John2000

Members-

Posts

11 -

Joined

-

Last visited

Everything posted by John2000

-

Thanks fellas. I’be got my plan together now so will be strapping, packing and bolting the next few days. Although looking at the old part of the house (100years old) nothing has moved and it’s half the construction work and support on that part. Makes you wonder how OTT some of this is. Even the old purlin has been cut and wedged in some form of bodged repair from back in the day. 😂 I’ll add the photo. That’ll be a repair for another day.

-

Yes thanks. I think both can be used. Clipping down to the purlins and the long restraints to tie the wall back. Pain as the house is wrapped boarded and wrapped now but would’ve been so much easier as he went round with the nail gun at the time. All I ever hear now is ‘that’ll do’

-

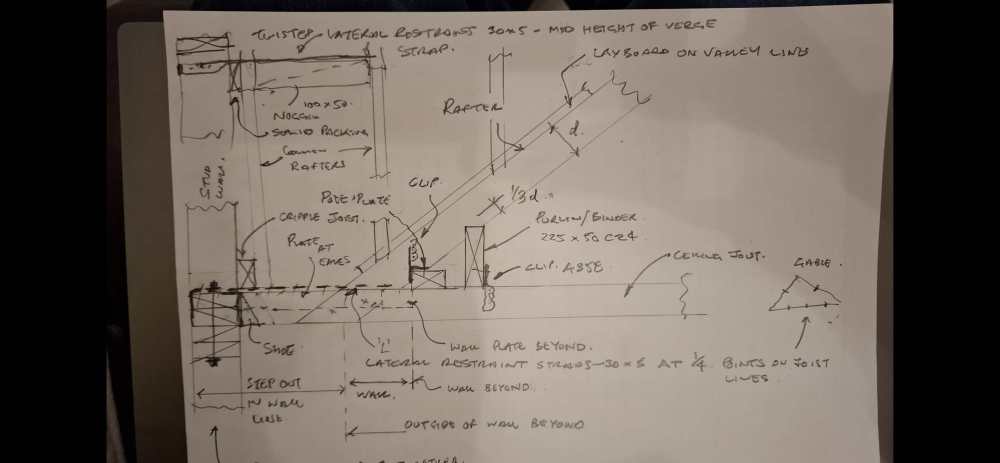

Thank you. Yeah that’s my view. It’s the restraint straps I was unsure of. The uplift/hurricane ties I’d go with as it’s a bit windy here and why not. The he’s mentioned twisted restraint straps - I’m assuming from gable end to joists… at 3/4 points along joists and mid height of verge. My head just thinks about the rafters spreading and pushing out. They’re birdsmouthed and nailed to purlin and to wall plate. Nailed to joists. And I’ve got 400c so plenty of them. Apart from the rafter and CJ spec everything else has been overkill and that’s what the BCO said. I really wasn’t sure on where exactly the twisted restraint straps would go.

-

I have had a timber side extension built. SE has put restraint straps on the drawings. Builder and BCO have said it’s all connected/nailed and not necessary. I understand that the hurricane ties might be OTT for my area but I still don’t like the idea of the rafters only sitting on the purlins then lower binder/purlin without any connectors. The ceiling joists are acting as rafters ties but just nailed to the rafters - no bolts or screws. Should this be beefed up a bit? Twisted restraint from gable end wall onto rafters and rafter clips on the purlins? plus better connection for rafter to ceiling joists/rafter tie? One side of the roof is normal gable, one side has a gable projection/doghouse front. - hence the rafters pointing into the stud gable end there. I also think the purlins should be packed out both sides with dry mix in masonry side and some noggins on timber side to stop twisting. (Don’t ask about the 4x2 - it’s what the SE spec’d - I asked builder to go with 6x2 but when I got back from work that day all the 4x2 was in) binders and outlines and internal stud walls support them but just another annoyance. Many thanks

-

I assume he let the labourer loose. I wasn’t impressed. He’s back next week to sort them out. I didn’t think about recessing the nuts in. Theirs another that’s nailed one side that’s again (near the pipework) some wierd F’ing situation that could’ve been avoided but it is partially nailed on top though. It’s just annoying and lucky I’m on top of the checks before I dragged BCO out only to fail it. Rest of the work is spot on or even overkill. Doesn’t add up. 3/4 money held back though until sorted.

-

Theirs a nailing schedule on the hanger. I.e 20 for face fix only. 8 for face and 4 top. The schedule doesn’t give a mix though although their are others ways around apparently without hangers but needed to know the best alternatives

-

Hello, the builder here has gone a bit well… I don’t know without being rude. He’s done a really good job throughout but let us down on these bits which are the joist hangers. One is a car crash which he said he let his labourer loose and is going to change. The other 3 are partially nailed. (One folded down at top but on a double for stair opening. The others on a single but just down one side or holes omitted. My BCO suggested extra nailing from joist direct to ledger but really should I be getting him to cut off bolts and re fit where I can? (The car crash one he will) the one with hanger bent down at top could be enhanced nailed direct into ledger? - although it’s on a double for stairs. The one that is only down one side is also not great but only on a single, as his the partially, they’re both nailed in top though so I thought the one jumping the patted plate is ok. The half side only - I don’t know. Any practical suggestions to get these fixed please?

-

Thinks Jimbo. It’s gonna be full of concrete so no access either side.just working out the best way not to bodge it up. Cheers.

-

I did consider that and smash it in but Anglian water want £750 for an inspection first, then no doubt they’ll want something more! where with a jump and build over which I have, I dodge the ludicrous payout and just remedy it.

-

Hello, I’m looking at extending a concrete slab to the the edge is a lintel that jumps a pipe. As you can see in the photos the sub base that’s already poured stops short due to shuttering. I need to extend the subfloor up to the edge of the inner course. The pipe is already incased in concrete from previous installation (I’m not touching that for love nor money) it’s disused but it’s blocked and full of water and crosses about 10 properties. More of a soakaway these days than the old soil pipe and rainwater it used to be. Anyway, I was thinking just putting down a layer of sand for compressible, then type 1 down and compacting (gently) then pouring a concrete/SBR mix up to the edge of the lintel. (With shuttering) insulation and screed will go over top. I’ve got to backfill around the edge of the slab anyway in parts to close the gap between the poured slab and inner leaf. I do have a bit of rebar laying around I could use as an additional support running across the void?? And bedded into the backfill. Thank you.