SillyBilly

Members-

Posts

30 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

SillyBilly's Achievements

Member (3/5)

2

Reputation

-

Connecting timber lintel to brickwork wall

SillyBilly replied to SillyBilly's topic in Floor Structures

I can see a problem using the pocket approach as I did the framing before the problem arose. I wont easily be able to get the timber lintel into the pocket! The hanger approach doesn't have that problem. Unfortunately the Simpson Strongtie SFHWI184/135/100 SafetyFastMasonry restraint hanger is not a stock item and I have been quoted £94.69 for one. If I do use a pocket I can surround it with dpc. I presume I would use my mortar gun to fill around the fitted lintel and some sort of silicone to make it air-tight. Do I just add 10mm at each edge? -

Connecting timber lintel to brickwork wall

SillyBilly replied to SillyBilly's topic in Floor Structures

Thanks -

Connecting timber lintel to brickwork wall

SillyBilly replied to SillyBilly's topic in Floor Structures

Thanks Gus. The loading is from 2 I-beams running at right angles to the 90cm lintel, chipboard flooring and the upstairs framing etc. On the right of the 3-ply there is a pillar of resin-glued and screwed 145 x45 as pic. I would have preferred to have used two studs on the left of the doorway but the waste pipe to the extension would have clashed -

Connecting timber lintel to brickwork wall

SillyBilly replied to SillyBilly's topic in Floor Structures

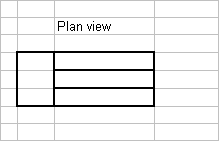

The first pic shows the actual size and position of the 3-ply wood lintel; the second shows the 900mm gap btween the framing and wall. The framing has the load of the I-joists which run parallel to the wall and the upstairs framing. The bottom of the wood fascia is at the level of the top of the brickwork. -

I am building a 150mm timber frame annexe extension attached to a flat roof single storey brick wing of my house. My original intension was to connect a 3-ply 150mm wood lintel over the new rear door using a metal joist hanger in the existing brick wall. I have since been advised that standard joist hangers need 9 courses of masonry above them and my first floor will be of timber! I could use a Strongtie SafetyFastWeldedMasonry Restraint hanger SFWHI184/135/100 which come with a restraint strap and doesn’t need masonry above it. This particular hanger is for 3x45 I-joists: the other range of Strongtie SFW doesn’t include that 3x45 width. If I go down this route I will have to cut out one course of the brick to get the overhang lip onto the wall. The alternative is to cut a hole for the 3-ply lintel but this is close to the end of the wall and would need restraining. Comments welcomed.

-

Cutting a BSP thread in 1/2" iron pipe using

SillyBilly replied to SillyBilly's topic in General Plumbing

I went for the Philmac 1143 at the same price. This is 21-27 x 15-21. The nuts are quite big at 70mm and I didnt have a wrench that size and the stilson wouldn't fit. Had a brainwave and used a oil filter wrench. The one I have is from Lidl and is thin and easy in a confined space. No leaks at the main connector but will have to remove the stopcock to fit insulation and tap. -

Reinforcement in blockwork over steel lintels

SillyBilly replied to SillyBilly's topic in General Plumbing

Thanks Gus for some useful comments. I had in mind to use Ancon products which reduce difficulties on levels and embedment https://www.ancon.co.uk/products/masonry-reinforcement/ancon-amr-x -

Reinforcement in blockwork over steel lintels

SillyBilly replied to SillyBilly's topic in General Plumbing

It will be internal when the single storey part is built but external until then: they dont recommend galvanised for external walls. Why considered? I have seen several cases where block walls have cracked possibly because of shrinkage after soaking, but am concerned because while the load is in compression the light weight blocks have little strength in bending, torsion, or tension. -

Reinforcement in blockwork over steel lintels

SillyBilly replied to SillyBilly's topic in General Plumbing

Because of the size of the opening and stresses at the ends, and to reduce the risk of cracks in blockwork. Extension will be built over 2 years and the blockwork will be external and subject to wind forces. -

Reinforcement in blockwork over steel lintels

SillyBilly replied to SillyBilly's topic in General Plumbing

It is for an internal single-glazed sliding door between two rooms in an open plan extension. So no impacts. Steel lintel over opening -

For a 3.6m opening in a 6.3m wall of 200mm Celcon blocks I will need reinforcement. The wall will be internal and loadbearing but I would prefer stainless steel reinforcement rather than galvanised or expamet type as it is structural rather than crack control I am looking at 3mm ladder type but this only comes in 2.7m lengths and width max is 100mm. I understand the reinforcement should extend 600mm beyond the opening. I asked the manufacturer what they recommend but their reply was that there were no standards set. What width should the reinforcement be for a 200mm block wall and what overlap should there be at the centre. Also how many rows above and below the lintels?

-

Cutting a BSP thread in 1/2" iron pipe using

SillyBilly replied to SillyBilly's topic in General Plumbing

The pipe is 21.5 or 21.7mm OD so I think I will use a Philmac 1144 -

Cutting a BSP thread in 1/2" iron pipe using

SillyBilly replied to SillyBilly's topic in General Plumbing

Thanks for all the replies. Is there one for iron to 15mm copper, or even simpler for my set-up iron to iron with no thread on either piece, because I could first cut a thread on the upper piece to fit my stopcock and riser. A link to one would be good to have preferably Toolstation or somewhere local -

I have had a standpipe tap from when the house was built. It came off the plastic mains at a T joint and leads to a gun-metal stopcock and the tap. Though the condition of the rest of the pipe seems good the pipe broke off just below the stopcock and took most of the pipe thread with it. Turning the mains off at the road I have effected a temporary repair using a hose and two good stainless steel pipe clips so we have now a water supply in the house on 1/2 pressure. I gave up cutting out the concrete to replace the standpipe but it was solid concrete and probably deep and the main electricity supply is nearby! So I have to cut a thread in situ and wont have a vice to stop the pipe stub turning! I have bought a Silverline pipe ratchet threading kit (868556) from Toolstation which includes a 1/2" die and have cleaned up the pipe. My plan is to use a long handled stilson to stop the pipe stub rotating. I have viewed someone on U-tube and wonder if my plan is realistic as I cant risk the pipe turning.

-

Excellent, so it just the length I have to sort