Tilbert

Members-

Posts

17 -

Joined

-

Last visited

Tilbert's Achievements

Member (3/5)

1

Reputation

-

Aaaghhh…. and Hello….! I’m hoping for some inspiration from you good people on this helpful forum….. We seem to have run into a dilemma on the slab construction from the UFH company we’re using. All along I had proposed the above slab layout with the UFH pipes in the 150mm slab. But, just as our builder is about to start the first layer of MOT, they sent the following email: Hi, We have had a look at the proposed floor construction for your extension. The optimum depth of screed is 65-75mm and it looks like you are proposing 150mm plus floor finish which not something we would be able to recommend. The absolute maximum we would occasionally see is 100mm. Having such a huge slab double the recommended depth will have some impact the performance of the system / running costs and make it difficult to control. We would strongly suggest that you build the floor up by either increasing the thickness of the concrete slab (below the insulation) or increasing the thickness of the insulation. I appreciate that insulation is expensive however you will save money on Screed and on the running costs in the long run. Aaaghh… so am now worried that the UFH method we had planned to use will not work. The structural engineer had said the 150mm needed, but I can run this alternative by him to see what he thinks… What do the great minds on here think ? Big Big Thanks, as ever

-

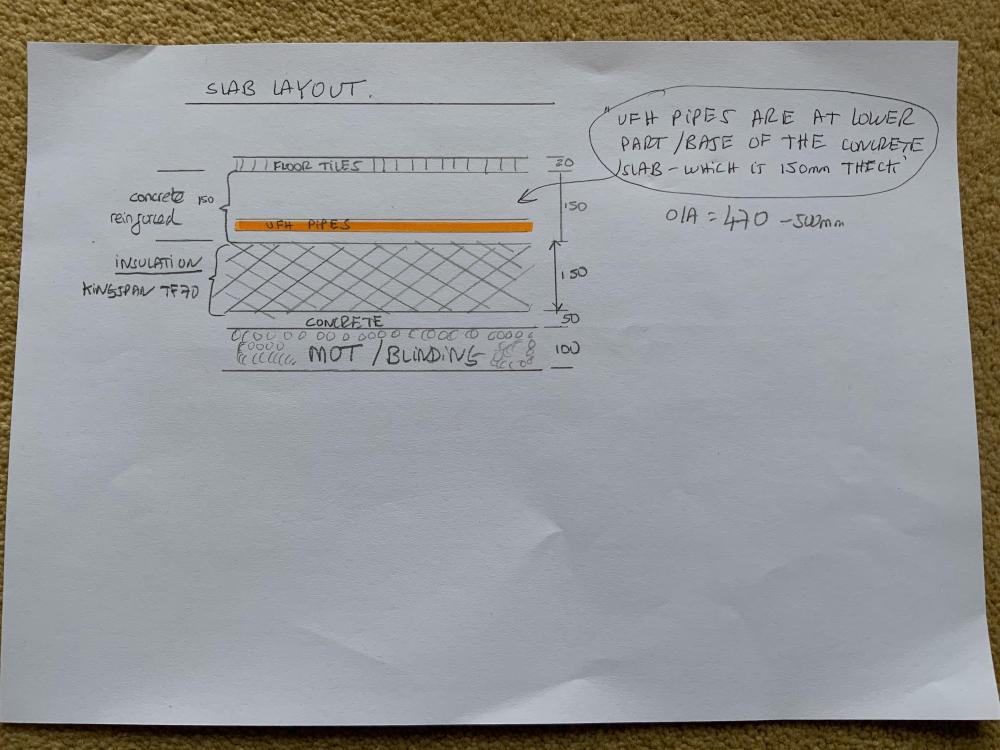

Hello all again, I meant to post sooner but we had planning delays …..! Seem to have some progress now and the floor construction we are planning is : tiled floor finish - 20mm concrete slab with UFH pipes tied to rebar mesh reinforcing - 150mm * Kingspan TF70 pir insulation - 150mm concrete - 50mm MOT blinding - 100mm ground (we have no existing foundations). So overall depth will be circa 470 - 500 mm, which is about as thick as we can go. * the slab is 150mm as we’re having a mezzanine floor built on top, freestanding in metal and structural engineer says 150mm needed. I did some U-value calculations and came out at: floor - 0.153 w/m2k roof - 0.15 “ walls - 0.18 “ New French doors - 1.5 w/m2k We have 2 old existing windows and a door, but no idea how (or if) to work these out. Any suggested amendments or observations, greatly appreciated. Big thanks all once again

-

Hello, we are having some repairs on the roof of our old barn, which we are converting into a kitchen. We are unsure whether to use lime mortar, or cement, or a mixture of the two on the area under and adjacent to some coping stones. The stones are in general good condition, but the existing mortar underneath is not and some of the supporting wall stones are also damaged. We plan to do build up the gaps around the damaged wall stones and bed the coping stones back on, but weighing up which mortar to use. same for the ridge tiles. any guidance greatly received. Many thanks.

-

Thank you all for your great input. I’m aiming on the ASHP and floor construction with the slab on top and UFH in the slab. The graphs and calculations are a bit over my head (tiny brain… ) - but I’ll try again when I have a clear head (feels a bit like going back to school…. …. homework time…..!! All is greatly appreciated

-

Thanks for your guidance, certainly helping to think it all through. I’m tempted with the ASHP as it’s a simpler install and there’s a difficult run from the oil boiler (some likely ups, downs and arounds… just to get to the UFH manifold). I’m not really sure how to calculate the ongoing running costs of oil vs ASHP, I have some data from a supplier but hard to factor in all the variables.

-

Thanks. Is it advisable to try to match the heat loss of the floor to the roof & walls ? My poor tiny brain is starting to ache…. . What does the 72 & 30 relate to in the above calculation please. Is there a formula or method to work out the ‘recommended’ insulation thicknesses using the overall area to be heated - or is it a case of separate calculation for the floor then one for the wall and one for the roof.

-

Thanks JohnMo and Nickfromwales, this helps and makes the ASHP more attractive. [ Also I realise that off-peak electricity would be a ‘no-go’ for me as I still have the rest of the house to consider and this would pull mainly daytime from the grid. ] I’ve read through some of the other posts on the forum too and with your comments am rethinking the floor. We’re digging out the existing floor and the original plan was to replace with; Screed on top (70mm) - with UFH in here Insulation below this (100mm) Concrete slab (100mm) DPM Sand for blind MOT as base (100mm) - the barn is 350 yrs old & we have no foundations So, if I understand the theory, this should be; Concrete slab on top (100mm) - with UFH in here + reinforcing mesh DPM Insulation (100mm) DPM Sand for blind MOT as base (100mm) Hopefully I have this correct…? Is the main reason for constructing this way to maintain steady heat in the concrete slab for longer ? As an aside, an earlier comment suggested we have more insulation. On the wall we plan to have 100mm & roof 150mm. BTW, this forum is massively helpful, thanks so much…!