Clark Kent

Members-

Posts

34 -

Joined

-

Last visited

Personal Information

-

Location

Kent

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Clark Kent's Achievements

Member (3/5)

1

Reputation

-

Generally the detail is a 100mm gap all round filled with shingle

-

Sorry can’t comment on drying time but I’d swerve the underlay and bond directly to the screed for heat transfer.

-

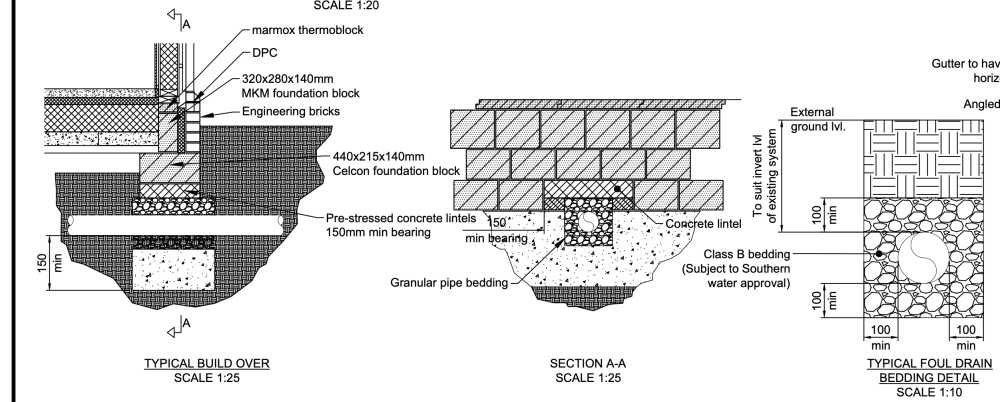

I don’t think concreting the pipe in is a good move, if there was ever any movement in the foundations it would damage the pipe. We had to get a build over agreement for our extension and where the solid pipe comes through the foundation (with a lintel over) it’s surrounded by shingle to take up any movement.

-

Thanks for your replies 👍

-

Thanks for your replies. I’ve done a fair bit of research on heat pumps and am quite aware that the rads will probably feel like they aren’t even on. We’re only putting them upstairs as we’re having UFH downstairs. So basically without the convector's the column radiator isn’t as efficient and will need to be even bigger to work with the low flow temps?

-

Had a heat loss survey with a Heat Geek, when it came to the topic of radiators the guy pooh-poohed column rads. He suggested they weren’t efficient and wants to use type 21 or 22. I’m not after using Victorian cast iron ones, just something slightly more aesthetically pleasing. I know that heat pumps run at a low temp so you have to have a decent surface area but I would have thought BTU’s were BTU’s…..

-

This is really interesting, I’m doing a similar refurb but cannot dig out the ground floor. This guy isn’t either and adding no insulation at all and yet reckons his heating bills are £80 a month?

-

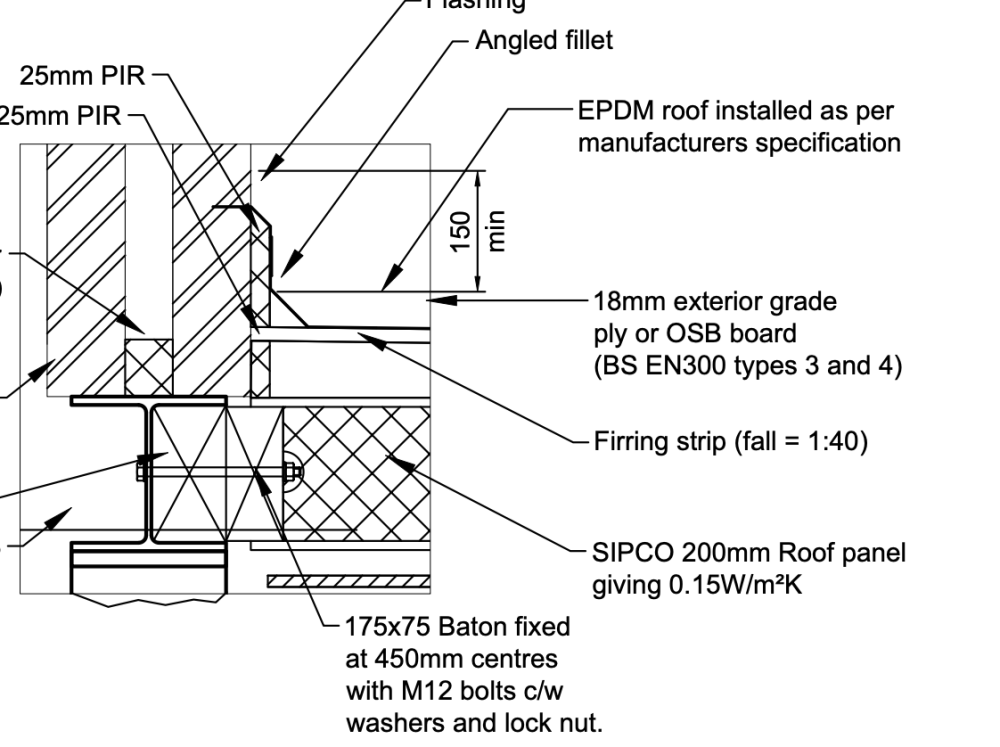

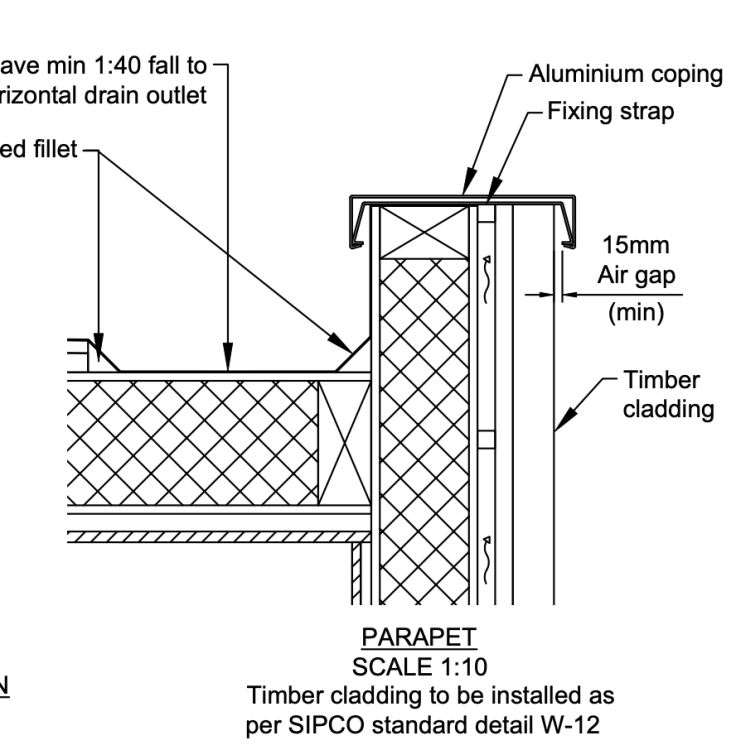

The parapet is a part of the design I need really as the cladding runs level all the way round, I don’t want to see the flat roof. I could probably just lay EPDM over the SIP if I were to be able to install it with a fall. I’m wondering if building the roof traditionally would be cheaper though as I could frame it out myself. I don’t believe SIPS is vapour impermeable, the SIP company specify a robust vapour barrier.

-

I guess there's always more than one way to skin a cat, are you suggesting some sort of fan to blow air through the vented cavity?

-

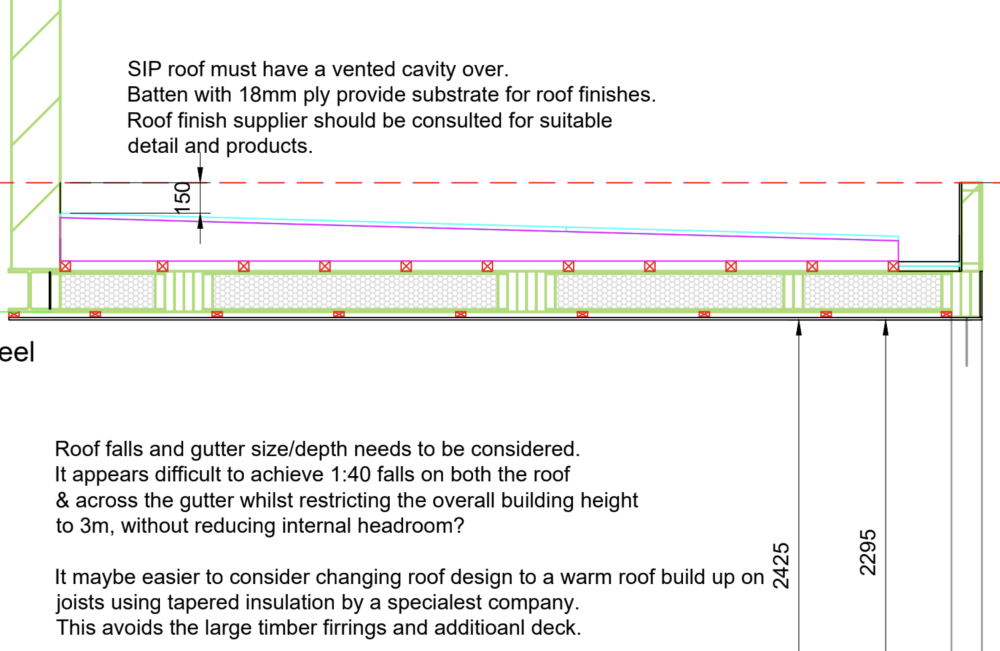

I'm thinking maybe I would be better looking at a warm roof as it appears to be lots of cold bridges with the supporting timbers

-

Basically the overall height is supposed to be 3m maximum (as stated by the permission). If I move to a warm roof this will need to be increased to 3150-3200mm Steel isn't in place, basically we're only just out of the ground. Trying to finalise the drawings from the SIP suppliers. The drawing you have referenced is their one, even if I used the batons and ply as they suggest I'm guessing I'd have to bring this void up the parapet and exit under the coping strip to allow ventilation?

-

Looking for a bit of guidance on the flat rood=f of our kitchen extension. Our rear extension is underway, we decided to go with SIP's and it was to be the full envelope. Roof, walls just bosh it up and off you go. The SIP supplier has doubts about the flat roof, they want to ensure that there is a fully ventilated cavity and now want to change the construction to a warm roof. At this point I must admit that I have done all the design drawings and naively had not considered this to be a cold roof and the intricacies of this system. I don't have an overall section of the roof build up but basically the build up (from inside to ou) is- Plasterboard, SIP, Firing, 18mm OSB, EPDM. It's to have a parapet running all the way round and this is the reason that makes me think I've gone completely down the wrong track, I don't see how this roof can be ventilated. Any advice would be greatly appreciated.

-

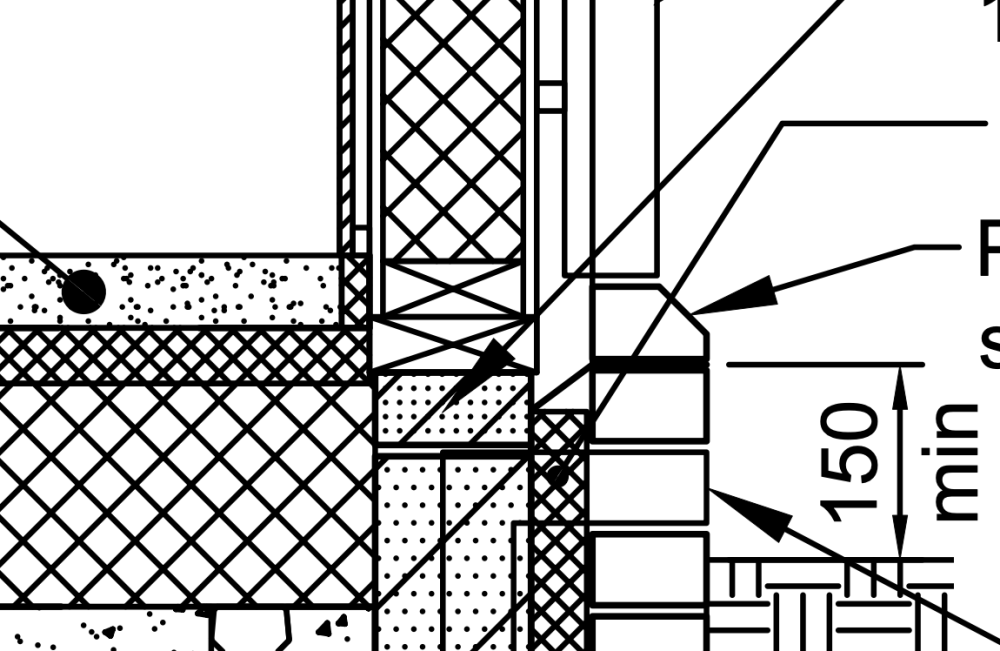

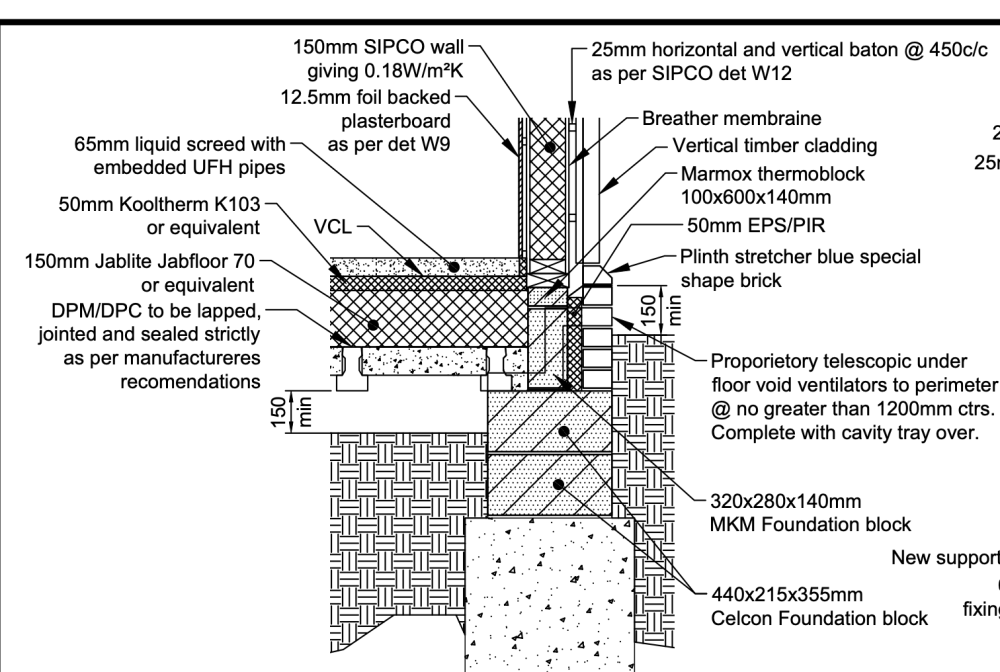

it's pretty hard to see as the scale is quite small but I do have a 25mm PIR up-stand at the edge of the screed. I Guess I could bring the 50mm EPS/PIR up to/slightly higher than the sole plate. I haven't had any design drawings back from SIPCO yet but their standards don't show anything to insulate sole plates. I did wonder how these work in reality, you have a nicely insulated SIP panel just nailed to a pice of timber which is fixed to an existing outer wall. Even if you we're building an entire new build out of SIP's you would have lots of similar details like this at corner junctions and window reveals etc so I didn't think the sole plate would be a massive cold bridge. In fact, do I really need to use a Marmox block?!?

-

@Redbeard thanks for replying. There's 50mm EPS/PIR up to the Marmox black. It's un-dimensioned currently though

-

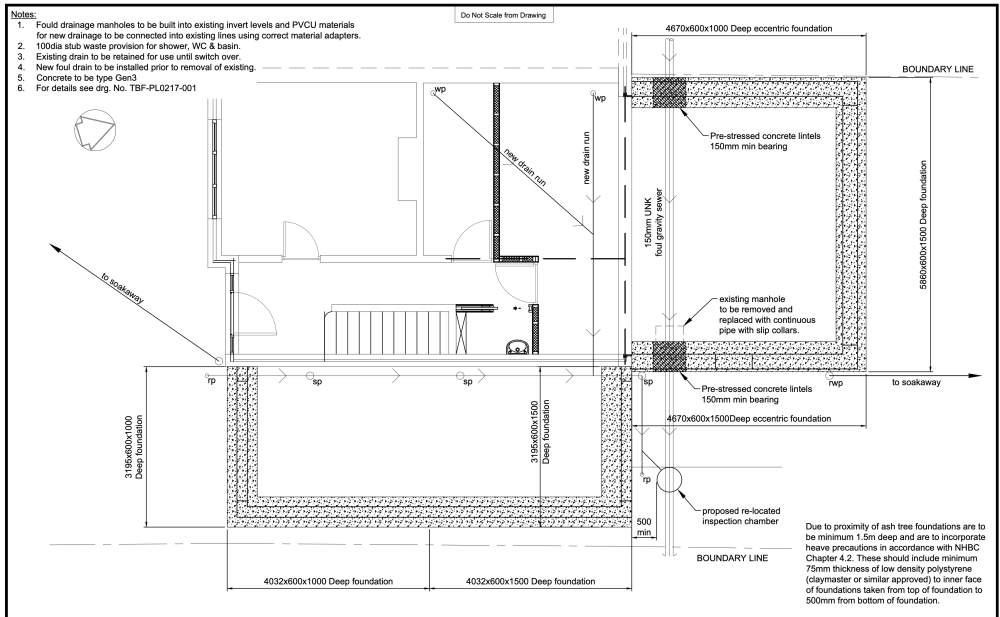

Hi Would be grateful for any feedback on these details. It's for my own extension, first time doing building detailing etc so if there are any schoolboy errors please let me know. The build is for a SIPS extension, I know it's probably very light but the proximity of neighbours tree means I've had to go deeper than standard. I've attempted to design out any thermal bridges, hence the use of a Marmox Thermoblock....hopefully this will mitigate any danger of condensation on the sole plate that I've read about. Thanks for the help in advance!