Smallholdertoo

Members-

Posts

33 -

Joined

-

Last visited

Everything posted by Smallholdertoo

-

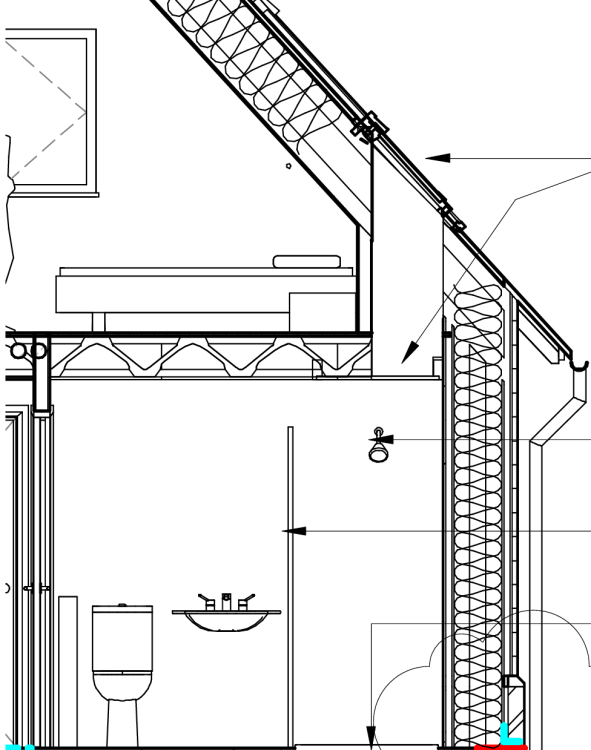

Thanks you both. I was coming to the same conclusion which was confirmed when I saw a friend is currently building a passivhaus. We will still take the three pipes, via the roof cavity, straight up adjacent to the north gable. The pipes will exit near to the top of the roof into a space between the flat ceiling of bed 1 and the roof, From there they will pass above the flat ceiling of the bathroom roof with one going above the ceiling in bed 2. As the ceilings don't yet exist i will need to cut off the pipes at the required lengths and initially leave them dangling! I still propose that the ducts to pass through 95mm holes within boards attached to the rafter when entering and leaving the airtight roof space, to aid the taping of the ducts and ensuring that the membrane does not rip.

-

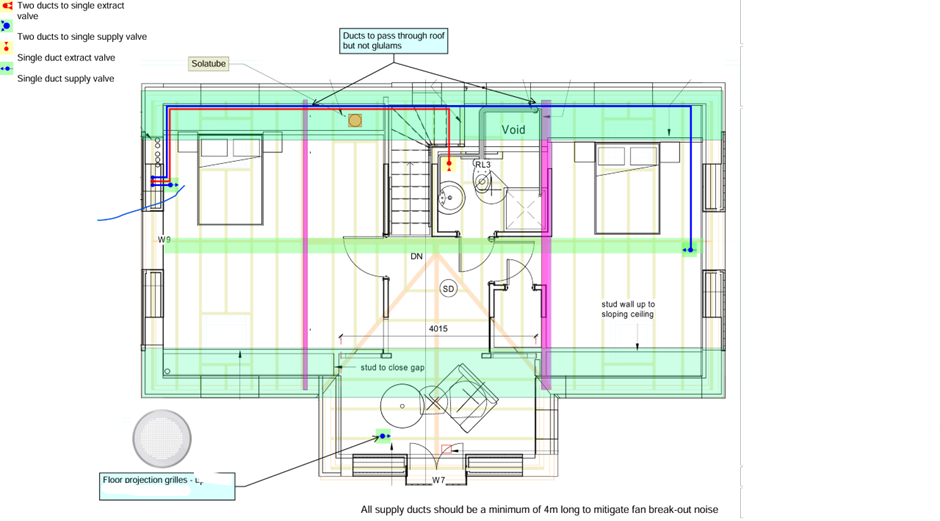

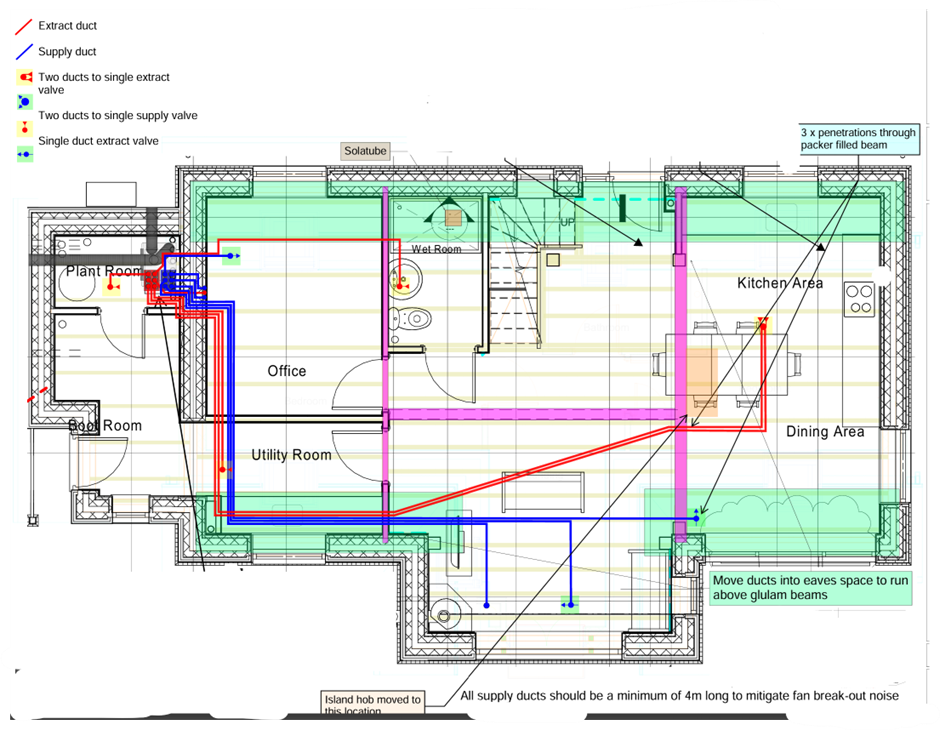

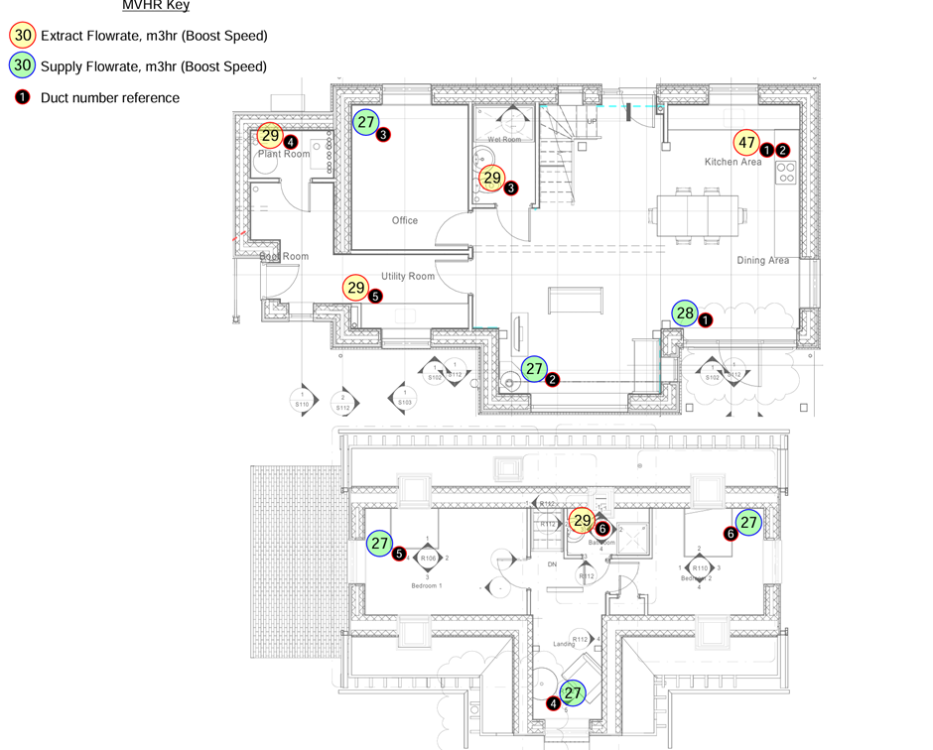

We are in the process of building our new house a 1.5 storey, well insulated house with MVHR. The timber framers are finishing the roof structure (400mm metal web rafters to be filled with cellulose fibre) and sarking is about to be fitted. MVHR ducts must be fitted next week per the framers ! We have a design for the MVHR which assumed that we could have ducts passing though the 400mm deep rafters, as suggested by the framing company early in the project. Unfortunately, the structural engineer added glulams that not only block ducts passing from the plant room to the south end of the house both in the joists and the roof joists . For most ducts we can bypass the glulams by moving from the joists up and over them within the boxed in section adjacent to the FF eaves. This sorts the down stairs ducts and all but 3 of the upstairs ducts. These relate to beds 1 and 2 as well as the bathroom. They will have to pass from the joists, within the boxed in eaves and through the roof rafters sometimes more than once (see photo). I am concerned that from an airtightness POV this will be a nightmare, as the roof airtight layer is Intello which will attached to the rafters and held in place by 50x25battens (to be covered by plaster board later). I have nightmares of long cuts or even worse – rips and endless airtightness tape. I can reduce the risk noted above by trying to persuade my wife that the vents could be on the sloping part of the ceiling or even the low wall that boxes in the eaves rather than the small flat area of ceiling in the bedrooms (-any thoughts). The use of the small wall would be easiest and would reduce the number of times the ducts will have to pass into the roof and therefore be sealed. I am also thinking of using offcuts of smartply with holes cut for the duct to be attached where the ducts will join and leave the roof to help with airtightness and to reduce the risks of rips. Although the plan shows a floor vent in the FF gable at the front of the house, We will revert to the original design of having supply 2 feeding the ground floor area within the front gable . My wife does not fancy a grill in the floor of her 'snug' Any suggestions would be appreciated? I will add photos of the roof shortly

-

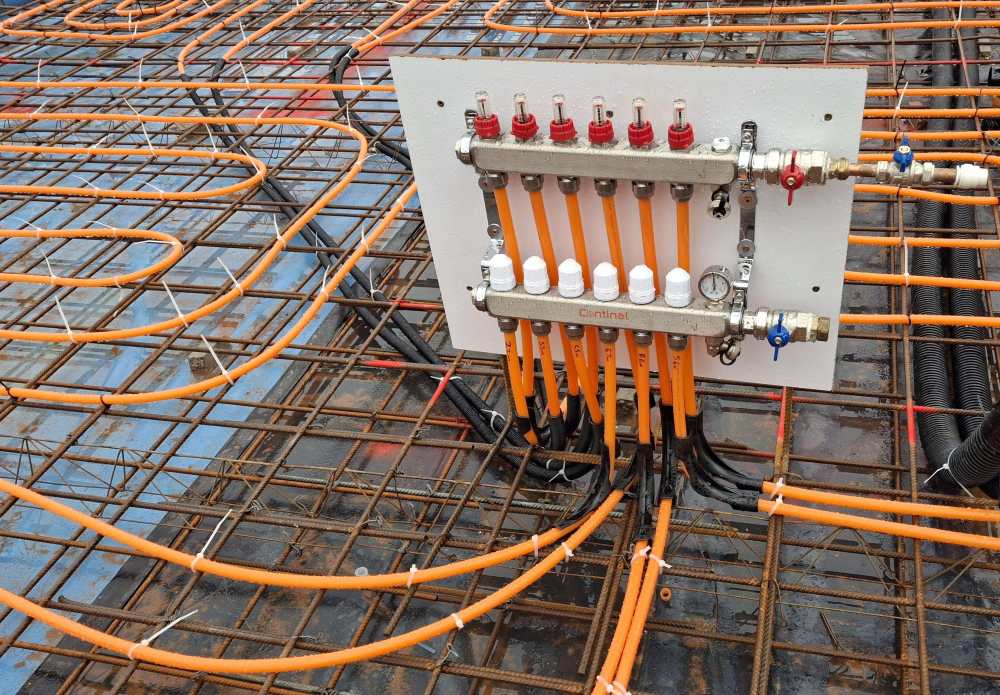

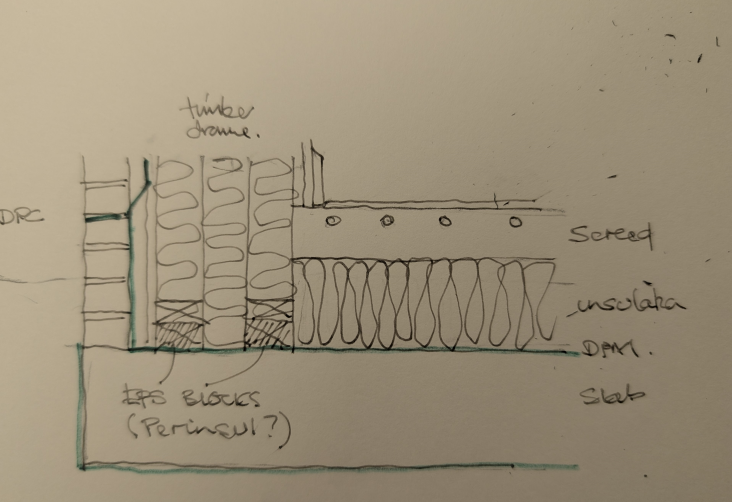

We are due to pour our insulated reinforced raft next Friday. It is all ready except for 1) sealing and tying down a block of XPS attached to the waste pipe to give a void for the shower waste. - Do I need to cover in DPM?, - PU foam around the pipe to seal concrete out - Is tying down the XPS with wire OK. - Should I lift it up from the rebar mesh using concrete "mars bars" to help continuity of concrete and 2) How to protect the pipes under the manifold from over energetic power float operators! Possibly boxing out the area with plywood? Any suggestions on the above or the pour generally would be gratefully received.

-

Ground works for our new timber frame house starts in a weeks time. The highly insulated 1.5 storey house with a footprint of c.80m2 will be on an insulated reinforced raft, 270mm deep concrete with wet UFH attached to the mesh. The concrete will be power floated to provide a surface for tiling. The water temperature in the UFH should be quite low due to the low heating demand (2kw when outdoor temperature is -9C.) ASHP. I have to order my windows and doors early next week and need spacers under the door threshold to provide for finished floor level. We therefore need to work out an appropriate depth of these spacers to retain a reasonably flat threshold to comply with Part M. We intend using large format porcelain tiles (as yet not chosen) throughout most of the ground floor - except the shower room but am unsure whether I need to allow for decoupling membrane (as recommended by tilers). Taking account of this , how many mm should we allow for the finished floor? The tiler has suggested 17-20mm. Also , how long will it be before I can get it tiled as it is a very thick raft? and should I put the UFH on first. I would appreciate your thoughts as to anything else I should be considering? Many thanks in advance

-

Suitable sun tunnels for a bathroom

Smallholdertoo replied to Smallholdertoo's topic in Skylights & Roof Windows

In a word No! Although it s only a periscope of sorts , it needs to be a1rtight and thermally functional and aesthetically attractive both internally and out. Maybe worth the effort if i needed 5. Thanks for your help. -

Suitable sun tunnels for a bathroom

Smallholdertoo replied to Smallholdertoo's topic in Skylights & Roof Windows

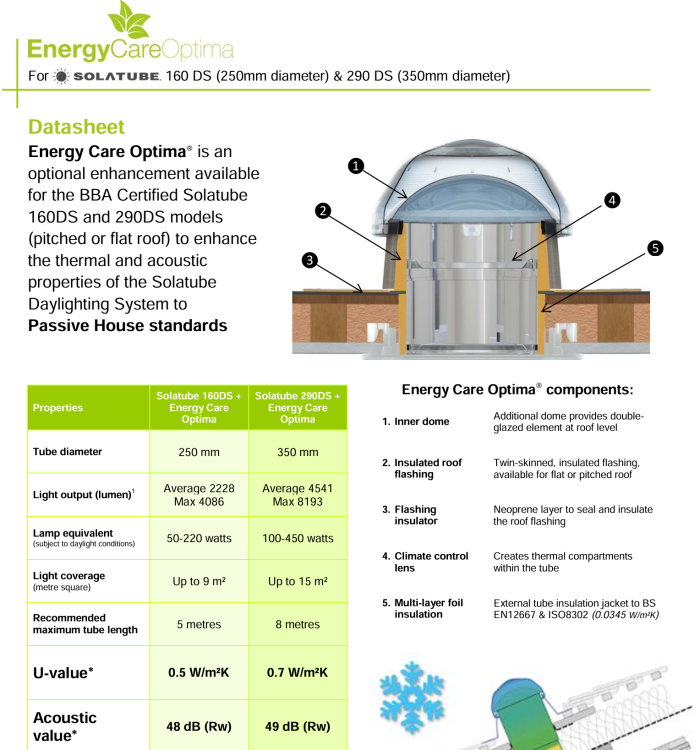

Contacted Monodraught. They agreed that their Sunpipe is not designed to be airtight, Solatube however do have a passiv house standard version of their product that has 0.5w/m2k u-value and gaskets to ensure that airtightness. So I am probably going down this route. -

Suitable sun tunnels for a bathroom

Smallholdertoo replied to Smallholdertoo's topic in Skylights & Roof Windows

Many thanks I will contact them on Monday -

We are due to start building a highly insulated 1.5 storey detached annexe in July. The downstairs wet room of approx. 4m2 is due to be lit by a small Velux in the roof at the edge of an upstairs. bedroom. I now need to use this area in the bedroom behind a bulkhead for MVHR pipes. My wife wants to have natural light in the wet room so she is suggesting a sun pipe. For me this will only work if it is well insulated otherwise condensation, due to cold bridging, may be a problem. We will have a number of Velux's on the roof so I thought that perhaps a Velux sun tunnel may work. However, these have a basic u-value of 2.9w/m2/k, though they do an insulation kit which drops the u-value to 1.8w/m2/k but only for the 14" version which would be too large for the size of the room. Has anyone used a Velux sun tunnel in a bathroom environment? and if so was there a condensation issue? Or does anyone have any other suggestions?

-

Wet UFH in 250mm insulated reinforced raft

Smallholdertoo replied to Smallholdertoo's topic in Underfloor Heating

Thanks for the comments and the support. The SE is yet to confirm the thickness though he has mentioned 250mm in the past. If it does turn out to be 250mm any thoughts how to persuade him to let it be thinner? Its probably worth mentioning that in readiness for the build we have installed 11kw of PVs and 20kw of battery storage on a new shed. This will provide the power to the new house. would this affect your choice of ASHP -

We are due to build a small very well insulated 1.5 storey timber frame house later this summer. Using the Jeremy Harris spreadsheet, the house will have a thermal demand of under under 2kw when it is -10c outside . U values of 0.09, 0.13 and 0.10 for the roof, walls and floor respectively. The house has passed Part O for overheating and will have MVHR. We are now definitely going to have an85m2 insulated reinforced raft. I want to have ufh in the raft and in line with what others have done on this site it will have 3-4 loops, a singe zone and one thermostat. We will have a small ashp perhaps 3.5-5kw. I expect water temperatures in the ufh will be under 25c. The ashp will also provide our hot water - a 250l unvented cylinder. I keep on being given the advice that a 250mm slab will be very slow to heat or cool e.g. from my designer "My concern with a heated slab of 250mm thick is that the response times will be so slow that you will find that you are unable to adjust internal temperatures when the house heats up to the required temperature and then continues to heat when you don't want it because of the thermal mass." I am aware that the raft will be slow to warm up and cool down but am I right to believe that with the weather compensation a single thermostat and a low water temperature I am unlikely to have the issues suggested re overshoot? It would be great to hear from those on the forum that have thick rafts, ufh in raft and a well insulated house . Thanks in advance

-

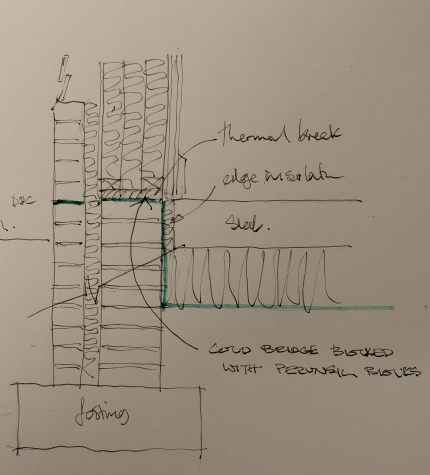

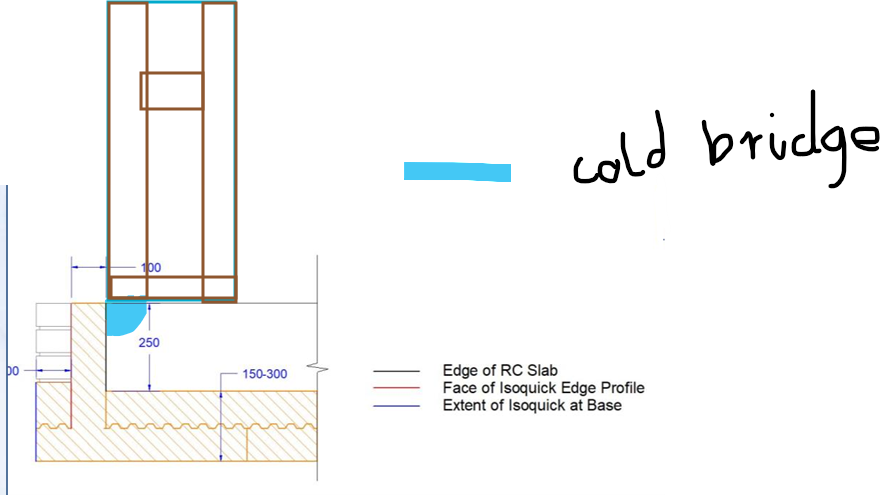

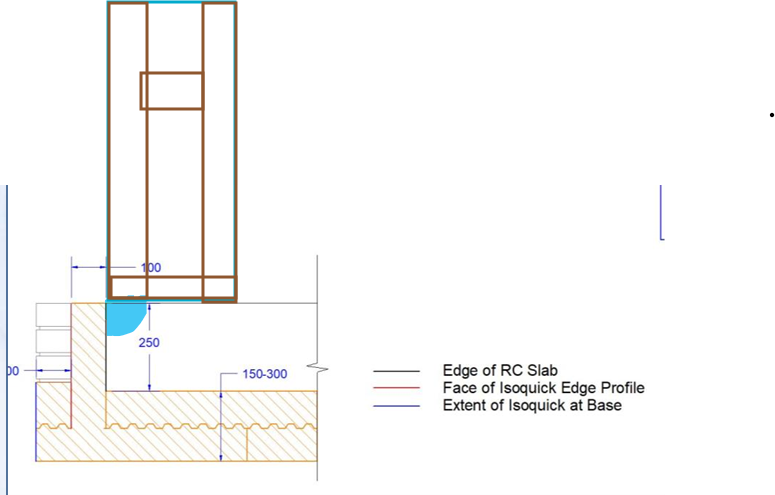

We are due to build a 130m2 near passiv house timber framed 1.5 storey house with a brick plinth in the early summer. We decided to go larsen truss timber frame I was hoping to have a highly insulated structural raft (u-value .10) with UFH in the raft but now my designer has been informed by the SE that the larsen truss will be structural both on the outside and and inside studs so will need to be fully supported, He had initially assumed that only the internal stud would be structural which would have allowed the non structural outside stud to cover the insulation between the brick plinth and the slab. This change produces a cold bridge as shown below in blue. He is now suggesting that we should go with strip or trench foundations and a slab as shown in the drawings below. I am concerned that there will be cold bridging and a u-value of.10 may not be achievable. Any thoughts on his suggestions and how they can be improved or how we can still use a insulated raft?

-

We didn't need to use British Gas as when Octopus rang, we explained that National Grid should be fitting the supply on the 12th of December. The man from Octopus replied that there was an appointment for the 13th if that would work for us. So hopefully we should have a supply in 3 weeks. Thanks for your help Sometimes I just worry too much!

-

Our 3 phase 42kVa supply is due to be installed on 12th December. It is to be installed in a new stable shed but will power our new annexe when it is built. On contacting Octopus I was told it will be more than 4 weeks before the smart meter can be fitted. I will find out the first available fitting date tomorrow. I believe that when you swap electricity suppliers you now do not need a new smart meter. I guess, I could get one of the other other electricity suppliers to fit the meter and then swap to Octopus once meter installed (and new PVs are on the roof). My question is - Does anyone know of other suppliers that are quicker to install 3 phase smart meters ? Thanks for your help, in advance.

-

@nod What are the main causes of the damage? - contact with the Power float, scuff damage from boots etc. and how to best avoid if determined to have UFH pipes in the concrete slab ?

-

Underfloor heating pipes within concrete slab

Smallholdertoo replied to Smallholdertoo's topic in Foundations

Many thanks for your responses - Luckily the concrete will not be the finished floor. We will be tiling over it! Are you aware of any youtube videos that show this?