DInwood

Members-

Posts

26 -

Joined

-

Last visited

Everything posted by DInwood

-

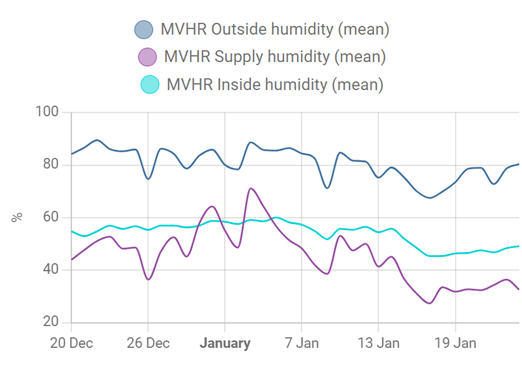

I was vaguely aware of this issue but chose to ignore it in my modelling. Perhaps I should look again. The Zehnder MVHR reports humidity as well as temperatures of the various airflows and Home Assistant logs 4 weeks of data. Looking at this I see a relative constant ~85% outside RH & 55% inside (measured at the extracted airflow, so from the humid areas). Here's the last 4 weeks daily averages for interest: We too always blade after showering.

-

Thank you all for reading my post and your thoughtful responses. It seems that nobody in this thread has tried do do this (predict daily heat requirements), but also nobody else is so dissapointed with their heating either. The scientific part of me is hurting because I really feel this is capable of being modelled and I can't yet see where I'm going wrong. Thanks to your comments I've gone back over my spreadsheet (which has data from before the heating started up and for a winter week it was off). I find that if I use a higher rate of heat loss (say 120W/C) then to account for the periods the heating was off, no realistic amount of internal heat sources would account for the house temperature. Conversely if I crank up my estimate of internal heating then the excess of Ecodan caimed heat output over predicted gets even worse. FYI I'm not ready to give up yet. Thanks also for the references which I shall now go away and study in more detail. In parallel I will continue with the efforts to increase the CoP. The MCS certificate used an sCoP of 4.1 - a long way from what I'm getting.

-

Thanks JohnMo. You are concentrating on the CoP side of my puzzle. That's fine - but are you saying I really should be achieving over 4 as measured by the Ecodan? If so, the installer needs re-educating as he thinks the current figures are realistic! I allow the DHW separately in my analysis. It is heated by ASHP with ASHP connected cylinder thermostat, there is an immersion but its never been needed as the ASHP gets the tank up tto 51C in about 45 mins.

-

No apologies needed. In all humility I'm looking to gain from the wisdom of more experienced people. So your feeling is that I'm underestimating fabric losses. Any idea how I could estimate what to allow for? I've tried some arithmetic modelling (eg looking at day-to-day variability and looking at empty periods) and if I increase the 88W/C by much then I couldn't make sense of the numbers (eg predicted negative heating days in winter). I fully accept I'm making some mistakes & I'll go back to my modelling to explore again. I'm very embarassed that I'm the only person who has tried doing this!

-

You are right, the MCS pack doesn't explicitly allow for internal heat sources. It does estimate annual demand & the document I've got doesn't say how this is calculated. It isn't hard to work out how it's done though & I'm certain they use "heating degree days" times their estimated heat loss per degree. I'm trying to emulate this "heating degree days" method by using actual outside temperature & estimated internal heat sources. I was hoping others had tried this also and had some experience to share or correct my efforts.

-

The MCS pack i was given was also wrong but only in its ventilation loss calcs. Indeed this gets at exactly what I'm trying to understand. I accept I might be wrong and am very open to ideas as to why. If I'm underestimating expected energy demand, what am I doing wrong? Is it my method of estimating other sources of heat? My method was pretty good at predicting when the heating would be needed. Is it ventilation load? Wind effects?

-

Thanks IanR. I'm puzzled why your average u-value is so high - have you got acres of glazing? My figure of 0.23 is the average weighted by area for each element and feels about right. Plus, as I said, my spreadsheet gives a very similar result to the MCS pack for the fabric losses. I'd be very interested to know what your actual heating energy input & outputs are. It could be I'm underestimating ventilation losses, but even if I double these it only adds 5% to the rate loss (ie I get to 94W/C), not enough to account for the discrepancy.

-

If you've lost the will to live imagine what my wife has to put up with! This post is really about the expected heat demand of a not-quite-passivehouse retrofit vs reality and whether the heat pump data can be trusted. To your questions: buffer, flow typically high 20s to mid 30C. 12 zones, heatmiser room stats controlling 12 zones of UFH. Operation: we have tried the all day constant temperature approach with very low flow temps but are currently experimenting with morning & evening operation with slightly higher flow temps (typ 30-35C)

-

Thanks for this: I think you are saying your actual heat use is significantly *below* what you calculate using the MCS methodology. In this, are you allowing for internal sources of heat as I described? For comparison, on our coldest day so far (avg ext temp -0.7C) we used 23kWh of electrical power for heating (measured at the consumer unit supply to the Ecodan) and the Ecodan itself estimated 39kWh of heat output. My method showed a net heat demand on that day of 34kWh & 10kWh power in. So one of the closest matches on heating but still poor electrical performance. I have no evidence that the house is haemorraging heat to the extent my analysis implies. With no heating it cools down really slowly - consitently with the theoretical u-values & ventilation losses. The architect who supervised the builder is pretty adamant the performance can't be that far off spec.

-

The Ecodan doesn't use that word, it is however set to "curve" which adjusts the flow temp according to the ambient temp. I think that is the same thing. However, as I implied and with no apology for the number of words used, this an anorak's discussion of theoretical vs actual performance and we are talking about huge discrepancies, not the fine tuning of CoP in my view.

-

I'm trying to reconcile the actual power consumed by our ASHP with what I expected: I'm finding it is taking more than twice the power I calculated, a combination of lower than specified CoP and higher than predicted heating energy output. I'll explain my reasoning below, but my interim conclusions are either the ASHP manufacturer's reported heat output AND their claimed CoPs are seriously overstated, OR I completely misunderstand the relationship between MCS heat loss calculations and reality. It may of course be a combination of both and I look forward to hearing what other people's experiences are of this. This is not simply a complaint that our CoP is too low (this is a fact, but the heating installer is on the case and making gradual improvements. However he seems to think our best ever day of 3.5 was good [despite manufacturer claimed 4.4 for those temps] but that ignores the issues I discuss here). For the avoidance of doubt, I’m discussing real measured evidence. I’m not talking about the system producing too much warmth – the house is about the right temperature, but I’m taking into account what is actually measured. I’m also discussing a “first world problem”, I know that compared to many we are using not a lot of energy. This is very much an intellectual exercise from a very analytical person with too much time on his hands (and who spent too much on building a low energy home)! So, the background: We bought a 1970's bungalow just before covid and refurbished/extended it into a 4 bedroom, 150m2 house intended to be energy neutral. It is well insulated, airtight (with MVHR), heated by ASHP and has plenty of PV. We asked the architect to get as close to Passivehouse as we could without incurring the costs of certification. We moved in in April '22 and when the heating was first needed in November, I was shocked at how quickly the kWh into the HP were racking up (regularly consuming >10kWh/day with outside temps of only 7C). I love a good spreadsheet so I quickly set out to try to understand what was going on. I was "lucky" that I had just started playing with Home Assistant and was able to produce good logs of actual daily average temperatures & energy use. My starting point was to model expected heat demand. I had the MCS design compliance pack provided by the heating engineer and it wasn't difficult to reproduce this in a spreadsheet using actual u values & dimensions (from the architect's drawings and suppliers). This gave me fabric heat loss figures almost exactly the same as the MCS pack. However I found a big divergence in their ventilation losses as they had not taken into account the MVHR. Instead I used the heating engineer's ventilation figures and the MVHR's claimed efficiency (verified by looking at the actual airflow temperatures). I've ignored draughts as we got a good air-tightness test result (1.1m3/h/m2 at 50Pa and we've since sealed a leak that accounted for some of that). This allows me to work out the total building heat losses per degree difference between inside & outside temperatures. At that time I didn't have room by room actual temps so I used a house average taken from the MVHR to be the temp of the air extracted. The actual outside temperature was taken from the ASHP. As a result of these calculations, I get a total house heat loss of 88W/C (and just under 12W/m2). Now for the difficult bit. In the MCS pack they estimate total annual heating demand using "degree days", an official annual figure which is in my view a shortcut to reality and a recipe for waiting for a year before you find out there's a problem! What is really going on is that the house is losing heat, some of which comes from background sources and the rest supplied by the heating system. These background sources are well known and some are listed & estimated in the MCS pack. These are: hotwater tank losses, heat given off by occupants, heat given off by electrical appliances and solar gain. HW tank losses are easy (from the manufacturer, pro-rated down as we keep our tank quite a bit cooler than they assume). Body losses are taken at 80W per person (and I'm afraid I really do have an estimate of daily occupancy since I started this - I know, a sad case). Electrical appliance heat output is going to have to be a guesstimate, although I have a good record of daily power consumption (& can take off the only large external consumption which is the car charger), some of this isn't going to produce heat. However I make a good stab at estimating this & can share my formula, which I think allows for the dishwasher & washing machine's discharge of hot water. That leaves the solar gain, which on our north facing site is pretty low in winter. Some sun does come in however and I have made small allowance for this from calculations based on the PV power generated daily (again, happy to share my thinking). We were away over the new year & my logs showed the house cooling down slowly (0.1C per day per degree difference between inside & outside temp). In an idle moment I looked at what I could learn from this and was surprised at the inferred thermal mass. It tells me that even small day-to-day internal temperature changes can consume (or release) a lot of heat. I now take this into account. So I've now got a speadsheet that can estimate the net heat input that should be needed to explain the actual inside temperature each day. I've got the actual electrical power taken by the ASHP (a meter on the consumer unit that I have to record every night - it's a scandal that I haven't automated this!). I have to take off the energy used to heat water (I'm pretty sure I've got a good way of calculating this as this was the only thing the ASHP was doing from April until November), so I know fairly accurately what power the ASHP is taking each day to produce heat. I know what I was expecting from the above net heat requirements & using the ASHP CoP tables (which allow for the ambient temp outside & the flow temp to the UFH). What I'm seeing is an electrical power usage that is 2.2 times higher (last week's average). Is my logic wrong or is the ASHP lying? In exploring the details I can look at the ASHP's own estimate of heat output which it does by measuring flow & return temperatures and the flow rate. They stress it's an estimate, but if my net demand calcs are right it must be a 50% over-estimate. They also give the electrical energy consumed (which is also slightly wrong compared to the panel meter) and from that I can see the CoP as they would calculate it: last week it averaged 3.0, compared to their tables for these temperatures of 4.1. This is beginning to feel like Dieselgate: manufacturers producing performance data that has no relationship with reality. Or I'm mad in doing these sums. Which is it do you think? My installation:- 157m2 4 bed house N facing, very close to the Torridge estuary (so winter average temp is warmer than Devon generally). The old structure had insulation & airtightness added underfloor (u-value 0.16) & external insulation added & cavities refilled (u-value 0.2). New flooring was slab on insulation u-value 0.14, new walls 0.15, flat roof 0.12. There is lots of Norrsken triple glazing, average u-value 0.79 & some roof lights 0.6. The weighted average is 0.23. We have: Ecodan PUZ-WM85VAA monobloc ASHP, Zehnder Q350 MVHR, Omni UFH, 6.4kWh of PV mounted on frames on otherwise flat roof. My calculations: A spreadsheet that works out heat losses in watts per degree C difference between average internal and external temp as discussed. A logic chain like this: Gross heat requirement = 88W x (outside - inside temp) - Internal heat generated = bodies x 80W + tank loss + f1(house power consumption) + f2(PV power generated) + thermal mass change = net heat requirement Electrical power expected = net heat requirement / ecodan claimed CoP at today's ext temp. I’ve been thinking hard about error sources that might explain a day to day variability in my data and the huge discrepancy discussed above. I did wonder whether wind might be a factor but the only article I found made me dismiss this (an Irish study which showed that as long as the outer vapour membrane as intact the heat losses were not dependant on wind speed). What else might I be missing? I’m grateful to anyone who has made it this far and wants to weigh in!

-

Choice of ASHP for near-passivehouse

DInwood replied to DInwood's topic in Air Source Heat Pumps (ASHP)

Thanks to all, consider me better educated... -

Does anyone have any experience of Alpha Innotec ASHP? (model LWD 50A/SX + HMD1 SE)? I've seen this on the spec from the heating engineer working on our house but have been unable to find out much about it, apart from some quite sparse documentation on Omnie's (the UK agent's) website. The house is 150sqm, designed to be carbon neutral, so well insulated with MVHR & UFH & 6kWp of PV (enough over full year to meet energy needs). Are there other small ASHPs that should be considered? Also, can anyone help me understand how an ASHP provides both low temperature output for the UFH and yet hot enough water for the DHW? I'm not doubting that it does, I just dont understand how it works despite studying the various plumbing diagrams on this forum. Plus what happens in the summer when in theory the ASHP could be cooling the "UFH" pipes yet heating the DHW? I'm feeling rather stupid despite my science degree (or is that because of...). I'll bet this has been well explained somewhere I haven't found yet. Thanks to all for a brilliant forum.

-

Hi there, Can anyone point me in the direction of Jeremy's blog as I'm getting error messages from mayfly.eu. I read him a lot earlier in the year but now I need more details of his systems I can find him! Jeremy, if you are reading this, thanks for being such an inspiration!

-

We are about to refurb & extend a house using a main contractor. It is currently empty, will be stripped, part demolished & extended. Our existing empty property insurance is about to run out. What insurance do we need until we move in? Excuse our ignorance.

-

Thanks to all for your input. I'm grateful to SteamyTea for the terminological correction and the re-education; I had believed that the heat capacity of the original walls (GF only) and new highly insulated GF slab would act as a store and also a sink for when the 1st floor overheats (most of the solar gain is from the 1st floor SW glass). If the inertia of timber & cellulose are better, then they are more significant on the 1st floor, so good news? If we are putting in UFH in the GF, is there much incremental cost in adding in the 1st floor (probably bamboo flooring)? I've read many times on this forum that moving heat from areas with high solar gain is one of the main benefits. What would be the energy source for a post heater in the 1st floor MVHR? Joth, not Barnstaple but Appledore - close! The decision to replace the original suspended floor was made to meet EnerPHit performance I believe. I could have a whole different conversation about finding an architect for a "zero carbon" project... but we are very happy with our eventual choice. Regarding VAT, we have been advised that we qualify for reduced rate as the house will have been empty for years when the works eventually start. Could I repeat my question about heating controls? I can't picture how the running of the UFH pump, demand for heat or switch to cooling are all controlled and what constraints it puts on the choice of ASHP.