runcyclexcski

Members-

Posts

28 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

runcyclexcski's Achievements

Member (3/5)

5

Reputation

-

running MVHR in the summer

runcyclexcski replied to runcyclexcski's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thank you, Mike. I could not have asked for a better reference! -

running MVHR in the summer

runcyclexcski replied to runcyclexcski's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thank you, John and Mike. Good point re: lack of ventiilation as the reason for mold growth. I hope the movement of air, even if the humidity is 70% (in the summer) is enough to make mold unhappy and dry it out. I did not mean to stop ventilation altogether in the summer, I meant whether I should bypass the MVHR in the summer. Ventilation is on at all times. I tried changing the filter less frequently, and I noticed that after I replaced the filter after only 2 months, the air flow increased by 25%. The filter became dark brown in colour. Must be the wood burning in my area (we have issues with air pollution in air valley when it gets cold). The filters are cheap. I bought two square meters following a link which I believe was from you; each filter is onlly 180 mm x 220 mm. So I do not mind opening the thing up to make sure everything is OK inside and get better air flow in return. I have seen some horrifying pictures of insides of MVHR units on this forum. There are also bugs that like crawling into the vents in the summer and autumn. So if there is a wasp nest being built inside, or a bunch of stink bugs, I would prefer knowing it early. I do have a coarse mesh in the untake, but somehow there is always a kind of bug that can make it through. I am also thinking to make a transparent window in the MVHR so I can look inside. -

I have been running a basic MVHR during the winter which I installed in Novemeber'24 -- upstream from a forced air filtration system (150 m^3/hr). I am mostly happy with the system, although it took some trial and error to set up a condensation run-off tray (for both internal and internal condenstation) -- in the coldest winter months, when the temps fell below freezing overnight, I would collect up to 1 L of condenste per night. I also replaced the input filter every month (using a helpful link to an RS item I got on this forum), wiped the insides of the unit and washed the exchanger under tap water. With this regular maintenance, it did not look filthy at all, so I am not terrified to open it now. In the summer, I typically run a split AC unit and the same 150m^3/hr forced air ventilation system (I am severely allergic to pollen). The AC seems to keep up with the ventilation. Should I bypass the MVHR unit during the summer, or should I keep it running? I expect there to be condensation from the input air (it gets +30C and 80% RH outside here). In principle, it sounds like a good idea to keep it running, but in my experience there can be surprises. E.g. I wonder if there will be mold growing on the input filter, given the warmth and the high humidity of the input air. But then it also it can grow on my HEPA pre-filters, but in my experience it was not an issue the previous summer (with no MVHR installed).

-

skhell, Indeed, horiculture filters release dust, this is why I put an "air purifier" grade carbon bed downstream from the horiculture carbon, plus two post-filters to contain the dust. I found that the amount of dust never settles with time: vibration always brings more of it; this is the nature of the material, I guess. One can get low-dust carbon pellets from manufacturers of respirator cartridges; that carbon is very costly -- I paid 400 EUR for a 20 kilo bag. I only use that for my DIY respirator and PAPR cartridges. This is prob the best carbon one can get, and still respirator makers use electrostatic fabric to capture dust from them (there is always some dust in carbon, no matter how good it is). There are "ball pan" hardness standards for carbon used in breating products, there are ASTM and EU standards for it. Currently I am using this line of blowers. My local shop is in Basel, but they are available all over Europe. https://www.visionofhemp.ch/shop/en/ventilator-125mm/11487-tube-fan-pk125-whsp-ectc-8594171433054.html I use them b.c. they are quiet, and my wife hates the noise; the EBM Papst motors are proper. There are three speed levels. Blaubergs are about 1/2 the price, nothing wrong with them. You can get "dimmer" adjusters for regulator-free AC blowers, but dimmers emits annoying noise at low voltages (at least cheap ones I've tried ). So I just use the three-sppeed blower instead. To balance, I measure the air volume per unit time for air in/out with an anemometer (calculated using the duct cross-section). Since the outgoing air in the MVHR has much less resistance (no filters), it ends up having much faster flow than air in, which is not good for me (I like the flat to be slightly pressurized, to prevent odors from getting in from the outside). To balance it, I attach a long narrow (100mm diam) flexible duct to the "out" on the MVHR (my MVHR has 100 mm connectors) and adjust the length of the dummy duct until the air volume per unit time at the "out" duct entry is slighly less than the fiow "in" downstream from the filters. The output duct ended up about 4m long to drop the air flow 1/2. Just make sure the entry is not blocked, the dummy duct likes to act as a vacuum cleaner and sucks itself to any surface. I have never dealt with CO in the outdoor air -- unless the inlet for it is in an enclosed area, like a garage. I think smoke and particulate pollution from emitters (diesel etc) are more of a concern. And even if the MVHR gets some smoke in, washing the exchanger and wiping the insides of the unit should be easy. Or, the cube can be replaced. Another concern for me is ozone in the summer (which can get to 200 ppb on hot days in my area, and inflammation in test subjects' lungs has been detected from exposure to 75 ppb --seen studies on that). Carbon deals with that pretty well. So my 7 kilo horiculture carbon catches ozone, ammonia and odors in the air (summer/winter pollutants that bother me) and the "air purifier" carbon then contains whatever dust is released from the horiculture carbon.

-

Thank you, all! I am getting a roll of G3/G4 fabric for this. Obviously, I was too naiive to think that my unit was UK-made, but at the time I did not know much about the technology. For 500 quid or whatever I paid for it, it's good learning experience. In principle, one's lungs are designed to deal with the crap in the air, but my lungs no longer can do it properly.

-

Mike, the carbon dust I was measuring was in the micron range; I do not think that would settle and form a visible soot on a flat surface of the exchanger. I do see a black dusting on my downstream filtrete post-filters (meant to remove the carbon sust) from carbon. In all air purifiers I've dealt with there was an additional post-filter after the carbon, and it was consistent with my particle counter measurements. The amount of carbon dust was much higher if there was vibration in the bed (at least 10x higher). With regards to the MVHR, I have decided that I can always wash the exchanger cube with tap water and wipe the insides of the unit, if needed. Observing how much condensation there was in the MVHR, I decided that I did not want to deal with it in my HEPAs.

-

Thank you, John. I buy from RS all the time, I trust them, so I should be able to source your fabric. I do not mind paying 50 quid for 2x1m pad; it's still "cheap" overall. I honestly do not know what the official rating of my "stock" MVHR filter is -- I am still waitiing for Boulder the manufacturer to respond. If G3/G4 works for your MVHR, chances are it will work for mine. Of note: I am perplexed what the difference is between these two fabrics; one is a 2 meters by 1 meter pad, the other one is a 20 meters by 1 meter roll. Similar cost, but once gets 10x more of the latter. https://uk.rs-online.com/web/p/hvac-air-filters/8279510 https://uk.rs-online.com/web/p/hvac-air-filters/1221771

-

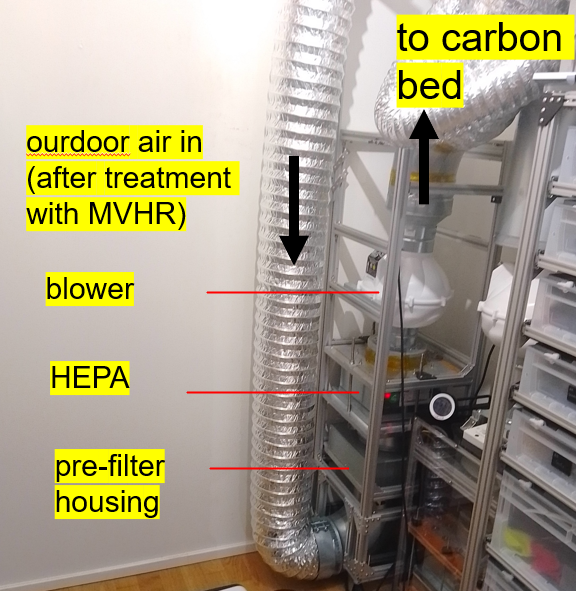

I have not tried the blauberg clean box, but the price is already pretty low as is (I found that it costs under 400 EUR?). It looks solid, and it should deal with the smell at least for 6 months (I doubt it would last more than a year). My IQAir carbon bed is about 2.5 kg, and it needs replacement in about 6 months at air flow of 150 m^3 per hr. I have two possible concerns about the clean box: -- the UV lamps will generate ozone which, in principle, should be reduced 10-fold by the carbon bed, but if you do not replace it on time, and/or do not measure the ozone in the output, it may be harmful in the longterm. Ozone meters are not cheap (mine was about 1000 EUR). Personally, I would disable the lamp, or regularly check the ozone output. The "safe" levels are about 50 ppb, but double-check this number. If the lamp generates 1000 ppb ozone, then, after the carbon, it will be at about 100ppb which is high for long-term exposure. -- The lack of an additional filter downstream from the carbon could be concerning. In principle, if there are no vibrations, there should be no carbon dust emitted by it, but if one does not have a particle counter, one cannot tell. I would add an additional electrostatic filter downstream from that and verity the result. I would not bother with DIY if the clean box works for you, since the box is very cheap at <400EUR (as long as you can source the filters for it). Here is a pic of my filter, it costed me way more than 400 EUR to build :), but I like it b.c. it uses generic parts, and I can upgrade/replace parts as needed. E.g. my initial Blauberg blower proved weak, so I replaced it with a 2x bigger unit. I used 3030 T-slot profiles to bolt it together. The filter is downstream from the MVHR. The MVHR is next to the window, then there is a 200mm duct that goes across the room to the filters (the wider the duct, the better). The carbon bed is not shown, it's further downstream from the blower. I used a 7-kilo horiculture in-line filter ("AIRCLEAN"), and an additional 2.5 kilo IQAir carbon filter downstream from that, and two 3M MERV13 30x30 cm filtretes downstream yet (to capture carbon dust). The filters drop the rated "free" air flow of the blower by about 2-fold, and I have so far not had a blower fail after 2 years of 24-7. This is the inline carbon filter: https://www.visionofhemp.ch/shop/en/can-filters-inline/8966-can-filter-can-inline-425-125mm-8718819995234.html This is the IQAir carbon filter downstream from it (the horiculture filter itself had a smell, but it does bulk of the work). https://www.amazon.de/-/en/IQAir-V5-Cell-Filter-Gas-Odour/dp/B0007U46T4 These are filtretes to scrub the carbon dust, and also used as pre-filters: https://www.filtrete.com/3M/en_US/p/d/b00040201/ HEPA was from here: https://www.ozcon.co.uk/products/hepa-filter/ They are about 150EUR each, and I got a pack of 10. The manufacturer is MGT (Turkey), and the HEPAs are very solid (stainless steel with separators), verified with a particle counter. The part number can be obtained from this PDF; my HEPA was 305x305x150 and rated as H13 https://www.ozcon.co.uk/wp-content/uploads/2021/07/High-Temperature-Resistance-HEPA-Filters.pdf

-

Could anyone recommend a generic non-shedding non-woven polyester fabric that I could use in place of my stock MVHR in/out filters? I am not sure what rating that fabric is... it can't be better than F7, it looks quite coarse. By eye, the fabric in my MVHR is about 3 mm thick, it's 20x30 cm and it has plastic-reinforced edges for slight reinforcement). I think if I get a slightly thicker 5mm fabric, I can just shove it and take it out and trash it once a month (my local air is quite bad in the winter). I tried a fabric from an Amazon (not total rubbish, claimed to be German-made, about 10 quid per sq mt). But it was shedding fibers, I was not impressed.

-

This is an old post. I have a MVHR combined with a DIY carbon (10 kilo can) and a HEPA filter (12"x12"x10"); the fine filters are installed downstream from the MVHR, and there is an additional booster for the input air. I have severe pollen allergy in the summer, and I am very sensitive to wood/weed smell in the winter, and the filtration helps tremendously (otherwise I would have to go to the hopsital all the time). In the summer, I bypass the MVHR and run the filters directly. Considering how much condensation there is the MVHR in the winter (which I am still figuring out how to properly deal with), I am glad I installed the fine filters downstream of the MVHR. Otherwise all my fancy HEPA and carbon filters would be soaking wet. The innter coarse filter in the MVHR is still there, I am hoping to replace it once a month (if I source the generic fabric). With the fine filters downstream from the MVHR, all the condensation gets captured in the MVHR and the air downstream from the MVHR is warmed to abt 16C which is well above the dew point in the flat. If I had to use a commercial product I would prob put in an IQAir box with a 200mm duct and its own carbon bed (about 2.5 kilos), I believe it's about 1K, and one can adjust the air flow between 50 and 250 m^3 per hr. I ended up making my own, b.c. IQAir's HEPAs have their own smell. One needs to be careful with the carbon itself serving as a source of particles. Some people use horiculture carbon as a cheap replacement (not meant for indoor air applications), and end up breathing the fine carbon dust. That carbon can be caught with a HEPA or a Filtrete, but a laser particle counter is necessary to ensure that it's safe. IQAir has a HEPA downstream from carbon, so it's safe in terms of carbon-emitted particles. Re: cheap car filters: I found that the amount of carbon in car filters is negligible to have any effect for an extended time, if the unit operates 24/7. Unless one is willing to replace the car carbon filter every week.

-

I have now taken a picture of the HVR unit filters after a month of continous operation (winter air at around 0C outside, wood-burning houses nearby). The outgoing air is on the left, the incoming air is on the right. I'd say, at least 25% of the soot is from New Year's eve. I am thinking to get a roll of generic filter fabric and cut these to size, rather than paying for replacement filters (I would like to replace the incoming filter once a month).

-

Thank you all for the comments. I have also looked at the Brinck system which has been mentioned on this forum, and it seems to have the exchanger cube mounted vertically, consistent with what I discovered with my unit (that having it horizontally restricts the condensation drain). I wonder how well this unit is insulated. Overall, it looks better engineered than the bare-bones unit I've got. https://www.brinkclimatesystems.nl/documenten/flair-450-600-technical-data-sheet-gb-617482.pdf

-

***Agreed and they’d also likely have the smell of smoke in the house. Kelvin, there is noticeable smell of wood smoke outdoors, especially at night. I slightly pressurize the flat, so that the soot does not get inside (and it does not -- apart from the filter). When I test air quality with a laser particle counter, the counts in the 0.3-1 micron range are 10 times higher outside (on the balcony where the air intake is) than indoors, on any day. When I drive on top of a local 1km high hill and test the air quality there, the counts in the 0.3-1 range drop 10x (on the same day/same weather), and one can see from the top that the soot/smoke stays in the valleys. There are more filters downstream from the MVHR (pre-filter with a pleated P2 fabric and a HEPA). The P2 pre-filter is black after 3 months of use and needs to be replaced. The MVHR intake filter is very course and prob does not trap the fine particles anyway. The outgoing MVHR filter, I think, is not needed, since my indoor air is already passed through three HEPAs working 24-7 and is "pretty" clean as is.

-

***My hunch would be mould is starting to grow considering the wet conditions you describe. Russdl, the "sooty" filter is on the opposite side from the drain, and is much dirtier than the outgoing filter (which is right next to the drain and does get wet). If the mold hypothesis held, it would have been the other way round. So I do not think this is mold. I live an area where people like to burn wood when it goes below 5C to "stay cosy" with their fireplaces, even though everyone has gas heating. I did not mean to say it's "black from soot" -- it's just a noticeable change of colour in to a slight biege. I am used to seeing this slight change of color on 3M P2 respirator before replacement: place the old filter next to the new one and you can see the difference.