Question

Members-

Posts

109 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Question's Achievements

Regular Member (4/5)

13

Reputation

-

Our plumber has put a tundish (not a dry trap one) next to our unvented cylinder, and it is connected to the waste pipe and we get a smell from the stack (there being no trap). Our plumber says that the tundish cannnot be replaced by a dry trap one designed for unvented water tanks and boilers (Hotun Hilfi). There are two tundishes and it is not the one close to the T&P relief Valve on the cylinder. Is there a reason why he cannot put a dry trap tundish ?

-

Mounting frame of recessed light gone in ceiling - can't get down

Question replied to Question's topic in Decorating

Hi all, I got the light down. I used a zip tie to tie the springs back. I did one spring and tied it, and then the other and tied that. It took a little while and was fiddly. Thanks for all your suggestions and advice. -

Mounting frame of recessed light gone in ceiling - can't get down

Question replied to Question's topic in Decorating

Thanks for your reply. Seems like a good idea. I tried googling and can't find out what zippy-strip is. What is it? -

Mounting frame of recessed light gone in ceiling - can't get down

Question replied to Question's topic in Decorating

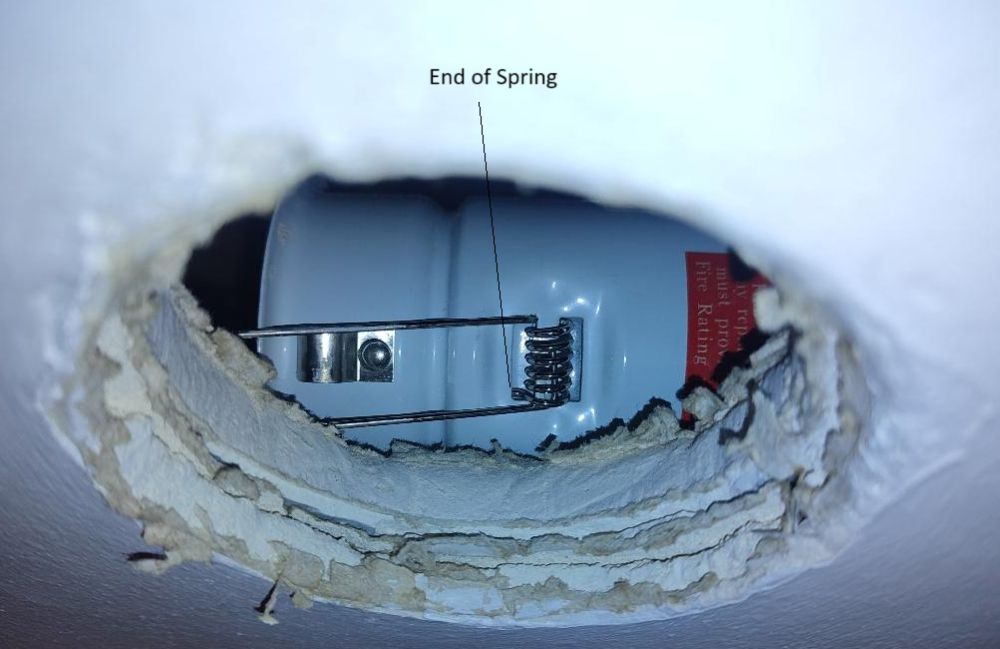

Thanks for your reply. I have taken a photo of the spring and the coil is wound around a metal centre which is integrated to the metal mounting frame - see photo. I can't remove the spring using a screwsdriver. I think the only possibility is to try to dislodge what I refer to as the "end of spring" in the photo thereby loosening the spring, pull down the light fitting, and then try to put the "end of the spring" back under the metal sleeve. I would be grateful for your thoughts. -

Mounting frame of recessed light gone in ceiling - can't get down

Question replied to Question's topic in Decorating

Thanks for the reply. The spring is strong and I can't take it off. I am running out of ideas. I don't want to make a bigger hole and then it is replaster the whole ceiling. -

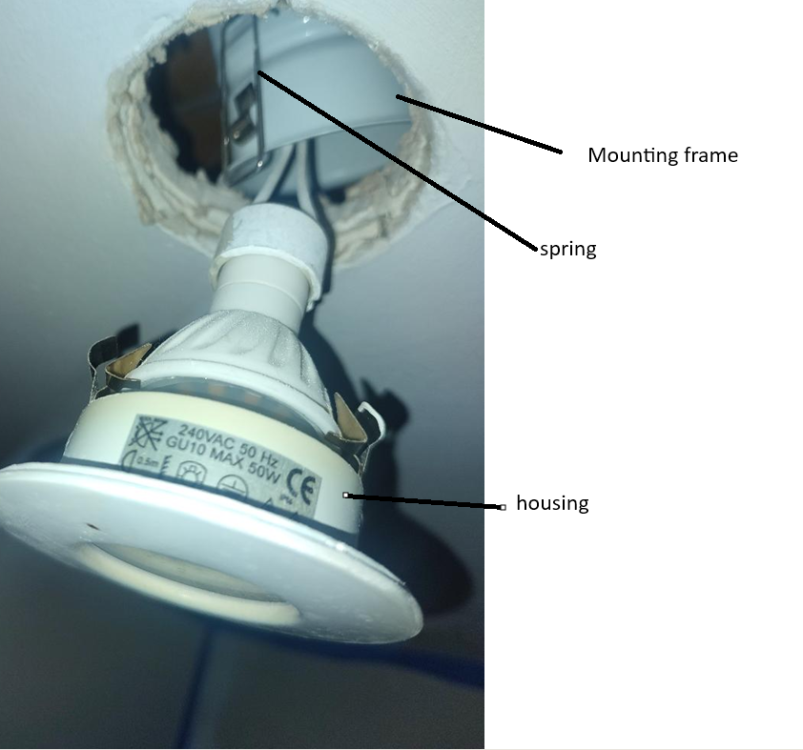

We were attempting to paint the ceiling of our utility room, and decided to remove the housing of the recessed lights. See picture with annotations for housing and mounting frame. Unfortunately, when I pulled the housing of one the lights, its mounting frame went above the ceiling as the hole in the ceiling is a bit wider than the width of the mounting frame (but not of the housing). My plan was to: (1) to get the mounting frame down and (2) put the housing back in the mounting frame which fits tightly and (3) put the whole light fitting back in the ceiling - the width of the housing is wider than that of the hole in the ceiling (and is wider than that of the mounting frame.) I am stuck at step 1. I can't get the mounting frame down, and the two springs (one shown in the picture) make it very difficult. (The springs are designed to ensure the light fitting is held in the ceiling and usually lie at 90 degrees to the mounting frame on top of the ceiling). Do you have any advice?

-

Clearance for a standalone washing machine

Question replied to Question's topic in Kitchen & Household Appliances

Thanks. -

Clearance for a standalone washing machine

Question replied to Question's topic in Kitchen & Household Appliances

Thanks, where do you get these white things from? -

Clearance for a standalone washing machine

Question replied to Question's topic in Kitchen & Household Appliances

2 or 3mm. thanks for your reply How do you get it out? -

Clearance for a standalone washing machine

Question posted a topic in Kitchen & Household Appliances

I am concerned that there won't be enough clearance for a standalone washing maching in a (nearly finished) refurbished utility room. Tthe builder had created a space for a standalone washing machine. On one side is a Howden's unit and on the other is a 18mm chipboard panel. The clearance on each side is a 2/3 mm and from the top of the washing machine to the new worktop it will be 10mm or less. We looked at the intructions and it says the minimum clearance for stable operation: side 25mm, top 25mm, which is larger. The builder will try to reduce the height of washing machine , or possibly make the worktop higher, but that does not address the sides. The builder has said that this has never been an issue before and he has been in the business a long time. That seems to be inconsistent with the instructions. My concerns are: - not being able to pull out the machine, - a lot of shaking of the worktop, howdens unit and the panel, which could mean they fall apart in the longer term. Washing machine vibrate a lot. We are near completion with new floor currently being laid and the worktop being installed end of this week. Are these legitimate concerns? -

most radiators get hot first at the lockshield valve

Question replied to Question's topic in Central Heating (Radiators)

Thank you. When I google images of lockshields, most don't have any arrows on them whereas TRV images do arrows. I also see a pair of valves that can be bought together, one TRV and the other lockshield, and it is only the TRV body that has arrows. Have you come across lockshields that are only good in one direction? -

most radiators get hot first at the lockshield valve

Question replied to Question's topic in Central Heating (Radiators)

Are you saying that I should look at the lockshields at the other side of the radiator to where the TRVs are? I had a look at them and there are no arrows on any of them. -

most radiators get hot first at the lockshield valve

Question replied to Question's topic in Central Heating (Radiators)

Now down to 1 radiator that does not have any markings on it and so I don't know whether it is bi-directional. all others are bi-directional. So can I forget about it. Water circulates fine through the Hot Water Coil. -

most radiators get hot first at the lockshield valve

Question replied to Question's topic in Central Heating (Radiators)

10 radiators are bi-directional, another Danfoss where the direction selector was put in the wrong direction (by the engineer I have already mentioned), and the two other radiators have no markings whatsoever. Any advice please.