health mechanic

Members-

Posts

40 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

health mechanic's Achievements

Member (3/5)

0

Reputation

-

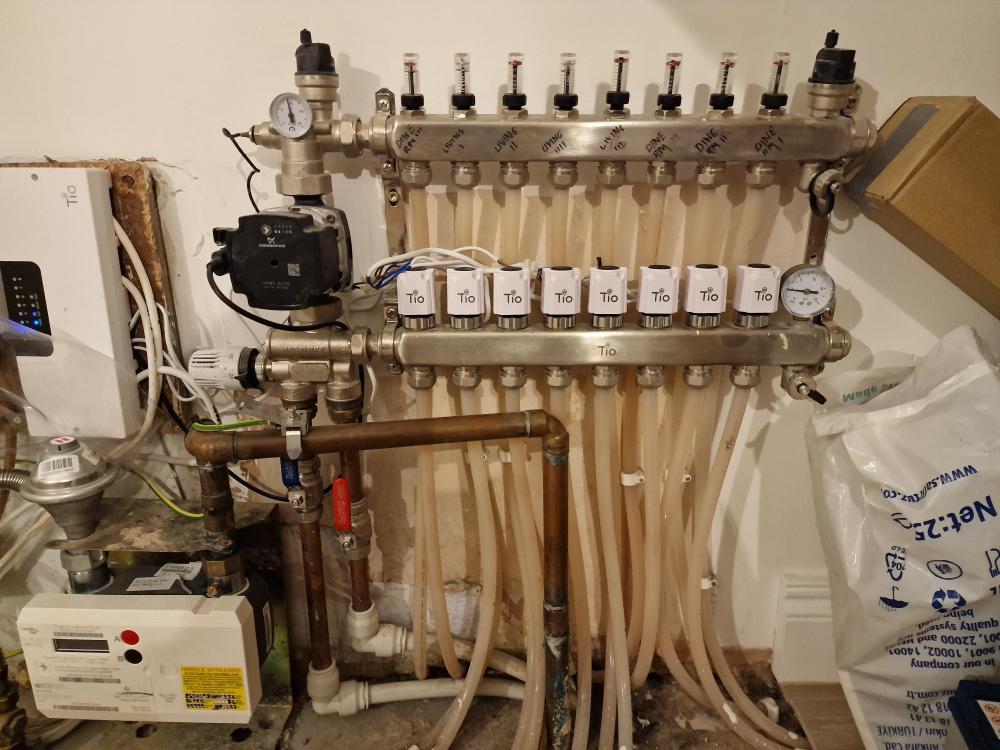

Oddly,out of 4 manifolds , one of the piping have started to show brown discolouration. See below. Using heat gun there does not seem to be any leaks on any of the runs to suggest contamination from tiling glue. So thought maybe corrosion...but why is this occurring in just 1 manifold and not all...or could this be contamination from small leak. Not sure of inhibitor was used on any of the ufh manifolds

-

Hot and cold water Valve location on ufh manifold

health mechanic replied to health mechanic's topic in Underfloor Heating

Good suggestion Dave, guess a bit late to do that now. Why is the temp warmer on the first config reading on the circular thermomemter, is it because it's not having a valve stopping entry? -

Have 4 manifolds in my property for a wet ufh...3 of the manifolds have been fitted with the hot and cold valves before the pump and one with the valves after the pump. Not sure if there is a correct way and why it has been done in the 2 different ways as manufacturer spec suggests the former. The latter config u can feel hotwater being fed to the manifold even when not running but on other not...otherwise performs well. See photos

-

Coping stone fixing on single ply parapet

health mechanic replied to health mechanic's topic in Flat Roofs

@Dave Jones is it definately a building control fail having a collection of water....the most annoying thing is that pool of water outside the bedroom is causing mosquitoes to gather. @steveoelliott have you had any issues since install -

Coping stone fixing on single ply parapet

health mechanic replied to health mechanic's topic in Flat Roofs

Hi dave Yes has cavity tray (if i recall). The plywood and single ply acts as a cavity closer. Building regs were happy with it. The outlet is 100mm..but agree too high. The roofing company are saying its water proof and suitable for swimming pools and do not want to change the outlet, the dip near outlet I suggested they build up to allow it to be higher than outlet, but they were not keen. -

Coping stone fixing on single ply parapet

health mechanic replied to health mechanic's topic in Flat Roofs

Don't get me started on the pool of water....whT happens when u get your builder to do random furling stripes...and a private roof company to do the membrane....cannot do anything about it now unless you know how -

How do people fix coping stones onto a single ply (vanguard) covered parapet warm roof. The upstand and top of parapet had plywood before the single ply was lapped completely over to the edge of of the parapet. Would you SBR the the membrane, allow it to dry few hrs and then apply a cement sand mix then while wet paint bottom of coping with sbr/cement mix and apply?, but at 35kg per stone would this work or would you allow the sand cement mix to dry and then sbr/cement bottom of stone and then fix. Also have a 45 degree area as per photo is this method okay in that area too. Would the cement mix close the membrane over the ply to protect and cappillary leakage into there

-

Leaking ufh overlay system post screed

health mechanic replied to health mechanic's topic in Underfloor Heating

Presume damaged while laying screed.....yep will leave pressurised for couple of weeks...is it worth taping......how on earth do you lift those clips up -

Leaking ufh overlay system post screed

health mechanic replied to health mechanic's topic in Underfloor Heating

Near edge....this is what plumbers done..is it okay to reschedule without wrapping with waterproof tape -

After due diligence with pressure testing downstairs....the screed was laid on the overlay ufh system upstairs (having carpet) without pressure testing a month ago. Got plumber in to pressure test today to 2 bars and noticed an hr later what appears to be a leak coming from master bedroom with crack in screed and water bubbling up. Have closed the Valves to the pipes which has slowed down. Now repair....is it okay just to dig that area of screed up and put a coupler in....plumber can place a push fit couple but doesn't have one that crimps that I would prefer. Anyone had similar issues. Annoyed as was done the 2 days I was away from site and builder did not supervise his subbies.

-

My rear part of my extension is timber on 2nd floor. My aluclad windows are being fitted in with compriband and then foam inside. Is there a need for flashing at the bottom reveal. Window fitter does not think so...as worried about sandwiching water in. But most videos I have seen seem to have some sort of flashing. Front of house is double cavity without flashing.

-

My zehnder unit has insulated 230mm insulated ducts going into a 250 external grill. Exit is in my warm roof on gable end. How are people drilling 250mm hole through standard block cavity walls. Hand drill will not cope with anything greater than 150mm diameter. Don't want to stitch drill as external already rendered. And the big rigs are extortionate to rent and have never used. Any help?