carlosdeanos

Members-

Posts

46 -

Joined

-

Last visited

Everything posted by carlosdeanos

-

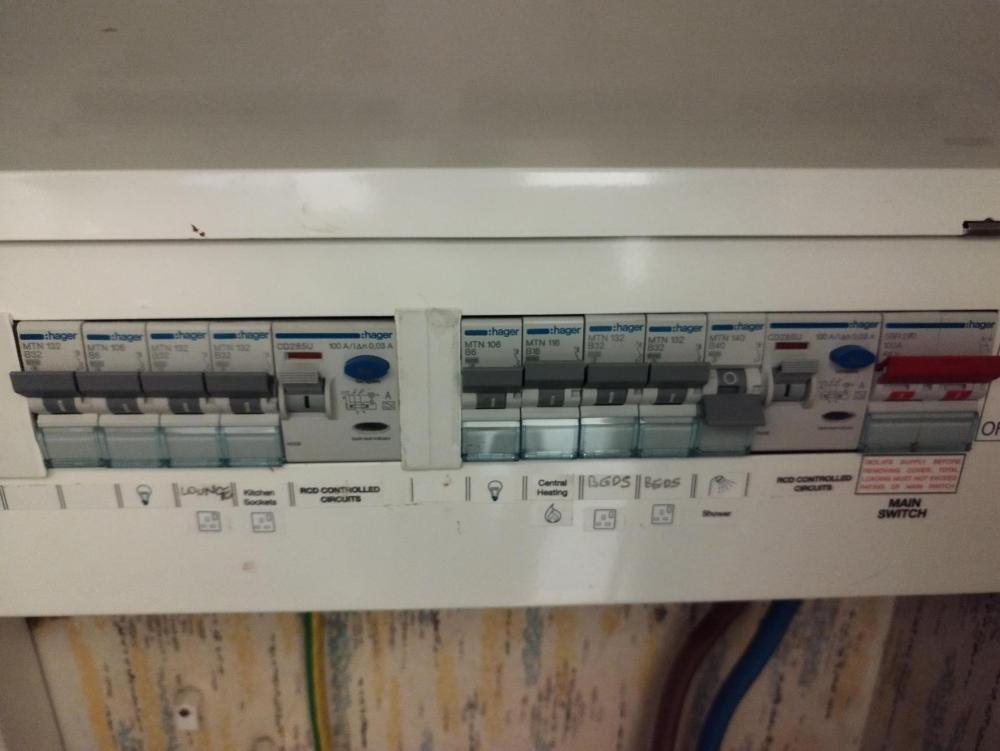

Hello, I have an EV charger going in. Image of consumer unit attached. Would i just need a 32a MCB in the very left hand spare way on the unit? Charger is a BG Sync with built in RCD - I think. I am just concerned about it being with the RCD in the panel. Also, possible surge protection not present. The guides i have watched seem to install a separate box. Yes this will be completed by a qualified electrician but i am just checking his advice as it seems a bit odd to me. If the single MCB addition will work, that will be great. Thanks very much.

-

Is there a good alternative to Plywood for subfloor?

carlosdeanos replied to carlosdeanos's topic in Floor Structures

Thanks all, look like about £300 for the ply so will have to go with that I think. -

Is there a good alternative to Plywood for subfloor?

carlosdeanos posted a topic in Floor Structures

I have floor joists and have put insulation board between them. I am then using pre grooved floor grade 22mm chipboards which I put the pipes in for my underfloor heating. They ask for a 6-9mm ply to be placed over the top before the final finish. At the moment the final finish will be a vinyl tile or laminate. I am just off to the building materials supplier and realised the price of ply may be really quite expensive. Can I use anything cheaper without causing issues? Cheers. -

How can I join a concrete slab to a suspended floor?

carlosdeanos replied to carlosdeanos's topic in Floor Structures

Thats a good shout. I think it will need damp proofing but i guess thats just a DPM layer then. I will have a look - thanks. -

How can I join a concrete slab to a suspended floor?

carlosdeanos replied to carlosdeanos's topic in Floor Structures

Seems to be concrete there. -

How can I join a concrete slab to a suspended floor?

carlosdeanos replied to carlosdeanos's topic in Floor Structures

@TonyT I guess so? Thing is the extension runs across two rooms, the lounge and the kitchen. Would i need to get more concrete to do that? You can probably tell this is just me completing the work. Thanks. -

How can I join a concrete slab to a suspended floor?

carlosdeanos posted a topic in Floor Structures

Hello, I have a concrete slab floor in an extension. Top layer is concrete, so the insulation is underneath. Original plan was to screed and put heating pipes in to bring the floor up to existing floor height. Now, I have left about 100mm to get the concrete up to existing, more than i hoped. Building control have also told me screed is a tough one to DIY. I asked if i could run joists on the concrete (as its damp proof) then board over, (I would insulate between and put my pipes in there) but they didnt like the idea. They suggested i use poly floor sheets to bring it up, then undefloor heating board (With the pipe runs built in) to match existing floor boards height . Do you think this is the best soution or does anyone have any other ideas? Thanks very much. Picture to help - -

Electrical Circuits Required for Kitchen

carlosdeanos replied to carlosdeanos's topic in Electrics - Kitchen & Bathroom

What spec would I need that to be in terms of cable? Thanks. -

Electrical Circuits Required for Kitchen

carlosdeanos replied to carlosdeanos's topic in Electrics - Kitchen & Bathroom

@ProDave that's brilliant thanks a lot. -

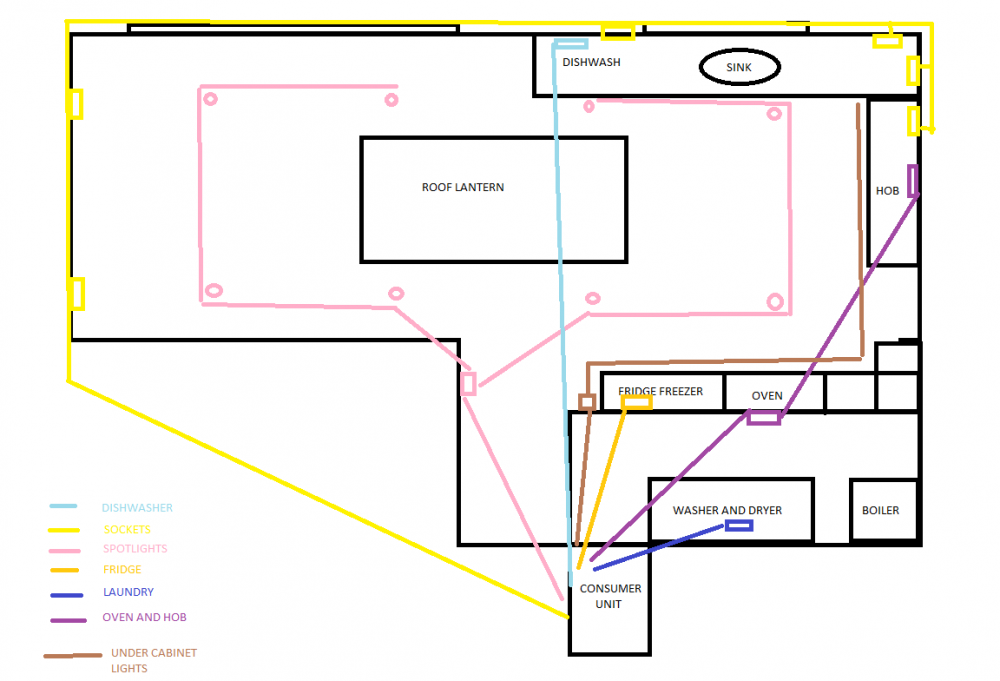

Hello, I am running in the electrics for a kitchen in an extension. I will then have a professional wire it up to the consumer unit and test. I was hoping someone could tell me what type of circuits I need to use in terms of Ring or Radial? I'm also a bit unsure on the cable thickness and amps. Image below with the following circuits I think I need and my 'guess' on what I need. I did just take a look in the existing consumer unit which was installed last year and I only appear to have 4 spaces left. I guess I will cross that bridge later. Dishwasher - 20A Radial 4mm t+e Sockets - 20A Radial 4mm t+e Spotlights - 6A lighting 1mm t+e Fridge - 15A 1.5mm t+e Laundry/Washer - 20A Radial 4mm t+e Oven and Hob - 32A Ring 10mm t+e Under cabinet lights - 6A 1mm t+e Thanks very much.

-

Single storey extension. Onto a bungalow, so sloping down to the flat roof on one side. At the moment i have the flat roof joists in place with an overhang, and 1 layer of OSB. Covered in plastic waiting for me to decide what to do next. I have no idea what to go for. I am looking at an EDPM finish to all these. May be worth noting the firings are running back to front as i was originally going for option 1. Options - 1. Cold roof. Probably the easiest to complete from this stage from what i can tell. Also the cheapest. CONS - I’m not too keen on a facia to finish. I think the other options would look nicer. 2. Warm roof - keep the drainage running back to front, still needs facia and guttering. 3. Warm Roof 2.0 - I think this one is called a parapet. Cut the overhang back and build up the outer leaf. Warm roof, then somehow run a drainage gulley to one side. By far the hardest and most expensive option for me. I am not a builder but i have got this far. What would you do? If there are options for nicer looking facia and guttering I would go for option 1 or 2 but I’m struggling to find anything.

-

Do i need structural calcs for a roof lantern?

carlosdeanos replied to carlosdeanos's topic in Flat Roofs

@MJNewton Great so I should be okay then really as I think mine is about 160kg. -

Do i need structural calcs for a roof lantern?

carlosdeanos replied to carlosdeanos's topic in Flat Roofs

Thanks both. @nod is that a warm roof? -

Hello, hoping I am in the right forum. I am putting a flat roof on an extension. Span is 3.7m at 400mm centres. I'm using 47x170 c24 timbers which I believe are over what I need based on span tables I have found. However I want to add a roof lantern that is 160kg. I was just going to double up the timbers around the lantern. I'm struggling to work out if it will support the load. I keep looking at the kN/m2 but I have no idea what weight it translates to. Any advise appreciated. I think I'm just asking if the joists will be okay? Cheers.

-

How long can I leave scratch coat on?

carlosdeanos replied to carlosdeanos's topic in Plastering & Rendering

@Declan52 Thanks. I have actually just stumbled upon something called Weber OCR and am toying with that now as well. Cheers though. -

Hi all, just about to render my extension. Dense aggregate blockwork. I think I will be going for Sand/Cement/Lime type render. If I get the base coat down and scratch it, can it be left for a few weeks before the top coat? Thanks.

-

@Russell griffiths that's great thanks. I have been being nosey looking at pictures of other places in my road and noticed some have the boxed in part and some don't - I couldn't work it out! So yea it would defo be worth it to have the ceiling run flush I think - but as you say I can see its quite a bit more tricky. Thank you.

-

From my endless posts you can probably see I'm asking for advice at every step - I have exposed the rafters on my bungalow extension and taken the tiles back - Picture 1. Under there is the current internal wall with the wall plate and rafters attached - Picture 2. Picture 3 is my very crude calcs provided by an engineer. So, what next, and where on earth does the beam go? My thoughts were to put across up to support the roof, cut rafters back and install steel on the internal wall (I am getting help on the physical install). Is that right? Or can it sit on the current outside wall that is lower? Thanks all.

-

@PeterW thanks I will take the fluffy stuff out then. Yea the cement board came up on a survey as asbestos cement when I bought the place so I'm taking the precautions removing it. Unfortunately I did drill a hole in one side of the soffit without realising so hopefully I will be okay! Cheers.

-

I think the soffit is asbestos. I am just taking it down, but is this fluffy type material also? It seems a lot like cotton. Thanks,

-

Can I attach joists to the top of a steel beam?

carlosdeanos replied to carlosdeanos's topic in RSJs, Lintels & Steelwork

@PeterW So I think it would need to be sat on top to get the height. By wall plate, is that timber attached to the top of the steel? Like the plate I am fitting to the new outer wall to attach to? -

Got to the steel installation part of my DIY extension (single storey to Bungalow). I am cutting back the eaves to the existing wall which is what I have built my new walls up to match. Turns out the external walls way lower than the internal ceiling height. My plan (from YouTube vids) was that I would prop the roof and drop the eaves into the internal side of the new beam, then run joists from the flange of the steel to form the new roof. So, is it possible to install the new beam and run the joists from the top of it for the new roof? Any idea how that's done? I was going to cut the ends to fit the flange previously. Thanks.

-

How do i plumb the wall?

carlosdeanos replied to carlosdeanos's topic in Bricklaying, Blockwork & Mortar

@JFDIY Thanks, i needed to hear this. I have been walking around checking random walls and i thought this was the answer. Should make it easier for me! -

Beginner here, attempting to build my extension. All blockwork but 3 courses of bricks at the bottom to match existing. I have two profiles (exactly plumb) set at each corner and i run a line across the two. I lay to the line. When i put the level against each brick none of them are actually dead plumb. I have been watching a lot of videos and they never seem to check the plumb on each brick when laying to a line. I can see the bricks are not completely square, some are really curved actually. So does laying to the line, keeping it level and checking the range mean it will end up plumb? At the moment its taking so long checking each brick and messing about with it. As i say, in the videoes they just run along the line.Cheers.