Crispy75

Members-

Posts

14 -

Joined

-

Last visited

Personal Information

-

Location

London

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Crispy75's Achievements

Member (3/5)

1

Reputation

-

The cavity has blown insulation already yeah. I understand the logic behind having the AT layer right on the inside, especially due to the risk of interstitial condensation. But once the additional EWI is added, even the outside face of the brick is "inside" from a thermal gradient POV. My calcs say it'll be 15° at that surface on a 0° day, so relative humidity would need to get up to ~70% indoors and stay there long enough for moisture to get all the way through the wall. MVHR will keep that in check. All that being said, it feels more like I shouldn't expend so much effort if there's going to be such large gaps impossible to seal. Maybe I'll rig up a DIY blower and see how bad a single room is. The rooftop extension (full footprint) that's also part of this project: that I will make airtight. I'll be putting in MVHR regardless, just for the air filtering. My wife's allergies demand it!

-

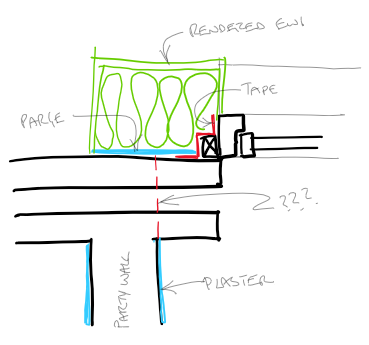

I'm adding external wall insulation to my 60's terrace and would also like to improve airtightness as much as possible too. I can't afford the disruption of removing all internal wall finishes & fixtures, so the boundary has to be at the outside surface of the brick. This will be a parge coat and taped external window support frames. The party walls are 215mm brick plastered both sides so reasonably airtight to start. I don't mind squirting stuff under skirting boards to fill any cracks there. But how do I bridge the two? Or is this a futile hope? The best I can think of is drilling some holes from the outside and squirting in expanding foam.

-

Fan Coil Units for use with a (cooling) ASHP

Crispy75 replied to ProDave's topic in Air Source Heat Pumps (ASHP)

11 sounds like a lot, but it's the existing compliment of 8, plus 1 in each new main bedroom and 1 in the new bathroom (towel rail). The total rad area gives me the heat output I need, so I'd only be able to reduce the count by replacing some with larger units. 4 FCUs would be the maximum. Obviously fewer larger units is better but it will be tricky squeezing ducts in. Talk of skirting the dew point makes me nervous I have to say. Not to mention the losses through all the uninsulated pipes. Distributed heating is ok (the way the previous owners installed the system, it means the hall and landing effectively have UFH!) but I'll only want cooling in specific places. In any case, I won't be doing this DIY. While I'd relish the challenge and love a project, I just won't have the time (family life, busy day job, postgrad studies). So for now I'm just settling on a strategy that I can then take to some installers. Thanks for all the advice btw. This is an excellent forum and I wish I'd foudn it sooner! -

Fan Coil Units for use with a (cooling) ASHP

Crispy75 replied to ProDave's topic in Air Source Heat Pumps (ASHP)

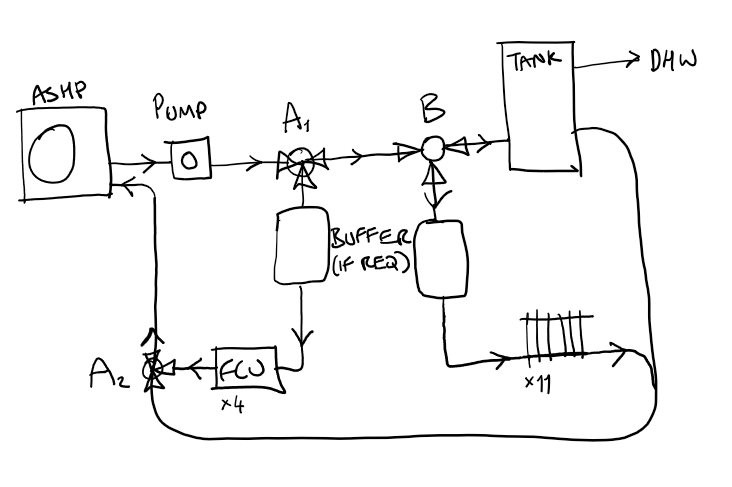

(quoting from another thread) So yes you're right about zones. I was confusing myself reading the Aquarea installation docs >_< But I can't send cooling water round my existing pipes and rads. The condensation would be a nightmare. I was assuming something along the lines of this, where the FCUs are all on a (short) run of new well-insulated pipe, while all the rads are on the existing loop, or extensions of it: Valves A1 and A2 operate at the same time to isolate the cooling loop from the DHW/CH loop and valve B switches between the rads and the tank. (No need for a bypass valve in the heating loop as the bathroom rad has no TRV fitted). I have only ever been MEP adjacent so am here to be schooled -

Fan Coil Units for use with a (cooling) ASHP

Crispy75 replied to ProDave's topic in Air Source Heat Pumps (ASHP)

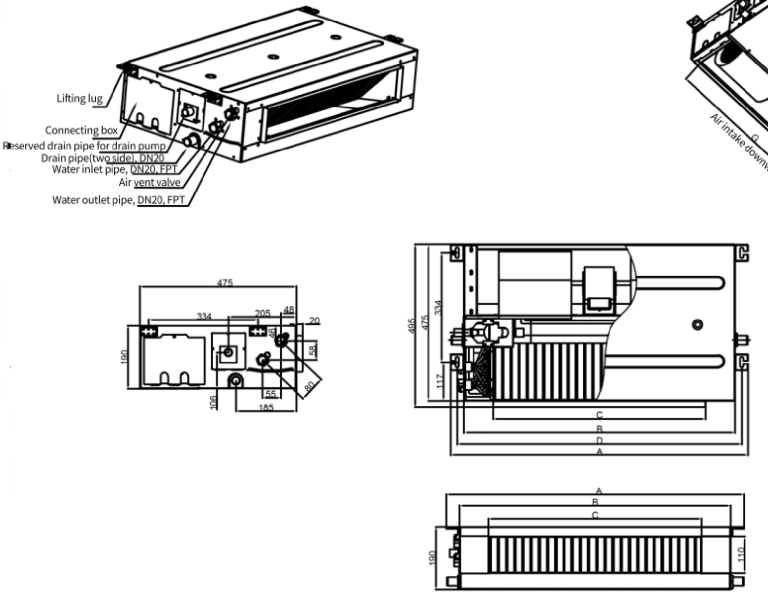

Yeah I was attracted to them by their simple shape and slim profile. 190mm is very compact. My understanding is that you care more about directed airflow for heating, otherwise all the warm air collects at high level and gets recirculated through the FCU. For cooling, convection does the work for you. Managed to find the Chinese manufacturer via google image search: https://aircolder.com/product/fan-coil-unit/horizontal-concealed-ultra-thin-fan-coil-unit/ power 48W-148W Noise 16dB(A)-51dB(A) Air flow 530m³/h-1750m³/h Cooling capacity 2.95kw-9/0kw Heating capacity 4.4kw-13.5kw Looks like the intake can either be from below or from the rear if you squint carefully. Also worth noting there are no filters, so you'd either need to roll your own or make sure you can acess the heat exchanger for cleaning. Product components Coil Fin 0.105mm thickness aluminum fins, distance between fins is 1.3mm Cooper tube Three rows, 0.28mm thickness, 7mm diameter, 30 tubes in total, FP-136,24tubes Drain Drain pan High density polyurathane material with plastic coating Drain pump Available(Biult-in for advanced, external for standard) Alertor Available( only for advanced) Shell Panel 0.8mm Al-Zn-Si hot-dip galvanized steel sheet Insulation EVA insulation pasted outside and inside the panel, B1 rating Motor Standard Low noise 3 speed fan motor , DC motor available Advanced DC motor with 0-10v thermostat Label Labels: model label, wiring diagram, precautions, fan rotation, logo, etc. Fan ABS material Centrifugal, forward-curved blades Control Standard LCD thermostat available Advanced Equiped with 0-10v thermostat -

Cheers, very useful, and checks out pretty close when compared against manufacture data. Also comes out less than my extrapolation, so I'd be running at dt25 or so to keep some headroom. Still well within sensible limits. If I try and get the boiler upgrade grant for the ASHP, will the installers accept PHPP's heat load calculations, or will they be forced to use cruder methods? (and therefore come up with larger rad requirements)

-

Yeah that was my 1st thought for the new rooms, but if I'm going to use FCUs for cooling also in rooms heated by radiators, it all starts to get a bit complicated in terms of control zones and plumbing. I'd want to send hot water to FCUs and rads, but cold water to FCUs only. Lots of valves! Also, I'm not really a fan (hah!) of having warm air blown at me. Cold, yes

-

Fan Coil Units for use with a (cooling) ASHP

Crispy75 replied to ProDave's topic in Air Source Heat Pumps (ASHP)

These look quite good: https://theheatpumps.co.uk/4kw-concealed-fan-coil-unit-for-heating-cooling.html - nice and compact. But there's little technical info, and all these guys seem to offer are their own badged units, no big name brands. Has anyone had experience with Megawave? Or recognise these FCUs from their travels on alibaba? -

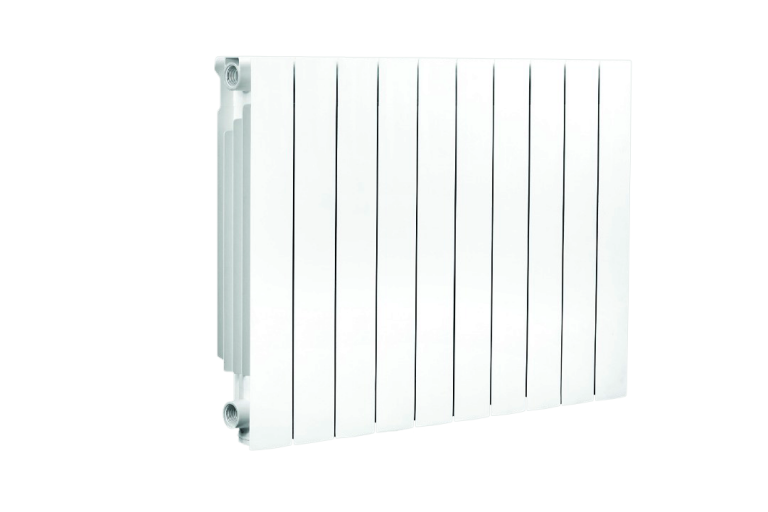

I'll be insulating my house, as well as the new extension (one storey up, on the whole footprint). All new windows too. Aiming for EnerPHit. The house is curently heated by a Vaillant Ecofit 825 gas boiler and mostly some rather fancy-looking cast-aluminium radiators; modular KAL models from Italy. The modern version is this: https://www.kazuki.co/en/product/radiators/aluminum-radiators/aluminum-radiator-kal-c which looks almost identical. The boiler has a 9kW capacity and I calculate all the radiators to have a total output of 6kW at dt50. After the works, the house will be 50% larger, but also much better insulated (U values: Walls 0.1, Roof 0.09 W/m²K). PHPP says my heating load will be 1.7kW at -10°C (or 2.2kW before taking solar gains and indirect heat in account, which is closer to the figure you'd get from a vanilla heat loss calc). This is a reduction of 75%, on a W/m² of floor area basis. I want to replace the gas boiler with an ASHP (and also get some fan coil cooling on very hot days, but that's for another thread, another time). I think I can get away with using the existing radiators at dt20 or 30, simply due to the much lower heating load. Now, the KAL radiators don't have data for dt20 or dt30, so I had to extrapolate from their 60/50/40 figures. There's also one Type 11 radiator which is easy to calculate. With the addition of small Type 11 radiators in the new bedrooms, I get a total output of 2.6kW at dt20, of which 2kW is the existing radiators. This roughly matches my load of 2.2kW, with a little headroom for error. Does that sound about right? Going down from 6kW@dt50 to 2kW@dt20 with the same rads? Is my roughly linear extrapolation correct? Will the flow rates be so wildly different that the pipe diameter will matter? I've attached the spreadsheet I used to do these sums and would greatly appreciate any advice. Thanks ^ KAL radiator. They're quite attractive so I'd like to keep them. Radiator Sizing.xlsx

-

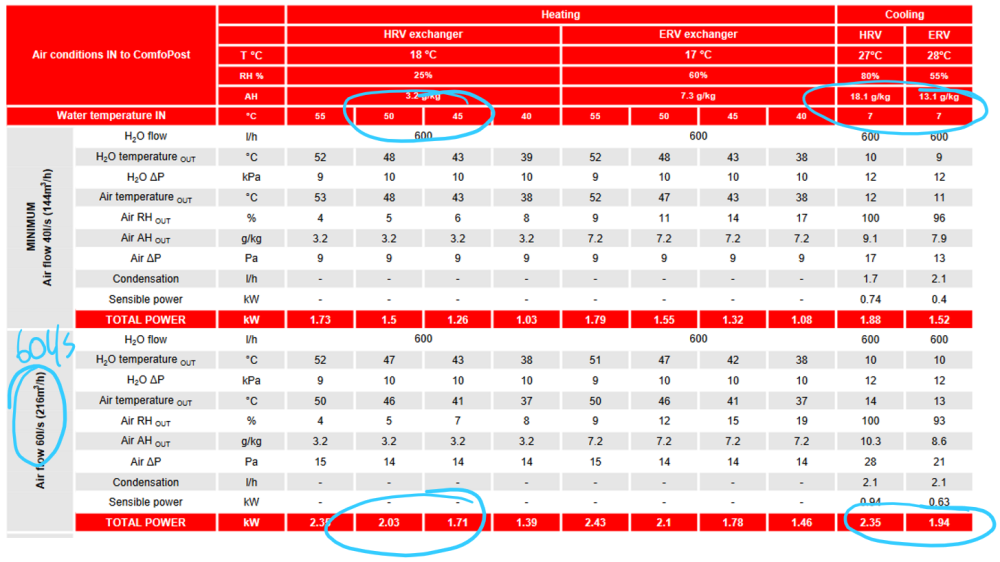

I hope @James Allen doesn't mind me hijacking his thread to ask similar-ish questions. My project is a whole-story extension and external insulation to the whole house. Aiming for EnerPHit (although not bothered about certifying), and have got the numbers in PHPP down to 1.9kW (15W/m²) heating load and 1kW (8.3W/m²) cooling load. It doesn't take much of a boost in airflow rates to get PHPP to say Yes to both heating and cooling via supply air (190m³/hr =52l/s). First I went looking for all-in-one solutions and got quoted an absolute fortune for the PKOM4 (£25k! Excluding install and commissioning!!) Now I think the ComfoPost as reccomended by @Nick Laslett alongside a more off-the-peg ASHP. The Zehnder literature seems to think so anyway. What air flow do you run yours at Nick?

-

EWI with cantilevered external fixtures - eg. sunshades

Crispy75 replied to Crispy75's topic in Heat Insulation

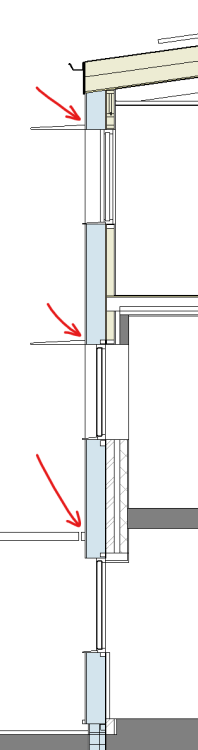

Thanks for the replies! Yeah I'm not too fussed about cold bridges from a few screws or bolts, but doing an offset frame in timber will be a pain to fit the EWI round. Lots of cutting and glueing and scraping and cursing. Thought there might be a "big chunk of GRP or nylon with nice square edges and concealed fixings" kind of solution. My experience in the construction industry has lead me to believe that you have to make things as simple as possible for builders if you want anything approaching a careful job. Much rather spend extra upfront on a clever product than have my carefully annotated NASA-grade details ignored or bodged. -

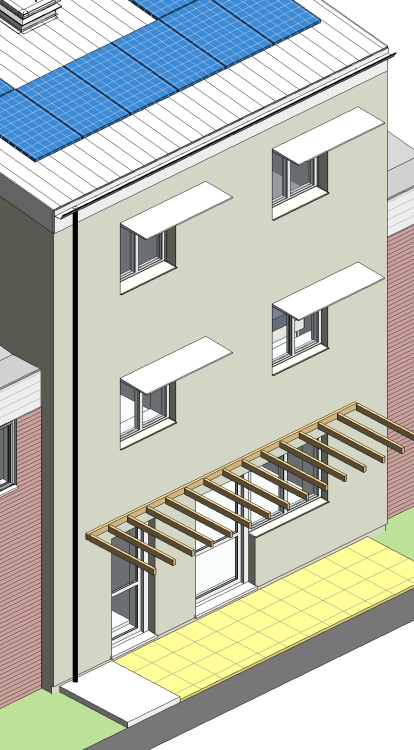

Hi, long time reader first time poster As part of a comprehensive retrofit and extension project I will be insulating my existing brick and new timber frame walls with at least 200mm EWI. I'm comfortable with specs/details for the basic buildup, but would like some advice WRT to through-insulation fixtures, in particular: I want to install brise soleil or awnings to south-facing windows to cut down on summer solar gain. I also plan to support one edge of a pergola at ground floor (so a long beam fixed to the wall). I can't seem to find a standard method for achieving this. I don't want to simply bolt something direct to the brick with a Farat pad and insulate/render around it. I'd rather provide a secure surface directly behind the render so the awning, beam etc. can be as simply fixed as if it was a solid wall. I've found the SWFix product, but that doesn't seem geared to anything heavy or cantilevered. Has anyone solved the same problem in an elegant and robust way? I'm not going to just bulk it out in timber am I?