bluebirdnick

Members-

Posts

24 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

bluebirdnick's Achievements

Member (3/5)

4

Reputation

-

Apologies for dragging up an old thread but I agree with this completely and indeed it is what I did above the old ceilings I was working with. But I've just seen a product call Ring Leader which looks like a neat and easy way to deal with this problem too (hence me dragging this up again). I still have one or two plenums to fit, and I'll be using these for it. On the subject of BCO: they send a different person along each time. The last guy didn't even comment on the MVHR; the one before that said he wanted to see the unit running but didn't have any concerns beyond that.

-

Thanks all. I have the Domus plenums too: I bought both types to see what the difference was, and in some cases I need the duct part to be over 300mm. I'd like one of those cowls - the mess these holes make is phenominal, in particular as I've boarded over old lath and plaster ceilings. But now I have a 133mm hole saw I'm not sure how I'd use the two together. I'll have a play.

-

Thanks Jenni. I'm beginning to think I'd not looked hard enough for a hole cutter between 127mm and 152mm! I've got a 133mm starrett cutter arriving today and I think I'd still be happier with allowing the plastic plenum to poke through the ceiling and be cut so I suspect I'll use that and see how I go. It will take me weeks to get it done from here, I had a week at home last month to get things finished but for various reasons I was unable to do much. So now I'm left trying to fit it in on weekends and with a toddler and a newborn it is going to be a challenge!

-

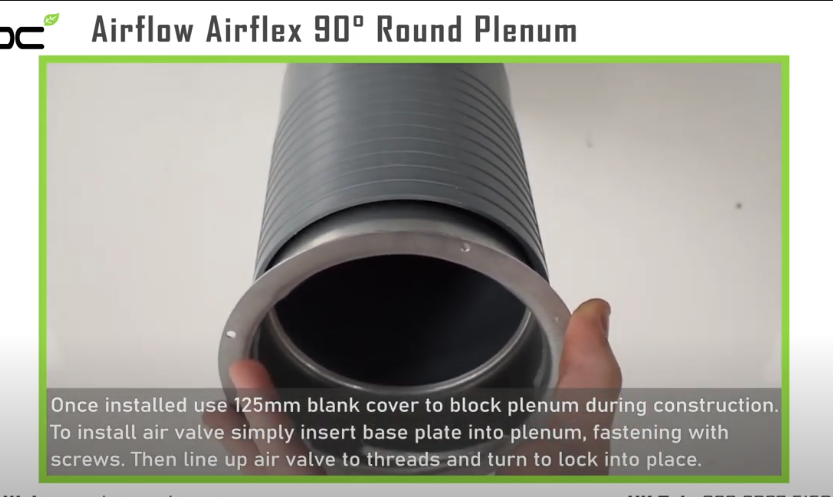

Airflow grey plastic ones, which have about 300mm of plastic duct as part of the unit. The video shows that the plastic duct sticking through the ceiling and then being cut so that the bottom of the plastic part of the duct is flush with the room side of the ceiling. So the hole needs to accommodate the outer diameter of the plastic part of the duct. However it does make me wonder if I'm doing this right. The room valves have a metal base plate that is inserted into the plastic duct and secured to the ceiling. It is quite large, but its outside diameter is clearly 125mm as it sits tightly inside the 125mm duct. Like this: So I wonder if actually I cut the plenum so that the 125mm plastic duct sits on top of teh ceilign rather than coming through it, and then poke the metal base plate up through the ceiling and into the grey duct that sits above it. I've got quite thick ceilings - probably about 40-50mm now - but the base plate is quite large and could span that gap.

-

Thanks. For £8 it's worth a go. I've found a 133mm one for £18 too so will get them both and see. I need to drill two holes in brick too. I was expecting that a 127mm diamond core bit would do it (and my builder has a 127mm bit), but clearly it won't. So I'll need to find one that does, and a drill large enough to do the job.

-

I'm curious as to how everyone else has cut holes in ceilings for their plenums. 125mm seems to be the standard internal diameter for these things, but the external diameter is wider than a 127mm hole saw. The next standard size up is 152mm which would be far too big. I've only installed one, using an adjustable hole cutter but it is fair to say that this is less than ideal as it leaves a pretty rough finish and isn't particularly accurate - fitting the metal collar became an issue as I had no ceiling to take a screw. So what has everyone else been doing? Is there some standard hole saw out there that I've simply not found? Starrett make one at 133mm which might be about the right size - has anyone used and can confirm? It's £50+ so not a cheap bit of kit. Or are people cutting them freehand with a plasterboard saw? The adjustable hole cutter just about did the job but I want to avoid using it if possible.

-

My choice was budget driven. I live in what is now quite a large 1930s house which we will likely extend again at which point we are going to be 220 sq m at least, so need a unit that can ultimately handle that. On the other hand - it is still a 1930s house, so I don't kid myself that I'm going to get brilliant heat recovery performance. So I need a big unit, but not a brilliant one. I like a bit of science and I am big into energy efficiency, so I am openly doing this in part to satisfy my own curiosity. I'll be the first to admit that I am doing this in part as a hobby, just to prove to myself that I can. If we can get stale air out of the house and make it a more pleasant place to be, I will be happy. If the energy bill is materially the same before and after, I won't be disappointed. BPC pushed the one you are looking at and I am sure it is superior, but they couldn't explain how or why, other than it being newer. So with all that in mind, a unit for under £800 that can cater for the house we are (slowly) renovating/extending was the obvious choice. I've not got it running yet so I cannot comment on its pros and cons, but I will say this: it is absolutely massive. Smaller than a washing machine, but not much. Fortunately it is very easy to strip down into its components, which is vital: it was too big to get into the loft in one piece but took 20-30 mins to dismantle and move. As regards installing the plenums: this is a first fix job, it would have been infinitely easier to do it when we were renovating the house (remember - mine is a renovation not a new build). We over-boarded the old lath and plaster ceilings throughout, because I like the sound insulation properties of the old ceilings and frankly it is cleaner to over-board them than tear them down. Also they had wallpaper or lining paper on them- in the last house we stripped it off so they could skim the original ceilings, but it is a truly miserable job and we vowed never to do that again. And we did the renovation 2 years before I'd even heard of domestic air ventilation systems. However if I'd always have intended to install the MVHR at the point we reovated, I'd still have cut the holes and installed plenums after having the ceilings skimmed because my plasterer doesnt like plastering ceilings with cut outs. But if I would certainly do it long before you have any finishing work done. If your ceilings are coming down then I don't imagine the mess created by cutting a hole with a 130mm diameter in new plasterboard is going to cause you much of a concern to be honest though. btw, the plenum itself can easily be cut to length with a hand saw or a mitre saw: just mark it; remove it and cut it. I'd find that cleaner and easier than using a multi-tool, but each installation will differ I am sure and there will be good reasons for using a multi-tool in other cases. A hand saw is also better at cutting the semi-rigid ducting than using a stanley knife, in my opinion. On loft height: your unit may be smaller than mine and the ability to duct out of the side may well mean that 0.8m is enough - but it does sound very tight, especially as you are actually going to need some space to work in. Just ask BPC- they should be able to tell you if it is practically possible.

-

Hello! Sorry for the delay in replying. It is going very very slowly. I installed the semi rigid radial ducts some time ago, in May I think. And I got the unit into the loft about 2 months ago (unconnected). But I've made precious little progress since for a variety of reasons. But this week I finally went back up into the loft. I installed my first plenum today, and as with all things relating to this project it turned out to be far harder than anticipated. The plenum is a 125mm internal diameter and 127mm is a standard size for a hole saw so I got one assuming it was designed for 125mm pipes... but it's not big enough. The next size up which is generally available is 150mm+ which would be far too big. So in the end I bought a cheap adjustable hole cutter which did cut a hole, but it is far from perfect and is perhaps 5mm wider in diameter than it needed to be. But then fixing the plenum itself; and the collar that sits between the valve and the plenum, have proven to be real challenges. I am actually quite enjoying these challenges now that I've missed my deadline wildly, and am taking my own sweet time over things. (by way of example - I need to move the unit about 5m across the loft, but there is no boarding between where the unit sat, and where I needed it to be. Rather than stripping it down and carrying it carefully over the joists which would have taken 30 mins, I instead bought 10 sheets of OSB; a pile of 100x47 timbers; and a few rolls of top-up insulation and cross-battened the loft space, topped up the insulation and boarded it over to give me a platform across which I could safely and easily move the unit. But this fix took an entire day). In answer to your questions: Paired runs: yes, to most of them. All of the wet rooms; the downstairs living room; and three of the bedrooms. My unit is in the loft, but I have the advantage of more than 3m of headroom and a cavernous loft to work in. Obviously it will depend on the size of your unit etc, but there is no way I could get mine in something under 0,8m. It needs some space underneath for condensate to drain away, and the 160mm ducting that my unit takes is bulky stuff which as you say increases the headroom needed. I'll try to share some photos soon to show you it part-installed so you can see what sort of headroom I eneded up with. My guess is that my unit would need about double the headroom you are working with. Above a bedroom: I'll give you my thoughts when I finally turn it on! The general wisdom is to avoid having them above bedrooms but if you don't have any viable alternatives then I'm not sure I'd fret about it for too long. I will be putting mine over the bathroom. I intended to house it in an insulated box, suspended from the rafters with steel wire. I am sure that this is total overkill and I've decided to see how it sounds just sat on a vibration matt on the loft floor first before doing the suspended insulated box thing.... although I do still want to do that just because it is cool. Split my order: yes and I am pleased I did. Nothing against BPC, but ordering did turn into an ordeal with them and they inexplicably dropped items off the order at random points, and didn't seem to have answers for many of my questions. The ducting place I used for part of the order has been really good -they manufactured some bespoke parts for me at a decent enough price and they seem really knowledgable which was a big help. Although BPC do sell anti bacterial anti static ducting , and I am not sure you would get it materially cheaper elsewhere, so not sure that is a good reason to split it. I wanted to split it primarily because BPC don't stock 160mm rigid ducting and my unit takes that - I didnt want to compromise and step down to 150mm.

-

downlights and flower pots

bluebirdnick replied to bluebirdnick's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks all. The former. But the downlights are already installed. I am personally not a fan of them because as you suggest, they are a bit rubbish at providing even lighting in a room, but my wife likes them and it wasn't something I felt so strongly about. Thanks - I assume you mean for sealing up the hole in the pots? I actually have a can or two of this left over from a previous sound insulation project. I do actually have that above the new en suite, but not in all rooms. I've not got two layers of plasterboard though, and it would be near-impossible to fit it from above now. So it seems that flower pots (or plasterboard cubes) would do the trick. For those that fitted them - what size did you use? thanks -

As I said in my other thread, I am retrofitting MVHR in my 1930s house. We have done quite a bit to improve the airtightness, mostly as a happy side-effect of the other work we have done, but I am now looking at what I can do specifically to improve airtightness. I know this is possibly a futile project given the age of the house and the construction methods used, but I still want to do as best I can with it. One of the big issues is that we currently have a cold loft. This will change next year when we extend into it, but for now it is a cold loft. All ceilings beneath have been boarded over and re-skimmed, and a vapour barrier installed on the cold side. Which is all very good, but then we go punching holes in it to fit downlights - about 25 in total. What can I do to mitigate the impact that these have on airtightness? The electrician has used fire rated units that take LEDs so tells me I need no "caps" above them in the loft space to shield them from the thermal insulation above, but presumably I can/should do so? You can buy plastic loft caps that look like they would be airtight, but they are very expensive for what looks like a very basic product. Would a basic upturned terracotta flower pot do the trick? And if so, presumably I would have to cover the hole in the bottom? I'd probably seal around the bottom of it too, just to make sure. I can't see why this shouldn't work, but have a nagging concern about moisture in the wet rooms getting trapped in the flower pot and condensing on the light. And what to I put above the smaller holes made by ceiling roses and other light fittings? And cables from switches etc where they come up from below? I'll be changing the loft hatch too (We need a new one anyway). Any thoughts welcome! Thanks.

-

As with all things, it depends! But if you are having radial ducting, then yes most people seem to go for 75mm semi rigid ducting, which runs from the distribution boxes to the rooms. The 75mm is the external measurement i.e. yes you need at least an opening with a diameter of at least 75mm. You can also get semi rigid ducting in 90mm; and there are a range of rigid ducting options with all sorts of sizes too. Airflow also make oval ducting that is shallower and meant to fit more easily between joists (I think). You can switch between oval and round too - they make connectors for that. That might save you a tiny bit of ceiling space. As regards other sizes: yes, you have a different size duct that runs between the MVHR unit and the distribution boxes; and the MVHR unit and the fresh air outside. In my case, the MVHR unit takes 160mm ducting so I'll have 160mm rigid metal ducting running from the outside to the unit; and the unit to the distribution box. You are not obliged to stick to the spigot size on your unit as you can get reducers - e.g. I could have reduced down to 150mm. For the avoidance of doubt, when I say "plenum" in my posts, I mean the bit of kit that sits beween the 75mm radial duct, and the valve in each room. Generally the plenums are set up for 125mm valves, but again - that is not a necessity and you can get room valves in other sizes too. As regards soffits: I would ask the builder where he thinks is best, as well as whomever is designing your system. It's not just the ducting itself you need to fit in, but the insulation around it too. Soffits are the only acceptable choice for me, but your roof design may make it easier/harder/impossible for you. You might want to consider maintenance from the outside too. Our house has two walls that are basically inaccessible without a scaffold so I wanted to avoid putting vents etc on those. Good luck with it!

-

In short: no. We were (still are!) doing a 2 storey side extension and the joists in that are 200mm, but I didn't touch any of the joists in the existing building. We have a dropped celing in the new en suite - dropped about 250mm; and a false wall hiding a service void of about 300mm in the en suite. I use this to get most of the ducting to the downstairs. There is then another dropped ceiling in the side extension which makes getting ducting to most of the rooms simple enough. On the other side of the house, I am going to run a duct down through a built-in wardrobe in one of the bedrooms to feed the living room beneath. The decision to drop ceilings and make service voids was unconnected to the MVHR, but it did make it much easier. The existing house was extensively renovated about 2 years ago so I want to minimise tearing it apart. Even with the luxury of extensive service voids, it is still a tricky retrofit project and I am beginning to think that the loft was the wrong location for the unit. My new issue is intake/exuaust to the outside. I have a hipped roof and I really don't want ugly metal chimneys poking through the roof (which we replaced in 2016). So that leaves the soffits, and mine are really shallow, at about 120mm. I have asked a local company to fabricate a round-to-square connector and radius bend that I can fit between the rafters - they will come back to me next week to tell me if it is possible.

-

Here is the link. I could only find this by using the search tool - I couldn't find it from their menu system. Same goes for the small plastic clips that hold semi-rigid ducting - once you know they sell them you can search for them but they don't seem to include them in the spec, and its not obvious where they sit in the menu system. https://www.bpcventilation.com/foam-flow-control-damper Plenty of advice on on how to install them too. Someone above has suggested (I think!) that these create noise if installed at the valve end, but not at the manifold end. Presumably you use a 125mm insert at the plenum end and shove it in the plastic pipe that pokes through the ceiling; and a 125/150/160/200 one and shove it in the metal/plastic rigid ducting that feeds the distribution box if you are doing it at the manifold end. I've decided not to order them and see how I get on for now - after all, I've got semi-rigid attenuation; drum silencers; an insulated distribution box and valves with dampers included! If that lot doesn't do the trick I'm not sure how much of an impact the foam insert will have, so I am leaving it for now and will use as a last resort if neccessary.