NickB

Members-

Posts

24 -

Joined

-

Last visited

Everything posted by NickB

-

Zendher Q450 Password

NickB replied to NickB's topic in Mechanical Ventilation with Heat Recovery (MVHR)

thanks so much, you are an absolute star. Worked so now i can set it up in the morning. Thanks so much. -

Zendher Q450 Password

NickB replied to NickB's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks for the suggestion. Sadly neither work... i have emailed zehnder but i'm assuming i won't hear anything over the weekend. -

I was all set to commission our Zehnder Q450 today and discovered that we don't have the service password. It says to contact Zendher but i was hoping to finish configuring it this weekend. Does anyone know what the 4 digit password is? Best, Nick

-

Hi, We are looking for recommendations for any concrete slab installers that can provide a good powerfloated/dryshaked finish for external drive and patio. Can't seem to find anyone online so was hoping to find a recommendation on here. Cheers, Nick

-

Sorry for such a slow reply. I'm not sure how useful this is now, but this is how we are doing it. We are using eps to the sides of the ductwork and then using some 3/8" thick 150mm aluminium that we have bought pre powdercoated from a supplier we have been using. The holes will be cut for the vents and then these vents will tidy up the holes: https://www.amazon.co.uk/gp/product/B08TC9HCH6/ref=ppx_yo_dt_b_asin_title_o01_s01?ie=UTF8&psc=1 Also, we have added 75mm of rockwool EW to the entire exterior of the house to put any steels inside the thermal envelope and use simpson strongtie brackets to take the cladding using 5mm thermal breaks. The insulation is wrapped in solitex fronta quattro with an open siberian larch cladding with 6mm gaps to keep it nice and ventilated.

-

Recent heavy rain has demonstrated that our building site and future home has some drainage issues that would benefit from a design by someone qualified, rather than just my groundworkers thoughts. Does anyone have a reccomendation for a good drainage designer or design service? Thanks

-

Haha, thanks! The brickes kept telling me it must be the most level block-work in England as i checked everything with the lazer level a thousand times until it made a very satisfying beep!

-

Did you do this yourself Roz? We are also debating this finish with our larch as to whether to go with the sawmill (Thousands £££) of just coat it ourselves.

-

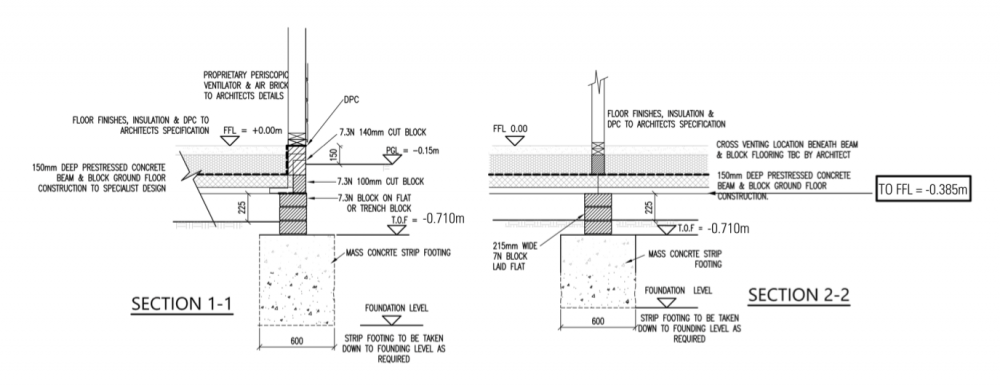

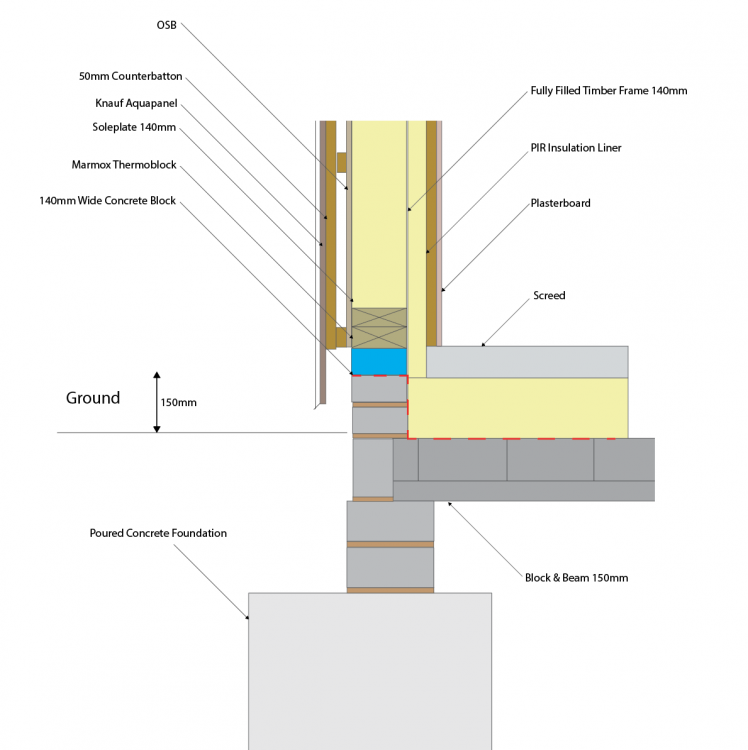

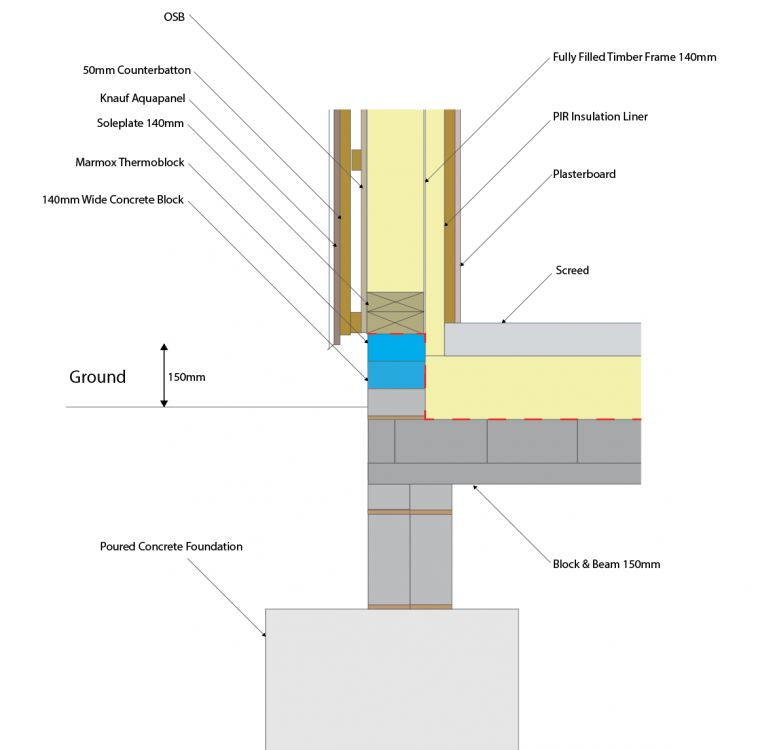

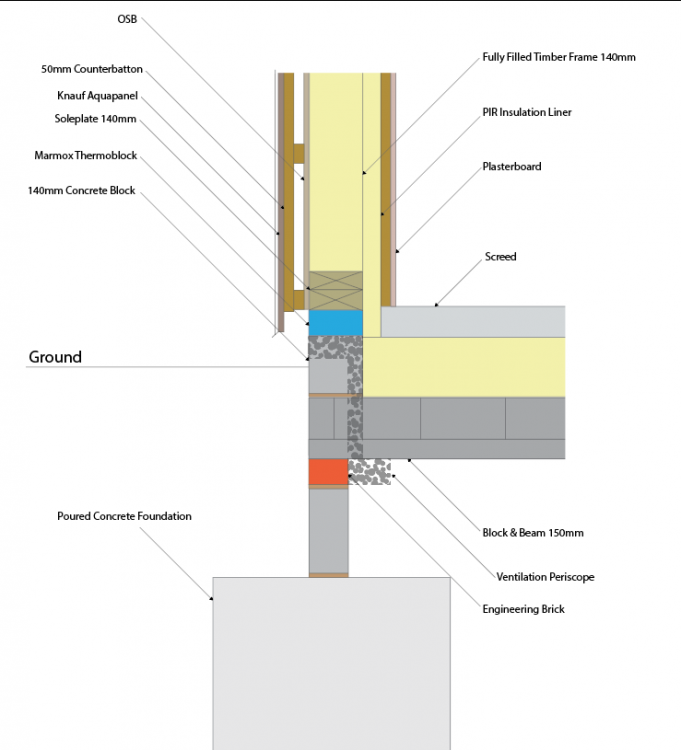

I thought I would update this with some pics. We pretty much have done it as the above drawing. Engineers drawing is attached too if it helps anyone else.

-

Does anyone have any experience with this product: https://www.resitrix.com/gb/applications-solutions/areas-of-application/renovations/ It is a heat welded EPDM that is 3.2mm thick as opposed to 1.2mm. It looks great and is super economical vs single ply PVC. I can't find much info on it except a local installer uses it and has hundreds of pics on his instagram installing it and it seems to be a good product that overcomes the weaknesses of EPDM, like the shrinkage and the glued seams coming apart after time.

-

Sorry for the slow reply. Yes there is one, it just isn't detailed but will sit over the PIR liner and behind the service void.

-

We are finishing the design work on our timber frame and finalising insulation and i wanted to get thoughts on soundproofing. All our walls are full filled with 140mm of rockwool with a pir liner. Wit the roof, we wanted to do a warm deck roof, with hardrock multifix and PIR combined to reach our .11 target. The problem is Rockwool and Kingspan are not comfortable with a hybrid system, and we don't have enough room for rockwool (355mm). We have about 210 mm to play with. Kingspan did the calcs and it all looks ok but then they emailed with concerns with regards to fire and condensation etc. We are near a road that can be noisy at times, and also concerned about rain noise etc. Does anyone have experience with 210mm of PIR and noise levels on a flat roof. I should mention, we have no plasterboard as the joists are exposed douglas fir. Also, is building regs .11 or .13 for flat roofs, i'm finding some conflicting info. Thanks!

-

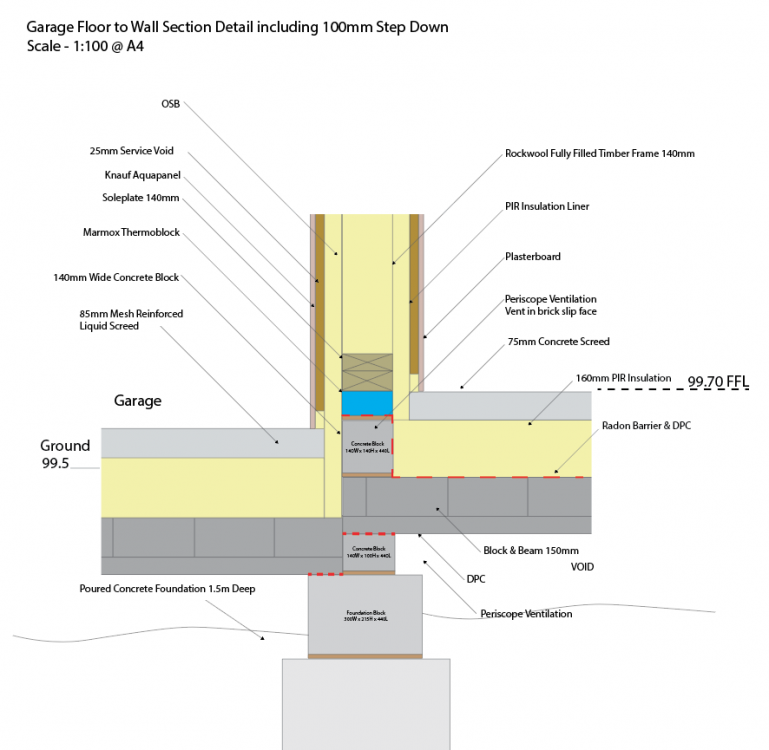

I had to make some amendments to accommodate the drop in height for the garage. Do these look ok with the wall sitting on the floor like this.

-

Yes of course i’ll do that.. i’ll do it in sketchup tomorrow before sending it to the engineer to check it all out.

-

Ok thanks, i’ll do that

-

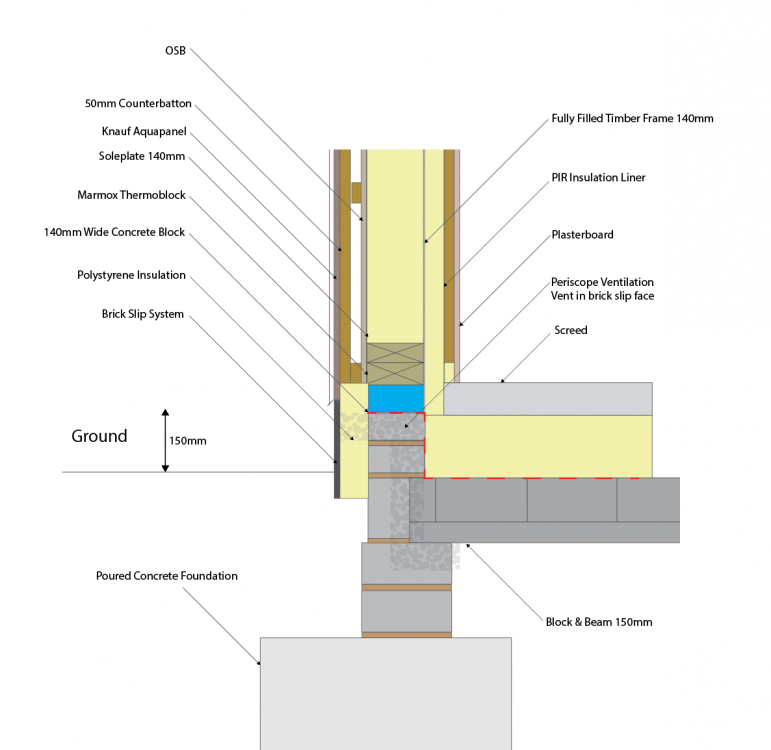

Ok i’ll add that. How do you ventilate the wall cavity well with that insulation there?

-

Where would you put a Radon barrier? Just where the DPC is or just in place of the DPC to replace it?

-

Thats super helpful Russell as i was looking into doing something like that but wasn't sure it would work with brick slips etc. Great to know people have done it. Does this look ok? Just added the 25mm rip too.

-

-

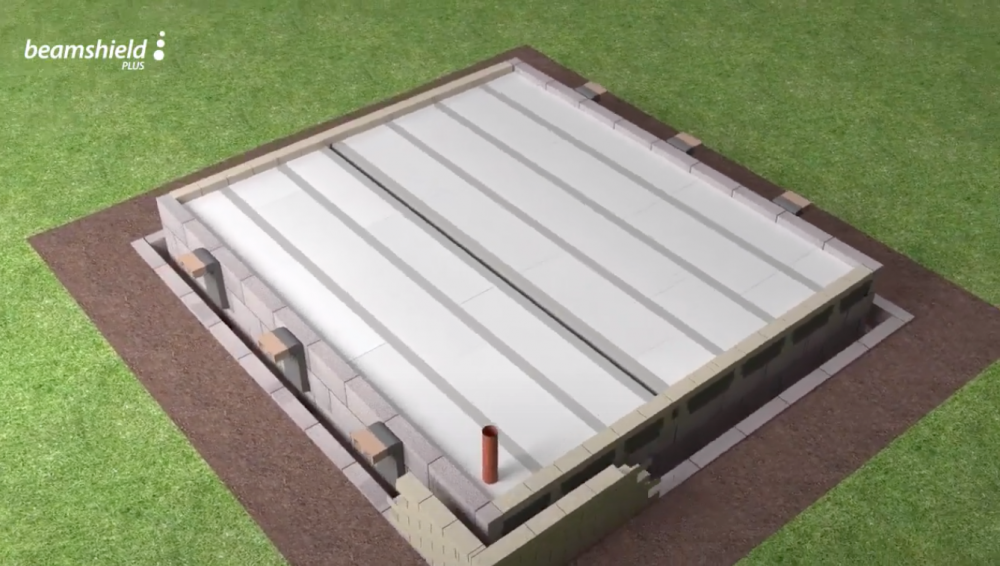

Yeah, i mean the the ends of the beams around the perimeter... if you had ufh it would travel through the screed and the beams to the ends which in my case would be exposed to the world. I suppose if you had a cavity filled with insulation it would be ok but with my timber frame i can’t see how it would work.

-

Any idea how can you avoid cold bridging through the ends of the exposed beams and into the screed with the Beamshield system?

-

Ahh that sounds really interesting, i'll take a look at that now. Have you worked out any detail drawings yet on how it might work?

-

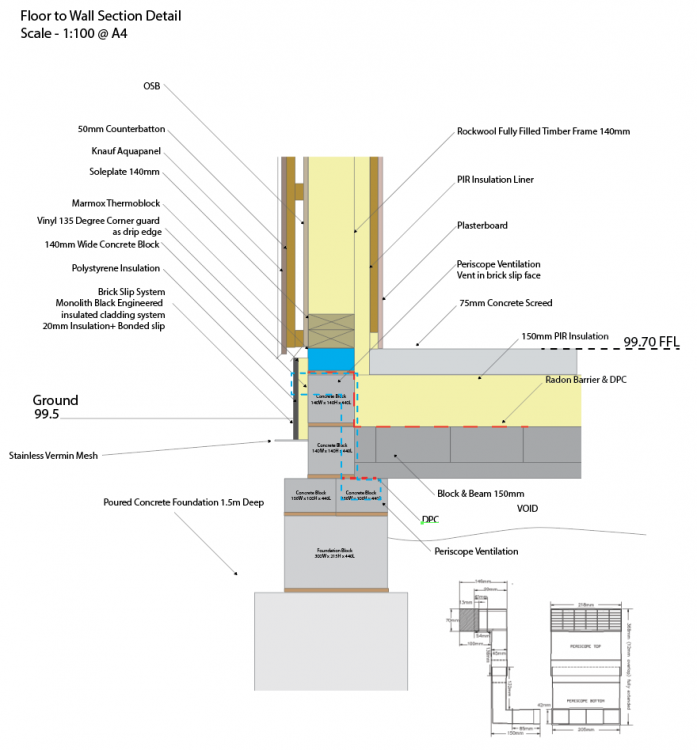

Thanks for taking a look. It's just a rough sketch I have done that i want to get right before sending it to the engineer tomorrow (it is to scale though yes), as they won't be looking at insulation, but more the structural side. My issue is we have a height restriction and i don't want to raise the internal floor too high as we will have to lose room height. The DPC has to i believe be 150mm above ground level, which means the frame has to sit roughly where it is i think other wide the frame would be pushed down a course. I have made a few changes, but it requires a vast amount of the Marmox which will be quite expensive so would be good to get any thoughts. Ive made some tweaks here. How does this look to you?

-

I’m building a modern timber frame house.. not to passive house but as best as i can. We wanted to go insulated raft but our site is no good due to the very close hawthorn hedge and soil conditions to so we are going with block and beam. I have attached a very rough detail and wanted to get some thoughts before sending it to the engineer. We are planning on putting drainage in beneath the subfloor to ensure there are no issues there. Does the Thermoblock location look ok where it is, just below the frame? It feels like there will still be bridging through the block-work beneath it. Thanks!