Search the Community

Showing results for tags 'tun dish'.

-

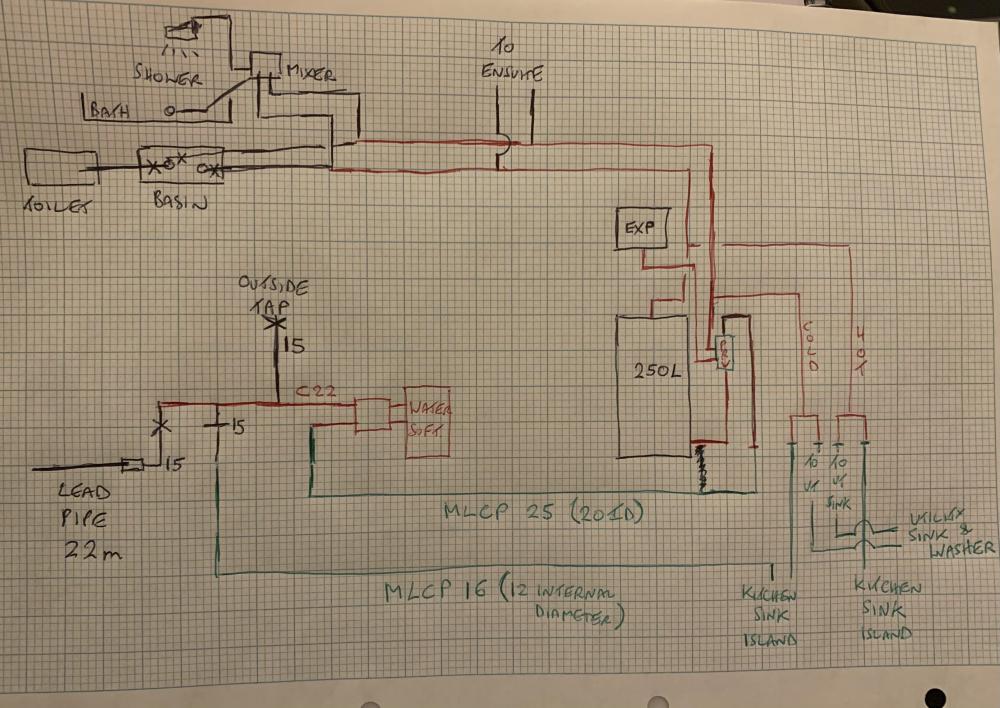

Old gravity fed water system has been removed and a new mains pressured UVC system has been installed by the builders plumber. ATAG Gas Boiler, 250L Gledhill Stainless ES Cylinder plus expansion tank. Mains supply currently via lead pipe connected to 15mm copper. Static mains pressure about 3.5Bar at outside tap connected directly to mains via 15mm copper/plastic. Flow rate from tap 20l/m. System has 3bar PRV fitted. Cylinder has 4.5Bar/95C over pressure/temp relief valve. System is fitted on ground floor. Questions/Issues 1/ Should there be a Tundish fitted as there is currently none. The overp/t relief valve has nothing connected to it at all and would discharge onto the floor ?! 2/we wanted to be able to run 2 showers simultaneously and still flush a toilet/use kitchen tap. Currently B/room shower gives static pressure of 2.8Bar and flow rate of 10l/m (hose only) or just 6.6l/m(from shower head/flow destructor removed). Noticeably weaker than old gravity system with 3bar(2.5bar at 9l/m) monsoon pump. If another tap is fully opened upstairs, shower static pressure drops to 1.4bar. Shower flow drops to 5.5l(hose only), 4.6l/m(through shower head). Hardly likely to support 2 decent showers at once. So what pipework should the plumber have installed ? Is the problem the pipe bores used, the pipe bends and Tees, the cylinder plumbing, the pipe lengths ? Very concerned now that plumber hasn’t installed adequately and not fit for 20 year use. How to know what exactly is wrong and how to fix it ? PS Current Pipes in sequence… 20m lead into property 15mm copper stop tap 22mm copper to water softener (not yet fitted bypass valve operating) 25mm MLC pipe to cylinder/boiler area 22mm copper to PRV, cylinder, and 22mm copper hot and cold to first floor landing. Then 15mm copper feeds from the 22mm pipe to upstairs taps and showers. 15mm Tee, 3 or 4 15mm right angles to shower mixer.