SilverShadow

Members-

Posts

172 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

SilverShadow's Achievements

Regular Member (4/5)

5

Reputation

-

Types of central heating pipework

SilverShadow replied to SilverShadow's topic in Central Heating (Radiators)

Ps, regarding your last paragraph: may I ask how long (or how many) systems you've used it on Just helps give me a perspective of reliability 😉 -

Types of central heating pipework

SilverShadow replied to SilverShadow's topic in Central Heating (Radiators)

Cheers, Simon - very sound advice! 😁 I'd not heard of it before, but this plumber swears by it. He's invested in the tooling - which means he has the kit & know how. Although probably means he'd push this as his preferred option regardless I was concerned about the joints - I've heard push fit on plastic pipew can give over time & leak. I presume with these, having them sealed on the inside is preferable to anything push fit & will be sturdy enough From what I gather, this has been used on the continent for a while, and also on commercial heating. So (to me) it definitely sounds robust enough. Being slightly insulated probably also helps with any freezing problems too 👍 My only concern is: if in the highly unlikely scenario of needing to maintain it later (eg: some leak), it would limit options on emergency plumbers We'd be looking to extend the heating layout later (after house extension), which I presume would be easy enough to do with this set up A good many plumbers shun it, and I'm trying to figure out what (if any) disadvantages there are. Or if they're just old skool & stick to what they know Plenty of useful info to consider tho mate 👍 -

Types of central heating pipework

SilverShadow replied to SilverShadow's topic in Central Heating (Radiators)

Indeed - the last one i mistakenly put in the wrong thread, so opened this one here -

Hi there, We're looking to replace our CH system from the Jurassic era. This will involve installing a new combi boiler (to replace old gravity fed boiler) & 8 double radiators (replacing the old single panel ones). As the system is so old (i'd guess >30yrs at least, probably 40+) we imagine it'll need a whole new pipework system (especially as the combi will be in a different location), so plan to replace the old pipes One plumber mentioned using MLCP - has anyone any experience of this type of pipework? While it's cheaper & more flexible, i wasn't sure if anyone had concerns over durability and if the connection joints degraded over time with systems like a combi? We'll probably end up with copper pipes & soldered joints, but always worth asking around before making a choice - Pros & cons are always worth thinking about up front! Thanks for your time & thoughts Shadow

-

The basic architect questions thread

SilverShadow replied to SilverShadow's topic in Surveyors & Architects

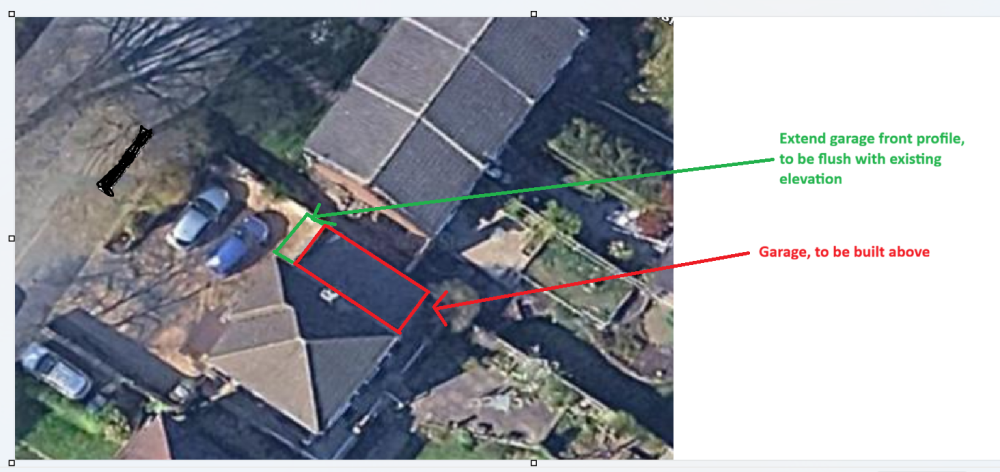

Cheers, Gus - very appreciative of you taking time out to explain all this to us. I'm not bad at most DIY stuff, and despite doing Tech Drawing many years ago, a house extension goes way beyond my mere mortal skills. We're opting to go with this company: https://planning-by-design.co.uk/ Our reasons being: All-in-one, solution - so there should (in theory!) be minimal issues with mis-communication & time delays between parties, prior to commencing construction We prefer to let somebody else take the strain with the design aspect - they're the experts & should know all the wrinkles, and ultimately be responsible & have the know-how for planning submission / approval & revising the design if approval is not granted The photos below, perhaps gives another insight into our proposal, as it shows the orientation of houses & rough size & scale of the extension. It's a good point about curtilage, but as you can see - the extension is almost completely built upon the existing garage (shown in red), so shouldn't increase the footprint. The only slightly contentious bit, is extending the garage front (1st pic - shown in green, which is approx 0.5m by 3m of extra footprint). Being flush might bend the subservient roof rule slightly, but if the pitched roof is lower than the main dwelling i'm hoping we'll be ok. I'm not 100% sure, but i'd guess our chimney will need an extra 1-2m of height, to accommodate the new pitched roof area Appreciate that pics can sometimes give a slightly skewed perspective, but these (imo), give a reasonably clear illustration of how our extension would avoid any terracing effect. I think they also underline how much lower than our neighbours the extension will be, so won't impact their light too badly In the meantime, i need to make sure we arm ourselves with plenty of examples of nearby properties where side extensions are flush with the front profile, and formulate clear documentation as to the reasons why our proposal should be approved. The draining (hopefully) won't be too much of an issue - there's a downpipe between to the garage/front bay window (in the green area of 1st pic) for the front roofing, and an old downpipe (disused) at the back corner of the property. Provided these are still in good working order we should hopefully have this aspect covered Thanks again, buddy - really invaluable stuff you;ve shared with us -

The basic architect questions thread

SilverShadow replied to SilverShadow's topic in Surveyors & Architects

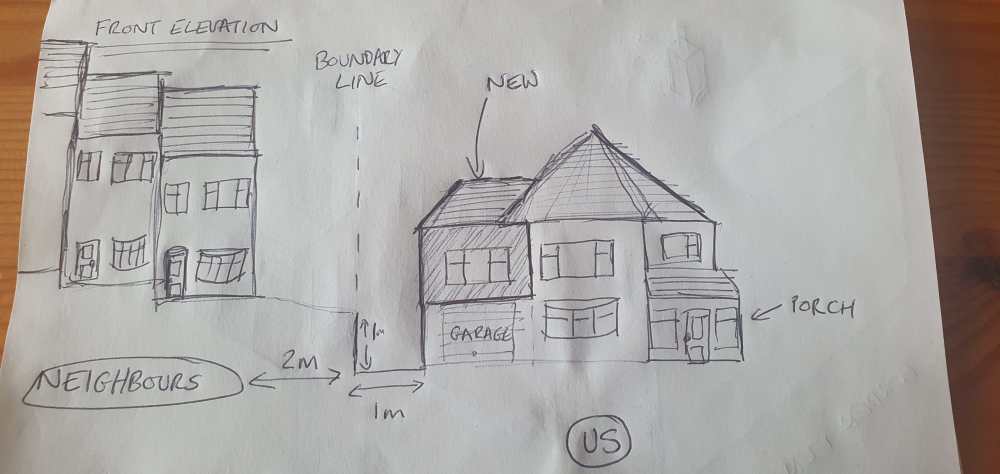

Hi again, Gus - hope you had a great Xmas, buddy 😁 Apologies for the late reply, but it's always a hectic time of year! 🍻 I've enclosed some very basic drawings, which I hope help a little. Apologies, if they're a little crude, but hopefully they give a clearer idea. I can also provide a rear elevation if that helps - but maybe this already gives you a clear enough idea. Please ignore our property's exact roof layout, as it depends on final plans. But it should show it's (currently) a pyramid shape & the neighbours have a gable end facing us I've shaded our new extension a little, to highlight the changes we're hoping to construct I've also put a few rough measurements & projection lines on, to give an idea of overall perspective of us with the neighbour To recap: Their property front elevation is at least 2m forward of ours (& ours probably 2m further back from theirs, at the rear elevation). I'd guess their ground floor is 2-2.5m higher than ours. We also have the 3m gap between properties. The sun hits the rear elevation 1st & swings clockwise (the side away from the neighbour) to the front Hope that gives a better idea, buddy - feel free to ask anything else & I'll happily provide 👍 -

The basic architect questions thread

SilverShadow replied to SilverShadow's topic in Surveyors & Architects

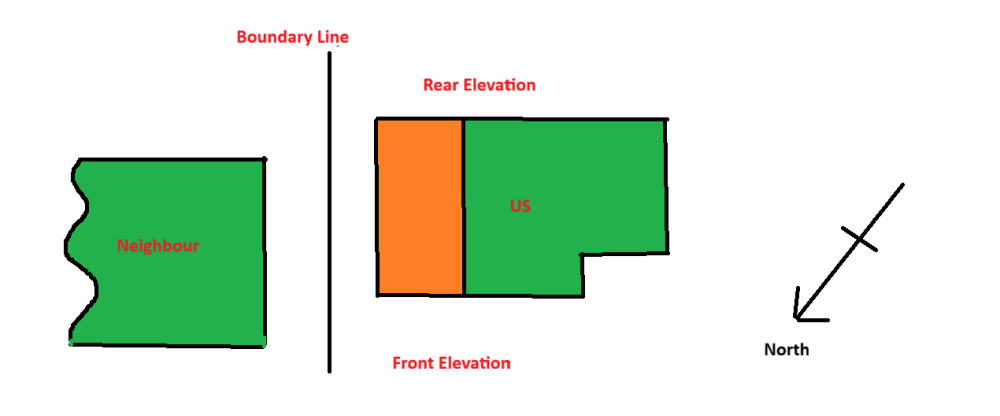

Cheers, Gus - those documents are excellent!! Really informative & clear. From what i can tell, the 2 main factors to consider in the design are: Orientation - avoiding a 'terraced' effect with other properties & being overly imposing Daylight & Sunlight - ensuring the proposal has no impact deemed significant enough for loss of light I've considered it as follows, for our side extension: Orientation: Our house is set back approx 2m from the neightbours There is a 3m gap between buildings The neighbours house is 1-2m naturally higher than ours Their roof is gable end, ours is sloped Our extension is 1m from the boundary line (neighbours building is 2m from theirs), making the 3m gap mentioned above Our side 2 storey extension 1st floor guttering is likely to be about mid-point between their ground floor and 1st floor rear windows Neither property has windows overlooking the boundary, nor will the extension There are a reasonable number of existing 2 storey side extensions in the neighbourhood, where they have built flush with the house front, and closer to their adjacent house, and in some cases not subservient in terms of profile or roof height (we'd add more details of the properties at submission time) It's likely we'd apply for party wall agreement, due to being only 1m from the boundary line Daylight & sunlight: Neither property has side windows, so the 25' rule shouldn't apply The 45' rule (horizontally from their kitchen window) - i can see by eye, that we currently don't cross this line with the existing garage, so wouldn;t anticipate the 1st floor extension to either The 45' rule (vertically from kitchen window - i wasn't aware of this until now!). It's unlikely we'd cross this from our 1st floor guttering level, but it would be within a meter i'd imagine Pitched roof - as ours will be a pitched roof, then it seems like we take the 45' vertical rule from the midpoint, in which case we'd definitely be fine. Is this pitched roof midpoint interpretation correct? Sunlight - both houses rear gardens are Southern facing (South-East, to be precise, so there might be some shadows cast early morning on their front lawn, side of house early afternoon & maybe the rear late evening/sunset As the roof is sloping and 1st floor halfway between their ground floor and 1st floor window, the amount of shadow is far less than it would be on even ground. The shadows would likely hit the side of their house (with no windows) likely no more than halfway up. There are a number of mature trees on the road that could obscure their property from sunlight, regardless of our extension, so hopefully we won't be causing any major impact We don't believe a VSC would be required, given the above All the above is only a high level appraisal, and would need more accurate measurements and assessments. But we feel this is a good starting point for our case This is a crude drawing of the proposed side extension (in orange). The footprint remains unchanged to the existing one, except for moving the front edge forwards 3/4m, in line with the existing front This is not to ask whether you consider the proposal would be successful, but more to enquire if there are other things we should consider when designing & applying...... -

The basic architect questions thread

SilverShadow replied to SilverShadow's topic in Surveyors & Architects

Thanks again, NFW 😁 Several architects have advised us, but it really seems like a mixed bag. Some we've spoken to err on the side of caution, and would produce a 'safe' design. Others seem a little more open to interpretation of the rules, and think that in our case we might attempt trying to maximise our footprint, due to the orientation of ours & the neighbours house Obviously no-one knows till it goes for submission, & we don't expect any cast iron guarantees. But this (for us) is where we really want their gut feeling & experience to shine through . This is where we feel they can really provide their worth. From what some have said, if the council rejects & asks for a wall to be moved slightly to comply, it can be classed as a minor revision & part of the original proposal. Thus incur no extra fees or restart the process. Is anyone able to verify if this assumption is correct? -

The basic architect questions thread

SilverShadow replied to SilverShadow's topic in Surveyors & Architects

Many thanks, SAS I have no clear insight into how they'll react. But they have recently gone very quiet after the initial positive dialogue we had. I can't be certain whether they're just waiting to see the plans or have some fundamental concerns, but think IF they do object it'll be possibly be due to Loss of Light. Hopefully though, it'll be fairly minimal, due to the building orientation and the gardens being south-facing, so the sun won't hopefully overshadow their property too badly (aside from the side of their house, which has no windows). We'll just have to see i guess - but if we can find some online service to check light/overshadowing that would be extremely helpful We've also found a service that does a 'Pre-Application' planning appraisal (for £100+VAT), that will take the basic extension requirements and assess the likelihood of PP success the the local Planning Authority (based on previous applications in the area). I'm not sure if this is just gimicky, but this sounds like a valuable service, to increase (not guarantee) the likelihood of PP approval -

The basic architect questions thread

SilverShadow replied to SilverShadow's topic in Surveyors & Architects

Cheers, NFW - tbh, i like the sound of Planning By Design, as they seem to offer services throughout the whole process. Arguably, an online service perhaps doesn't have the ability to see things 'on site'. But we've struggled with getting local architects on board (a lack of engagement, when we've tried to contact them). With a larger company like this, the service is likely to be less-bespoke - but at least we're likely to always have someone to hand! While cost is a factor, having a team there every step of the way is equally vital (especially, as we think getting PP approval from 1 of our neighbours might be tricky). I have noticed a number of side extensions in our area that don't appear 'subservient' to the main building (ie - they are flush with front elevation & in some cases roof continues at the same height). Seems like council rules are 'malleable', if you know how....🤔 -

The basic architect questions thread

SilverShadow replied to SilverShadow's topic in Surveyors & Architects

For anyone still keeping tabs on this thread (and i wouldn't blame anyone for not doing so! 😆) Has anyone had experience of using some of these big name architect companies, like: Arkiplan Homz Planning by design They seem to be more of an online service, but appear to have a wealth of services to offer & can provide a comprehensive 'all in 1' package for several £k cheaper than others we've had quotes from. We definitely won't skimp unnecessarily at this step of the process, but likewise would be happy to try these companies if folks have had positive experiences with them For the record: we are still hoping to use a local architect if possible, but been let down recently & so exploring all options to try and push ahead Cheers, all Shadow -

On another front, one of the architects replied to me, stating his party wall surveyor friend says that it's 'an unwritten rule' that exploratory pits generally don't require a PWA in place I've no reason to doubt him, but couldn't find anything around this. I definitely won't be rushing into anything, as its likely he's not privy to their potential location They would be within 1m of the boundary & approx 3.3m of the adjacent house

-

Many thanks guys- very valuable stuff indeed 😁 Agree with the comments above & have reached out to the neighbour (landlord) about the desire to renovate, who was happy to send via email Within the email I contained a couple of rough 'before' & 'after sketches', together with bullet points of the work & rough guesstimate start date. I stressed that this is at the very early 'vision' stage, so likely details would change as things progress. I made sure to explicitly state we want them on board at an early stage, to gather feedback & concerns. I also mentioned we would likely need to dig exploratory pit(s) and mentioned PWA, together with a link to a website around Party Wall info. The opportunity for them to formally review plans via communication from the council was also something I stated We've since discovered their father is an Architect, so I imagine they will appreciate the heads up & work required in the proposal. With luck, it may work to our favour, in terms of understanding process & the need for some of the tasks to be done

-

Brilliant stuff - many thanks! We are planning on contacting the neighbour next week, and sending an email detailing our proposal and rough start date. If email is acceptable then this will be an amazing cost saving to our project. The neighbour has tenants in the house, which i believe also need to give consent? Either way, if we can get this sorted next week, then we could start exploratory holes early/min Jan (as i think we need 2 months notice before commencing).