rhymecheat

Members-

Posts

65 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

rhymecheat's Achievements

Member (3/5)

2

Reputation

-

Hum, good shout. I'll try this and report back. Thanks!

-

No, it keeps going. edit: also, I’ve been keeping an eye on energy usage since turning the pump speed down on the ashp, and it seems to be short cycling now 🤔

-

Okay so that still oscillates. I’m now tempted to reduce all the pump to min (even ashp) and start taking flow measures to see. thanks for the insights btw. also, the pump after loft is there because it serves both downstairs UFH and upstairs rads.

-

So I’ve already got Salus actuators on the UFH manifold. That manifold is set to constant pressure speed. Other than that I can set it to 1,2 or 3. If I’m understand this correctly you’re suggesting I change it to a constant speed instead? How long do you think it would take for me to tell if it’s not oscillating anymore? other than the ashp pump there’s also a pump after the buffer tank. That one is set to 2 currently.

-

Hi there, have a question about my ashp (Altherma 3 H HT). when the compressor is operating the flow rate oscillates between 29L/m and 31L/m. This oscillation is very quick (I’d say half a second in 31, and down for another half sec in 29 then back up again). I only noticed this as you can hear the pump on the indoor unit sounding almost like it’s getting throttled and it’s quite an annoying sound. I’ve checked the settings and the pump speed is set to “no limit”. If I set it to say “80%” then I get a flow of about 28L/min constant when compressor is on. here’s my questions: * is this limit okay to set? Or am I compromising efficiency? * why could the “no limit” be behaving like this? As in, where would I look for what’s potentially throttling the pump. btw, it feeds UFH and the delta is set at 7

-

Running Ethernet cables on a drain vent box

rhymecheat replied to rhymecheat's topic in Networks, AV, Security & Automation

Yeah ironically, because there are pipes there and they're boxed, that's the easiest way to run cables through the loft without having to mess with wall insulation, studs or external walls 😆 -

Running Ethernet cables on a drain vent box

rhymecheat replied to rhymecheat's topic in Networks, AV, Security & Automation

I'm a novice. Would probably avoid adding “remake boxing” to my list of skills. Hole saw is a plan. I was thinking of just going at it with a screwdriver until its through just to gather the thickness of it. But seems like after the first 10/12mm it gets harder so I'm scared I've gone through the plasterboard and I'm now either facing wood or something else. This is why I'm asking specifically about that extruding bit along the top (that's where I'm thinking of drilling) -

Running Ethernet cables on a drain vent box

rhymecheat replied to rhymecheat's topic in Networks, AV, Security & Automation

Given the length of the boxing I'm thinking there's more than one pipe on there. I guess I could possibly try an inspecting camera down from the loft to about the expected height of this boxing. -

Hi all. I'm planning on running some Ethernet cables throughout my house and step one is to get access from the loft to where the switch/router will be. There's a drain vent that seems to be open all the way down from the loft to a pantry. This pantry has a boxed bit (in the picture), but in wondering what that top extruding strip is. I've not yet adventured to drill there yet as the shape of it is making me think there's a tube there for some reason. Would anyone have seen something similar to this that can shed some light? Further to that, how could I drill safely in there to check what's on the other side?

-

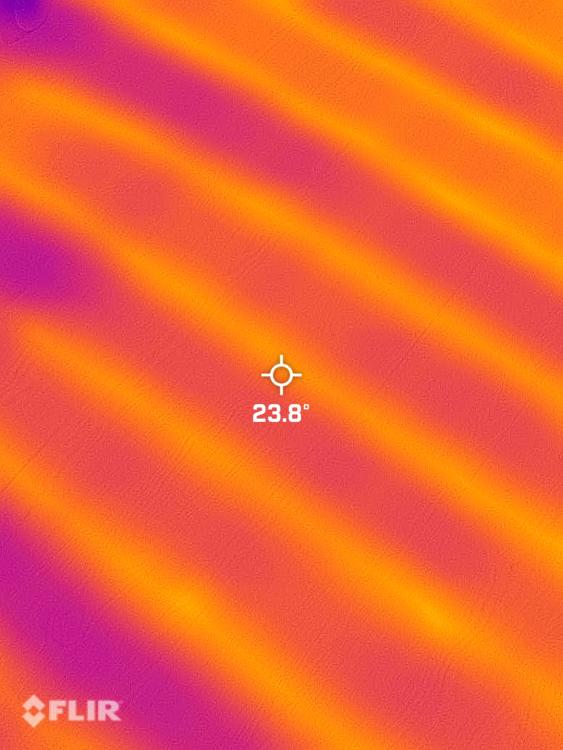

Thanks for the FLIR tip! Are your flow tubes clear? Mine are all brown so I’m guessing there’s some funk in there. I’m gonna go ahead and drain them tomorrow then refill. I’m convinced there’s crap/air in there preventing them from heating fully.

-

What’s your flow temp and how the hell are them loops so hot? My flow is at 55C and the loop is only at 24C max

-

Also keep in mind this is every room. The ones exposed to external walls, the ones that are not, the hallways. It’s all suffering. also, the upstairs has rads instead and it’s always hot with the same insulation and exposed to the same elements.

-

I tried pressing the pins but they all look okay. Unsure about spreader plates tbh. The thermal cameras clearly show hot loops on the floor but only the loops. Would I see a bigger spread with spreads plates?

-

Well that’s no good! Im calling the installer tomorrow morning for him to come and have a look. im secretly hoping there’s air on those loops because even the floor isn’t warm enough for this temperature imo…

-

So I’d been running all night and believe it or not… temperature inside has dropped .5C the return temperature is now close to 50C with flow at 55C One thing I noticed when opening the actuators is the red pins don’t fully go down no matter how much I turn them. Don’t know if relevant.