sb1202

Members-

Posts

60 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

sb1202's Achievements

Member (3/5)

6

Reputation

-

Installing parquet over overfit type UFH boards

sb1202 replied to sb1202's topic in Underfloor Heating

200micron is the thickest foil available. I haven't seen 400mircon anywhere? Tile can be direct bonded on thinner foil boards, it's the kpa rating that matters for tile. These are 400kpa rated for tile, which is overkill for engineered wood. Cracking may not an issue with slc over concrete, but these are xps boards which have a lot more movement. There are a lot of horror stories with Wunda floors, particularly with slc and glued down floors. Common issues are chunks of slc lifting, hollow spots and slc turning to dust along cracks. Most problems are with lvt, but people have had the same problems with tile and engineered floors. Over 27°? Curious you say this as I install a lot of this parquet. I've never seen any engineered wood that's rated over for 27°. I haven't heard or seen any complaints about the wunda system needing to run at high temps. -

Installing parquet over overfit type UFH boards

sb1202 replied to sb1202's topic in Underfloor Heating

I've tested this with some spare boards and the SLC doesn't fill the gaps as well as direct bonding the parquet to the boards. The parquet is fixed with an MS adhesive which is sticky, has a viscosity similar to honey and has self levelling properties. When the parquet blocks are laid onto the adhesive and slid into place, the adhesive spreads and is forced into any gaps. It makes a solid seal. With the SLC, it's less viscous and certainly flows faster but it flows along edges before settling and leaves small pockets under the foil. A spiked roller didn't make any difference or compress it into the pipes. -

Looking for advice from anyone who has installed a "wunda" rapid response type UFH system. Currently installing one in a reno property but getting so much conflicting advice from manufacturers and floor installers about fixing the finished surface, which will be 15mm engineered parquet. Wunda, who are the market leader, say that engineered wood (and ceramic tile) can be bonded direct to the xps tiles. However, from googling, speaking to suppliers etc, the Wunda overfit boards and pipes are identical to all every other suppliers. The boards are all exactly the same spec which is essentially 20mm overfit, EPS400 (400KPA compression strength) boards with a 200 micron foiling on top. Whilst the boards are all the same, no one seems to be in agreement when it comes to installing the finished floor. Some say there needs to be a min 5mm SLC screed over the boards, some say min 10mm, some say min 12mm. Flooring installers say min 15-30mm? After numerous searches on installing SLC screed over the boards, I found loads of posts where people have experienced the SLC cracking - despite following instructions. With that said, it's made me a touch uneasy about this system and looking for anyone's experience. (I have since found a few influencers who installed parquet direct to the overfit and so far, they don't have any problems. (See pic))

-

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

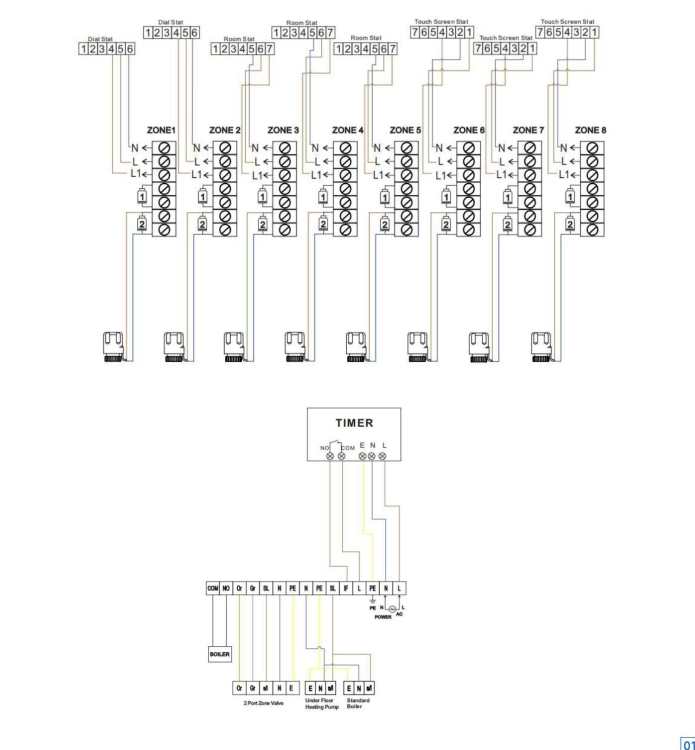

See the OP. It was originally spec'd with an 8 zone WC. The reason this has gone off topic is because someone suggested using the navien (which comes with the boiler kit). -

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

No, they didn't and if you read the OP, you can see its an 8 zone wiring centre. The navien WC is supplied as part of the kit. No. -

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

That's my reading of it too. The problem is the drawings don't match the mainboard on the boiler. When we spoke with Navien tech about it, they walked us through and asked us to remove a jumper on the mainboard but when I said there was no jumper, they went "oh!". I suspect the mainboard is a newer model and the manual refers to an earlier model. Waiting on Navien to come back to us meantime. As for the UFH 8 wiring centre, it's a nightmare. It has no branding, manufacturing batch number to go by. All I know is that it's a "Waterline" circuit board and there are different revisions of this particular circuit board and different manuals. As soon as Navien come back, I'll probably end up ditching the current UFH-8 wiring centre and buy a branded one. See above. You're right, it should have been simple. -

Contesting final invoice - please help!

sb1202 replied to Tom's topic in General Self Build & DIY Discussion

The company I used are lawyers as are the other companies I contacted for quotes. They all informed me of the same process. Due dilligence checks performed on debtors, nature of debt, director checks etc. This all had to be provided before they would accept and enter a service agreement with me. In the end, I got the full invoice total back plus 8 interest back dated 2 years. The interest covered their fee and left me with more than the invoice total. -

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

We spoke with Navien and the plumber beforehand. They were given the UFH spec and they said it's no problem. The boiler can modulate to demand and the flow rates are set at the manifold per zone. If Navien had concerns, they would have told us. Thanks for taking the time to reply, but this is going off topic. -

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

Sigh.... read my OP. Boiler is 2 ZONE s-plan pipe circuit. CH = ZONE 1. UFH = ZONE 2 UFH ZONE = 5 ROOM ZONES which need an 8 ZONE wiring centre in order to accommodate wiring for 5 actuators, thermostats, zone valve etc, The Navien wiring centre is a 3 ZONE wiring centre - which means it physically cant take all the wires for 5 actuators, thermostats etc I'm certainly not going to rip out a £6k bolier and replace it. -

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

Cant. It's only for 3 zones. -

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

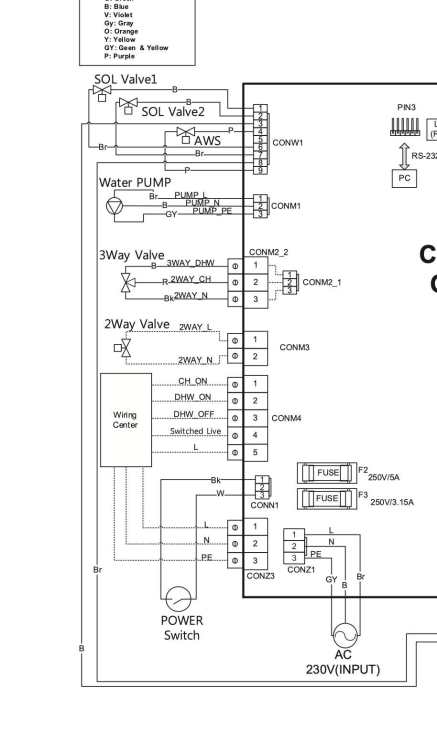

Yeah, and that's the problem. It uses their own "smart plus" technology which us LORA RF based. All calls are made from RF smart stats to a RF comms module that is wired to the boiler. Presumably, with all the calls to the module, they decided there was no need for a volt free terminal on the main circuit board. It does s-plan, multi zone etc as standard, but it relies on adding their smart RF wiring centre, and again, this communicates with the RF module. -

Contesting final invoice - please help!

sb1202 replied to Tom's topic in General Self Build & DIY Discussion

It should be 8% annual interest accrued daily. It's a statutory interest charge - see here - https://www.gov.uk/late-commercial-payments-interest-debt-recovery/charging-interest-commercial-debt Yes. If they're talking about adding interest and refusing to back down, I'd take this as a signal that they are considering debt recovery/collector. You entered a contract with them when you instructed them to start work on your project. If you part or pay any invoices, that cements the fact you entered the contract. I've been through all this a few weeks ago, but I was the pursuer. If a debt collector does get involved and starts contacting you, you can be assured that they will have done the legal due diligence to ensure they get their money. -

No connection on boiler to receive wiring centre - what to do?

sb1202 replied to sb1202's topic in Underfloor Heating

The COM/NO connection here is a volt free/relay connection. It sends a signal from the wiring centre to the boiler to call for heat. Most boilers will have a 230v terminal side and a low/no volt terminal side on the main circuit board for connecting external controllers. This particular boiler doesn't and Navien confirmed it doesn't. The plumber knows his stuff and has never came across this scenario before. -

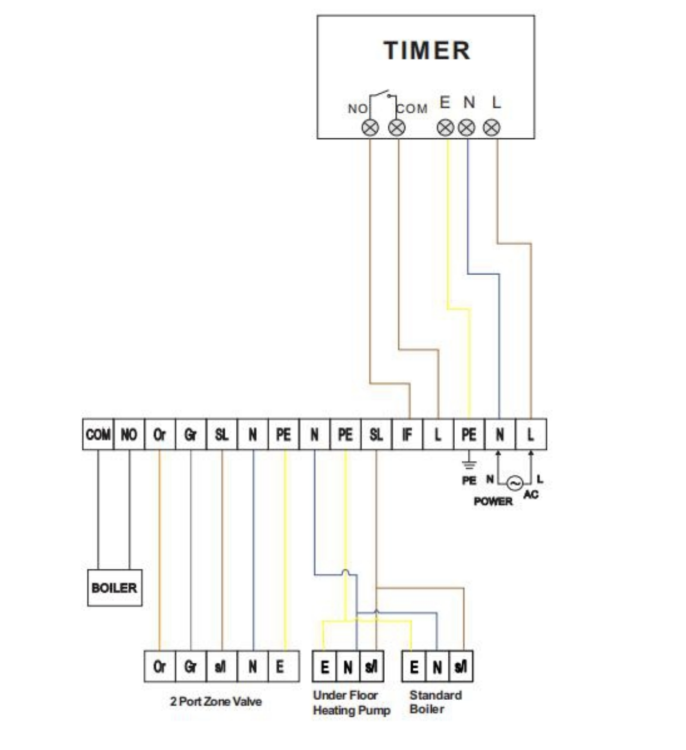

Need a workaround for this situation. Having retrofit UFH installed. Plumber installed the s-plan pipework for 2 zone (UFH + CH). Everything went to plan until we tried to connect the wiring centre to the boiler and hit a big snag. There is no connection on the boiler for the COM/NO from the wiring centre. It's a Navien LCB700 oil and when we spoke to their tech support, they confirmed there is no connection. Setup is: ZONE 1 (CH/DHW) = Drayton 2 port zone valve to be wired to boiler via Honeywell wiring centre/terminal. ZONE2 (UFH) = Drayton 2 port zone valve, 5 port manifold + 5 actuators, 5 wired room stats. Waterline wiring centre (diagram attached). Everything hooks up to the UFH wiring centre correctly, but we can't connect the wiring centre to the boiler and we're both stumped. Would this work for the UFH zone? Connect a timer to the wiring centre, and use the COM/NO connection on the timer instead. (Thinking of a Danfoss TS710). This way, leaving the timer on full time, the room stats will control the UFH. The timer would connect to the boiler via the CONM4 terminal live/switched live. (See Navien diagram)

-

Mortar mix for pointing granite.

sb1202 replied to sb1202's topic in Bricklaying, Blockwork & Mortar

It's definitely VERY old so it's not cement. It's at least 300 years old according to historical maps and possibly goes back to the 1400s. Our deeds say it was part of an estate and the castle was built in 1604 on top of an existing watch tower from the 1400s. The walls aren't regularly wet - we're in Aberdeenshire which is broadly similar to the SE of england for rainfall. I've been researching what I can but drawn a blank. I do know that the rubble isn't bound with a mortar - it's just mud/soil. The folks at historic scotland said this was common and this type of property last hundreds of years with the original walls.