YodhrinForge

Members-

Posts

55 -

Joined

-

Last visited

Everything posted by YodhrinForge

-

What I want to add to my plans isn't actually a conservatory per se, more of a glass porch, but the prices I've seen both by doing research online and in a couple of cases from local companies are, to my eye, lunacy. Assuming an aluminium frame, triple glazing, and the groundworks already being done the small lean-to design I have(which isn't even a full lean-to, it's a pitched roof 1.6mx3m and a 2.5m front elevation, plus a triangle on one side of the pitch - it slots between two existing extensions to the building) I'm getting back numbers in the 9-14 grand range. For something that - even buying stuff at pleb non-tradie prices and building a frame from scratch - can't have more than 5 grand's worth of materials involved, and that's using the worst pricing I could find, I could get it down to 3.5 if I went dealhunting and compromised here & there. It's a job that would take two or three days, max, for two guys(you'd need four guys for about an hour to do one heavy lift). Are they paying their lads like FTSE100 CEOs? Are the frames alloyed with gold? I get that you pay a premium to have professionals do a job, but almost doubling the cost of labour & materials seems like simple banditry.

-

Decent "middle of the road" brand for plugin tools?

YodhrinForge posted a topic in Tools & Equipment

Not too pricey, not too crappy is basically what I'm after. I've got a decent set of battery tools already(Milwaukee for important/frequently used ones, Parkside cheapies for anything I only use occasionally), but when I finally get the chance to start work on my reno project I'm going to need stuff for bigger jobs that won't require me to faff with batteries; plunge-tracksaw for sheet goods, mitre saw for framing, mains SDS for taking out the old fireplace and various bits of outdoor work to rid myself of crappy concrete things, a punchy shop vac(ideally with power passthrough and tool-start) etc. There's loads of decent reviews out there for battery brands but all the stuff I find searching for mains tools is AIslop listicles. EDIT: Oh and none of this "jobsite power" guff please - mains 230vAC, I don't want to have to faff with transformers. -

M'Lord, I present to the court Exhibit A. First of all, I am unfailingly polite in person. That's why I like pseudononymous internet forums. Secondly, I'm not demanding access to trade shows, or that I be given the same priority as a volume housebuilder, I'm literally just saying if you're bothering to put together a website and you're bothering to claim you sell to the public, there is *no reason* not to put up a per-unit price unless you want to retain the flexibility to fiddle individual people based on your estimation of how clued in they are. If you're still running a business in this day and age on the basis of "okay he wants this much, what can we fleece 'em for" rather than "this is the volume I need to move at these prices, and so each unit must be sold at X - if you make a really big order I might consider a volume discount" then that's a perfect example of the kind of Victorianism I'm talking about. The fact you make so many assumptions - oh he must just be doing some silly wee thing, a bit of wonky sopping-wet CLS from B&Q would do him, what's he moanin' abaht etc - is absolutely typical of the attitude I'm talking about. I'm conducting an eco deep-retrofit of a 19th century stone cottage with a late 20th century masonry extension that will be receiving an additional wooden extension - not using whatever CLS is shunted through DIY stores once the good stuff has been sold through proper BMs, using specialist engineered timber products because long-term dimensional stability is important for maintaining airtightness - and so far as a complete layperson I have discovered exactly two things I'm not comfortable doing DIY - electrics and traditional slate roofing - because frankly it's not exactly rocket surgery, and I have the free time. But that's not what the industry wants. The industry wants you to hire an architect, who instructs their pals who're QEs and SEs, and then call up their buddy who's a builder, who then goes and chats to his pal who runs a BM and gives him a lovely jubbly little deal, and if the plebs try to butt in to any step of that inefficient, incestuous little process we're given as much of a runaround as possible to try and discourage us.

-

So I've been in my new-old place for a few months now and I've noticed that over the past few weeks there's a really bright mint green colour that seems to be bleeding through the cream wall paint at various spots, and increasingly so(primarily at edges like the wall/skirting line or next to trim and doorframes). Pretty sure it's not mould or anything like that. Redecorating was something I wasn't going to be doing for ages yet, but I am planning to do renovation work that will involve fiddling with one of the greening walls, is it anything to worry about do you think?

-

Not really how it works in this case, I'll have sufficient access to create a seamless airtight layer even though it's a retrofit. Attic & floor membranes and doors & windows will be taped off against the masonry, then lime parge applied to the masonry will seal the walls over those joints. The handful of tight corners where getting tapes in would be a faff will get a liquid application membrane product applied and that can be taped off to. I shouldn't have any appreciable gaps, and all those products have been through enough testing that I can be assured I'll be long dead before they risk losing any performance.

-

Oh here's another bugbear - if your timber is 45mmx45mm, then don't bloody well advertise "47mmx50mm joists" and then put "lol jk that's the size before we regularise it" in smallprint at the bottom of the page. I was aware of that pitfall in advance but it still boils ma pish every time I see it, plus even if you're aware of the problem it still makes finding actual 50mm(or whatever size) material a gigantic pain in the bum when the dimensions actually matter. All the joists and rafters in my old house come from a time when the stated dimensions were the *actual* dimensions so trying to find stuff that will match them when I need to deepen, reinforce, or sister one is rage inducing.

-

Honestly starting to think you're right. I went back and ran the rough calcs for just deepening the joists to 200 or 250mm and using ecologicalbuildingsystem's retro-ecofloor technique and it's coming back somewhere between 0.13 and 0.15 which is in the same range as the thermally broken approach and would be easy as widdlin' up a wall by comparison - grab some joist stock, tack them on underneath with the nailgun on an angle, a few screws up from below, then it's all vanilla. I don't anticipate there being any missed bits, I'll actually have pretty good access to everywhere I'll need to do comprehensive airtightness and I'll be handling that aspect of the project personally to ensure no bodging, but tbh that aeroseal thing looks nas-tee to me. "Non-toxic water based" but requires full-face breather with VOC cartridge during application hmm yuh-huh. Looks to be an aerosolised acrylic caulk, no info on longevity testing, no info on whether it is or how long it stays flexible to deal with wood movement etc, can't see vapour permeabilty numbers in any of the docs on their site. Seems like it would be a useful tool in the context of the volume housebuilding sector to save them time and effort, if they were building near-passive homes(and assuming engineered timber rather than sopping wet CLS that will look like a plate of spaghetti by the time the house dries out), but in a back-to-masonry deep retrofit I don't see the value really.

-

I have to say that so far in life, I've enountered few experiences more mindlessly, needlessly frustrating than trying to give the building industry my money. It always seems that you need to put on the fez hat and give the special secret handshake to prove you're One Of Us before any sod will even tell you how much something costs. Something as basic as a webstore with a simple per-unit pricetag is apparently beyond ~95% of suppliers, even the ones who ostensibly sell to the public - like, why even bother pretending? Just say "trade only, DIYers bog off", don't waste my time submitting requests to perhaps maybe be considered for the possibility of buying something, only to turn around and refuse to even give a price unless I provide complete structural plans for the project - I want to know the rough price *before* I get to that point or how else am I supposed to sodding well cost the different options against each other. Computer building, car and bike mechanics, even other trade-esque areas like furniture carpentry and small boatbuilding are at least *somewhat* open to laypersons who want to do things themselves and just need access to buy materials - hell I've never had better customer service than from a local-ish sawmill where I get hardwood and the first time I went there I was completely clueless - but heaven bloody forefend I try and find out how much anything that isn't bog-standard DIY store CLS from a construction materials supplier is going to set me back. Everyone in this crappy country seems to want to pretend they live in the Victorian era for some reason.

-

If the sarking boards are wind-tight, which they are as they're rated for roofing, I don't see how it would make much difference, as it will all be fully outside the thermal and airtight envelope as is the wall the chimney sits in. We're still talking about 3 pretty small vents feeding one small duct, it's not like it's going to generate a howling gale; back of a napkin prelim calcs suggested it would only be a bit more than double the present airflow which is with only two functional vents, and still below what modern regs spec for with air bricks every couple of metres around the house perimeter. I was also under the impression that a closed up chimney has to be ventilated somewhere regardless and since it won't be from the heated interior I don't see how the solum air is going to be colder than air direct from the exterior. It's not either-or man, I'll be investing the time and money on airtightness anyway. All exterior and adjoining walls are being stripped back to bare masonry and will have a lime-based parge/levelling/airtight layer applied before lime adhesive & hammer fixing woodfibre insulation boards. Appropriate tapes, membranes, and where needed liquid-application barriers will tie the lime parge into new passive rated windows & doors and a complete rework of the current room-in-roof attic conversion which will have contiguous insulation and airtightness on the interior of the pitches from apex to eaves(ventilation gaps will be maintained to regs "outside" the insulation), as well as to the ground floor with the airtight layer under the insulation - which in the concept being discussed would be the airtight T&G sarking boards, or in the "normal" method a vapour-open roofing membrane stapled to form "slings" between the joists for the batts. I'm already committed to going whole-hog on this, that's why I'm trying to figure out how to maximise every aspect as much as I can without going *too* mad on costs. Insulation boards over the top of the joists kind of negates the object, which is to place as much of them as possible *inside* the insulation envelope, which should ensure only the very tips embedded in the walls on the coldest days get close to hitting dew point and even then should quickly recover to a temperature that encourages evapouration and allows them to expell any moisture through the vapour-open buildup. All that said, this notion seems much easier to work with than my plan and should work fine with the "membrane sling" airtight concept with only a little bit of faffing. Rough calcs suggest I could hit aroundabout 0.15 with that - could be more, but factoring in the depth of the flange hanging down I think I'd only be able to fit 60mm insulation under the joists with the requirement to maintain a 150mm cavity.

-

Aye it's this stuff: Seems to be granite from what I've read online? Thinking about it, I could somewhat over-order my concrete ballast and mix that in, end result should be fairly type 1-esque just lacking the few bigger ~40mm chunks.

-

Just wondering if it's allowed/sensible. I have a garden absolutely rammed with that heinous red gravel that was big in the 80's and early 90's and want to replace it, but paying to have it lifted or just posting on FB inviting randoms to come and shlep about my garden with shovels doesn't hugely appeal, so given I'm going to need a bunch of hardcore for the foundations of my new extension, my planned garden room, and as a subbase for a couple of new concrete floors putting it to productive use and saving myself the costs would gladden my tightfisted little heart. Maybe by mixing some sand into it to make up for the lack of fines?

-

Almost: 35mm WF(no need for a membrane with the T&G sarking boards), flexi WF, VCL, subfloor(the floorboards evidently went away sometime in the 20th as its particleboard at the moment), LVT or somesuch top layer. Ventilation is definitely a concern as there are presently two vents, one at the narrow front and one diagonally across from it at the wide rear(the best way to envision the property is a wide cottage divided internally into two properties shaped like interlocking Ls - mine is the small front wide back one). I suspect there was a third directly back from the front vent at one point but it was covered by the old kitchen & covered porch extensions, since the porch is getting ripped out and replaced with a new utility room I'll be restoring that one via a duct. Preliminary discussions with architect came up with the notion of using the pipe-converted chimney flue that will be left after I have the gas fire ripped out and carrying the pipe down into the subfloor, changing from cross ventilation to constant draw on all ground vents via stack effect on the chimney pipe(with anti-backdraught cap). That has to be modelled though, to make sure it'll work. I have been thinking over torre's notion a bit more and trying to figure out if I could make the install easier by deepening the joists with 50x50mm rigid wood fibre board "battens" ripped from insulation(ordering a bunch of that anyway for the stone walls) and screwed in diagonally from above, just need to figure out a way to do the membrane underneath - maybe instead of trying to keep it whole and stretch it across crosswise to the joists I could cut it into strips sized to cover the gap between just a few joists and tape them(apply the first one "properly" by nailing off a runner to the wall plate, then secure it to the first joist with tape, then just move across taping each strip off against an extended joist, and then the next strip over that). Lots of expensive tape but easier to manage, and would still break the thermal bridge.

-

I'm going basically-EnerPHit - "wasting time and money for only microscopic improvements" is essentially the job description lol I appreciate for most people it's not worth the bother, but as I'm DIYing a lot of this project and it's a "generational" retrofit of the building which will almost certainly be my home until I shuffle off, I'd rather do as much as I physically can and get the best possible end result, even if it wouldn't make sense for a commercial project. Adding 35mm sarking to the underside of the floor assembly bumps the u-value from over 0.2 to under 0.18 on the rough calcs which both hits regs(and I'm trying to show willing there whenever I can because there are a few things I want to do that will require the BCO to sign off exceptions, so better to not push my luck) and will actually make a bit of difference in the long run in the context of a highly airtight(MVHR) heatpump-heated home up here in Scotland. If I break any of the tongues eh, I'll just slap some Tescon Vana tape on the join. Lifting the floor unfortunately isn't an option as the doorways are already only just big enough for me to walk through without ducking and I'm avoiding structural work if I possibly can so going around and remaking all the lintels to be a course higher doesn't appeal. @torre I considered something similar to your suggestion about the backer board, but I'm having to be very mindful of maximising the ability of the floor assembly to dry out into the cavity as these old stone cottages only have a small amount of ventilation and being in a conservation area means I can't just go around punching more holes into the wall, so I'd be hesitant to introduce even small elements that aren't as vapour open as possible. That's why the sarking is such an appealing product, being wind-proof and resistant to moisture but still basically transparent to vapour.

-

Pretty close to deciding I CBA with slabs and UFH and just insulating the existing perfectly good suspended timber floor as flooring has to come up for other work anyway. Easy option would be membrane slung between joists filled with wood fibre, but that leaves the joists as cold bridges, so I'd prefer to use the approach of adding tongue & groove 35mm wood fibre sarking underneath the joists(which doubles as the vapour-open windproof layer) - trouble is my solum cavity isn't gigantic, about 270mm below the joists, and even with a right angle drill attachment etc I can see getting under there with the thermally broken fixings is going to be a pain in the bum. I'll do it if I have to like, but if there were a ready made easier solution I'd be interested to hear about it - some kind of heavy duty plastic L or T bracket that could be hung from the joists maybe? I could screw in diagonally from above but I'm not sure if that's going to be secure enough long-term.

-

Alas I'd already tried that and my original issue stands - any inclusion of the phrase "party wall" almost exclusively returns results concerned with the Party Wall Act and the fact it doesn't apply here, and even using quotes just sprinkles in a few links mentioning the fact the scottish building regs exist. As far as I can tell from checking them directly, having done so previously, the regs only mention the concept specifically in relation to not undermining the structural integrity of the building, and in terms of requirements for fire resistance. There are mentions of *boundary* walls, but those explicitly refer to walls external to the house constructed along property lines eg garden walls, not part of the structure. I can't find any info on what processes, if any, actually govern situations like "I want to attach something to an external wall that is also a party wall wot do?".

-

I know the Party Wall Act does not apply in Scotland and that things are done differently here because that's what every single online search result I get tells me immediately before not saying what those differences are or linking to them and immediately going on to discuss the E&W Party Wall Act in detail. Whether my google-fu is weak or search is just enshittified nonsense now I can't wrestle any more than that out of it. Does anyone happen to know what if any legislation *does* apply here? I have a useless little part of my garden that sits between me and my neighbour's extensions that I'd like to make into an enclosed porch with a mini lean-to conservatory, but that will require at minimum a few bits of silicone sealant on their extension wall(based on both deeds and my own comparative measurements their extension wall is built running *on* the property line, not merely facing up against it) and sticking some butyl tape to their guttering, so while I fully intend to take the idea to them for discussion and come to a reasonable accord rather than just spring it on them as a fait accompli, it'd still be useful to know if I have any legal rights or legs to stand on.

-

I have this odd little space on my property around the back between my neighbour's existing extension(built up to the property line, so is a party wall) and my own house's existing extension. It serves no real purpose, it's north facing and the ground level is shaded by the extensions so nothing useful will grow there, it's inconvenient to use as a bin store, and it features the downstairs bedroom's only window so regs won't permit a "proper" extension there, it's just generally dead space. My only initial idea was to stick a couple of sheffield stands around there in case any visitors come by bike, but sitting in my little back porch the other evening which unfortunately will be getting demolished to make way for a utility room(and moving that isn't an option since it needs to be in that spot for various reasons) I found I actually quite enjoyed having a sheltered wee space to read and listen to the rain hitting the roof looking out to the garden. The space is about 2.5m wide x 3.6m deep and apart from having to faff with the drainage and guttering(which all needs to be addressed as part of the broader renovation work anyway) it *seems* like it would be a fairly simple extra project since it would only need the roof and frontage, but from attempts to research it I'm finding the "conservatory industry" seems pretty thoroughly geared around a few standard designs all of which are intended to project outwards from a wall rather than be fitted between two existing ones, so I take it I'd be looking at a custom design? Does anyone have experience with rough costs for that sort of thing? Would it be easier to go to a specialist company or could I be better off just getting my existing architect and structural engineer to specify it and order individual components myself? Given I'm in the central belt of scotland and it's north facing it'll have to be triple glazing so that narrows my options.

-

Yeah I probably will have to drill it in the end, bloody inconvenient though due to the way the extension was done(hipped roof into middle of existing pitched roof so no easy access from the attic, walls inside are tiled and the roof has that really tough popcorn plaster, probably have to go in from outside and then just jam the hole with silicone for the short term). On the plus side your comment made me double check and I was just being dim with the garage - it's single skin on three sides with solid double on the front with the doors in, they just put some lines into the render on the front side so it would resemble the wall of the extension hah.

-

I'm starting to get into the weeds of detailing with my architect about my renovation and was just wondering if there's a way to determine cavity size without having someone digging into the walls? I suspect I know the answer but might as well check. There's an extension on the back of the house that definitely has some kind of cavity as there are exterior wall vents, exterior leaf is blockwork(it's just painted so is obvious), inner leaf could be brick? Can only barely see it through a tiny hole in the back of the cabinets at floor level - you'd think it would be block as well if the outside was, but there's also a masonry built detached garage that seems to have been put up around the same time as the extension and that's brick inner block outer(although the block outer might just be a facade? there's a layer of engineering brick visible just above the paving slabs and the block layer protrudes out from the top of that by ~30mm or so) so who knows. The approximate thickness of the extension wall is 320mm, the garage wall is 230mm. Trying to decide on relative merits of different insulation systems & materials but it's all so dependent on if there's a cavity and how thick it is.

-

Re flue liners; the issue there is *air* tight is not necessarily *radon* tight. Radon is capable of diffusing through a lot of materials that can stop air molecules no bother, it's why you're supposed to use a specially rated DPM in known radon areas. It would also - assuming the standard metal option - be putting a huge condensation generator in the middle of a stone wall outside the insulation envelope which doesn't seem great for the health of the wall long-term, as you'd have an air cavity around the pipe where moisture in the wall assembly could evaporate and then a metal tube drawing cool air from the solum space - completely coating the interior of the flue would firstly seal the flue from the wall assembly so water vapour couldn't pass into it from the wall itself, would make condensate less likely in the first place as nothing in there would be cold enough to let significant moisture form out of the air before it was expelled through the chimney, and any that did form could drain back down into the solum rather than being trapped in the air cavity. The Visqueen(or other brands) stuff is designed for exactly this sort of issue it's just normally applied to seal floors or walls rather than the inside of unused flues. At the three access points the measure depth of the cavity between the bottom of the joists and the earthen solum is ~270mm. Re soil gasses; other than maybe radon in a former mining area there's also potentially methane, though that's more common on former waste dumping sites that have been built over, and also just water vapour - you have to be really careful with moisture when renovating these old stone buildings because they were designed to be draughty as hell and have active or residually-hot fireplaces pushing air out through the chimneys pretty much 24/7, so even using the proper vapour-open materials as I will be you have to watch the solum space with so few vents compared to modern structures, soil moisture can elevate the humidity of the space and then you get water condensing around joist-ends and other inconvenient places. Re radon maps & measuring - the maps only report testing that's already been done and most people don't even know radon is a thing they should be testing for. The map data is also not particularly refined - your neighbour a dozen doors down could submit an all-clear result and if that's the only result your whole area could be marked as lowest possible risk, but *your* house could still be sitting on top of a plume of the stuff. You also really have to wait for winter to get proper results, and on top of that results before & after a renovation can be totally different. For my money testing is more something you do to confirm that there isn't an issue *after* you've already done all the mitigations you can within your budget and project scope. And the issue with the recommended methods Mike are they all pretty much assume either old and draughty or modern and airtight, whereas I'll be making an old property airtight(or as close as I can manage) but using vapour-open(and so radon-open) materials to control moisture buildup, so they won't really work in this context because if it stops radon it'll also stop water vapour. Everything about these kinds of renovations is non-standard really.

-

Okay brief background - property is circa 1900 semi-detaches stone cottage with early-mid 90's extension/attic conversion, slab in the latter suspended timber in the former. Building is getting an EnerPHit-style eco retrofit with all the proper vapour open materials wood fibre yadda yadda. Original plan was for new insulated slab floors with underfloor heating throughout but the project is going through a bit of the old "value engineering" at the moment and my current instinct is to cut down to just the kitchen extension and treat the existing suspended timber floors with a special system that uses a vapour open but windproof membrane to seal the floor structure(allowing them to still dry out to the solum cavity), then wood fibre batts between the joists, then a vapour barrier on top before application of the subfloor. My one reservation about this is it's a former shale oil mining area and so there's a possibility - albeit a small one - of elevated levels of soil gasses and radon. The inhabited space will have MVHR so I'm probably just being paranoid, but I'd rather do too much now when everything's being taken apart anyway than find out come next winter there's an issue and have to dig everything out again. The solid floor plan would have involved a ventilated sump and radon-rated DPM and while I *might* be able to use one of those as the vapour barrier(yet to hear back from architect about it) I still think I'd like to increase the ventilation of the subfloor space as right now there are only three grates(imagine division between the two properties as interlocking L shapes, mine has the narrow front and wide rear so one front vent two at the back). The actual question then: There are two chimney flues originating in the downstairs front & back rooms which I wanted to close up anyway, so I wondered, could extending the flue down into the subfloor space with some ducting and sticking anti-backdraft caps on the chimneys provide extra passive ventilation via stack effect creating a stronger draw on the space? And if that could work, is there a process and what sort of ballpark price could I expect to pay to have the interior of the chimneys coated with something like a Visqueen liquid gas barrier(no point removing any potential radon from the subfloor just to let it diffuse through the completely vapour-open wall buildup into the interior anyway)? I've seen companies that will do a concrete-ceramic spray coating for chimneys with active fireplaces in them, but I've no idea if that sort of equipment would work and if any would be willing to run something else through them.

-

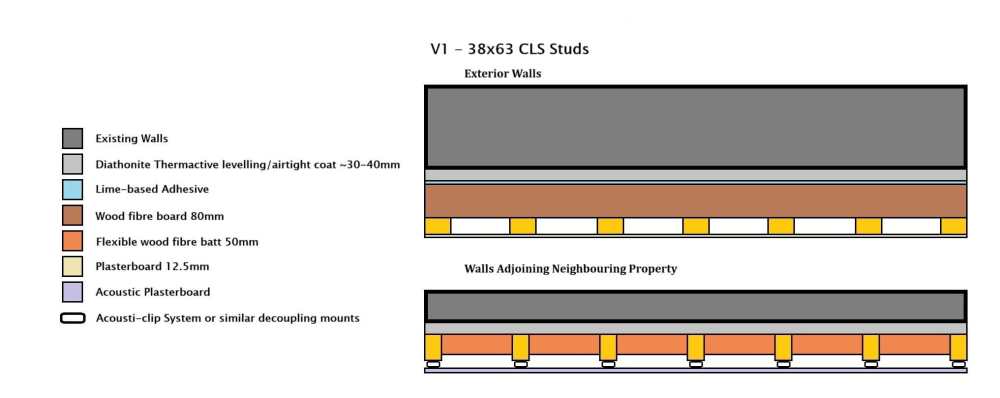

I'm aware. The Diathonite was planned anyway for the exterior walls inner face, and to be applied thicky both to level, decrease the chances of cracking in future which would compromise the airtight layer, and for its excellent wicking and moisture management properties. And while the cost isn't small, in this plan for the adjoining walls it would be somewhat offset by dropping the inner layer of rigid insulation I had thought to add behind the stud wall. Anyway in the end it's all subject to WUFI/PHPP modelling anyway, I'm just trying to get an idea of how to balance everything optimally.

-

Having finally found some more detailed reference material, I've amended my buildup again(turns out Diathonite Thermactive has a final density of 250kg/m3 +/- 15%, which is basically double rigid wood fibre, so pushing that from a ~30mm parge/levelling coat to a ~40mm base layer will do both the extra mass and thermal decoupling adequately).

-

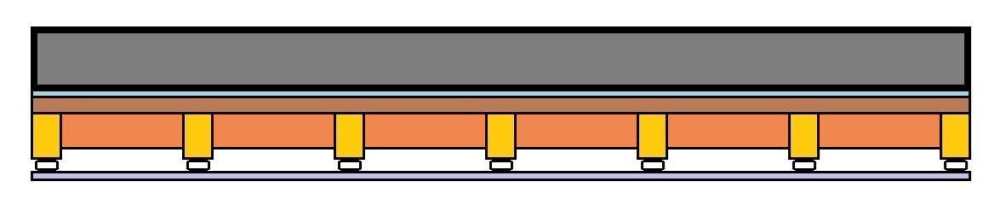

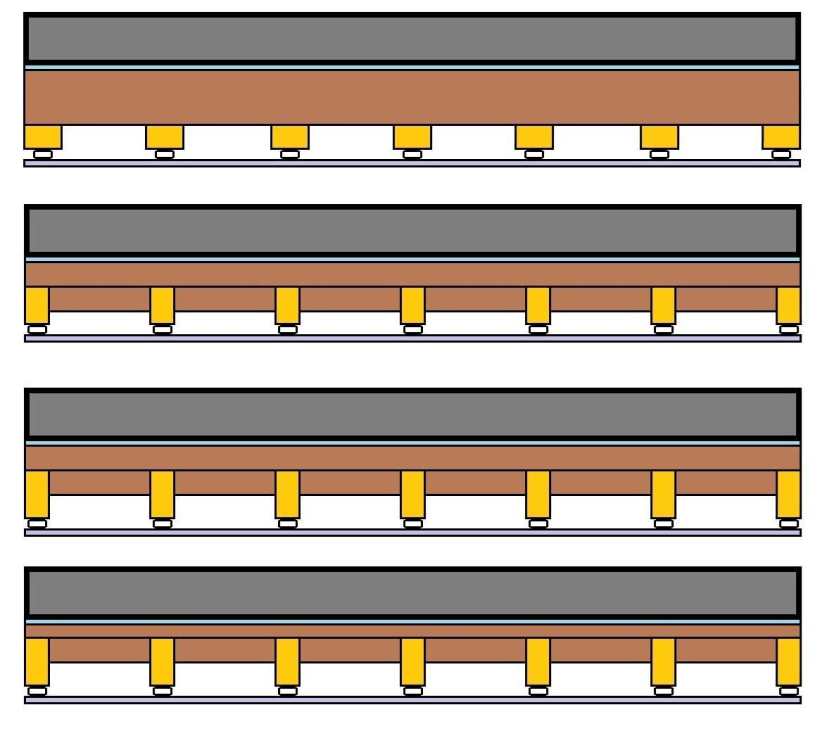

I'd considered using flexible batts, but the wall will be getting coated with some kind of lime-based material anyway as that will form my airtight layer(using enerPHit principles, just not fussed about getting the certification), I also have to be careful about managing dew point and avoiding unintended cavities. How about the pictured; lime parge/adhesive > 20mm rigid wood fibre(thermal break) > stud wall w/ 50mm flexible wood fibre between > clip & rail system > acoustic plasterboard. When it comes to the floors, whichever solution I go with will be carried through the floor as much as possible to achieve continuity of insulation and airtightness, and I was intending to use a sound dampening subfloor for any suspended timber flooring. There's also the benefit that the run of the joists is front-to-back while the neighbouring property is to one side.

-

The physical decoupling occurs in the decoupling system I mentioned, one of the polymer mount & channel type systems for fixing your plasterboard to, the insulation layers are for thermal performance and mass(rigid wood fiber has a similar or better kg/m3 than the best acoustic-rated rockwool and I'm using it on my exterior wall interior facings for insulation anyway). I'll be stripping all exterior and adjoining walls to the masonry to add vapour open airtightness, insulation and, for the adjoining walls, soundproofing. Here's a shitty MSpaint of what I've been discussing with the architect. Top to bottom on the buildup is existing wall, lime adhesive, wood fibre, stud wall, decoupling system, acoustic plasterboard. The variations are just different thicknesses of wood fibre(top to bottom 80mm, 40+40 between studs, same, and 20+40 between studs) and sizes & layouts of CLS(top two 38x63, bottom two 38x98), which I end up with will depend on space constraints of the final designs and what the structural engineer wants. Second one down seems the best compromise of depth, mass, & thermal performance to me. Oh and for clarity I say excessive because the existing wall is two rows of brick in a circa 1900 stone building, so you already have to pretty much be *trying* to be loud to annoy each other, I just figure that since I'm pulling everything down for airtightness & insulation work anyway I might as well see how I can tweak it to maximise acoustic performance too.