Selexus

Members-

Posts

44 -

Joined

-

Last visited

-

Days Won

2

Everything posted by Selexus

-

Thanks Yes already had that conversation with them. It's one of the few aspects of this build I'm not doing myself. We also discussed dry shake surface harder powders for colour enhancement. although that decision is yet to be settled. Still trying to get a delivery date on my pre-fab ground beam cages 😡

-

No definitely not. Warehouse is perfect. We'll have rugs and other stuff around that will soften the look and feel of it.

-

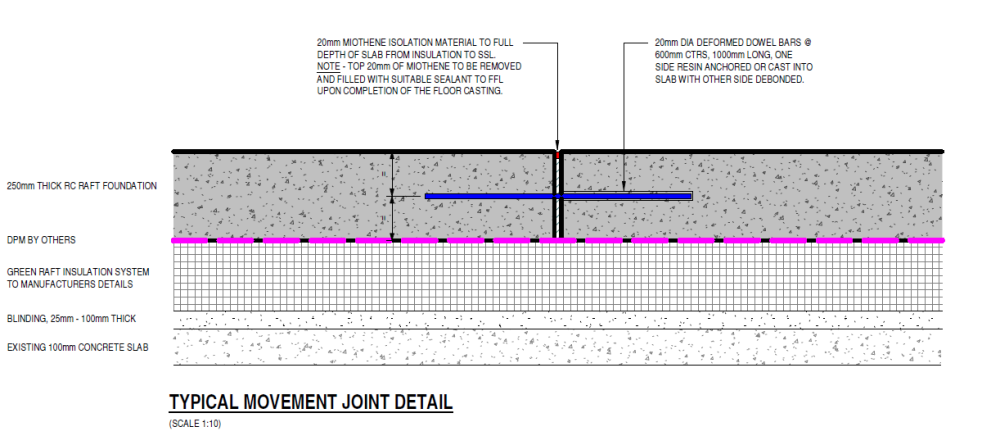

Polished concrete. We'll make a feature of the cut joint that the SE has now agreed to. Inlay it with a brass strip or something.

-

So... Had the conversation with my SE and after some discussion we settled on a standard cut control joint at these locations. The dowel joint was mainly specified to potentially placate the over zealous requirements of warranty providers that the SE has recently come up against in recent jobs. The SE has no issue with standard cut joints as there is minimal potential of differential settlement. He mentioned that contraction was the major concern, and if was ok with the cut joint opening up slightly over time, then he had no major concerns. We have agreed to present a united front (from a risk and technical perspective) to said provider if they question the use of control joints, rather than dowelled joints. The more I talk to him, the better I feel about this work.

-

Don't put ideas in my head. 😆

-

I don't disagree, but how do i get the SE to agree to this ?

-

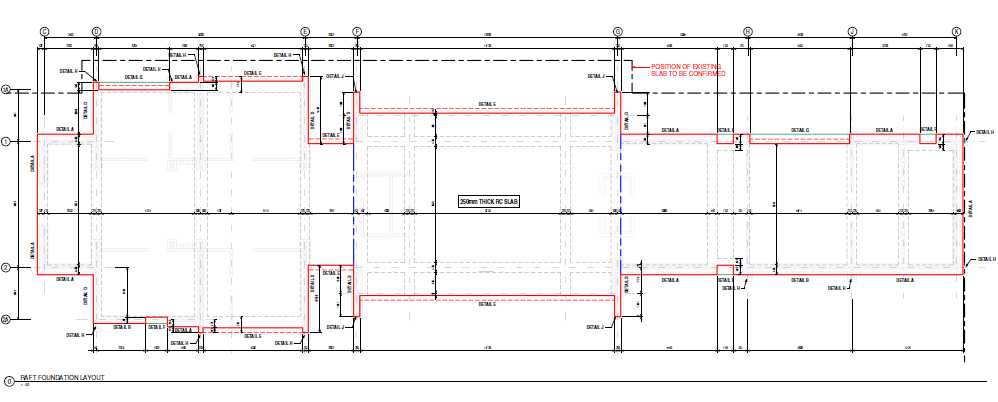

Blue dotted lines are the 2 joints specified by the SE. I'm happy with the whys and wheres of these, as the slab is 42m long and NEEDS some form of expansion control. What I'm looking for is a recommendation of a product (preformed joint) or method, that would allow simple construction of this joint prior to our single pour (90 cubic meters). Thanks S

-

Thanks Gus. I did have a chat with him and his explanations made good sense, although on the risk averse side His reasoning was very similar to what you have pointed out. Ease of build (we have a fixed flat base - existing concrete slab) and so incorporating all elements into the raft, and making it capable of surviving differential movement (like that's going to happen 🙄) of this existing concrete, is how we ended up with the 250 slab with integral ground beams. He certainly has put the hrs in thinking about how to design AND how i am going to build it, so fair play to him.

-

Here. Left pipe is the hot return (from the local ensuite hot manifold) middle is the hot feed (now run in) and right is cold feed. All 20mm Pex-al-pex. This ensures hot circulation at the main manifold (center of the house) and therefore short runs from there to each en-suite manifold.

-

I used these on my last house. Would not go back to sand and cement, or other methods. So easy to install and level.

-

Hi All, Now that my UFH pipe placement and other such incidentals have been settled I'm turning my thoughts toward how to create the 2 x 6m long expansion/movement joints in the 250mm raft, that also have 20mm sleeved dowels through at 600mm intervals. Never done it before but I'm thinking some aluminum angle supporting 20mm compressible foam, through which the dowels poke and are supported by rebar either side ? Suggestions very welcome 🤔 Thanks

-

Not yet, but it's a good shout. Don't want a bit of rogue concrete blocking a water pipe and giving issues later....

-

Oh yes.

-

Its Sopera XPS. Interesting stuff to work with. I've bought a hot knife gun and have routed all the first fix pipe and conduit into the top of the insulation.

-

On top it is! The partner will be happy to hear that 😆😉

-

*selexus goes to look at Samsung watch step app*

-

Bugger.....hadn't thought of that. It's a 57m walk..... Scooters....electric scooter....that's the solution 😃

-

I'm with you Steve. I challenged our SE about the 250mm slab and he said his calculation fell apart at anything less than 250mm. On this design every 25mm of concrete is £1k 😲 The exiting concrete (and the substrate) is absolutely fine (as confirmed by a Geo Technical survey). Blinding has been dispensed with as the existing slab has a 10mm variance across it's entire 57m length with a good surface finish (used to be a chicken shed). I'm committed to this design now as any more delays and my build program goes seriously off track, but I'm definitely with you on the over engineered observation. On the bright side, I should be able to use the telehandler indoors 🤣 Anyway i've just sent the SE an email asking about the reinforcement build up as to my sums we have 170mm of reinforcement with a 50mm bottom spacer, which leaves me with only 30mm of top cover (i think) 🤨 Why is nothing every simple.......