ian33a

Members-

Posts

7 -

Joined

-

Last visited

Everything posted by ian33a

-

Happy Christmas everyone - not building anything next year, just making what's already there a bit better than it currently is.

-

It's something that we have considered Dave. Sadly though, the leet which originally fed the pond has gone and so has another stream shown on old maps. It would be fantastic to have a wheel back there but goodness knows how much it would cost and how much it would cost to get it there and install it.

-

Thanks all, great replies! I was born in South Devon but moved away with work about 35 years ago. My parents and my brother remained there and it was something of a plan to relocate westward once we retired. It didn't have to be Devon - anything which took us away from a busy road and which gave good value for money in housing cost was viable. When we sold and bought, competition was fierce and we offered above asking on this place because it ticked most of the boxes : a lot of house for the money, on a quiet road but not down a long narrow lane, in a friendly village, unlisted, able to get a reasonable broadband speed, plenty of workshop space, bigger living accommodation than we already had and manageable garden/land (not much to ask then!). We wanted something with a bit of kerb appeal and, looks being subjective, to us, it has that, and so much more. This picture is taken from the lane outside. We've since discovered that the front grass was, in olden days, the mill pond. To the left of the property was an overshot water wheel. The wheel pit is still there, as are a few metal fittings for the wheel. Sadly, the wheel is gone. The section to the left of the door was the former commercial mill. The front door was a later addition. The living quarters were between the front door and the end of the front roof section. The two storey bit at the end is my office and a bedroom above (added in the 20th century). The back is more plain - as is often the case. We had decided to try to be patient regarding upgrades. We wanted to find our way before extensive work took place. Already aware that it wasn't to our taste, and only partially functional too, we decided to update the main bathroom very soon in. The house is very much a hybrid so we were able to have something modern but with a nod to the past and are very happy with the outcome. Unfortunately, the chimney sweep ran a mile when an asbestos flue was discovered. So we had to shell out for two new chimney flues, the front chimney needed to be rebuilt (as the render was damp) and we decided to upgrade one of the wood burners at the same time. Then, when we wanted to fill the oil tank, the driver refused to fill it on account of UV damage and hairline cracks. So we needed to have a new, this time, bunded tank. Then we've had issues with the underfloor heating - mostly sorted now by me. I wanted space for a decent workshop. The house came with a three car car port - brick on three sides and open at the front. I infilled that to have a triple workshop. This had to be done quickly because all of my workshop equipment was otherwise out in the open! As for the rest of it, well, in the south east the mentality was always "now, now now". It hasn't taken long to relax into a mentality of "soon, soon, soon". Toughbuttercup is right, it is good to wait and see. I built myself a to-do list with 42 items on it. A few were couple of hour jobs, most were couple of days jobs. Some of the shorter jobs were fun to do and gave a great sense of satisfaction. Other jobs, such as repoint all of the mortar on the cob, will take weeks and can wait until I have the time and the skills to do it. The house wont fall down in the meantime so, no big deal. Equally, all of the facia boards need doing. They appear to have been stained and the stain has worn off. The wood isn't rotten and, with a decent quality scaffolding tower, next year, I'll deal with it. I look at my to-do list and my wife worries that I'm beating myself up over the size of it. I'm really not. I just need a list to that I can remember what needs to be done, not to make me do it. Could we have gone further west and bought, sure. However, even on the Devon coast, let alone the Cornish peninsula, house prices are daft, totally daft, and value plummets. We can be at the coast in 45 minutes from here. We can wake up in the morning, fling open the curtains and there is a magnificent visual vista from our window. Nobody overlooks us. The nearest neighbours are 50 yards away and there is virtually zero chance of the view being interrupted as we are surrounded by a flood plain (only a small bit of our land floods - never any buildings!). Just open fields and a river. In our previous place we had 14,000 vehicles passing each day. The lane outside may manage a hundred or so. A car passing at 7am is considered the rush hour! Totally magical. One final thing: we saw this place back in February and decided to buy. It was a bit of a whirlwind as it was an open day and we had two other places to see in Somerset on the same day. The area we saw in February seemed nice but dormant. When we moved in in May it had utterly transformed. Beautiful green rolling hills, fertile fields, green forests, Dartmoor visible from the garden. A walking and cycling dream! We feel very fortunate to have moved here. ... and we can get to Cornwall really easily too if we wish! 😉 A quick aside - I have notifications turned on but is there a way to get email notifications if people reply to threads that I am following?

-

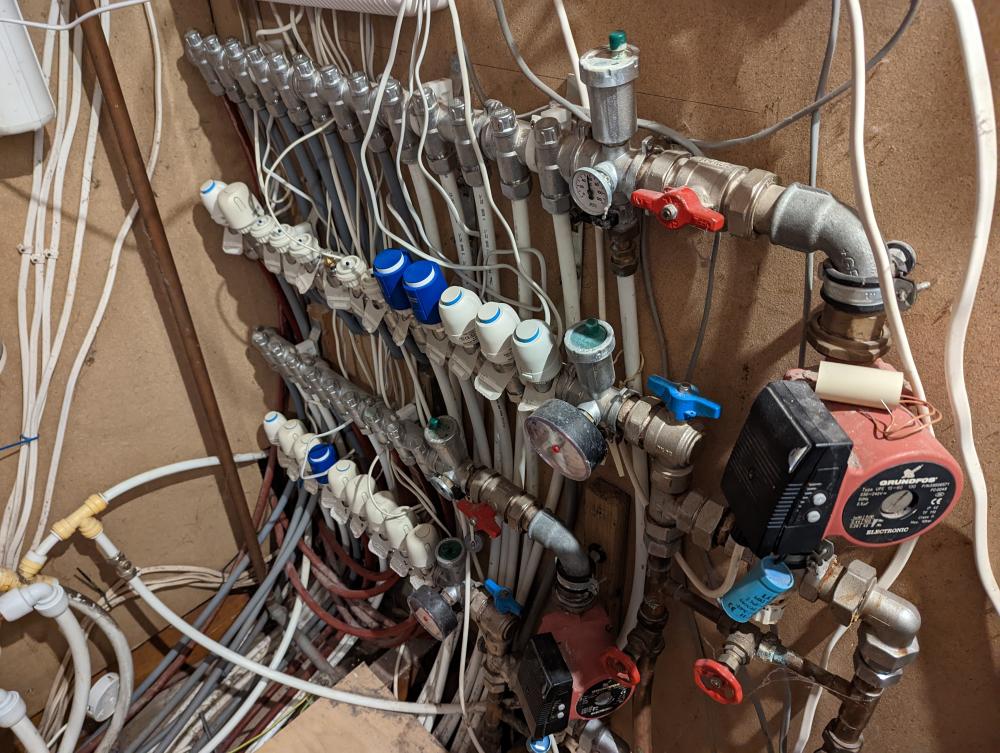

Thank you all, ever so much, for your replies. I was especially pleased when JohnMo offered his thoughts last night but decided to mull things over (in my sleep) before replying. Then, over night, the confirmation from Nick was especially pleasing too. I did take some pictures of the thermal store, or at least, tried to. It's really difficult to take anything that is meaning full as the units appears to have been assembled and a cupboard built around it and the the manifold and a doorway through the middle and in to the bathroom - hard to visualise, I appreciate. All I can show is an open cupboard with a load of pipes ... but here goes: The black expansion vessel is about a third of the way down the picture on the left hand side of the store. The coil of wire isn't part of the thermal store - it's part of a temperature monitoring system for something else. Not shown here is the expansion tank. This is stored on a platform above the ceiling of the walkway through and sits above the tank thus confirming what has been suggested : this is a vented system. There is no red pressure vessel, anywhere, as far as I can tell. Everything that you have described is what seems to be happening. In a quiescent (rest) state the amount of static pressure falls away to near zero on both gauges. There can only be a metre or so of static head between the top of the highest manifold and the top of the thermal store so this is consistent with there being no pressure. It does, indeed, build, with heat demand and is somewhat variable depending upon how many zones demand. Looking back (before my meddling) I only ever looked at these pressure gauges a few times and they always had pressure. I guess I just never looked at them with interest at a time when the system was at rest. You can't imagine the relief that your confirmation of what we have here is OK. I was really concerned that I had caused a massive issue which was unsafe for family visiting over Christmas! With regards to bleeding, and the automatic air vents, certainly, I'll have these looked at (there's no way my wife will allow me to do this right now!). The affected manifold is on floor one and the circuits are below on the ground floor. When I bled the top manifold, I did the following: I connected a mains feed to the inflow (just below the top inflow temperature gauge - just as in the picture) and a garden hose to the outflow manifold. Then I closed the inflow and outflow gate valves. I then made sure each of the circuits was closed and opened just one (at the far end). I opened the gate valves on the hoses (inflow first) and ran water through the circuit for about 10 minutes. I lost the will to live waiting any longer. Some air came out at first but, after that, it was just a gentle flow of water. I then closed off that circuit and moved to the next one, repeating the process. Once complete I closed off each of the gate valves on the hoses. Then I put the mains pipe on the outflow and the garden hose on the inflow. I opened the manifold gate valves and ran water through the mixer and the pump. If I was to change the auto air vents, it seems like a similar process to this, as, Nick, you have described. I think I will have a go at this once Christmas is over - no sense paying somebody to do it in January when it seems like I have had a fair bit of practice already - plus there's a sense of achievement in managing to do it myself (with assistance from my ever patient wife). Out of interest, if I had to bleed the lower manifold (which drives UFH on the same floor), what process needs to be applied for bleeding (just in case changing the auto air vents threw up issues)?

-

Hi Dave, Thanks for your reply. I've looked far and wide but haven't found a red or white one - just the black one, with a factory set pressure rating of 4 bar (but I haven't checked it functionally). I assumed that the CH pressure setting would be around 1.5 bar anyway. Ian

-

My first post, so please make allowances! We moved into a property back in May and are now finding that the cost of heating it has been more than we anticipated, even with the price hikes. I started checking out the 20 year old UFH system and uncovered half a dozen duff actuators (which I've replaced) and six circuits where the actuator pins are solid (again replaced). All circuits and zones are now functional. What I have found though is that the manifold pressure isn't constant, on even close. I'm learning about UFH as I go, terminology and methods easily throw me but, I'm gaining knowledge, but it's taking time. The system to me is a rather untidy mess. Nothing was labelled, no design documents. I've documented as I go. As far as I can tell, the whole system is fed via a Grant Eco Vortex oil boiler. It does a great job at providing heat and there appears to be plenty of water pressure - it being a closed pressurised system as far as I can tell (the thermal store being on the first floor and shower roses at equivalent top of tank height). In terms of UFH topology, it seems like a common inflow and outflow to two Far manifolds, one driving the top floor, one the bottom floor. Each manifold has a Grundfos pump and there is one additional pump (not sure what that does tbh). Each circuit is controlled via mechanical blending valves. The top manifold drives the ground floor, the bottom, the top floor. Each has a separate wiring centre with wired 240v thermostats. Having replaced the actuator pins (some on each manifold), I've done my very best to bleed everything using the inflow and outflow ports on each manifold. After one false start, I'm now pretty confident that the bleeding has done a reasonable job. All room circuits now get warm and the thermostats demand heat as and when necessary with the associated actuators doing their job and, the rooms get warm! All of that said (and pressures and temperatures were working as expected before I meddled) I now find the following: - Zero heat demand for several hours and the manifold pressure gauges drop to almost zero - the top manifold being worse than the bottom one. The inflow manifold temperatures drop down to 20 or 30c (not unexpected with no heat demand) and the outflow temperatures are a little below that (again expected). - If a demand is made in a circuit, the associated pump energises, the associated actuator begins to open, the inflow manifold temperature starts to increase and the pressure gauge starts to rise. - At some point demand will cease, the pump will turn off and pressure on the gauge will slowly fall, quite slowly. - Over many cycles the manifold pressure will get to between 1 and 2 bar and cycle up and down as heat is demanded. - If no demand is made for a lengthy period (I don't know how long - certainly hours) the gauge pressure will gradually fall away and finally go back to the state described in the first bullet. I think I'd expected the pressure to remain relatively constant all the time - but maybe it shouldn't? I haven't touched any of the flow adjusters and have no plans to go near them. I have played, a bit, with the inflow, outflow and mixer settings - the manifold temperatures being about 55 when I started (but less now). I don't know if I've upset something there - we got a bit desperate over the weekend when we had zero flow under any circumstances, thankfully addressed the next day with more copious system bleeding. Our property gets it's cold supply from a bore hole that we own. The mains is pressurised using a big blue space rocket like thing in the cupboard above the manifolds. I found this pressure vessel by the thermal store I don't know if this pressurises the hot water for personal use of for the central heating. I struggle to see where the pipes go - and again, no documentation. So, is the variability in pressure on the gauges normal? If not, any suggestions as to what I have done wrong or simply haven't done at all? I have an engineer coming out later in January (my wife got fed up with me meddling) but would like to understand ahead of time what may be wrong (and possibly improve things) ahead of his visit. It's the engineer in me ... just that I'm not a heating engineer! Many thanks in advance Ian

-

Hi everyone, In May of this year my wife and I moved from a mid 20th century house in the middle of the south east sprawl to an old property right in the centre of Devon. We've never owned an old place before, well not this old. The front middle of our place was built in the early 1700's, the rear middle is Victorian and there are 20th century extensions on each end. It's in more than reasonable condition and was extensively updated about 20 years ago. Now though, much of what was done then is tired. Luckily though, it retains much of its old character and has, thankfully, escaped listed status. My current project is to overhaul the hydronic underfloor heating system and its this which helped me find this forum. I'm sure that, once the heating is sorted there will be many other projects requiring the gathering of knowledge. Ian