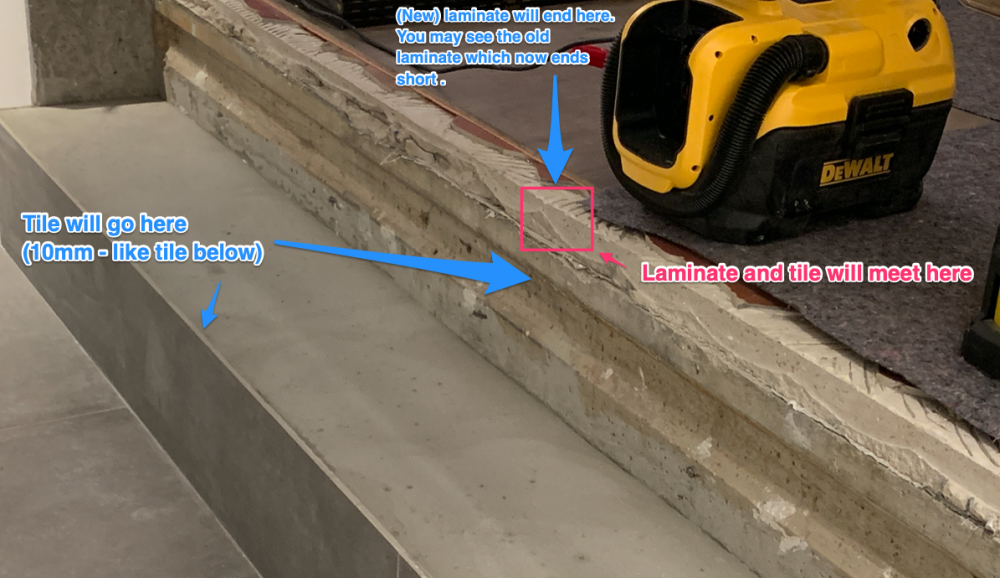

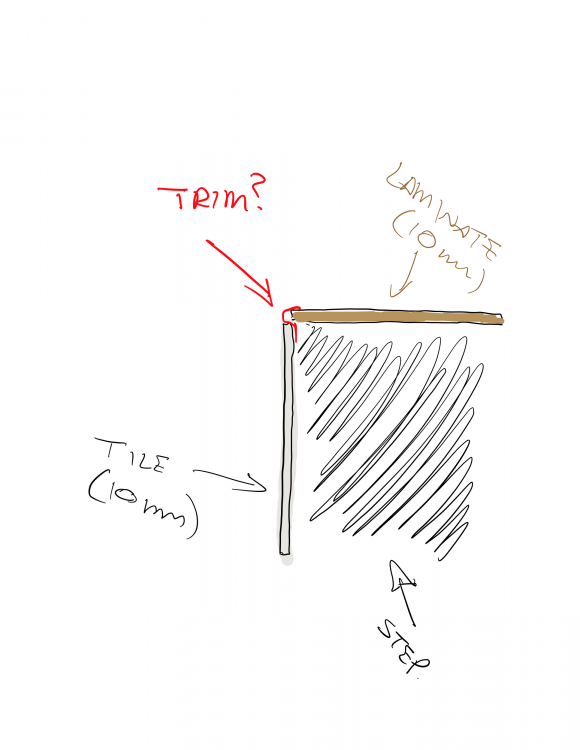

Hi all, I have a step, which will be faced with tile, then meet a laminate floor. Does anyone have a recommendation for a trim /arrangement so I can finish the laminate floor of nicely with the faced step (tile). I think I need something that lips over the laminate. Hopefully pic below shows what I mean...... and also a drawing..... thanks! Neil

-

Thanks for this. Very helpful. Isn’t a wago connector a lot easier? (And I believe also maintenance free). this is just a question of curiosity not judgement! I don’t know the regs. Although this way looks cleaner for sure. thanks again Neil

-

Hi All, I just wanted to know what best practice was when extending (moving a socket down) on a wall. I'm in Amsterdam, so I know the regulations are different - but still looking to hear best practice from UK perspective. My thinking is: I use a connector (I have wago 203 connectors for this) to connect the new cabling. Keep this in the old back box Chase the wall Wire new socket below Rinse, repeat. Plaster over once ll sockets are done (as whole wall will be plastered). My other question - if you need to take a socket no only down, but along the wall. Is it still ok /best practice to chase the wall horizontally? It doesn;t quite 'feel' right to me....but thought I'd ask. Edit: FYI, the walls are made of this soft white concrete block stuff (horrible! - same material inside plasterboard). thanks! Neil

-

Hi all, Not sure if this should be in the flooring forum or the tiling forum ? - I'll try here first..... I have a step, which will be faced with tile, then meet a laminate floor. Does anyone have a recommendation for a trim /arrangement so I can finish the laminate floor of nicely with the faced step (tile). I think I need something that lips over the laminate. Hopefully pic below shows what I mean...... and also a drawing..... thanks! Neil

-

Solid conductor wire to 2 stranded circuits

NeilScotland replied to NeilScotland's topic in Power Circuits

Aha. Nice. Cheap fuel ? -

Solid conductor wire to 2 stranded circuits

NeilScotland replied to NeilScotland's topic in Power Circuits

I did ask the electrician a few weeks ago why floors are intertwined - he said so that if one goes out - you can still get some light to get out the house...... ? where in germany are you? -

Solid conductor wire to 2 stranded circuits

NeilScotland replied to NeilScotland's topic in Power Circuits

I think so. The groups seemed to be mixed. every time I think i’m turning the lighting circuit off, computers and stuff also go off. Mid i remember correctly, UK distinguishes between them? still seems off the garden shed would just be seen as one of the plugs /lights on the circuit..... it is a properly constructed ‘shed’ - concrete base, stud wall construction etc - maybe it’s simple classed as part of the house. -

Solid conductor wire to 2 stranded circuits

NeilScotland replied to NeilScotland's topic in Power Circuits

hmm - i guess not. This is original builders wiring. They do seem a little less stringent here. I’d have at the very least expected them to be on a separate circuit /rcd on the main board too. But doesn’t seem to be the case. -

Solid conductor wire to 2 stranded circuits

NeilScotland replied to NeilScotland's topic in Power Circuits

Hi Peter, The wago I had was lever type - the cable was too thick. I'll measure properly. The problem is - the wago is perfect for the stranded wire but not for the solid wire. And Prob vice-versa..... I could just use conductor block - but I like the neatness and quality of Wago. Neil -

Solid conductor wire to 2 stranded circuits

NeilScotland replied to NeilScotland's topic in Power Circuits

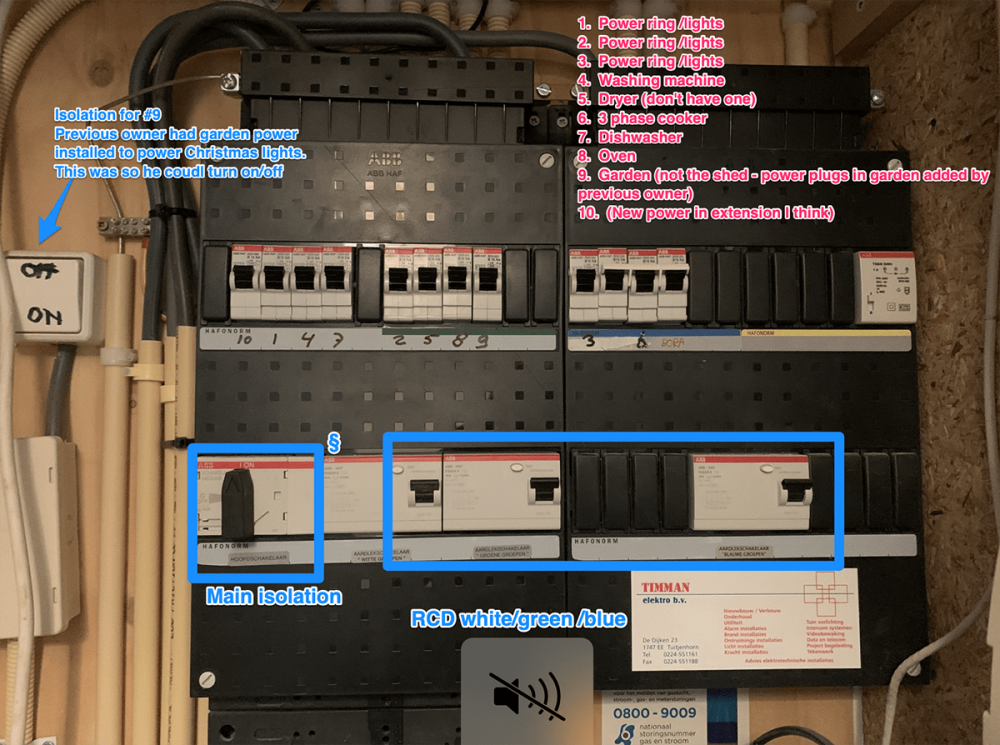

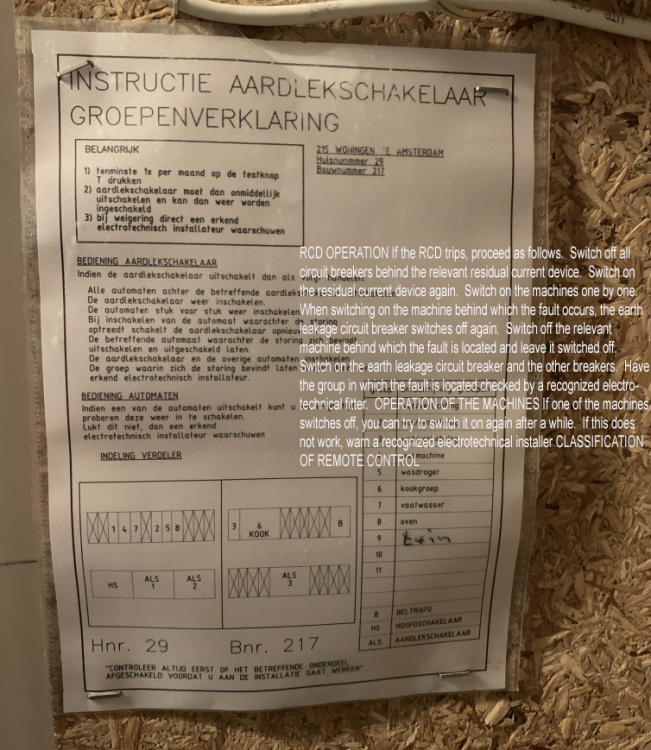

OK.. so here are some pics. - 1st pic is the main CU / board - 2nd pic - same but wider view - FYI - 3rd pic the switches for light in the shed (other line is for outdoor light) - 4th pic - this is the junction box where the supply that comes from the house goes into the shed (it's about 1m below the switch in pic above). - 5th pic - 'instructions' in Dutch. But has a diagram I've still to test which of these controls the shed. Can't do while Mrs is doing her work calls! - but I think 1 2 or 3 will control the power in the shed. thanks, Neil -

Solid conductor wire to 2 stranded circuits

NeilScotland replied to NeilScotland's topic in Power Circuits

haha - I know...... I'm not sure if i can change it or not. I'm originally from there (and actually have an electrical testing question relating to my house in Scotland that I'll be posting soon! haha)......