alfaTom

Members-

Posts

45 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

alfaTom's Achievements

Member (3/5)

16

Reputation

-

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

Yes it is, at least the one used on the newer ET models. They need to sort a few QoL bits out, the WiFi pairing via the app was a mess, and they have a temp sensor pocket on the buffer and the DHW cylinder, but it only supports the DHW temp sensor in the wiring centre. I have Cool Energy coming out shortly to do the final commissioning so I'll try get a bit of info from them then. I'd love to try work out the COP of the unit but all the center gives me is the compressor Amps which isn't enough -

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

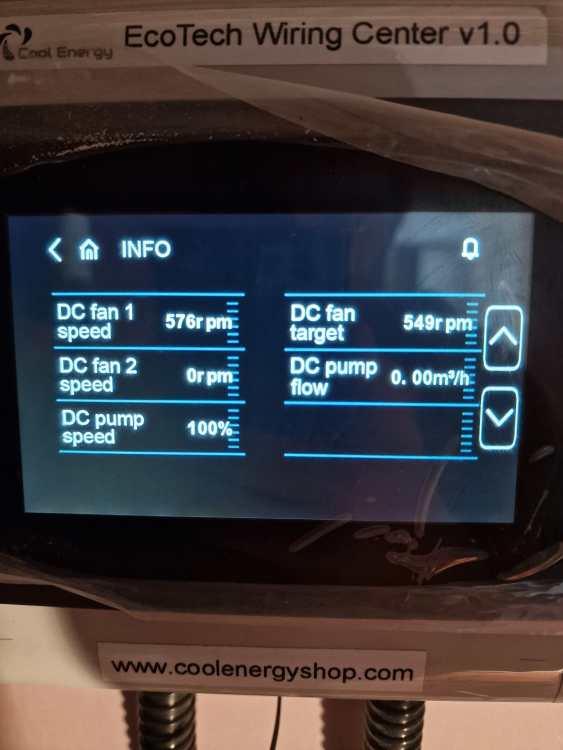

Had a look at mine today, also only the one LED on the Duca pump. Screen shows DC pump on, but without the installer password I can't edit anything. Interesting that it doesn't know the pump speed, definitely like they're not talking to each other. I also have a 10C difference between outlet and inlet temp. One to pick up with cool energy I think. -

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

Just seen this chat ongoing - realised mine is doing the same - just the first LED lit up. Can you see the pump speed in the readouts on the screen? I can't remember off top of my head so will have a look tomorrow. -

Also a late reply but we did B too. There's actually a decent amount of space to get a fix still, but you can always increase the number of screws for fixing if you're nervous. The biggest recommendation I can make is to get your 2400mm distance from the first bar spot on even if it means moving that bar slightly so there is no faffing with board edges and cutting; caught me out the first time.

-

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

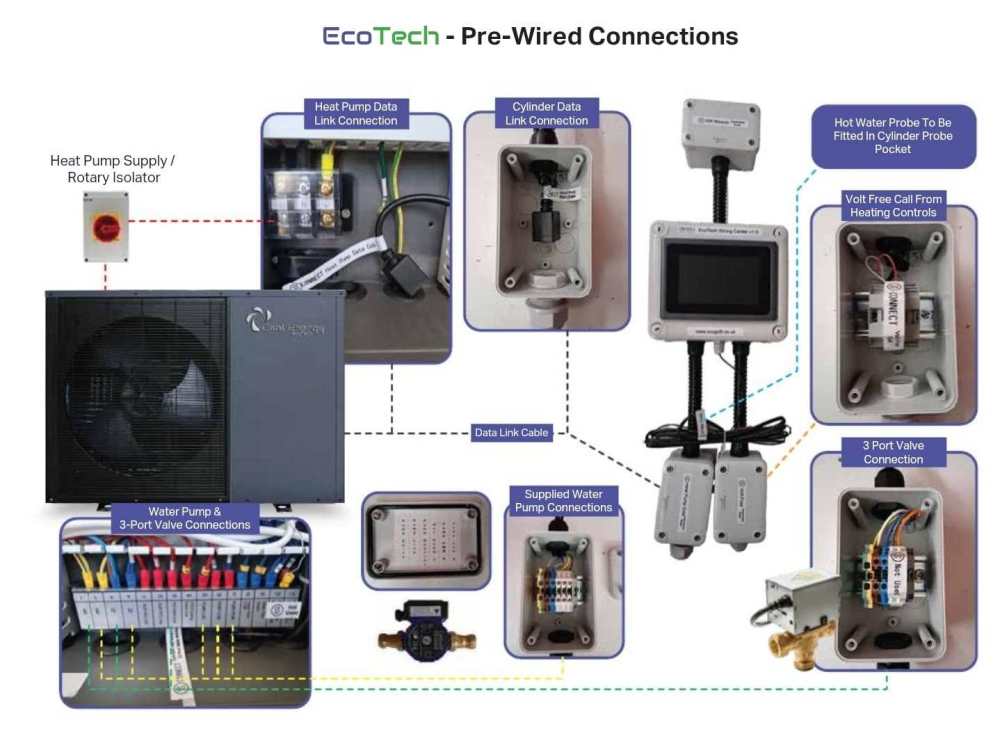

The documentation shows a 5 core and 3 core, but they both use the neutral & earth on there so there is duplication. It will be wired into a wiring centre on other side of wall where I can pick up the required cabling out to the pump/valves etc. Good point to call out though. What sort of setback signals are you picking up off the unit? This is the install sheet given to me alongside the wiring schematic: -

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

Cheers HughF, I have an ET-10; one of the newer units. Looks like a 30mm knockout now. Just waiting on the spiral glands to arrive to fit them and some 7core control cable. (No local electrical distributors stock this) Paired it with a Drayton Wiser stat as they do climate so I can use it for heating and cooling in the summer. Will report back when it's all up and running; I don't think the ET-10 is even on their site yet. -

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

So we're a few months on now and I realise I should really get the pump up and running now we're coming into winter. What did people do in terms of control cabling for these units? Ours is a cat6 cable with plugs either end, but I also need to stuff two 5 cores down the conduit to allow the controls for the diverter valve, pump controls plus another signal line for for CH valve & secondary pump. What sort of conduit fits onto these units? I think it's a 30mm punch-out with a rubber collar on but getting a gland or similar to fit is proving tricky... -

As saveasteading said - you'll have to ask BC. We can't inform you of that as councils will want to see at different stages BC are really friendly and helpful round here so may as well just ask them.

-

I'm not that mad 😁 when we moved in it was an old 7kW thing. New one is a fancier 10kW thing with a wee touchscreen, this was the finished article. Mrs had a requirement at least one room in the house wasn't a horrid old 70s maroon bathroom... Yes - that sits as part of the inlet control group block - one feed to UVC and one to soft cold manifold. I do need to add in drain cock and NRVs in still that I didn't mention.

-

Thanks all, some good points and looks like I've simplified compared to previous plans. I think 15mm runs are likely to be fine, even for the furthest distances. All the information on this site is a blessing and a curse as I wouldn't have known about half this stuff if I hadn't been reading up 😁 Thought the electric shower would get people asking. When we first started the work it involved taking the old oil boiler out so we had no hot water. Electric shower went in so we could still shower, and it's not worth the effort of removing now given how often it'll be in use going forward.

-

I wouldn't like to guess - I'm not an SE. If you do go digging out then it's always best to do it as quick (and safe) as possible to reinstate the floor. I would have thought 500-600mm would be ok for a short term bit of work. Soon as you're at depth in goes the hardcore so you star to build it back up. But then I'd also say that might not be worth the effort going deeper - heat loss via the ground is less than the roof or walls etc so I'd probably rather put the money into those.

-

Our foundations in the old part of the house were about 650mm from finished floor level. I remember the builder looking at them and saying you couldn't even build a conservatory on them nowadays let alone a house 😁 If you need to find out the depth of your foundations you could dig a borehole near the external wall for that room - you'll find the foundation jutting out if you dig right down against the brickwork. Then just dig down on the edge of the foundation until you find soil under it and that'll give you an idea on depth. We've had to cantilever pile the old section of house to underpin and the new foundations are ringbeams on piles now so the foundations have been beefed up to a degree which gave me some confidence we wouldn't seriously impact the foundations.

-

I made a previous post where I got way too far into the weeds on satellite manifolds. To try and clear things up and provide a bit more clarity (as well as help anyone else in a similar situation) I thought I'd post a new thread with the current plans for plumbing in our property. Earlier this year I relaid our water supply and put in a 32mm feed. It's probably OTT, but the cost difference between 32mm and 25mm was so close I decided to go for the larger bore. The house has had all old plumbing ripped out; it used to be on a copper branched system and was gravity fed. I'm going to replace this with a manifold system to each wet room, and the DHW will now be via ASHP & UVC rather than oil boiler and VC. The water feed rises in the plant room where the UVC will be sited (with ASHP on the other side of the wall to UVC) to try keep things together otherwise I'd have a few runs crisscrossing the plant room. Water feed to UVC/manifolds: Tee with 15mm feed to outdoor tap with separate stopcock Main 32mm stopcock with reducer to 28mm Tee with 15mm feed to downstairs toilet and sink (This is because they are the other side of the wall to the feed so easy to supply) 28mm continues to control group (3.5/6) Cold water from control group is then split into hard water and softened Hard water heads to manifold Other feed to water softener (yet to confirm brand; don't really care about single/dual cyl or mech/elec function, more about not losing that pressure.) Softened water will then be sent to each bathroom in 15mm Manifold supplies and their estimated distances: Cold (Hard) water manifold Name Pipe diameter Pipe distance Utility Sink 15mm 8m Kitchen Sink 15mm 3m Cold (Softened) water manifold Name Pipe diameter Pipe distance Downstairs shower 15mm 2m Kitchen Dishwasher 15mm 3m Utility Washing Machine 15mm 10m Family Bathroom (Bath/Shower, toilet, sink) 15mm 8m Guest Ensuite (Shower, toilet, sink) 15mm 9m Master Ensuite (Bath/Shower, toilet, sink x2) 15mm 12m Hot (Softened) water manifold Name Pipe diameter Pipe distance Downstairs shower 15mm 2m Kitchen Sink 15mm 3m Utility Sink 15mm 8m Family Bathroom (Bath/Shower) 15mm 8m Family Bathroom (Sink) 10mm 8m Guest Ensuite (Sink) 10mm 9m Master Ensuite (Bath/Shower) 15mm 12m Master Ensuite (Sink x2) 10mm 12m (Note: No Guest Ensuite hot for shower as it is electric) For the above I am mainly concerned on pipe distance for the hot feeds, with the master ensuite being the furthest away at about 12m of pipe. I've split the sinks into a separate 10mm feed to try get hot water there quicker for handwashing etc, but otherwise I think the rest is ok in 15mm. I've ditched any thoughts on HRC and decided to keep it simple. All pipework will be run in Hep2o where possible. I could reduce the manifold size further by grouping the utility sink & washing machine, and the kitchen sink and dishwasher feed into shared 15mm runs but it should be easy enough to run a second bit of pipe if needed. Most joists are new posijoists so easy to run the pipes, just a bit interesting to clip to. Have I made any obvious mistakes? There will be isolation valves in various parts to help with maintenance so haven't listed them (i.e. control groups, softener). Only other thing I can think of currently is if manifolds should be fed from both ends or not to help when more than one run is active. Thanks all!

-

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

CE are working from my sizing - heatpunk shows roughly 8kW heat loss for the property. Couldn't get any heatgeeks or other engineers to attend to review and they all quoted £14k+ to fit ASHP & UVC. -

Another 'Cool Energy' heatpumps thread

alfaTom replied to HughF's topic in Air Source Heat Pumps (ASHP)

Thanks for the update @HughF. I'm currently in the process of arranging delivery of an ASHP & UVC from CoolEnergy via their MCS grant service. All the other installers wanted an extra £6k on top of the BUS, whereas CoolEnergy can supply the units and do the commissioning for the grant effectively "free" as long as I can arrange the install. I'm looking at the CE-IVT10-EVI which is billed as 4.89kW - 10.47kW @A-3/35. There is a newer model, the CE-ET10 but the capacity on this was slightly smaller at 3.89kW - 7.46kW @A-3/35). It's not on their website yet as far as I can tell. I've attached the spec sheet incase it helps anyone else. Once I've got hold of the kit I'll report back on ease of install & findings. CE-ET10 (QR).pdf