John Carroll

Members-

Posts

552 -

Joined

-

Last visited

-

Days Won

3

John Carroll last won the day on December 26 2025

John Carroll had the most liked content!

Personal Information

-

Location

Cork

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

John Carroll's Achievements

Regular Member (4/5)

107

Reputation

-

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

It was, on this very boiler, but in another Site/Thread, "Bypass Valve" in DIYnot.com, the pump speed fell to 30% which by my calcs meant a flowrate of 6.3LPM at a head of only 0.35M, shared through 11 Type22 & 4 Triple rads. This was before the boiler HEX was changed, so yes, would be interesting to see a full set of data if tried again. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

The 150, 200, 250 & 400mb or whatever settings in the WB are CP (Constant Pressure)settings. At the 400mb (4.0M) setting the pump will be running at 100% to just about achieve 20.9LPM at 4.0M (residual head) at the rads, if TRVs reduced the flowrate to say 10.0LPM then the head will remain the same 4.0M but the pump speed will fall to 81%, if the TRVs throttled down the flow to 5.0LPM then the pump speed will fall to 75% but the head remains the same at 4.0bar. If the boiler pump was like the 8M Wilo Yonos Pico set to 4.8M in its PP mode then that will achieve 20.9LPM at 4.0M, if the TRVs throttle down the flow, the pump speed will reduce to give 10.0LPM at 3.0M & 5.0LPM at 2.7M but the TRVvs will be opened a bit further, obviously if the PP setting is lower then the heads at 10LPM & 5LPM will be lower still and the TRVs will open still further. This boiler has, I think, a variable speed setting, 0?, I think it aims to get the flow/return dT to ~ 20C, the rad output then for any given flow temp, outside temp & room temp will start reducing, the boiler output will then reduce to match this. The latest Vaillant boiler has this, where the dT can be set between 10C & 20C but doesn’t seem to work very well on at least on one user's boiler that I’m aware of. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

Like most Boilers, there are several hydraulic options, one of which is pump modulation based on boiler output, this option would not be the one I would recommend for a system with long pipe runs as the pump head then at low boiler modulation might not produce enough head to circulate sufficiently through the furthest away rads, resulting in boiler cycling, one of the options is a constant pressure Residual Head of 4M (400mb) which, because of the Boiler Hex loss and the rads/system loss will/can result in the pump running at 100% to maintain this required residual head. None of the selected options should cause the above problems. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

A LLH will not cure a BOILER problem which IMO this boiler clearly has. It reached Targettemp after 25 minutes yet it took another 20 minutes for its output to fall from 36kW (100%) to 23.4kW (65%) but reached a flow temp of 64.8C during this period. It then took another 50 minutes to fall from 23.4kW (65%) to 17.64kW (49%) and finally return to its Targettemp of 60C (59.9C) I would be very embarrassed to look someone in the eye and tell them this is normal operation. On 25 minutes (target temp reached) Flow 60.1 return 39.0 dT 21.10C Burner 100% 36.00kW Pump 100% 21.50LPM dT 24.00C Flowtemp 63.00C On 30 minutes Flow 63.2 return 42.8 dT 20.4C Burner 95% 34.2.00kW Pump 100% 21.50LPM dT 22.80C Flowtemp 65.6C On 35 minutes Flow 64.8 return 46.4 dT 18.4C Burner 85% 23.40kW Pump 100% 21.50LPM dT 20.4C Flowtemp 66.8C On 45 minutes Flow 64.8 return 50.2 dT 14.6C Burner 65% 23.40kW Pump 100% 21.50LPM dT 15.60C Flowtemp 65.8C On 55 minutes Flow 61.9 return 50.7 dT 11.2C Burner 49% 17.64kW Pump 100% 21.50LPM dT 11.76C Flowtemp 62.46C big time gap now as I stopped measuring till it settled to actual target temp of 60'c On 1h35mins Flow 59.9 return 47.8 dT 12.1C Burner 49% 17.64kW Pump 100% 21.50LPM dT 11.76C Flowtemp 59.56C -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

This is some of your data after the HEX was renewed. The Target Flowtemp was 60C. The bottom line of each set of data are my calcs using the pump flowrate and your dT (as measured with the external sensors), it gives a calculated flowtemp not too far away from your measured temp so will mean that the boiler output based on modulation is quite reasonably accurate but maybe no harm to do that gas meter rate. On for 5minutes Flow 30.6 return 15.6 dT 15.00C Burner 62% 22.32kW Pump 93% 20.00LPM dT 16.00C Flowtemp 31.6C On 15 minutes Flow 50.9 return 29.0 dT 21.90C Burner 100% 36.00kW Pump 100% 21.50LPM dT 24.00C Flowtemp 53.00C On 25 minutes (target temp reached) Flow 60.1 return 39.0 dT 21.10C Burner 100% 36.00kW Pump 100% 21.50LPM dT 24.00C Flowtemp 63.00C On 30 minutes Flow 63.2 return 42.8 dT 20.4C Burner 95% 34.2.00kW Pump 100% 21.50LPM dT 22.80C Flowtemp 65.6C On 35 minutes Flow 64.8 return 46.4 dT 18.4C Burner 85% 23.40kW Pump 100% 21.50LPM dT 20.4C Flowtemp 66.8C On 45 minutes Flow 64.8 return 50.2 dT 14.6C Burner 65% 23.40kW Pump 100% 21.50LPM dT 15.60C Flowtemp 65.8C On 55 minutes Flow 61.9 return 50.7 dT 11.2C Burner 49% 17.64kW Pump 100% 21.50LPM dT 11.76C Flowtemp 62.46C -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

@SimonD, in your experience of Worcester 8000 system boilers, have you come across this strange? behaviour on both this boiler and others, where, after a HEX change, the indicated flow temperature doesn't match the Target temperature even under steady demand conditions and with the boiler demand well above its minimum output, can you suggest any reason for this behaviour?. and which WB says is normal. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

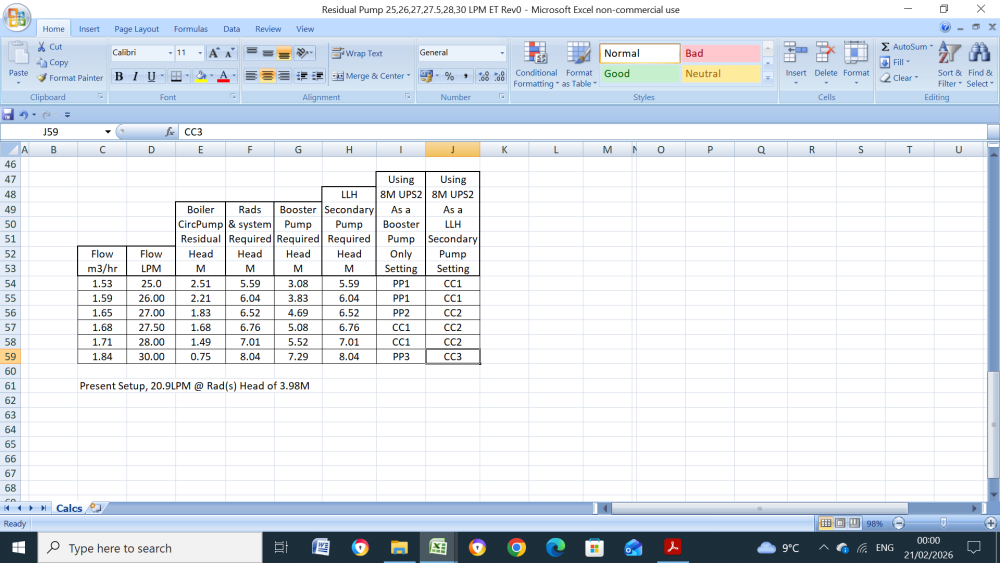

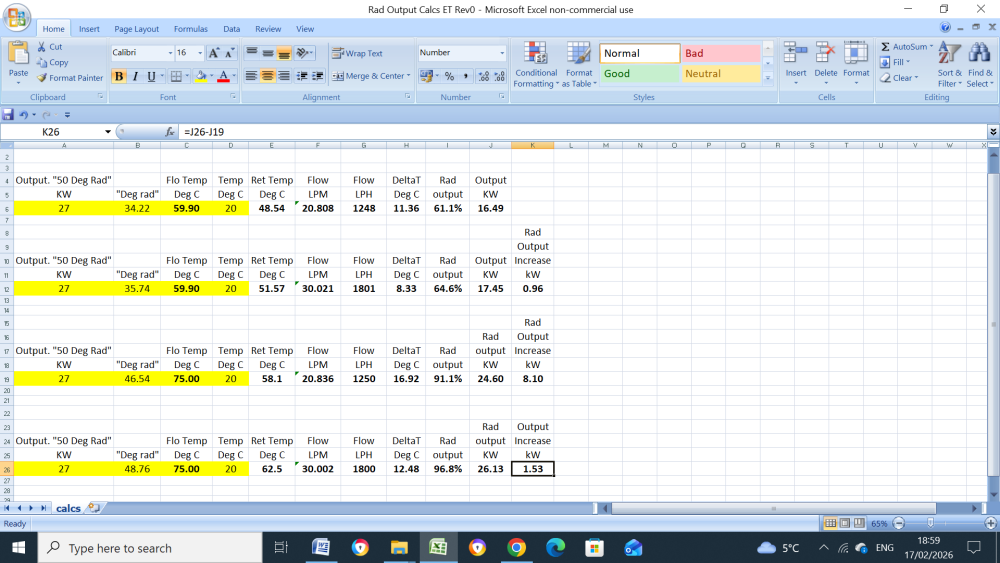

Meant to post these as well a few days ago. If you do choose a 8M UPS2 Pump then you can see from the attached that it should satisfy a flowrate of up to 30LPM based on your present flowrate of 20.89LPM at a Rad head of 3.98M. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

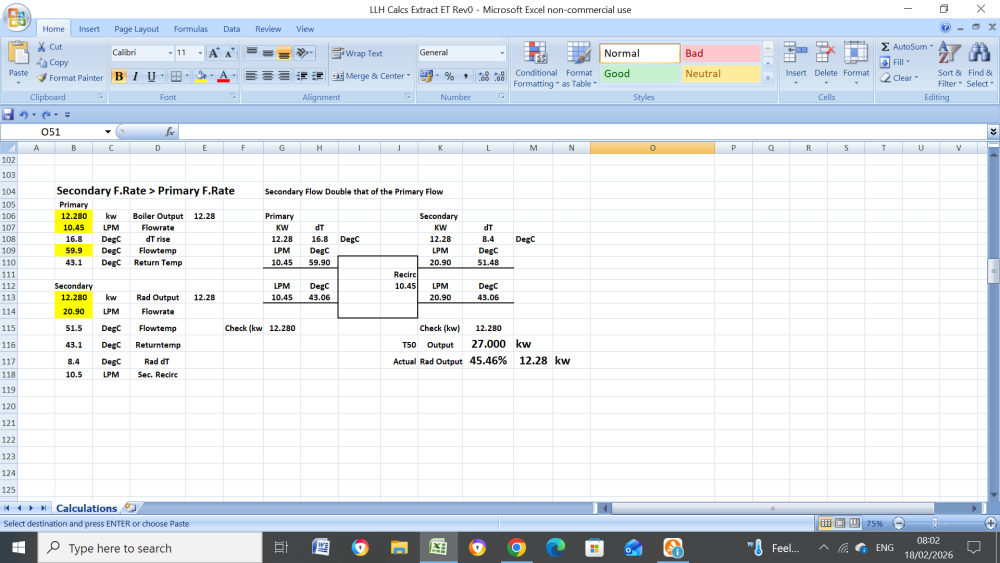

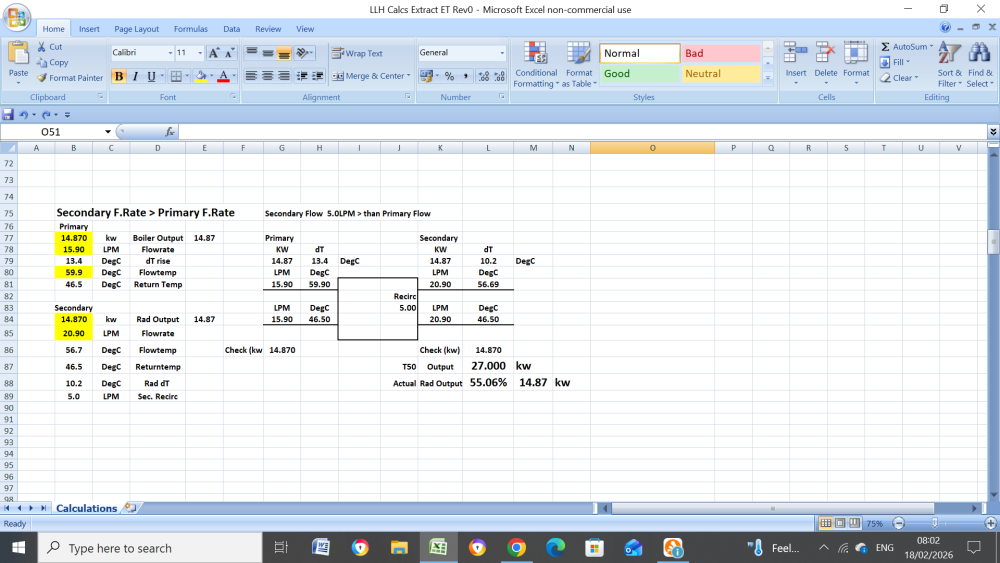

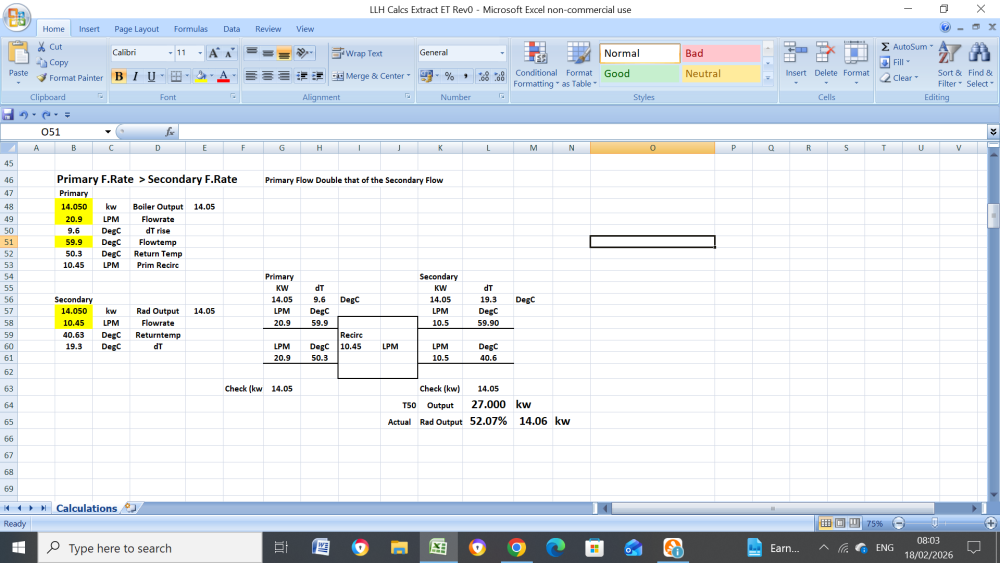

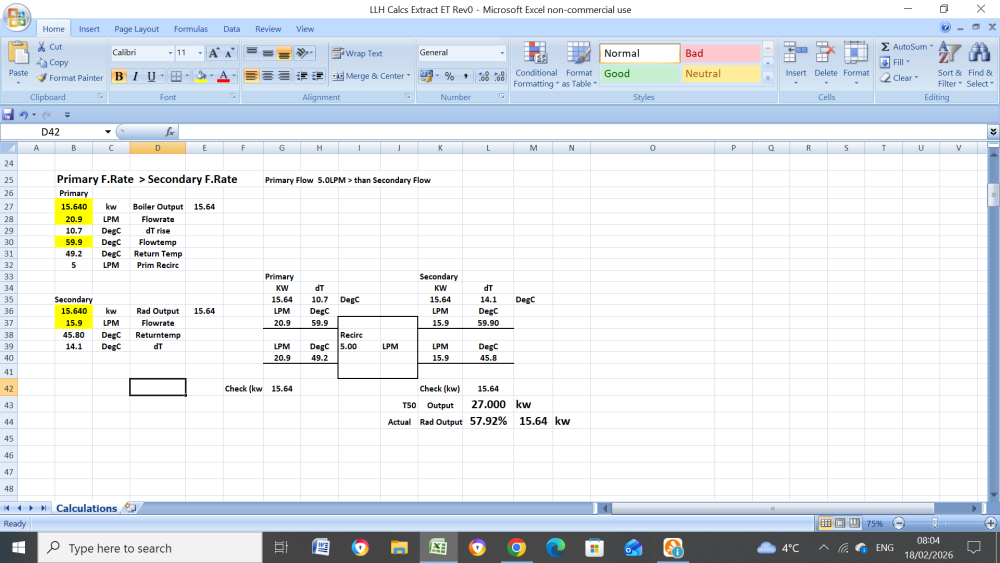

Here are the screenshots from your LLH with both balanced and unbalanced primary/secondary flowrates. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

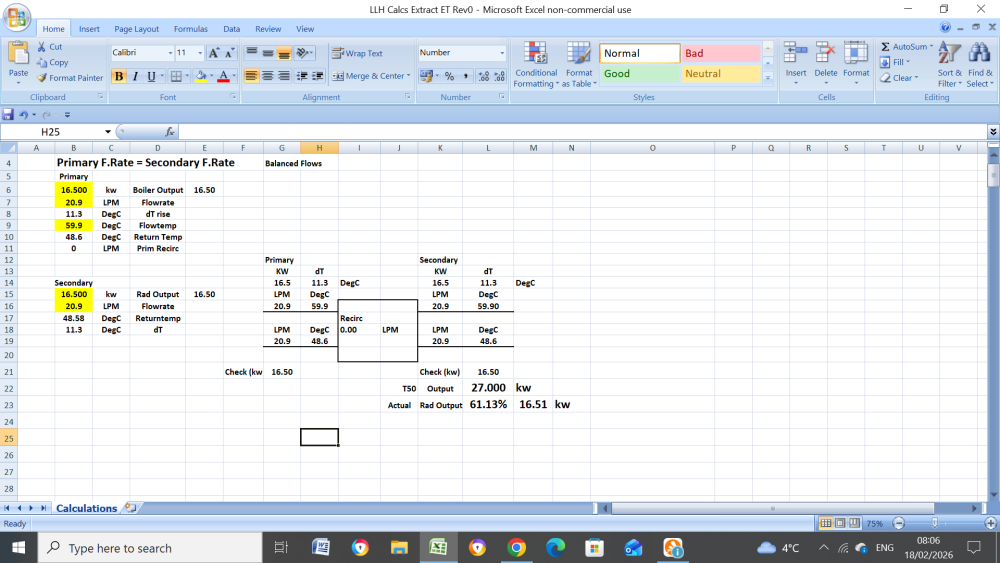

Increasing flow rate will have a very small effect on rad output, temperature increase, if possible, is the name of the game, again as said previously, a small increase in flowrate requires a big increase in head which can be very beneficial in balancing rads. You can see, quite clearly below from your set of readings that a flowrate of 20.8LPM with a flowtemp of 59.9C gives a rad(s) output of 16.49kW, increasing the flowrate to 30LPM will only give a 0.96kW increase to 17.45kW, not a lot. IF the flowrate remains at 20.8LPM but the flowtemp is increased to 75C then the rad output increases by a substantial 8.1kW to 24.6kW, if the flowrate is now increased to 30LPM, (flowtemp 75C) then the rad output only increases by a further 1.53kW to 26.13kW. Also, attached, some LLH numbers, for interest. LLH Calcs Extract ET Rev0.xlsx -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

There's no way a 6.0M or even the "normal" 8M pump will give you 30LPM even with a LLH based on our tests. The Hex loss was 1.54M @ 20.89LPM, this = 3.5M @ 30LPM, The rads loss was 3.9M @ 20.89LPM which will require 8.04M @ 30LPM. Any of the conventional 8M pumps will only give a head of 5.5M ish at 30LPM but the 8M UPS2 which is a giant of a pump at 140W will certainly supply 30LPM and far more at a 8M head, its actually a ~ 10M pump but the "fixed" "CC" speed curves are almost fully CP (constant pressure) curves, no other pump that I'm familiar with will match that performance. If you do think of going for that pump then it might be worth just installing it as a booster pump at minimal installation costs as the boiler circ pump will still have a residual head of ~ 0.66M at 30LPM, enough to avoid cavitation in the UPS2 which requires a minimum inlet head of 0.5M at 75C. The UPS2 other "CC" curves of 7M & 6M can also be useful if the need arises, the LLH can be installed if the above doesn't work out, it's your choice. I will post a few screenshots later of a LLH based on one of your tests to show the effect of balanced & unbalanced flowrates. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

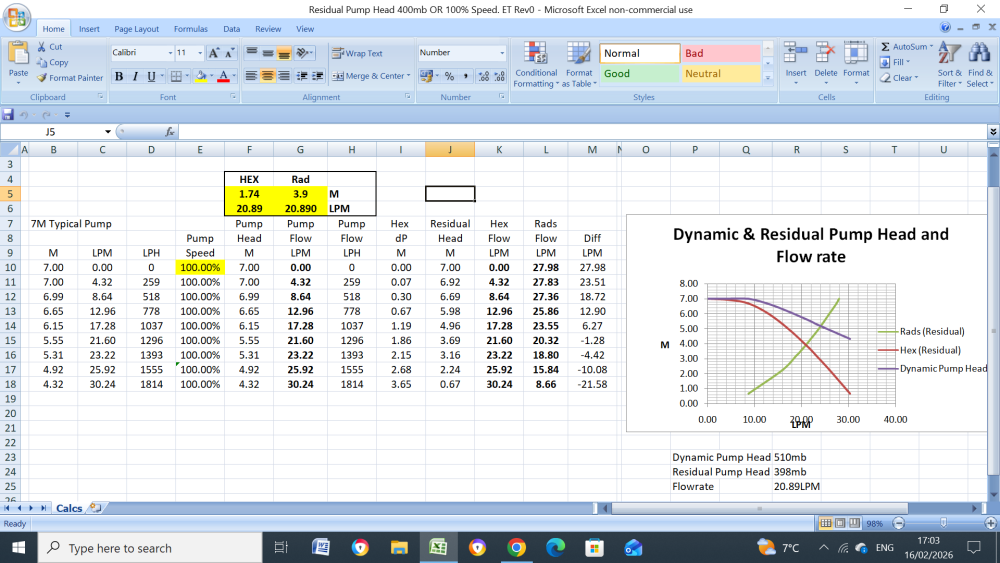

Had a look at installing a 6M Wilo Yonos Pico as a booster pump. It should, IMO, provide a modest boost in flow from 20.9LPM to 25LPM or slightly higher, might not seem a lot. but if your problem is getting a higher flow to a few cooler rads then it may be beneficial because the residual pump head now available to the rads should rise from 3.98M (398mb) to 5.7M (570mb), a 1.72M (43%) increase. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

Dynamic Head, above should read ~ 570mb, not 510mb. -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

-

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

Their answer(s) is a bit illogical, to me, at least. As stated numerous times before, any control system that is controlling a system that is running under steady conditionds WILL and certainly SHOULD get the process variable (flow temperature) within decimal places of the Setpoint (Target Temperature), and worse, since your flow temperature is apparently being controlled at least > 2.5C above the Target temp then this cuts down the tolerance before the burner trips on overshoot. Again, regarding the maximum 400mb residual pressure setting, this does seem on the low side but now that we know the boiler HEX pressure head loss, (CDI+8000 Chart) its quite easy to see why your system will run at 100% pump speed when set to 400mb. You can see from one of your set of readings, attached, below, that the residual pump head is almost 400mb (398), the pump dynamic head (before boiler HEX loss) is 510mb to give the calculated flowrate of 20.89LPM. I will have another look at installing a second pump but can't see much merit in it just now as it would just reduce (rob) the existing pump's residulal head (when running flat out at 100%) and you could just end up with the same effect as having no extra pump. On 1h35mins Flow 59.9 return 47.8 dT 12.1C Burner 49% 17.64kW. Calculated flowrate, 17.64*860/60/12.1, 20.89LPM Residual Pump Head 400mb OR 100% Speed. ET Rev0.xlsx -

Worcester Bosch Greenstar 8000 System Boiler Issues

John Carroll replied to EinTopaz's topic in Boilers & Hot Water Tanks

Yes, but remember the flowrate is a indicated 21.5LPM at 100% pump speed,a pretty hefty flowrate. If the engineers haven't come and gone please ask them for the boiler HEX pressure loss as I used a assumed one.