Dmitri

Members-

Posts

11 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Dmitri's Achievements

Member (3/5)

0

Reputation

-

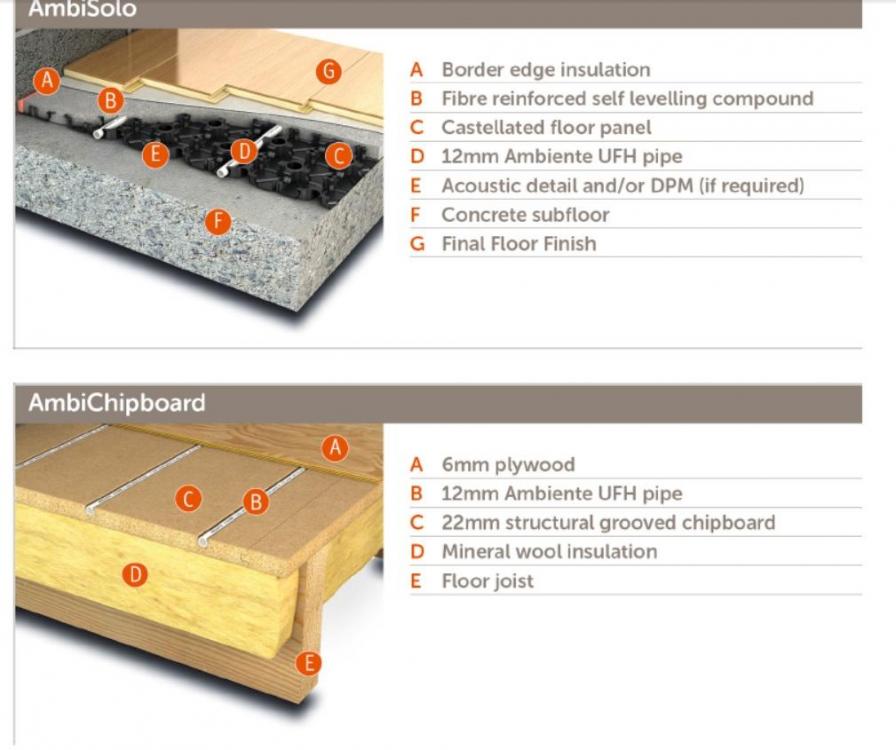

I just checked through their supportive information and this is what they claim about this system on their website: The AmbiSolo system is a low profile castellated underfloor heating system, designed for refurbishment projects where floor buildup is at a premium. The system incorporates a 12mm Ambiente underfloor heating pipe within a plastic castellated panel, which is then covered with 20mm of reinforced levelling compound. The way that this system is designed means that it must be laid directly onto a structural and level sub-floor, not onto any loose flooring or insulation layer. This can be a concrete sub floor or chipboard floor, but it must be a structural layer as the 20mm compound is not structural in its own right. There are many unique benefits of the AmbiSolo system, even above other retro-fit UFH systems. Firstly, the response time is very quick, heating up in 15-30 minutes (depending on the floor covering), very similar to the response time of a radiator. Secondly, the output of the system is exceptional – while we recognise there may be a small downward loss of up to 10% (due to no insulation layer beneath it), the quick response time and overall output of the system more than compensates for this.

-

I will wait for their response first. But I have a gut feeling that this won't bring us anywhere.

-

That is exactly how we do! Without the electric heaters though, as the stove does it's magic.

-

Not at all. Nothing is cheap in our days.. All together 18K+ got spent on the heating project. Not really fancying to get the rads back. Would rather invest in the tank. Don't you think the tank would help, if to disregard the ground floor issue?

-

I did have that feeling previously, but I think it is a little bit too late to complain now as more than a year has passed. The supplier has actually lost all interest in us as soon as we have settled the bill. But nothing new here. That is why I am looking for the solutions to reduce the costs in the long term, and to try to utilise the system in a little more efficient way.

-

Thank you for these precise calculations SteamyTea, very helpful! I must point out that we are not using the UFH anymore in the living room downstairs as we have fitted the wood burner. The main usage of it is in the bathroom (small area downstairs) and the upstairs bedrooms.

-

That is correct. The house is nearly 100 years old I believe

-

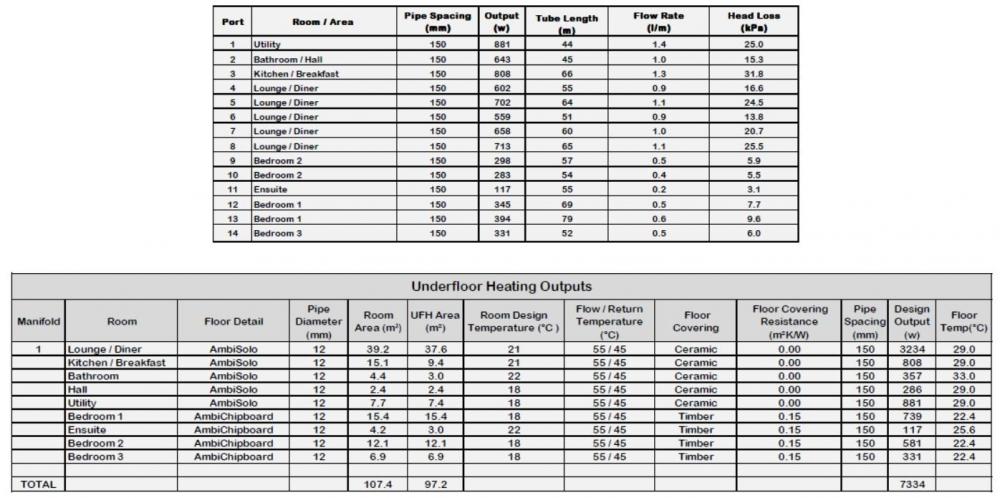

I have attached the screenshots of the designer's drawing. Hoping that this would help to understand what we have got. In short, our downstairs was already concreted when we got the property, I do not know if there is any insulation. So I assume that there isn't any. Between the floors we have 100mm Rockwool (between the joists) and also have an air gap between ceiling boards (battens on the old ceiling with new plasterboard on top)

-

-

Hello, Many thanks for everyone's replies and inputs in this post. I would like to make it a little more clearer as it seems that the "intro" does not reveal the actual question. First of all, I do not complain regarding the heat from the system - it works great. It works great, but at very high expense. This is where my problem is. When we moved in into the property (January 20) we were running central heating for 24/7, with radiators being installed in every room. The gas consumption was nowhere near as high (referring to the meter readings, not the rates) as it is now with UFH which was installed during the summer last year. And the house was nowhere near insulated as it is now. So I am looking for the solution to reduce the gas consumption. I know for instance that the Air/Water Heat source pumps are using storage tank to contain the heated water. So why there is no option for the buffer tank with Combi system??? I think that the problem is that there is not enough volume of water in the system. I think by having the tank installed the running time of boiler will be reduced drastically. What I mean is that currently boiler heats up very small amount of water which cycles between boiler and mixing manifold (approx 30 meters of combined length of 27mm copper) plus a volume of manifold. And it burns gas all this time, keeping it heated. But if to put, say, 100 litres tank between the system and set the tank temperature to, say, 75C, and ask boiler to reheat it once temperature of the tank will drop below, say, 50C. With the mixing valve set to 50C there would be "reserved" temperature of 25C in the whole volume of the tank. How long would it take to get it cooled down to the 50C? 30 minutes? 1 Hour? I do not know how to calculate this, so only guessing. But anyway, the boiler would kick in maybe once or twice per hour for smaller period of time? Please let me know your thoughts.

-

Good day all, I would like to get some advise and perhaps the solution to the issues with my UFH system. We did install UFH in an entire house and got rid of all radiators. The system is 14 port manifold (only 12 are in use) feeding 7 zones. Total room area is 97 m2, with the biggest zone being 37 m2 (uses 4 ports). The volume of the system is approximately 35 litres of water. The systems output around 7.3 kW (as per drawings). System pressure is 2.4 Bar. The system is fed by the Vaillant Ecotec 838, with direct loop (feed and return). The Heating Output temperature is set to 60C. The manifold temperature is set to 50C. The Delta T between each zone’s Flow and Return is set to 8 – 10 C dT. The heating kicks in in the morning around 5AM and lasts until around 9AM. Then it kicks in again around 3PM and goes until 9PM (not all zones work in the same time). Thermostats in the rooms are set between 19C and 21C, depending on the rooms. The Upstairs bedrooms are covered with 14mm Bamboo, UFH is installed within grooved chip floorboards (22mm). Ground floor - all pipes are screeded in; living room has 14mm Bamboo, other rooms porcelain tiles. Not having any issues with the heat output. The issues what I have are: 1. While there is “call for heat” the boiler is always on, without having a chance for performing “condensing”, until it goes into cooling (possibly cycling?) mode. 2. While boiler is in the mentioned “cycling mode” the temperature can drop down below 30 degrees C and be like that for 20 odd minutes. 3. The consumption of the gas, only for the heating, was initially around £5 per day. This got reduced down to £3-50 (equals to about 100 kW of gas daily) by turning the heating output from AUTO to 10 kW. I did try to run it on 7 kW option, but it does not produce enough heat for the all 7 zones. The Flow temperature can only be achieved of 26C on that setting. To be honest, even 10 kW is not enough to keep the all 7 zones at 50C Flow, but I am sacrificing some rooms to the others. I am baffled. What we were sold is the “efficient” underfloor heating system. Which suppose to be far more better than ordinary CH system. While we had the central heating in place, even with all the radiators running, the consumption was nowhere near this high (measuring in the kWh). The supplier could not suggest anything, other than to speak to the Vaillant. After speaking to Vaillant nothing was achieved either. Reading through the forums some people suggest to install buffer tank. But no further advise is there on what exactly is required. Perhaps there is a “formula” on what size tank is required? Please could you advise the solutions to bring at least the running costs down and bring the efficiency of the boiler, as from my understanding having it constantly running with dT of only 10C – 12C won’t do any good in the long term, never mind constant cycling. Many thanks for reading the above.