Pipes

Members-

Posts

5 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Pipes's Achievements

New Member (2/5)

0

Reputation

-

Boiler frequent cycling with underfloor heating - Common problem??

Pipes replied to Pipes's topic in Underfloor Heating

Sounds good, at the very least it will be a good idea to confirm the problem and give an indication of how much additional volume/heat loss will impact the cycling. I was assuming that when operating the underfloor heating only (most of the day) I'd need to close the TRVs on the majority of radiators (instead of the overall radiator zone valve as current) in order to avoid upstairs being heated when it's not required then open them again when heating upstairs is called for again. Not sure how a standard £10 thermostatic valve will do that or am I missing something? @DamonHD's Radbot seems to be able to achieve something similar, instead of me telling the system when I'm not going to be upstairs Radbot would automatically detect that I'm not there but it's a similar cost to other smart TRVs (£50). Anyone have any guidance on an acceptable boiler cycling frequency? Assume that's going to determine how many radiators I'd need to run with the underfloor heating or the size of a buffer tank. -

Boiler frequent cycling with underfloor heating - Common problem??

Pipes replied to Pipes's topic in Underfloor Heating

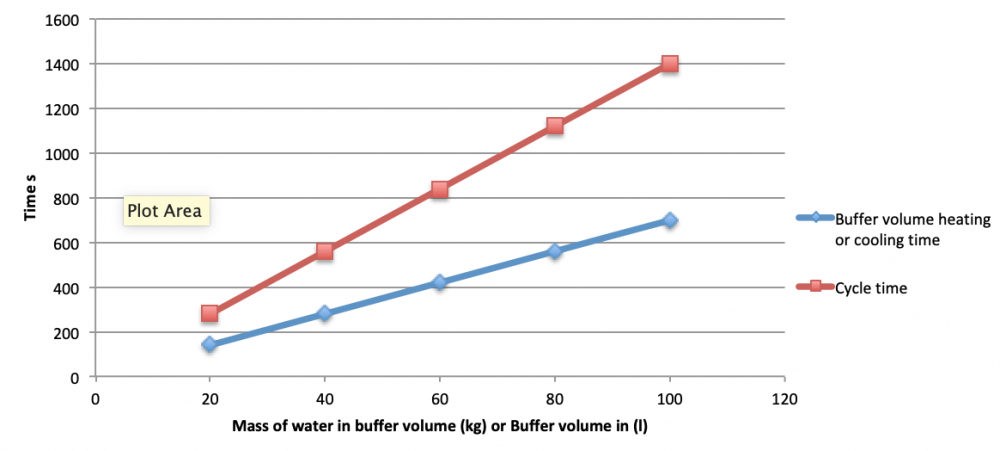

Radiator circuit open option does sound like the easiest option. How would you close all other radiators so that you only get flow through the one? Smart thermostatic valves on all other radiators? My initial thoughts were that it seems a wasteful to dump the extra heat being produced by the boiler into rooms that are unlikely to need it. I'm sure there are significant limitations however I had a shot at initial buffer tank volume calcs using a similar method to @Temp. Underfloor heating buffer tank initial calcs.xlsx -

Boiler frequent cycling with underfloor heating - Common problem??

Pipes replied to Pipes's topic in Underfloor Heating

Thanks for the thoughts guys. @Temp Yes the UFH works well otherwise, when the radiators are running as well and there's a consistent feed of hot flow to the UFH manifold it heats up reasonably quickly. I agree with @Nickfromwales derating the boiler for UFH operation only (if it could be done) would limit direct hot water and potentially operation with both the radiators and the underfloor heating. Seems that there aren't any nice quick fixes with setting changes (damn!) which still confuses me given that most UFH installers treat this as a standard setup. As @Temp has suggested next steps are to select a buffer tank configuration and size it to see if it can be fitted anywhere in the house or whether there's still potential to draw through the highflows internal tank. Can anyone help with this or suggest a company that would be good to contact? I haven't found any companies who are proposing thermal stores for this particular application. I got as far as looking to confirm the min power of the boiler and compare it with the power requirement from the UFH. From gas usage and the boiler display it gets down to around 11 kW during one of it's short on periods. Heated floor area is approximately 60m2 by 4 ~90m loops typically operating with 40C in and ~30C out. Multiplying the floor area by an approx heat requirement of 0.1kW/m2 gives a power requirement of ~6kW. As another wild card are there any tricks that can be used with a low loss manifold? -

Boiler frequent cycling with underfloor heating - Common problem??

Pipes replied to Pipes's topic in Underfloor Heating

@ProDave That's where my head is going at the moment but there seem to be a lot of systems without them working fine. @Temp The mixer in the manifold is set to 40C in order to limit the temperature in the engineered wood flooring. I agree that increasing this will help the cycling and should be able to get away with a slight increase but probably not a lot. Wood suppliers advised a wood surface temperature of <=27C which we get close to if it's run for a while. The UFH manifold is a JK Basic (see link below) with a max temp pump cutout at 55C. FYI they have a clever router that cut the UFH channels in the existing screed without raising the floor height. https://www.jk-gb.com/downloads/jk-quick-start-manual.pdf -

I seem to have what must be a common problem when using underfloor heating with a boiler however I haven’t managed to find a standard solution online. The boiler cycles at a high frequency due to the difference in boiler power compared to what the underfloor heating manifold will accept.Setup (underfloor heating recently added by local plumber) – see image below Worcester Greenstar Highflow 440CDI combi boiler (Central heating power of ~29kW down to ~7.6kW) Radiators upstairs with separate thermostat and actuated valve on the CH flow. Underfloor heating downstairs with separate thermostat and actuated valve on the CH flow. Manifold including recirculation pump and mixer valve to maintain the inlet manifold temperature at ~40C. " class="bbCodeImage LbImage" alt="" data-url="http://<a href="https://ibb.co/0DLwm3M"><img src="https://i.ibb.co/tm6dQ5s/UFH-current.jpg" alt="UFH-current" border="0"></a>" />IssueThe Combi boiler cannot modulate low enough when running the underfloor heating on it’s own therefore it cycles frequently on and off. At a high level, The thermostatic valve on the underfloor heating manifold gets close to the required temperature and throttles flow from the boiler. Boiler flow then bypasses the manifold through the pressure relief circuit and causes the boiler flame to turn off. The flow temperature drops The thermostatic valve on the underfloor heating manifold then starts to open because it’s not getting heat, pulling in cool flow and opening more and more. The boiler restarts when it’s anti cycling timer or temperature limits have been reached and quickly exceeds the underfloor heating thermostatic control valve temperature so the process restarts. If the anti cycle timer is put to it’s minimum of 1 minute, the boiler will run for 1 minute and turn off for one minute (the run time will further reduce when the underfloor heating gets up to temperature). At this frequency the flow temperature remains above the temperature setting of the underfloor heating thermostatic valve so the underfloor is happy.I assume that this boiler operation isn’t efficient and I doubt it’s doing the boiler any favours?When the radiators are operated concurrently with the underfloor heating the CH flow temperature remain stable and the system works nicely.Variables currently available in the system Boiler cycle time or temperature limit, currently 1 minute – If this is increased above 1 minute the underfloor manifold pulls in low temperature water as it cycles and therefore takes a long time to heat up. CH flow temperature, currently 60C – If this is increased it takes a little longer for the boiler to achieve the temperature however an increase of 10C only added 25s to the cycle time (by the time the high temperatures are achieved the boiler is mostly short circuiting around the bypass). Boiler pump speed, currently set to three – Assume a reduction would result in higher temperatures (lower flowrate with the same burner rate?) may also impact on the boiler/radiator operation? Boiler pump operation modes – Don’t know enough Underfloor heating pump speed, currently set to three – Don’t think this will have a significant affect. Underfloor heating thermostatic valve, currently 40C – Increasing this temperature risks overheating the engineered wood flooring. Next steps – help please! Is it a problem to leave the boiler cycling so frequently (1 min on then 1 min off)? Can any of the existing settings be adjusted to help? If current operation is a problem the only significant improvement I can think of is to add thermal mass between the boiler and underfloor heating manifold as follows (see image), any tips on these or is there a better alternative? a. Add pressurised tank (are these referred to as heat banks/or thermal stores?) upstream of the underfloor heating bypass loop. b. Draw the underfloor heating flow through the heat store in the boiler. This is the wild card option and I don’t like it because a connection would need to be made within the boiler (although it is accessible) and there may be an unforeseen impact on the hot water supply. I’ve mentioned it because it wouldn’t require another tank to locate, continually heat or pay for! " class="bbCodeImage LbImage" alt="" data-url="http://<a href="https://ibb.co/bLpkNgq"><img src="https://i.ibb.co/6b6kDRV/UFH-options.jpg" alt="UFH-options" border="0"></a>" />