DIY_Amateur

Members-

Posts

15 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

DIY_Amateur's Achievements

Member (3/5)

0

Reputation

-

Thanks Nick - I went for plan (3) and created a hole in the wall that I could slide the sensor into and remove it, so I've saved having to drain down and hopefully the new part will fix things. Thanks for the advice

-

Hi Peter- that's very helpful thank you The sensor is pressed against the wall so would need to slide 10cm or so into the wall! I'm tempted to see if I can find a way to carve a hole for it to slide into but if not it plan (2) - any thoughts on whether strapping it to the manifold would work adequately?

-

Hi - I'm pretty sure the thermostatic head (with capillary sensor) on my UFH manifold is knackered. I can get a replacement and the head will just screw onto the valve body but accessing the current sensor and having room to remove it is going to be a pain. Two questions: 1) The sensor is held in with a grub screw so I assume it's not actually immersed in water inside the manifold (Uponor Vario B, maybe cocooned in a sleeve?) Is that right/likely and if I was able to remove the grub screw and get the sensor out would I need to drain the manifold first? 2) If I really can't get the old sensor out can I attach the sensor directly to the flow side of the manifold with some cable ties and maybe some aluminium tape/insulation - would this work do you think? There are surprisingly few pictures/video of this job so I appreciate any knowledge of what it involves. Thank you

-

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

Hi JFDIY - That sounds like it has potential, is a floor temperature something that can be retrofitted? Thanks -

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

Thanks Zed - interesting about the high temp epoxy I'll have to find out about that, thank you for mentioning it. Ed - the room in question is about 15-20 years old and although I don't recall if it has building regs it appears to have been built to a good standard. The window are double glazed (<10mm gap between panes) and don't leak but you do notice the cold when stood by them, the UFH/screed is laid on insulation, looks like polystyrene but I don't know what thickness, the room is exposed on three sides and has a vaulted ceiling (which is insulated with celotex at a guess 80-100mm), so I am aware that it has some challenges. I know it's hard to guess but assuming a reasonable standard of construction should UFH be ok for a room like this? -

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

Thanks for all the replies. I don't think the system will go above 3l/min and it's meant to auto balance the loops although I've seen no evidence of it doing that as the actuators just appear to be either fully on or fully off. No changes have been made to the layout of the room so it's as the previous owner built it but I don't know pipe spacing and I have no idea how much effort went into working out the heating requirement of the room. I suspect not a lot! I have checked the floor surface temperature and it seems to be heating to around 25 degrees and the mixer is around 27-29. The room stat is set to 19 but I've also checked that against another couple of thermometers and it appears to be 1.5-2degrees too low ie I set it to 19 but it's trying the heat the room to 20.5-21. I would try 45 degrees but I am constrained on the mixer temperature as one room is tile so could take a higher water temperature but the other is going to be vinyl tile (the screed is new so it's still drying and not being heated), since I can only have one mixer temperature it has to be set low because it will be serving the vinyl tile floor and that can't be above 27 degrees. I will have a go at measuring flow vs return temperature differential on the plastic pipes to see what that shows. For the past week I have given up on having any kind of set back temperature so it's been on 24/7 at 19 degrees (20.5-21 actual) and whilst I know it's slow to respond I just didn't expect it to struggle 7 days in when the first cold-ish night arrived. All in all I have to say I am underwhelmed by the whole UFH experience and yet I know many people can't speak highly enough of it so I will persevere (I don't have much choice) but I appreciate all the comments and experience of others as the information helps me compare and maybe rebase my expectations. Thank you! -

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

I wasn't sure whether to start a new thread but I have a follow up question... My under floor serves two rooms each with 2 loops; one half was existing when I bought it and the other is new underfloor that I have installed. I can't run the new bit as it's new screed and I'm letting it dry out but the old section has been down for years. Last winter (before putting in the new section) I noticed the room took an age to warm up and it never really felt like it was doing more than 'taking the edge off'. I hoped it was a fault with the old manifold and that new manifold if set up properly would sort it but now I am not so sure. Last night I left the system on and set to 19degrees (no set back or anything), I checked it as various times and by 1am it had fallen to 18.2 and stayed there until at least 4am. It's now 9:30am and it's only risen to 18.6. The room measures 35sqm and the flow rate is 3l/min and the thermometer claims the water is 35 degrees on the mixer; the flow temp to the manifold is very hot probably 70degrees. I have no way of knowing how closely the pipes are laid but I can see that there is some insulation under them and the screed is approx 70mm, when my IR thermometer comes I guess I can try figuring out the pipe runs under the tile floor to check spacing. Appreciate it's hard to diagnose but does this sound right, are my expectations too high? Thank you -

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

Thank you everyone for the replies. I've ordered an IR thermometer and some strips so that should help. I'm still not sure how to set the lockshield but if I can find the sweet spot where it is sufficiently open that no airlock occurs then I suppose that's the best I can do. But if anyone reads this who has set up an Uponor of this type I'm very interested in your experience! Thanks again -

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

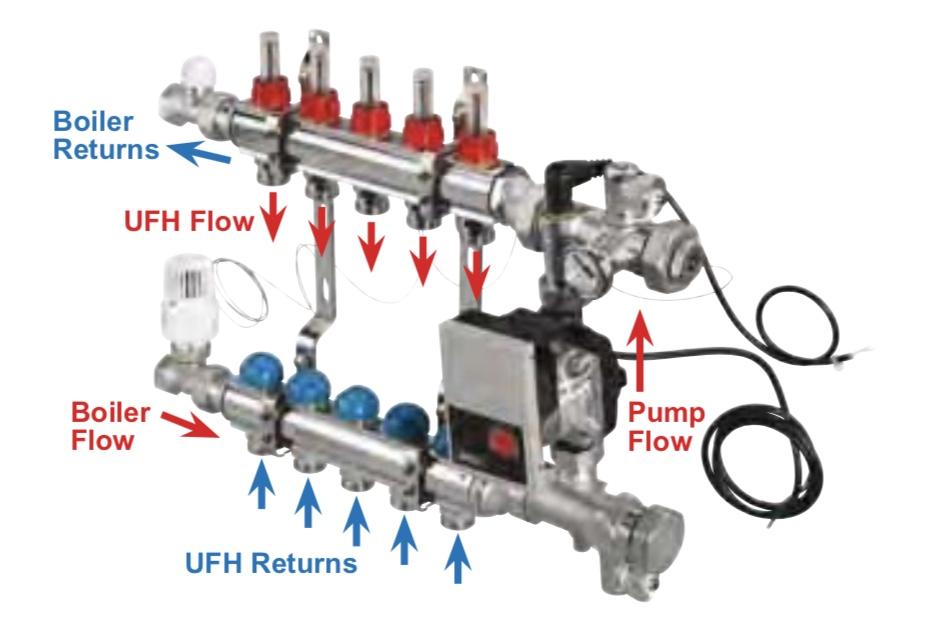

Hi Dave - thanks for the reply. I have a oil boiler supplying the heat. I'm pretty sure the temperature moves in the right direction when I move the thermostat so the manifold seems to be responding correctly. Out of interest how do other systems control how much water gets sent back to the boiler and how much gets recirculated round the UFH pipes? -

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

Yes, there's an AAV on the return just out of shot to the left of the allen key, there's also one on the flow from the boiler -

Uponor balancing using return lockshield

DIY_Amateur replied to DIY_Amateur's topic in Underfloor Heating

Thanks for the quick replies, I've attached a pic from the manual so most of the parts are labelled. Also a picture of my system with the allen key in lockshield and the thermometer vs injection head. @Triassic I have leaning towards your view that these are a guide rather than exact values, I'm just mindful that my flooring type will be vinyl tile and the floor temperature needs to be very low (<30 degrees) so I am not sure which of the two things to trust. Maybe I need to an IR thermometer to check? Uponor seem unique in putting this lockshield on their manifold so it's hard to find much about this on the web. I appreciate all replies, thank you! -

Hi For the past couple of weeks I have been trying to get my new UFH balanced as per the instructions Uponor provide for the Compact V5. The final piece of the puzzle is calibrating the lockshield that is on the return of the manifold; to be clear this is a single lockshield on the return pipe not on the manifold ports. The instructions provided by Uponor are as follows: The lockshield valve needs to be opened so that it forces the majority of the water around the UFH system. The primary and secondary pump speeds, existing primary pressure and manifold size will affect how far open the lockshield valve needs to be. To make an adjustment first unscrew and remove the white cap. Use the included Allen Key to adjust the valve. To calibrate it is recommended that the lock shield valve is first fully closed and then opened until you see the thermometer continuously reading the same temperature as the setting on the injection valve head. I have followed these instructions as best I can but I never get the temperature on the thermometer to match the injection head it is always 5 degrees higher (ie I ask for 30 and the mixer provides 35) - thats the first problem. The second is that I can hear and feel the water flowing through the flow and return and I am mindful that the instructions say they want the majority of water to flow around the UFH but it seems like I get the occasional air lock so I end up opening the lockshield a little to release it. Perhaps I am just being to cautious and it needs to be a little more open (and maybe that will fix my first problem too) but for something described as calibration the instructions are rather unhelpful; some description of what happens when it's too closed and too open would help me determine the right setting. Does anyone have any experience of calibrating this manifold and any words of wisdom please? Thank you

-

Thanks JS for your opinion too - I have learnt from experience that sometimes things are best left but it's a difficult to fight the instinct to 'fix' it. Just to check, I am assuming the flow is ok because the flow rate is at 3l/min which is the same as the other three on the manifold. Thank you

-

Thanks for replying, yes very weird as the locking nut isn't gripping the pipe so it's not twisting when I loosen/tighten it. My plan was to leave it if possible as these pipes do seem pretty resilient, but always nice to have a second opinion - thank you

-

Hi I have recently had some UFH installed and am having some teething problems. After a bit of fettling the system is running air and leak free but I noticed that one of the pipes coming out of the screed into the manifold is kinked; on the first pipe with the metal guide, you can see the blue lines are twisted. I have tried relaxing the nut on the manifold but the pipe doesn't untwist and when I run the system there does not appear to be any detriment to flow. I did a search and came across an old thread, which brought me a little comfort and I think mine is similar. https://forum.buildhub.org.uk/topic/2521-pipe-kink-should-i-worry/ However, better safe than sorry I hoped someone might be kind enough to take a look at advise if I need to get this sorted, somehow! Thank you in advance!