nostos156

Members-

Posts

43 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

nostos156's Achievements

Member (3/5)

2

Reputation

-

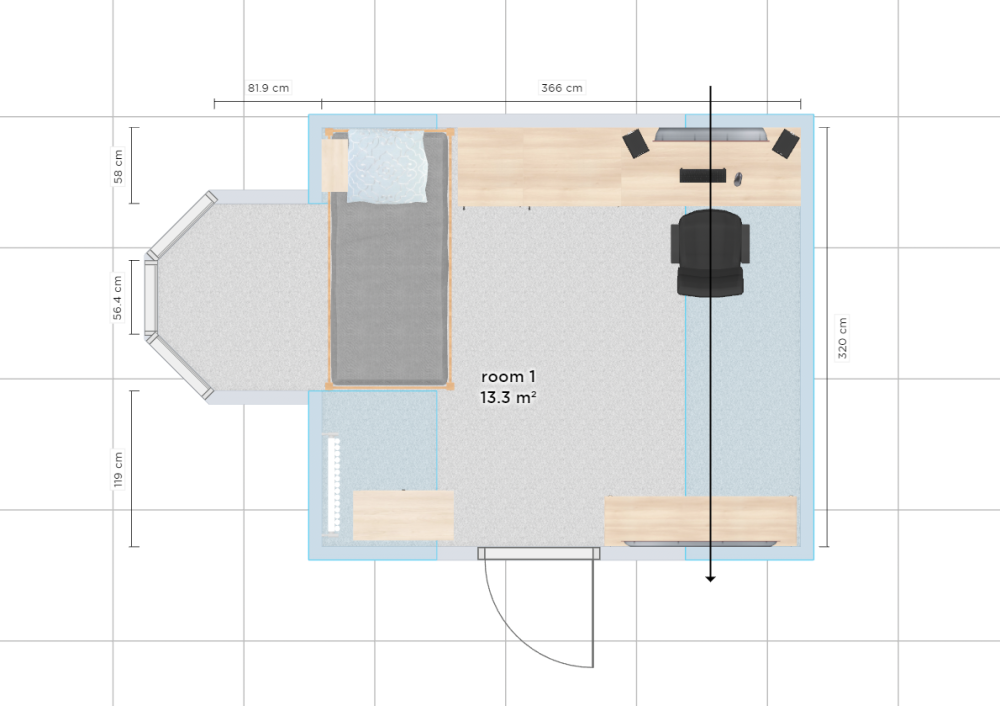

That is unfortunate. I've got a room with sloped ceilings I'm trying to figure out lighting for. I've got downlights in the flat sections because I use it as a task room as well, but trying to figure out accent lighting is proving a nightmare. The knee walls are too low to put wall lamps on, and floor space is limited for floor lamps. So been trying to tinker with the idea of putting flush wall lights on the slopes themselves, but finding anything that would work has been... difficult. Maybe I'm just wanting something totally unworkable in the first place?

-

Which lights are those? Looks surprisingly very low profile.

-

Breathable membrane installation (Scotland)

nostos156 replied to nostos156's topic in Roofing, Tiling & Slating

Was it the PRO version of Vent3 you used? The gsm figures for both are similar (proctor is 185, PRO is 165), but Vent3 has a light/classic etc version that is much thinner. -

Breathable membrane installation (Scotland)

nostos156 replied to nostos156's topic in Roofing, Tiling & Slating

Proctor Roofshield is like 3x the cost of what I can get the Vent3Pro for. What was wrong with it? And yes, just reusing the proper old slates. Cost is a factor for this since the flashing I'm replacing I'm going with Ubiflex/IKO Lead-E as well since the cost of lead is atrocious these days. I'm not redoing the whole roof, just the area above the dormer while I have access to it. Main reason would be to cut down on wind getting to that part of the roof since its the least insulated area of that room by nature of it being a dormer. -

Hi, Got a dormer window in a bay shape that needs work done to the roof framing of it, as the flashing on the sides has failed over the years as well as the mortar that sealed between the slates at the peaks. Will involve ripping the slates off and repairing any sarking/framing that requires it along with replacing flashing. At the same time, I figured putting down a breather membrane would be a decent idea while I'm at it, as due to the roof age, it's just bare slate nailed into the sarking boards. Question is, can I get away with installing the membrane straight onto the sarking boards? Was thinking of using Cromar Vent3 Pro (I'm in climate region 4 for wind uplift) but all the installation instructions I look at when it comes to membranes always seem to just talk about using battens on top like how they do in England. So, can I just staple/nail (which is preferable?) the membrane directly to the sarking boards, tape the laps as what seems to be required for my region, and then just nail the slates on top? Is that sufficient or will wind uplift still be a problem there? Thanks.

-

Old house, old studs. Everything's gonna need cutting I suspect. Will probably need to spec a decent insulation saw as well to cut down on fraying.

-

So if I read that correctly - you offered up the 600mm slab to the stud, then used the next stud along as your straight edge to get a perfect cut every time? That's pretty damn smart tbh. My studs are rough sawn old style so probably closer to the 50mm. Hope it works in that case, some of them go more diagonally than plumb and your method would account for that well.

-

One last question. I asked Rockwool about how much overlap I should leave in order to friction fit. They said 50mm total to the gap, so 25mm on each side for an ideal friction fit. This seems way higher than what I was reading on places like here, where people were just using 5-10mm excess to friction fit? Feels like with 50mm it would want to start bowing in the middle!

-

Sounds promising. You just left it like that into the open and didn't cover or strap it? Holding up absolutely fine with zero sag? No issues with having to shove a bunch of offcuts into areas? I'd probably end up having to squeeze two 200mm ends cut to fill up some areas to make full use of the packs.

-

Hi, So at first I tore down a really badly done exterior facing wall in a loft space. I rebuilt it out with timber and used PIR in between and over the top (50mm + 25mm), in order to maximise insulation for the least space. And also because I wanted to ram a wardrobe up against that wall without having condensation/mould issues on the back of it. Job done there, I hope. Well, I'd like to imagine 75mm PIR would stop the wardrobe issues. Anyway, the rest of the room was still old plaster/lath, and I was getting tired of trying to make the old cracked or blown sections good. Seriously considering an immediately regrettable choice of taking it all down and replacing. At the same time, I was thinking of adding some more insulation (there is fibreglass in the attic all around the room and on top, but…) in between studs and joists while I was at it. Decided that rockwool would suit me best, as unlike PIR, it does a good job of dampening airborne sound on top of insulating. I'm aware that the one wall I did PIR up won't help much, but I'm not looking for soundproofing—just dampening a bit to replace the one job that lath and plaster does very well and get something remotely similar. Most sources seem to indicate RWA45 is the common go-to choice for this application: insulates well, dampens well (thinking of going 75mm). However, as I'll be putting these in studs that will be completely open to the attic space at the back, is it self-supporting enough for that application not to settle over time? Is the denser RW3 a better pick? It would cost a bit more per pack, but given how my studs and joists are closer than the 600mm the packs come in, there will be a lot of jamming offcuts together if I don't want wastage/more orders; maybe the more rigid RW3 will cope better with this? I did read one excerpt from someone who mentioned the RWA45 goes springy when supporting stacked slabs, whereas the RW3 was completely rigid up to the ceiling… but that was for building sound trapping, not in the walls.

-

By the way, if I go ahead with this, what should I use to add extra insulation? The wall I tore down I used PIR (wanted a wardrobe there so needed to ensure max performance and no cold bridging to the back of it), but it would be fairly expensive to do that on every other wall + the sloped ceiling. I'm also not sure if there are concerns about enclosing a cold roof loft room entirely within PIR when it comes to moisture. The insulation already up there is the fiberglass crap so likely doesn't offer much performance after probably 30 years. Was thinking maybe cramming some rockwool up there would help, RWA45? if I go for that, can it freestand within the wall cavities that are exposed to the open eaves (like PIR can), or will I need to brace it with something on the eaves side to stop it slumping out?

-

So you basically skimmed your walls flat then boarded and joined edges where there was only lath support with foam glue?

-

One thing I'm not sure how to figure out is getting a good fixing for the PB at the corners, as mentioned. They're built out and curved at the slopes and ceiling, so I'd have to chip them back straight and hope the screws can find timber along the egdes there. I've done removal before like with this wall and to be honest with a half face P100 it was effortless, it was just the sheer mess on the floor that was annoying.

-

It may be possible, but I'd have to skip the battens and screw the board straight into the plaster, and just have the plaster act as a batten/packer. The ceiling is barely 230cm high and to make matters worse, it's a sloped ceiling with bloody curves at the corners, so I'd have to chip them away and refill into straight edges to get this to work.

-

Huh, from the reading I did it seemed those boards, even when double boarded, still had nowhere near the density of plaster? Double boarding does seem the better option from those two choices because hauling full sheets of heavy sound stuff up a flight of stairs sounds like a good way to die.