AChristie

Members-

Posts

30 -

Joined

-

Last visited

Everything posted by AChristie

-

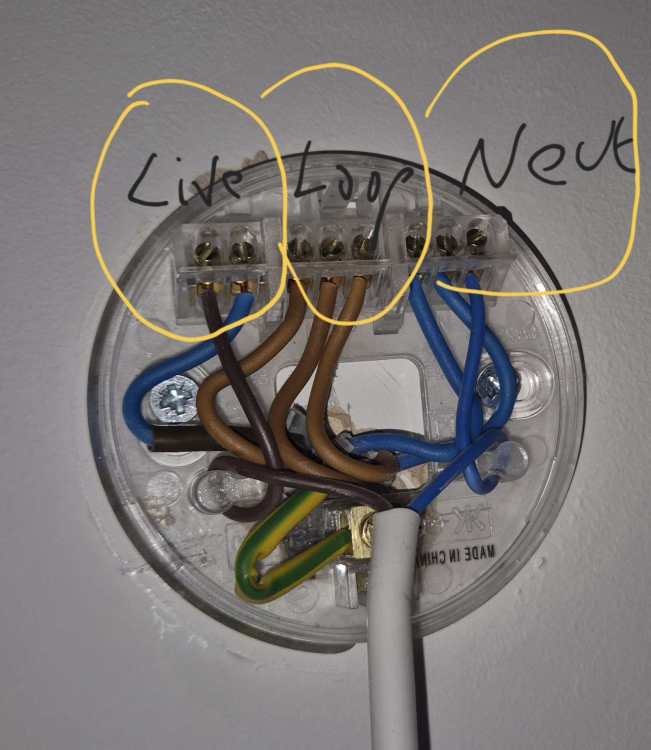

Do the 3 brown wires need to be placed in the same order in the connector block as they are currently in the above original picture? The reason I ask is I've done the above, the new light works. All other bedroom lights still work too. As does the landing light. HOWEVER.... The upstairs bathroom lights (downlights) and extractor are now not working.

-

Hello I've unscrewed the standard pendant light fitting to find the below combination of wires all hooked into various positions, 2 wires into Live, 3 brown into Loop and 3 blue into Neutral as labelled. My new pendant is a Class 2 and only has 2 positions for the Live and Neutral. See pictures. How do I go about wiring up the new pendant? Where do all the other wires need to go? I know for class 2 I'd terminate the earth and then wrap it up in electrical insulation tape. But no idea how to deal with the other 6 wires. Thanks

-

Thanks @JohnMo Dulux Trade has been my 'go to' for all walls and ceilings in my renovation so far. Is it the trade satinwood, or diamond trade satinwood you're suggesting?

-

Can anyone recommend a good paint for wooden stair years treads? I've removed carpet and will be adding a runner, with white painted on either side. Cheers

-

In that case I'll definitely leave it as is, there's only a couple of loose creaks here and there. I'll know for next time! Cheers guys.

-

It's all boarded up and decorated finish, the space under the stairs has pull out drawers and a cupboard. Oh dear! On the bright side, knowing this, at least I'll not waste time or screws attempting to fix it from this side.

-

Does anyone know where I should be looking to add additional screws to sure up some squeaky flooring on my stairs? Removed all the carpet and underlay today, ready for some decorating and a floor runner. However I'd like to try and address a few squeaks and creaks before getting on with that! I can't access under the stairs, so need to address from what can be seen in the photo. Cheers

-

Laying Porcelain Patio or New Fence first

AChristie replied to AChristie's topic in Landscaping, Decking & Patios

Thanks both, saw some conflicting advice online (no surprise there i guess). Good to get this confirmed. -

I've got a large area across the back of my house to lay a patio. On both sides of the garden, I'll need to replace the fence, on one side it'll require new concrete posts for the fences. So my question, is there an order in which I should approach this? Patio or fencing first? Cheers

-

Evening, so we're in the process of installing some new rads into a gas boiler CH system. Also have a new towel rail in an en-suite (with a manual valve). I have purchased the rads, based upon BTU requirements and i ordered some TRV valves to go with each new rad. There are a couple of old rads still hanging around (which we may replace also TBC, they too have TRVs). However, just recently heard about another type of valve - Lockshield. Done some reading up and can't understand in what situation i would need them, or how many etc. I went back to where I purchased my TRVs from and can see there is an option to have TRVS with (and without) lockshield. How do I know if i need lockshield, valves? What do they do? Cheers

-

Hi, I'm after some advice when it comes to rendering my house. I have been recommended K Rend as a quality, low maintenance product, albeit at a premium price over sand and cement. When speaking to a K Rend technical advisor through emails, i was advised that due to the exterior of my house having both a combination of block work (new extension) and EPS board (over original building) as the external facing surfaces I would have to go with a Silicone Thin Coat - TC15 product. K Rend told me that Silcone TC 15 was my only option and that ruled out their Monocouche product (K Mono). I hadn't actually heard of monocouche, so don't know what i am missing out on. Is the difference between them down to finish / colour / maintenance / price / install process? On doing some basic searching I can see Weber are a big name of Monocouche. I also don't know whether i should be considering any other product to K Rend TC15. Any advice, or thought provocation would be appreciated. Cheers

-

I did some digging through all the old documents that previous owner left. Looks like the cavity wall insulation was installed by a company called Megafoam (from Kent) back in September 1980. So chances are it is UF Foam, but having done some rudimentary reading as @Redbeard has suggested, enough time has passed. Funnily enough, document also states the Megafoam is guaranteed for the life of the building - ironic, as it doesn't look like Megafoam still exist

-

This sounds like the stuff i have found in other other wall, i imagine it was done a long time back (can't really tell, only been in the house a couple of years) crumbles to nothing when you hold it. I was able to take it out in fairly large chunks. You can see some of it hiding in this small cavity, it's the white stuff protruding, comes out it largish chunks, but will crumble quite easily. Do I need to worry if it is formaldehyde? There are two piers, they line up with the two ends of the house, possible thermal bridging, but i am hoping to avoid messing around with them.

-

Thanks @ProDave - You have me doubting myself now, we have taken down one of the walls on the leaf of the house which was brick and this did have the pumped insulation inside the cavity - but i will need to double check the blockwork forms part of a cavity. I was looking to hide the piers with the render TBH, as i am not a fan of the colour/type of brick. I take it you're suggesting that isn't advisable due to having to render over two adjoining different materials?

-

Hello, we've removed old 1960's tile cladding from our house and intend to have a render finish. Before render, we'd like to add some external insulation (the cavity walls have an injected foam insulation, but it's not super effective). The hope for the insulation is that we can also achieve a flush finish with the existing brick piers at either corner of the house. As per the attached, you can see that the depth is around 190mm (200mm in places). I understand K Rend will have a finished thickness of somewhere between 14 and 18mm. So this means i need to find approximately 180mm of insulation. Does anyone have any ideas on what my options could be for application beneath the render? If i could aod having to do too much wood work to batten out, that would be ideal to reduce cost. So if there were any 'direct fix' solutions. I'm also not sure whether would need to leave an ar gap, as yo dou with a PIR when inserting into an external cavity. Cheers

-

Don't ASHP have to be a min of 1metre from neighbouring boundary??

-

We're into the build phase of our renovation and currently engaging with glazing companies to supply and fit our windows and doors, alu / alu-clad. The rear of the house is SW facing and as such whilst we're looking forward to the 90% of the year when we can enjoy brighter rooms, we also need to plan for the height of summer. Given i have windows, gable glazing and bi-folds, maybe i need to adopt a couple of different approaches. Keen to learn from anyone that have gone before me

-

Kingspan v Knauf (or phenolic boards v glass mineral wool)

AChristie replied to AChristie's topic in Heat Insulation

Thanks Kelvin, yes I hadn't meant you had traded off, sounds like your plan was clear! I meant your approach for me would mean that's where I'd trade off.- 16 replies

-

- phenolic

- mineral wool

-

(and 1 more)

Tagged with:

-

Kingspan v Knauf (or phenolic boards v glass mineral wool)

AChristie replied to AChristie's topic in Heat Insulation

Just found the below document online, thought it summed up some different options nicely. Basically, my original spec was Option 5. Part L1B of the Building Regulations – Extensions Under the new Part L1B 2021 for Extensions, Alterations & Conversions, there are some key changes you should really be made aware of. Below is a summary table for the changes for new extensions for extensions with an initial notice lodged after 15th June 2022: Element Part L1B 2013 (Current) Part L1B 2021 (From 15th June) % Improvement External Walls 0.28 W/m2.K 0.18 W/m2.K 36% Roof (Ceiling Level) 0.16 W/m2.K 0.15 W/m2.K 6% Roof (Slope) 0.18 W/m2.K 0.15 W/m2.K 17% Roof (Flat) 0.18 W/m2.K 0.15 W/m2.K 17% Heat Loss Floor 0.22 W/m2.K 0.18 W/m2.K 18% Windows 1.60 W/m2.K 1.40 W/m2.K 13% Rooflights 1.60 W/m2.K 2.20 W/m2.K -38% Doors 1.60 W/m2.K 1.40 W/m2.K 13% The general improvements are standard,. But the external wall stands out as a challenge because the planning drawings may be drawn with a 300mm cavity wall. The original U value for Part L1A 2013 was 0.28 W/m2.K. Typically, a 100mm cavity within a cavity wall would achieve this. Under the new Part L1B 2021 regulations, this will need a 35% improvement to achieve 0.18 W/m2.K. Typically, you should allow a 150mm cavity to achieve this. Some options are presented below with cavity width ranging from 100-150mm: OPTION 1 – FULL FILL MINERAL WOOL WITH AIRCRETE BLOCKWORK – 150MM CAVITY 102.5mm brickwork 150mm cavity with; 150mm Knauf Dritter 32 insulation (0.032 W/mK) 100mm aircrete blockwork (0.15-0.18 W/mK); 12.5mm plasterboard on dabs OPTION 2 – PARTIAL FILL PIR INSULATION WITH LIGHT MEDIUM DENSE BLOCKWORK – 150MM CAVITY 102.5mm brickwork 150mm cavity with; 100mm Celotex CW4000 insulation (0.022 W/mK) 100mm light medium dense blockwork (0.49 W/mK); 12.5mm plasterboard on dabs OPTION 3 – PARTIAL FILL PIR INSULATION WITH AIRCRETE BLOCKWORK – 135MM CAVITY 102.5mm brickwork 135mm cavity with; 85mm Celotex CW4000 insulation (0.022 W/mK) 100mm aircrete blockwork (0.15-0.19 W/mK); 12.5mm plasterboard on dabs OPTION 4 – PARTIAL FILL PIR INSULATION WITH BLOCKWORK – 125MM CAVITY 102.5mm brickwork 125mm cavity with; 75mm Kingspan Kooltherm K108 Cavity Board insulation (0.018 W/mK) 100mm aircrete blockwork (0.15-0.51 W/mK); 12.5mm plasterboard on dabs OPTION 5 – FULL FILL PIR INSULATION WITH AIRCRETE BLOCKWORK – 100MM CAVITY 102.5mm brickwork 100mm cavity with; 100mm Xtartherm CavithTherm (0.021 W/mK) OR 90mm Kingspan Kooltherm K106 Cavity Board insulation (0.018 W/mK) 100mm aircrete blockwork (0.15 W/mK); 12.5mm plasterboard on dabs- 16 replies

-

- 1

-

-

- phenolic

- mineral wool

-

(and 1 more)

Tagged with:

-

Kingspan v Knauf (or phenolic boards v glass mineral wool)

AChristie replied to AChristie's topic in Heat Insulation

Thanks, I had to Google the fabric first principle.... but makes sense, achieve insulation during initial construction, not by 'topping up' or having to take remedial action later.- 16 replies

-

- phenolic

- mineral wool

-

(and 1 more)

Tagged with: