Rick734

Members-

Posts

42 -

Joined

-

Last visited

Everything posted by Rick734

-

Cheers @Iceverge another super helpful post. That AVCL is exactly what I was looking at earlier so would make sense to go with that. Random q about the service cavity, I had assumed it would be empty so you could feed through pipes/wires at later dates as needed. I guess the assumption is that we are organised enough to not need to do that, if we are filling it with insulation?!

-

Thanks @Iceverge, super helpful stuff here. Take your 11mm OSB. It has an Sd value of 2.5m which is quite vapour open. A house with an internal RH of 60% at 20deg will exert a vapour pressure towards the outside on a winter's day. Assume it's 5deg and 90% outside. Over an hour about 0.18g will diffuse through 1m² into your wall. What are your thoughts on sealing around edges of the OSB and just using that as the vapour barrier?

-

@Iceverge can give us chapter and verse on this but my understanding is that a vapour barrier completely blocks moisture, which means that if any does get behind (e.g. leaks, perforations etc) it makes it impossible for it to escape again, potentially leading to interstitial condensation (between surfaces inside the wall) and therefore mould etc. Whereas a vapour control layer slows down the rate of moisture transfer, but is still technically slightly moisture permeable so trapped moisture can escape. Shoot me down if I'm wrong... If anyone's interested I have a link to my conversation with ChatGPT...seems to have a strong opinion on this subject: https://chatgpt.com/share/e/694b98bc-d6a8-8000-a4b4-5b08ee8d0ea9

-

@Redbeard this is super helpful as the Pro Clima is one of the options I was looking at. Any comments on performance (or I guess there's probably not much to tell)? Did you end up doing the OSB at all or leave it off altogether? Just wondering now if it's best to put the membrane inside or outside of my OSB...

-

Thanks Mr Punter - just tossing the coin on whether to do a 25mm service void or not at the moment...due to the layout of the room it may be the case that I do it in some areas but not others. Any recommendation? The construction is a 145mm C47 timber, 120mm PIR with 9/11mm OSB on the outside plus renderboard and Fassa render system.

-

Thanks @JohnMo - any particular vapour barrier? Are the smart/intelligent ones e.g. Pro Clima Intello / Isover Vario KM Duplex worth the money? Re timing - yes I don't want to bodge it, but I do see people on here looking at getting the ultimate performance from a project as it is their forever home and they are prepared to put significant effort in to achieve that. As long as it isn't going to cause damage or serious building issues in the long term, I'm not super worried about getting the highest possible specs out of it. I guess I'm looking for more of a balance of performance of practicality, speed and performance, rather than just performance, if that makes sense?

-

Further addition to the post...decided to have a bit of a chat with ChatGPT to get his views on the subject. The interesting bit was that when I mentioned I would be lining the internal face of the external walls with 18mm OSB (for fixing purposes), he/she/they/it decided that OSB can replace the whole vapour barrier/air tightness thing and is fine by itself...?! Sounds great, but I am cynical unless someone can weigh in on this please?

-

Afternoon gents, Been racking my brains on this one a bit and thought to turn to the helpful people on here. Who probably could run the country a lot better than the current shower. Anyway... Stick-built TF extension on the side of my house, over the existing garage walls. Everything up, roof slated, external walls currently being rendered when weather permits. Now working on the inside on the first floor and my understanding is a VCL around the walls is a good idea on TF to prevent moisture moving into the timber frame from the inside - fine. I have myself some silver reflective VCL from Tradestore ready to go - but a couple of questions I've been thinking about: 1) How to seal the edges of it, where it meets the existing house - how much do I need to worry on this front. Can I just lap it over onto the render, run a bead of silicone down & tape over? 2) At floor level, is it just a case of taping it down onto the chipboard? Or is there some technical way to seal it? My brain says just seal it down and be done with it, but at the same time there is the ground floor below, so surely moisture could rise through the ceiling structure and get up into the wall structure...or is that just overthinking it. I should add, I am more about speed and getting the job done at this point, rather than perfecting it. Definitely not a forever home and I'm in a hurry so not trying to spend time achieving microscopic increases in building performance...if that makes sense - quickest solutions that are acceptable, ideally! Over to you! Image below of one of the vertical junctions where the TF meets the masonry...

-

Perfect thanks @Gone West, that's the image I had in my head! Musta seen it before somewhere.

-

Thanks @Temp I had been wondering about STs fibre cement boards, because of my wall-hung (that was what I meant earlier) toilet which can obviously put a terrific amount of force onto the backer board so cannot have any flex...I will be doing a low profile shower tray as well, just can't really see that much point in full wet rooms.

-

Awesome, thanks @Nickfromwales 👍👍

-

Just jumping on the back of this thread if that's OK. Got a bathroom coming up which I'm just doing studwork for and then will need to go through the process above. Any particular kits/brands/methods recommended for tanking please? And to go off topic very slightly, I seem to recall from some other threads on here that cement fibre boards doubled up or with a layer of ply behind, are the go-to where you have a back-to-wall toilet...?

-

System boiler size dilemma...any advice?

Rick734 replied to Rick734's topic in Boilers & Hot Water Tanks

Good evening gents, many thanks for your advice - afraid I haven't had a chance to go through it properly yet today but just wanted to acknowledge your assistance and links/details provided - this is what BH is about! 😎 Will go through and follow-up hopefully tomorrow if I have time. -

System boiler size dilemma...any advice?

Rick734 replied to Rick734's topic in Boilers & Hot Water Tanks

Thanks my fellow Rick Makes sense. I guess I am somewhere in between accepting the logic of the low and slow approach, while also liking the ability to warm up the house quickly if desired! Regarding insulation/air-tightness, I have been: renewing some of the 200-300mm loft insulation, replacing all windows & doors with new double glazing, adding expanding foam every gap I can find 😅, dry-lining walls with DPM and 50mm PIR where I am converting single skin areas into living space. Any other suggestions you would add? Thanks! -

System boiler size dilemma...any advice?

Rick734 replied to Rick734's topic in Boilers & Hot Water Tanks

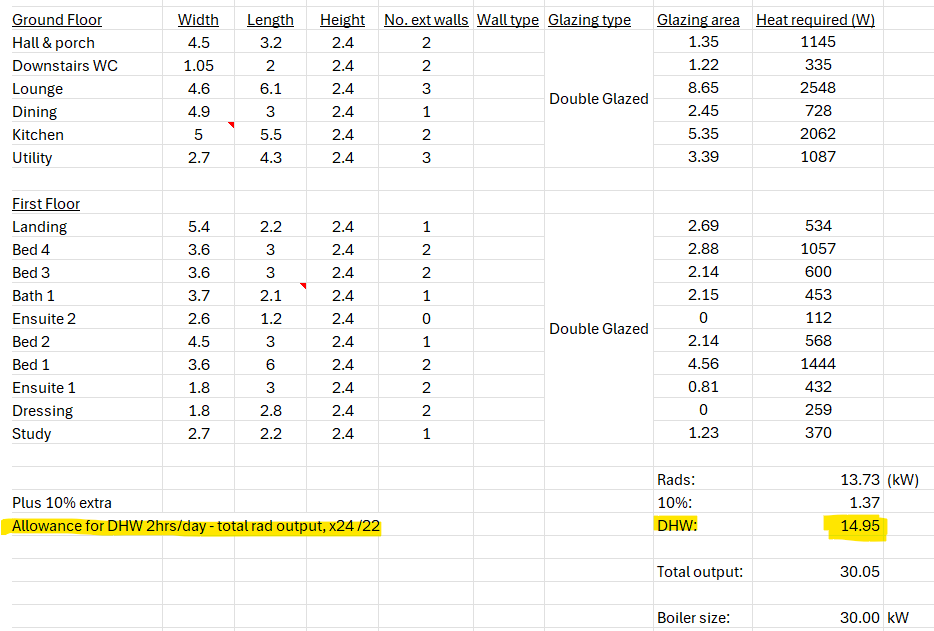

Thanks JohnMo super helpful, so just so I've understood your point about the DHW requirement correctly...my rad kW requirement x 24 then /22 should give me the DHW element of the boiler size? So as below...would you say that's correct? -

System boiler size dilemma...any advice?

Rick734 replied to Rick734's topic in Boilers & Hot Water Tanks

Thanks Marshian - will get my head around weather compensated but PDHW definitely sounds like the way to go here. Hopefully the gaff won't be too leaky and definitely isn't huge so as you say will have to get one that modulates down to house heat loss. Have run heat loss calcs based on Stelrad's online tool which suggests 75deg flow temps as standard... -

System boiler size dilemma...any advice?

Rick734 replied to Rick734's topic in Boilers & Hot Water Tanks

Thanks @JohnMo, super helpful. I did wonder about many boilers being oversized. Was going to give Stelrad site a try to do some heat loss calcs and see if I can figure it out myself. Do you know how much should be added to allow for the DHW rquirement? Thanks, will definitely consider that one. Glad to see that, thanks, as I had come across it earlier and was wondering if it was worth a shout - will definitely request it! I'm redoing all pipework so no excuse not to do it. Feel pretty thick on this subject - no real idea on what things to ask for e.g. if there's any particular specifics to ask for outside of what we've discussed here, to make it more efficient to run, more intelligent controls, Open Therm(?) etc. It will have a Nest or Hive control etc anyway and all rads will obviously be installed with thermostats etc... -

System boiler size dilemma...any advice?

Rick734 replied to Rick734's topic in Boilers & Hot Water Tanks

Edited to add a bit of detail. -

Evening good ladies and gents of BH, Question on my new boiler if you would be so kind as to vent your opinions. Doing a full refurb on my 1960s 4/5-bed detached in Devon. Been getting quotes on a new system boiler and cylinder from a few local plumbers and have a bit of a dilemma on the kW of the boiler. So firstly a bit about the house - it does have cavity insulation (albeit probably a bit patchy, is evidently not too new), approx 2200sq ft GIFA, 1 main bathroom (separate bath and shower) plus 2 ensuites each with 1 shower, updated loft insulation (another ~200mm on top of the original), brand new double-glazing all round, radiators will be all-new as well. I need the capacity to, in worst-case scenario, have a house full of people in the middle of winter, with all 3 showers running at once. Cylinder will be 300L. Have had 4 quotes from various firms - 3 guys have quoted for a 30kW, which to me seems reasonable given the size of house and what I've seen in other similar-sized houses (but only gut feel) - however the guy I was thinking of using has quoted on a 24kW. He is the Ideal servicing firm for the area, has multiple engineers and should definitely know what he's talking about, and assures me that he's done all the heat calcs and it's absolutely fine etc....however the fact that everyone else has quoted on a 30kW is leaving me uneasy, and (gut feel again) a 30kW just seems like a bit more appropriate for the size of house (Which obviously you good people can't really judge from afar). What do you guys think is the best approach here, I'm practical on quite a few aspects but plumbing & heating is a bit of a grey area for me. I'm willing to challenge him again, but would like to get some independent opinions from the forum here to give me something to think about. Also not entirely sure what is the best way to do the calcs myself, if anyone can point me in the right direction...tried working it out earlier and it was recommending a 6.3kW or something...any help appreciated! Thanks,

-

T&G chipboard flooring fixing over ply diaphragm

Rick734 replied to Rick734's topic in Floor Structures

Thanks guys - super helpful thoughts. I'll run them past the chippy today and see what he thinks 😃 -

T&G chipboard flooring fixing over ply diaphragm

Rick734 replied to Rick734's topic in Floor Structures

Thanks @MortarThePoint - apparently a diaphragm to prevent racking or something like that. Pretty sure he's overengineered the whole thing but better safe than sorry I guess... Helpful - so basically glue and nail then to prevent any chance of rubbing at all... -

T&G chipboard flooring fixing over ply diaphragm

Rick734 replied to Rick734's topic in Floor Structures

-

Evening all, Just wondering if anyone can advise with a flooring query. I'm doing a TF extension on top of existing single skin garage walls, and the SE has specced a 9.5mm ply diaphragm over the joists, with flooring substrate to go over that (nothing specified for the actual flooring substrate so was going to use 22mm Caberdek). My chippy was saying they'd obviously glue and nail the ply onto the joists, and will use 63mm nails down into the joists through the ply anyway, but was then asking if I want them to glue the chipboard down onto the ply as well. Any thoughts on this? I just want to prevent any squeaking or movement - is adding or not adding glue between the ply and Caberdek likely to have any impact either way?... Thanks Rick *edited for clarity

-

Thanks for that @Nickfromwales - apologies for the delay! I've got some STS 12.5mm insulation board - would you normally ply behind that board as well? It does have extremely high compressive strength but maybe not so much 'bending' strength, if that makes sense...

-

Thanks, got it. Don't think I ever took it out of that noggin (just leant the top half back) so should still be correct. Now onto boarding...