Lemna gibba

Members-

Posts

35 -

Joined

-

Last visited

Everything posted by Lemna gibba

-

Hello everyone, We are renovating our solid brick 1930s house and want to get exterior wall insulation. I have read about many of the problems, and feel that it's vital that we find a reputable company to work with. I think recommendations would be really helpful. We're based near Loughborough. So if anyone can recommend some high-quality installers in the Notts/Derby/Leics area, that would be really helpful.

-

Hi @Super_Paulie, Thanks for commenting. I found your thread quite hard to understand. I think in the short term our set ups are quite similar with mix of rads and UFH in part of the ground floor. I assume that you would still do a buffer if you were installing something similar again. Cheers, Tony

-

Thanks, I realised that I needed two-port valves. That thread was very useful highlighting the need for a buffer, but I'm not keen on sourcing one from ebay after that saga!

-

We have a two phase approach to remodelling our house. At the moment we are replacing a conservatory with a single story extension to make a large kitchen area. This will have well insulated floor (150mm PIR) and we are putting UFH in. The room is about 30 m2, it will have two loops but obviously be a single zone. We've had some heat loss calcs done and worked out the pipe spacing and I'm playing in loop cad with designs. The rest of the ground floor will be done in 4-5 years time. Almost certainly add an additional 4 loops. At the moment we will run the UFH from our boiler, but our plan is as soon as we can do phase 2 and insulate the whole house to run the whole thing from an ASHP. We do not want to dig up our newly laid kitchen floor then. It would be way easier to have 2 manifold locations (all be them separated by only 30 cm of wall). One of them for the phase one renovation, and the other for the phase 2. This is because we don't want to lay a porcelain floor then dig part of it up in 4 years. The alternative would be to knock through a part of the wall, install a small beam, buy a 6 -port manifold now, use 2 of the ports but have everything ready for the next phase. The problem is this would come out into our hall. Currently this is (I believe) an uninsulated concrete slab which we will dig out in phase 2. I really don't want to start digging out a section now or try digging around UFH pipes. Can you see a problem with having two manifolds other than price.

-

Dear all, thank you for your comments. I'm sorry, I wasn't clearer. This is a renovation project not a new build. Furthermore, it is a multi year renovation project. We did get an as built EPC for the renovations we intend to make over the long haul, but won't do a final EPC until the very end. At the moment we're building a single story rear extension and replacing our existing kitchen floor with a well insulated slab. The linked pdf document is very informative. Things like documenting the insulation at the door threshold is not something that I might otherwise have done, but will now.

-

Combining 3 phase and 1 phase systems?

Lemna gibba replied to Lemna gibba's topic in Photovoltaics (PV)

A big thanks to everyone for their input. I just want to update on our final decision. I came to the conclusion that there was no single right answer. I had several different suggestions that all had benefits. It's impossible to know what the best option was, but I think we have chosen a good one. National Grid got back to us and were happy for us to add the extra solar to single phase as long as we capped export at 4kW. In total we will have 3.2 kW panels on the South roof, 1.5 kW on the East and 1.5 kW on the West. WP also quoted us 1.3k for moving the single phase supply versus 2.8k for installing 3 phase. We've gone for the single phase option. -

I'm not sure this is the best forum section for this question, but I couldn't find a better one. I realise that there are many problems with EPC, but I have a straightforward question. We've started building (only digging the footings at the moment). Our house will be better insulated than the current standard. We don't need an EPC at the moment, but I'm sure at some stage we will. I want to make sure I collect enough evidence of the environmental measures that we install. I can see this information online. Acceptable documentary evidence includes, but is not limited to, official letters, certificates, warranties, guarantees. The assessor must be confident, and able to demonstrate, that any documentation relates to the actual property being assessed and that there is no physical evidence to the contrary. Evidence of intent to install does not qualify as acceptable documentary evidence. What does this actually mean in practice? For example, if we install 150 mm of Celotex in the floor. I could keep the uValue calcs from the Celotex product. I could photograph the product going in. I could ask the builder to save the delivery document. I'm very happy with our builder so far on building, but I would say that paperwork isn't his strong point. Would it be appropriate to ask the BC to sign a document at the end confirming that X, Y and Z insulation has been used? Any advice here would be great. I'd rather collect too much evidence than too little.

-

Help with thermally broken lintel.

Lemna gibba replied to Lemna gibba's topic in RSJs, Lintels & Steelwork

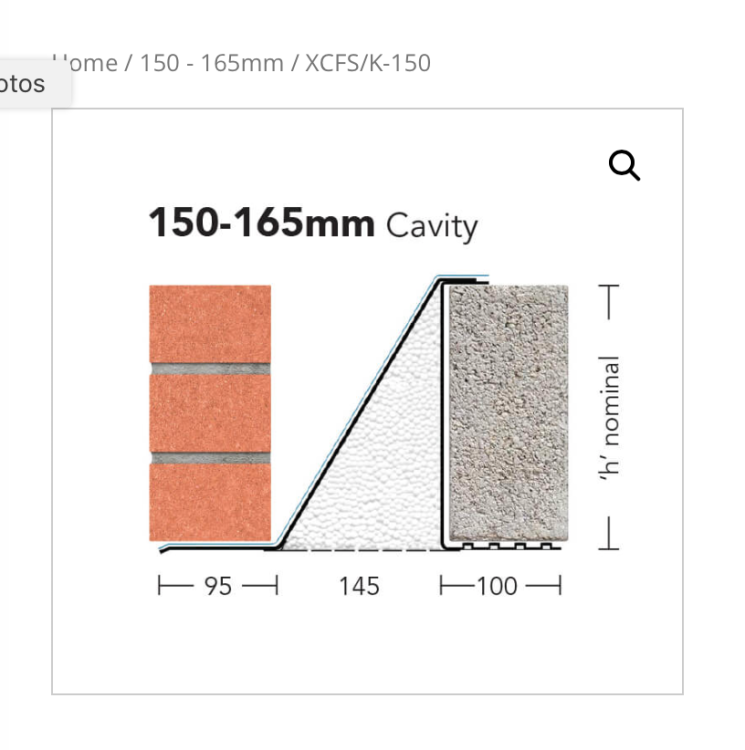

As an update Catnic have a thermally broken lintel but at the cost of 2k from a builders merchant. This seems beyond our price range. Keystone have suggested this beam XCFS/K-150 , but looking at it I can't really see the advantage of it over the UC with a bottom plate that was originally proposed. Birtley don't have thermally broken lintels that would make a 3.8m span. I understand that the detailing around split lintels is complex, but this remains an option. -

Combining 3 phase and 1 phase systems?

Lemna gibba replied to Lemna gibba's topic in Photovoltaics (PV)

@Dillsue and @sharpener Thanks for the comments. I'll let you know as soon as we hear about our request. -

I feel that I'm spamming these forums with different questions, but have really appreciated the advice that I've been given. We are building a single story extension. It will be block and brick with a 150mm cavity. We will have large 3.8m sliding doors. The extended part of the room is about 5.9m wide and extended by about 2.4m. In case it's important it will have a 10 degree roof with a 1.2 x 0.8m roof window. We've got triple glazed sliders with a uValue of 0.8. We are trying to be very efficient with this build. We have specified Celotex Thermoclass cavity wall insulation, good insulation in the roof and lots on the concrete slab. Our SE made the calcs ages ago and specified a 152x152x30 UC with 8mm bottom plate. At the time I didn't realise about cold bridging. We're at the stage where we can address this. The rest of the house is mostly solid brick. As we will wrap EWI around this, I'm not concerned about the beams for that part, but I am thinking that having cold bridging above the expensive sliders may well negate the effect of the very expensive triple glazing. I asked our SE about this. We paid him for the calcs ages ago, so he didn't have to come back on this. He suggested that we reached out to a specialist lintel provider. I reached out to Catnic, and they said the catologue price would be nearly 4k! They specified an extra heavy duty one. I'm going to try Keystone next. But at this rate I think this is going to be too expensive. I understand uvalues well, but am having a problem understanding how much of a difference a thermally broken beam would make. If anyone has any input, either on how worthwhile or the best way to get one specified then I would really appreciate this.

-

Combining 3 phase and 1 phase systems?

Lemna gibba replied to Lemna gibba's topic in Photovoltaics (PV)

@sharpener We need to move the supply anyway. I don't have a price for changing to single phase. But moving the supply and rewiring to 3 phase would be 2.8k (including VAT). I think single phase would be significantly cheaper. Our electricity supply is very illogical. It comes into the East side of our house, goes round the outside of our house at mid height tacked onto the wall and then comes in on the West side with a meter, fuse and consumer unit squeezed above tho door. We would put everything on the east side. If it is just 1ph, then I think they simply need to replace the box on the East and put everything there. 3ph requires coming from the road and us digging the trench. We won't add any more PV (as we don't have space). Heat pump is on the cards in 3-4 years. Our house will hopefully be so efficient by then that a small heat pump would suffice. An EV in the future will be very likely. We have sent the G98 to WP, so we'll see what our options are. I feel that they will insist on 3ph. -

We are designing our kitchen and working out what would be a suitable hood. Our house will have an MHVR system. Therefore, we are looking at recirculating hoods. This will be located above an island and we will have an 80 cm induction hob. All the information that we see regarding sizing of re-circulating hoods doesn't seem to apply for houses with MVHR. The two bits of information that we see are that the physical size of the hood should be wider than the hob. The other is that the capacity of the hood should be 10 times the volume of the room, which in our case would be 750 L/h as we have an open plan area. We think we need to focus on the second rule and the first doesn't match with the hoods we see. Does this seem reasonable? Also we would be very happy if people gave recommendations for hoods that had worked will for them.

-

Hi, I would appreciate some advice. We extending our kitchen with a NNW facing single story extension. We're looking at putting in a skylight, but are very mindful of overheating. We're thinking about future climates. The extension part will be about 5.7x2.4m. In midsummer the window will be in shade between 11.30-4pm but will get sun outside of these times. Our roof will be very low pitch (ca. 12 degrees). Option 1 would be a Velux low pitch roof window 114 cm wide x 118cm with anti heat shutters. This would be uValue of 1.1 but if we shut the shutters at night then this will improve. we can also shut out the sun if it gets too hot. This is around 2k Option 2 would be a Roof Maker style roof. This wouldn't open, but we're fine with this. I feel with the upstand this might not look so stylish, but again we're ok with this. The uvalues are better and we can get solar control glass However, I cannot see any options for blackout shutters outside. There are several options for blinds inside. And of course there are solar coatings. I feel that the inside blinds won't be as good for blocking heat. At the moment this will replace a conservatory which has much more glazing but gets unbearable in summer. I would much rather be conservative regarding overheating. If you were in a similar position would you go for option 1 or 2?

-

Combining 3 phase and 1 phase systems?

Lemna gibba replied to Lemna gibba's topic in Photovoltaics (PV)

Many thanks for all the helpful input. I think I've found the information that Dillsue said on page 81 of this document. Just bookmarking it in case it's useful for others. As it seems like the most economical option for us. https://www.ofgem.gov.uk/sites/default/files/2021-12/Feed-in Tariffs_Guidance for renewable installations_V16.pdf For everyone else. We have been in touch with a super helpful company. They have suggested that in our situation the best thing would be to ask WP for permission for 6 Kw on a single phase. If they agree then that will be our best route forward. I'll update with what WP say -

Combining 3 phase and 1 phase systems?

Lemna gibba replied to Lemna gibba's topic in Photovoltaics (PV)

That's very interesting. I just had a call with a company who were adamant that if we changed the meter to a three phase then we would lose the FiT payments. I'm wondering if they were thinking along the lines that they don't want to be involved with additional complication and paperwork rather than a set up similar to what you propose. The three phase net metering is the next challenge. -

We currently have a 3Kwp system from 2015 on the East and West roofs that we get FITT payments for. As part of our renovation we would like to add a 3KW system to the South roof connected to a battery. Western Power need to move our supply anyway, and are suggesting upgrading to 3 phase at the same time. I don't think we exactly need 3 phase, but later in our renovation we will install an ASHP and at some stage need car charging. This future proofing would be worth while. I can get quotes for and spec out the new system as a 3 phase system. What I don't understand is how this will play with our existing system that is on a single phase. Is it possible to have two systems in the same household with one on 3ph and the other a single phase? Would it be best (and permissible whilst maintaining FITT) to replace the inverter in the existing system with a 3ph one? Alternatively, if we asked for 6KW solar on a single phase what would the chances be that WP would allow this? I will discuss with local suppliers, but would rather go into the conversation with a bit of knowledge. If it was permissible then option 2 looks the most sensible to me. I really appreciate comments. I have tried google but mostly seem to get information about Australia!

-

Thank you both. I think Crispy Wafer's suggestion sounds very good. I have a plan for the whole house UFH, but wanted to have an idea about what was possible. Jilly, we haven't spoke to underfloor. But had a very reasonable UK Underfloor Heating. Really appreciate your input.

-

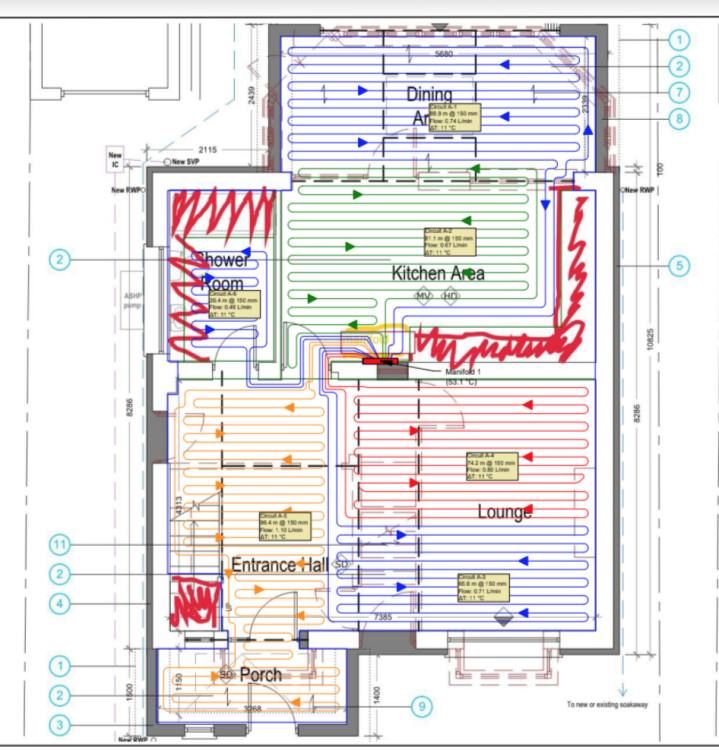

Let me try again. It didn't help that I said "manifold" when I meant port. In the long term we plan to run UFH throughout our house from an ASHP, with a unitower located where the manifold is in the schematic. Our house is currently unsuitable for a heat pump, but we are planning to get it heat-pump ready by concentrating on insulation and airtightness as we renovate our house. Due to costs, we will do our renovation in two phases. The first will be the rear extension (dining area) and kitchen. We will replace the floor as port of this. Insulate with 150mm PIR and run UFH in this area. This should need a manifold with two ports, and by my understanding this can be run from our combi boiler with a two-port valve. In the coming years (3-4) we would then replace the floor in the rest of the house with an insulated slab and run the UFH throughout. We really can't afford this at the moment. At this stage we would need to replace our two-port manifold with a four port manifold, and the whole thing can be run from an ASHP. The problem that concerns me with the above plan, is that we would have to dig out a bit of the screed in front of the kitchen door in a few years, to add the additional UFH pipes for the rest of the house (as per the diagram). My concern is that as additional pipes came to the same manifold then we would need to dig out screed very close to the existing pipes. Perhaps this could be done carefully, and would be slightly easier if we used one of the egg crate mats that would help protect and locate the existing pipes. I'm not sure if I'm over worrying about this. My other thought was that when we do the rest of the house, is it feasible to have two manifolds (one 2-port serving the kitchen area & one 4-port serving the rest of the house). If we can do this, and locate them on different sides of the same wall, then we will not need to dig out the screed in the kitchen. I assume that this is possible, but have no idea if it is sensible? I also might be overworrying about digging out the screed in the area by the kitchen door.

-

OK, this might sound like a silly question, but I hope you don't mind... We are renovating our house. Originally, we planned to replace the entire ground floor with an insulated slab (150mm PIR) with 75mm screed and run UFH throughout the ground floor. Our plans have had to change such that we still plan to do our renovation, but will do it in two parts. We'll do the part marked kitchen and dining this year, and the rest of the house in 3-4 years. We can't do the whole floor now, as our plans involve removing internal walls and the cost just gets too much at the moment. We have a layout below with several loops, but will just do the green and blue loops this year. I can see a couple of possibilities. We could install these loops, and leave the screed in the corner (by the manifold and the door) free of pipes with the idea of digging the screed out in 3-4 years to run the other UFH loops through, when we do the rest of the house. But the more logical idea to me seems to be to install two manifolds in the kitchen now, and to put the other 4 manifolds on the same wall, but on the other side when we do the rest of the house in 3-4 years. Is this possible?

-

Please ignore if this is not helpful. We are also planning to install wood cladding over EWI. I thought page 26 of the linked pdf was useful. They suggest two methods, one similar to the one suggested (unfortunately without details of the fixings) and the other a double layer of insulation within a framework. https://www.robbins.co.uk/wp-content/uploads/2021/02/TTF-Cladding-Handbook.pdf

-

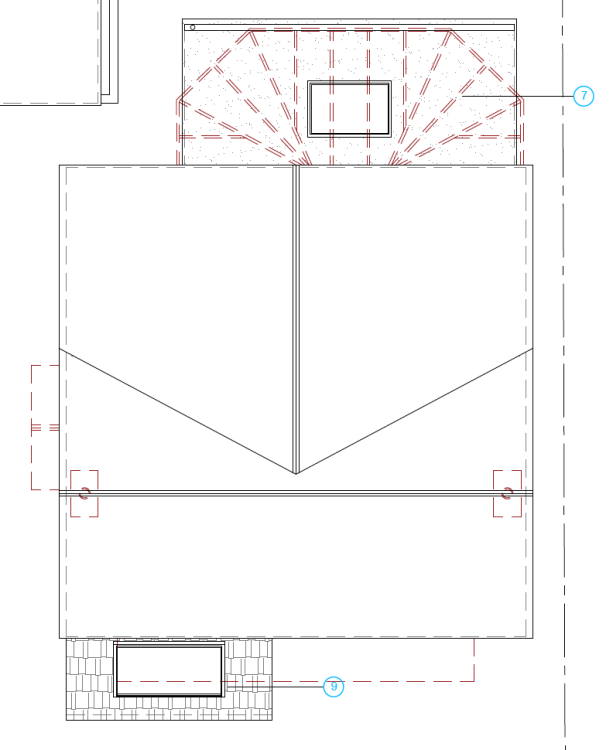

Thank you for your quick replies. I had thought about a warm roof, but assumed that it would be too expensive, partly due to the complex shape below (the porch and rear extension are single story so not included here). However, we do need some work done on the roof. Our ridge needs replacing. We are removing the chimneys and we want to add more solar. We'll have the scaffolding in place. I will start to enquire about the price.

-

We are designing an energy efficient refurbishment to our house to coincide with some internal remodelling. Briefly, half of the house is single brick 1930s, the other half is an 1980s extension. We want to insulate properly and run an ASHP. We completely understand that we need to make big changes to the fabric of our house. For the rest of the house, I think we have a clear idea how to do this. We will replace our conservatory with a SIP built extension. We replace the existing ground floors (suspended timber and uninsulated concrete) with a new insulated slab with 150 mm PIR (happy for comments if more is better) with UFH in screed. We fill the 1980s cavity wall. Currently thinking bonded beads is best. Then we run 100 mm EPS around all of the house (solid and cavity walls). We can change this to Kingspan if it is available - but currently it looks prohibitively expensive. We will replace all the windows with triple glazing. We will make sure we attain a good level of airtightness around the windows, and have would like to use wet plaster throughout. At the moment we have a PIV system. Without this we have condensation issues. We are under no illusions that we will have an airtight house, but are keen on MVHR due to air quality. The last problem is our loft. Currently it's a bit of a nightmare! The house is made up of two gable roofs joined at 90 degrees. The 1930's part is boarded out. This is probably a mistake. Below the boards is probably around 20 cm of fairly compressed rock wool. The loft feels bone dry, but I haven't lifted the boards yet. At the apex it's 130 cm above the boards. We do use the loft for storage. In the 1930's part: There is plasterboard over the rafters (and above the purloins). These are coming off in places. Below the purloins is what looks like paper. This has mostly degraded and falls apart if you touch it. Then there is an airspace, and a fairly modern looking white membrane. I can feel the batons through this and presumably the slates attach to it on the outside. If I go to the edge near the eaves, there is massive gaps in the current insulation. I can see the edge of the brick wall and the ceiling of the room below. It would appear that the ceiling is made of lath and plaster! The 1980s part has exposed rafters that look in good condition and what appears to be look like bitumin roofing felt. The old roof has not been taken down where the two roofs join and I can only get in the 1980s part by some contortion under the purloin. Between the two walls looks like no mans land. It is totally devoid of insulation. Parts of the original wall exist and parts of the original roof join them. I am sure some are structural, and most are trash. Many of the slates are still on the roof. They really didn't tidy up. I have been going round in circles about the best option for to properly insulate and get some degree of airtigthness. Currently, I think the best option will be: remove all internal ceilings. Place airtight vapour control layer under the rafters. We would then leave a service void with batons for electric cables. This can then be re-boarded and skimmed. We would clear as much of the old roof as we can out. Then re-lay and top up mineral wool. We do some very minimal boarding with a significant air gap above the wool so that we can crawl to things we need like the MHVR and the solar inverter. Removing the internal ceilings sounds doable as we would need to fix them anyway after the internal work. The disadvantage of this system would be that the MHVR will be in a cold loft (although we pipes should run under the insulation), and that we are going to have to cut many holes for ventilation pipes through the airtightness barrier. We also lose any real capacity to store things in our loft. I've been toying with insulating between and under rafters and moving the airtightness barrier there. However, the complex shape of the two walls and the difficulty working in the tight space make me think that this could be really hard, expensive and open to errors. I'm sorry to have written such a long post. I'm also aware that a very similar question was asked recently. I have been reading a lot, but not always sure that I am reading the correct things and making the correct connections. I'm very motivated to get as energy efficient house as I can, but have no real experience of the practical aspects. We are at the planning/costing stage with the aim of starting work in the summer. We've started talking to contractors, and this last part is bothering me, as it seems like the loft is going to be the main source of air leakage into our house. If you read this far, thanks for taking the time!

-

Thanks for the comments. I'll engage with the SE who made the original calcs. I have contacted him directly, as the previous calc went through the architect. I will ask about the floor and also about the EWI in relation to floor level. I can see plans of how to insulate below ground here https://retrofit.support/detail/21/ It looks like they use XPS for the part close to the ground. But they mix with other insulation parts higher. Hopefully the SE can advise if this will be compatible with the floor.

-

We're struggling with the final stages of our renovation project. Our architect has been interminably slow, not explained the process to us and in our opinion failed to engage with parts of the design. For the last part, I'm not sure if I am being unreasonable. Briefly, we have a house built in the 1930s and extended in the 80s. We are altering the internal layout, building a front porch and replacing a rear conservatory with a single story extension, as well as improving the energy performance of the property. We want to run UFH throughout the ground floor, and proposed to our architect that we would replace both the uninsulated 80's slab and the 30's suspended timber floor with a concrete floor with an insulated concrete slab with 150 mm PIR that we can place the UFH and screed on. We spoke to a builder about the approximate price, and were ok with the price. Our architect has now drawn plans for building control and ignored this request and put the insulation on the existing slab. We have queried this, and he says that the scope of the floor lies with the client/contractor/approved inspector and building control. He suggests that I should raise an invoice with a structural engineer over the floor design. It seems that they are keen to submit the plans to BC without including our preferred floor layout. I'm a little bamboozled by this process. I do not think it's productive to send documents to BC that differ from what we plan to build. I'm happy to engage with a SE if it is necessary, but the builder didn't think that this would require this. We also will have EWI fitted. I would like to propose that this is installed down to footings with a french drain, and that some details of how it joins the eaves and the flat single story roofs is important. Our architect suggests that we reach out to a specialist to determine the material, method of fixing the EWI and how it joins the existing structures. I'm happy to do this, but I had naively thought that the architect would help with this. Our architect gives the impression that he wants to push this through building control and out to tender when presumably he washes his hands of it. I think it's important to get the build specification right before we submit it to building control. Am I being unreasonable on this? At the moment we have plans that don't have any of the downpipes marked, and have a roof joining a bay window the porch that we have absolutely no idea what it's made of. I can't see this information anywhere on the specifications, but our architect assures us that there is sufficient information for the contractor.