Obi_wan

Members-

Posts

16 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Obi_wan's Achievements

Member (3/5)

0

Reputation

-

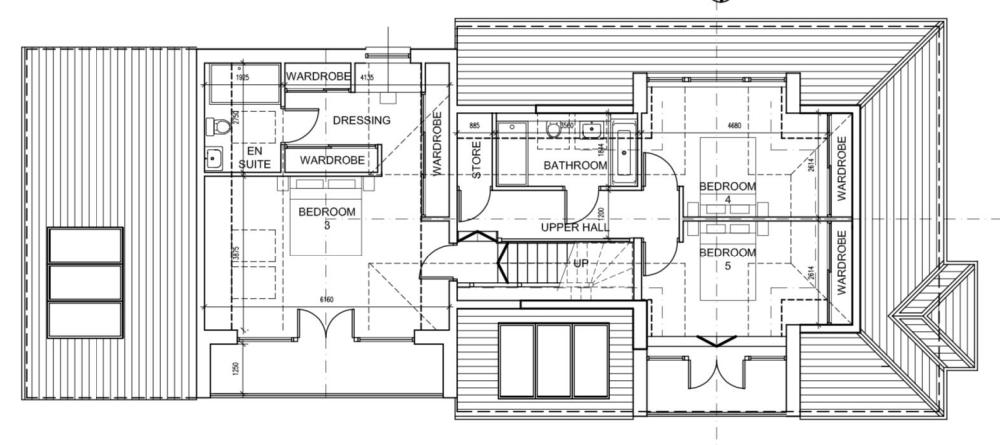

I would but they keep advising that they are supplying 2/3s of it loose timber and I’ll be paying a premium for trusses. I think I might have got a workable outcome with the engineer yesterday where I can buy c24 for everything up to the dormers and then switch to trusses. Once that is fully confirmed I’ll be able to price the cost difference and see if there is enough to bother splittt it. I like the idea of loose as it can be worked on site, especially if the walls are not straight or square etc given that the original part is 100 years old. the feedback from the engineer is that the trusses can do things that he couldn’t due to the consistency of truss joins compared to on-site fabrication and I will need to incorporate 5 additional steel beams and use multiple flinch plates were the truss manufacturer doesn’t.

-

-

you’re not the first to say that 😂. I am afraid that it is too late and I’m a reasonable way through, although plenty still left. I am content that the design works, if the roof goes well.

-

-

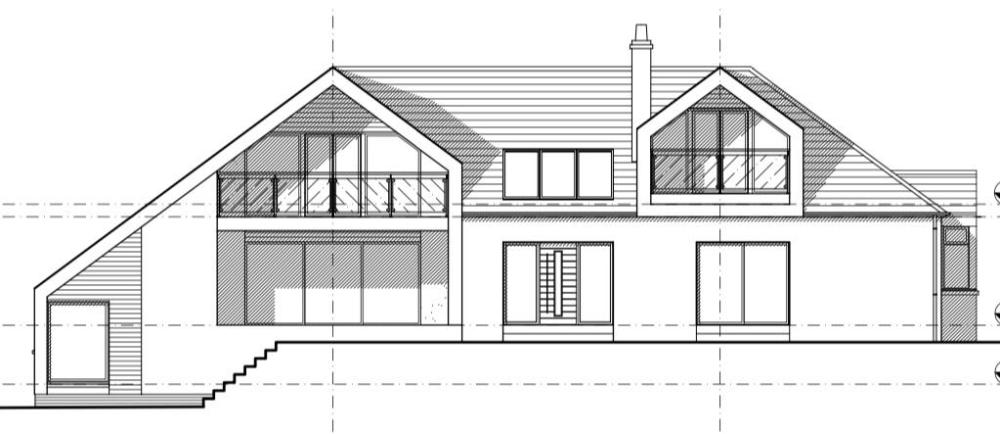

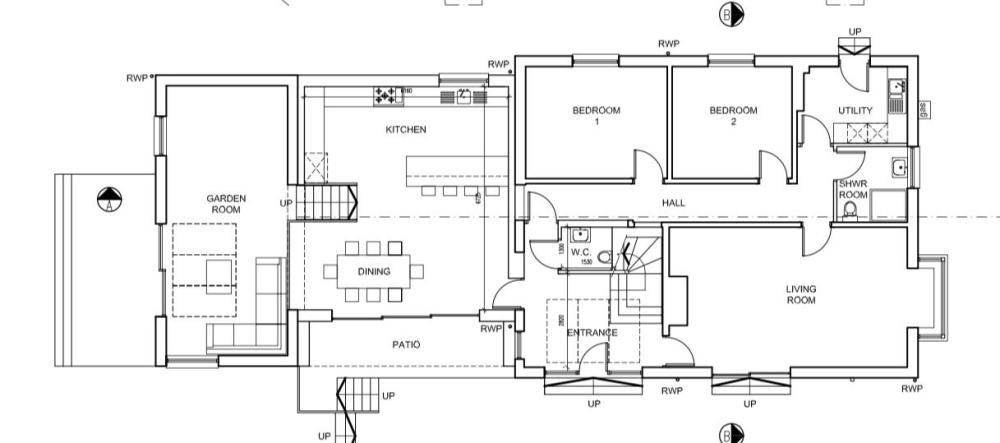

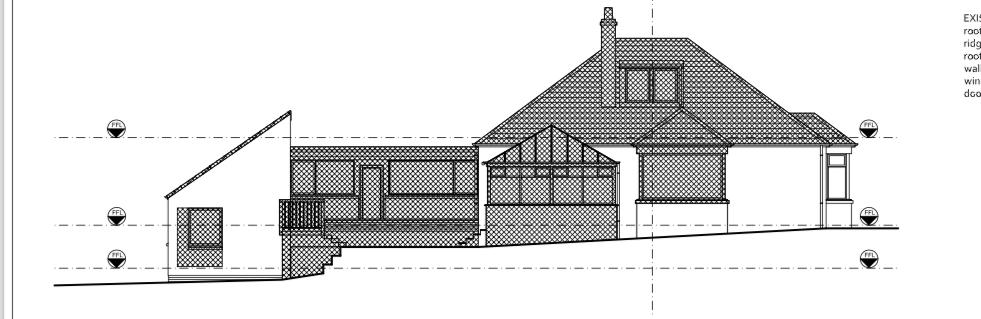

Undertaking a renovation of a bungalow and quickly approaching the most complicated part of the renovation, the roof. The renovation involves a 1 1/2 story extension being built in the middle of the house. This made the joining together of roofs complicated and large chucks were being removed anyways. It was proposed by the engineer and architect that replacing the whole roof would be more sensible. Which I think is correct. Truss manufacturer has provided a proposal but advised they are supplying 2/3 of the roof as loose timber and believe a traditional build might be cheaper. Engineer is advising I should stay with trusses. I want a warm house that is wind, water tight and as air tight as practical. This part will be mostly up to me. link shows the 3d design. any thoughts and advice appreciated. https://sketchfab.com/3d-models/x55138a-80d3ee68d50d471387bbe02d507b80be

-

the cement board like no more ply would be on top of the pug mix or latex screed as you have suggested. It would then accept tiles and provide a structural floor.

-

Ok thanks. I haven’t bought the caberdek yet, but thinking I could place it on top of the joists and before the pug mix. It should contribute to the thermal resistance below the ufh and provide the structural flooring. Alternatively I could look at cement board and put it on top of the pug mix and it will contribute to the heat dispersion. Not sure what thickness of cement board would be required for a solid floor feel, spanning between the 400mm centred battens.

-

What’s your finished floor buildup plan?

-

The finished floor is undecided and could be tiles, LVT or wooden floor. Am I right in saying that this build up would only allow for engineered wooden flooring because this is being substituted in for the structural floor. Does that mean 18 or 22mm moisture board, like caberdek, or OSB could be used instead of the 12mm OSB and I would have more flexibility in the finished floor selection?

-

I have read that you created a ledge under the I joists to hold the insulation. The plug mix covered the depth of the battens. What is the purpose of the 12mm OSB? Is it to stop the insulation being compressed by the dry mix? I am wondering if I could omit this if I used PIR instead. I have the joists so I can adjust the centres but not the depth. At 200mm frametherm wouldn’t meet the U valve.

-

I tried 4 different BM nearby in Glasgow area, 2 local and 2 national, that I have been using for other materials. They were all going to the same place, Robslee. Prices varied very little. All were double the price per beam of those I found down south.

-

this is interesting. Was the frametherm just friction fit or did you uses something to hold it? what depth of dry plug mix? Thanks

-

Sloped plot with 1.2m going to 2.0m drop. Too late now but do have a beam and block patio. From organising that I have discovered the following. Beam and block has proven to be very expensive in Scotland. Robslee are making to order with 4 week lead. Much better prices down south, but few suppliers willing to ship. The ones who have quoted have big transport fees. Moving beams are going to be challenging.

-

Planning to construct our extensions suspended timber floor next week and looking for feedback on getting a good airtight and insulated ground floor. I would like to install underfloor heating in this room but could give it up. the most common proposal seems to weave the an airtight membrane up and over each joist, insulate between joists and vapour control over the top. Is this aimed at retrofitting and not newly constructed floors? Could the bottom airtight membrane not be laid below the joists? Alternatively I have thought about 150mm PIR between the joists. Finished with PIR going over the top of the joists to deal with cold bridges. This top PIR could be used to clip the underfloor heating pipes. any advice would be appreciated

-

I googled bellcast as wasn’t familiar with it. So it looks like the roof would overhang the ring but not sure how this would change the cold bridge, unless the underside of the roof was also insulated. I might have misunderstood. I am adding dormers to the roof so it is planned to be completely replaced. I wondered if I used 150mm eps on the wall then a band of 50mm where the concrete ring is. This would remove any overhang. Obviously less insulation over the concrete ring but I might have to compromise from the perfect arrangement. Although this might mean the roof details need redesigned.