RedSpottedSev

Members-

Posts

19 -

Joined

-

Last visited

Personal Information

-

Location

Manchester

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

RedSpottedSev's Achievements

Member (3/5)

1

Reputation

-

X3 Immersion heaters on a single radial

RedSpottedSev replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

Thank you, I do appreciate I am making this more complex than it needs to be. Part of the need for 'smart' control is that the setup is in the loft and I can't run any more cables. I would like to easily adjust away/holiday settings. I am now leaning towards simple timer switch for hotwater tank. Our water usage is 2 showers morning, 1 shower and bath(3 young kids) evening. Buffer supplies ufh only and in recent cold spell the flow temp of 37drgrees was sufficient (and still some more insulation and airtight work to do, loft hatches to close etc...) trying to run it as low as possible. I would definitely want on a smartish system for the buffer, Minimum remote control, love Shelly's power monitoring. @Mike thanks for that diagram, very helpful -

X3 Immersion heaters on a single radial

RedSpottedSev replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

Thank you guys This really is a great forum. I have to say a fair bit of this is over my head, I do however want to pin down my final plan. To recap I want to have tight and remote control of x3 3kw immersion heaters. 50Amp RCBO at the main CU. 8m straight 10mm 3 core to loft. Aux CU. Option a) x3 of: Shelly Pro 1pm (16amp) , then 16amp RCBO then contactor then to immersion. RC snubber but.not really clear if this goes across the shelly pro? Does it have to be physically very close and how does it sit in a DIN CU? Option b) Shelly pro 4pm (40amp), then 16A RCBO, then contactor... same question re RC snub Option c) forget Shelly, 16A rcbo in aux CU, then immersion heater, and use this for remote control https://www.tsmart.co.uk/ I couldn't get my head round the 24vdc setup yet. Thanks again -

X3 Immersion heaters on a single radial

RedSpottedSev replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

I think I understand now that the shelly doesn't take on the job of the MCBs after it, so the x3 MCBs would be needed eitherway. -

X3 Immersion heaters on a single radial

RedSpottedSev replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

Thank you, I need to study a little to fully appreciate what you are describing. Especially to save my head from spikes and such... No heat pump, but set up for it and a large solar array that is likely to come pending planning etc.. @Nickfromwales there are x2 10mm cables running side by side, a distance of 8m from main CU to attic. Nil else with them. Only to be used for heating, maybe future vent/aircon. Nothing connected to them currently. At most maybe power a smart hub if we get signal drops across the house/outside. Instead of 10mm to Shelly PM4, then from there to 3 immersions, you are suggesting 10mm to auxCU, then x3 RCBOs then shelly (I assume a different model) then immersion. Is it so that they don't all go off if PM4 fails? -

X3 Immersion heaters on a single radial

RedSpottedSev replied to RedSpottedSev's topic in Consumer Units, RCDs, MCBOs

Thank you all, It is a custom build. Main hot water cylinder has x2 (top and bottom), another in a buffer tank. On first glance the shelly looks spot on. I will certainly have a read. I can't run any additional cables down to the main consumer unit as all conduits full and decorating done in the rooms that would need new chases. So I assume I am going with a mini auxiliary consumer unit in the loft to house the Shelly. Will the 10mm cable be ok to power it if all 3 immersions if they come on together? -

Hi, Some help please. We have moved our boiler heating system to the loft. The new system in total has x3 immersion heaters, 3000kw each. I would like each of the immersion heaters to be controlled by a smart fused spur (SM FSTWIFITU WiFi Controlled 13A Fused Switched Spur - Tuya Compatible) I was wondering if a radial 10mm 2core twin earth will be safe to supply them all, if it was protected at the consumer unit with an RCBO. What is the best way to wire in the spurs from the 10mm cable? Do we daisy chain off the back of the line side of each spur with the 10mm cores? This will all be done and checked by the electrician, however I just want to make sure the plumber and builder have the first fixes all set up right. Thank you Thank you

-

Thanks @JohnMo I appreciate the advantages of the 2 pipe system, as the call for heat comes off early from the Tee, particularly good for ASHP; but if I am adding additional heating into the buffer (act as future heat store) then it might not make a big difference for us. 30 is oversized for us, I think ideal would have been 24ish. But my understanding is that some of the smart controls are limited on the Worcester 4000s which come with lower heat output. Do I need a dedicated control module for the buffer tank? MM100? Does the boiler need to see it as a second cylinder acting as a heat store? As we dont have valves on the 2 circuits from the boiler, we dont need a bypass valve right? heating design v2.pdf

-

sorry, edited

-

Thank you, I have made some progress with the design and decisions. I have put the design in a file attached. I have absolutely zero experience/expertise in this so please do critique/add and modify. If there are critical safety things missing then please also do tell me. I am not fitting this myself but do want to make sure the plan is as tight as it can be. I would say that I appreciate it isn't the most efficient design as I have had to make do with some kit that I bought previously, and make future compatibility options available. - With regards to the wiring, the 8000+ has a temp sensor input for LLH. Am I correct I can use that connection for the buffer tank? This way the boiler can modulate the heatoutput to the buffer? - I would appreciate help on what settings I would then select with this set up in the 'Hydraulics' of the boiler system menu. Attached - I am still not clear/got myself in a muddle with what happens when it is 12 degrees outside vs 2degrees outside. The boiler will modulate to keep buffer at set temp. But the mixing valves on the manifold are manual. So when there is a call for heat from any sensors, the manifold will draw a set temp (mixing valve temp) to the floors. Do we then accept that if it is 2 degrees it may take much longer to heat up if flow temp is set lower, and then perhaps there will be a chance of overshooting/yo yo if the flow temp was set higher? Therefore keeping the system always on helps avoid this? Can you point me to a tutorial/guide to help me get my head around setting and adjusting the flow temp at the manifold? -- are you suggesting I remove the blending valves entirely (or set at 38 for safety), and I adjust the buffer tank temp as outside temp changes? If so, are there controls that allow me to remotely adjust buffer tank temp? Or is this where weather comp can adjust the buffer tank temp to try maintain a certain flow temp to the manifolds? I think I need to learn more about WC controls on the 8000+! Thanks again LLH sensor.pdf heating design v1.pdf

-

Would you advise against decoupling membrane for porcelain tiles flowing throughout over 85m2? I worry about cracking, but not sure how insulating decoupling membrane is

-

Thanks again @JohnMo With the buffer tank, as I will likely only heat it with a boiler or stored solar in battery stack... would it be OK for the buffer to be a Direct Unvented one with an emersion heater? Does this part of the system also need expansion vessel and pressure release safety valves too? With it being a 100L buffer, as an alternative design, would a straight up heat only boiler supplying a 300 to 400L heatstore (I've seen the advance Appliances pre plumbed multifuel, 28mm outlet for ufh https://www.advanceappliances.co.uk/product/70-multi-fuel-universal-thermal-store-sfuts/) not be an easier install? Is there a significant amount of energy saving with the previously discussed buffer and cylinder system vs one big heatstore?

-

I have just realised a flaw in my plan, as one Heatmeiser can't control 2 manifolds, so it is looking like the buffer tank set up.

-

Thank you, Great advice and I think I am getting close to my design, feedback and corrections welcome please. Greenstar 8000 plus with internal integral diverter kit, to allow for DHW priority and setting temp for cylinder and ufh with weather comp. Becomes a 4 pipe system. 2 pipes to a Telford Tempest indirect unvented heat pump cylinder 300L. Hot water feed has to travel 8m to my hotwater manifold that then supplies each outlet around the house. I am deciding if I need an electric heater/circulater as a secondary return or if there is a better set up. Other 2 pipes to Buffer tank/LLH (to be decided as I am still figuring this out) From this the pipes to my 3 ufh manifolds (2 downstairs, 1 upstairs). If I only use 2 heatmeiser UHF-RF V2 (upstairs/downstairs), I can have the downstairs heatmeiser controlling the 14 loops, as I understand each 'zone' on the heatmeiser can control 4 actuators..... Then I can link the 2 heatmeisers as primary and secondary, with the primary calling for heat direct from boiler on a switch live. So the idea being if any manifold/heatmeiser calls for heat, the boiler kicks in, and heats the LLH/buffer and the manifold pump draws the heat from there. I do like the alternative of the boiler just concentrating on keeping the buffer tank at a set temperature, and then heatmeisers just activate the manifold pump and not communicate with boiler. But if feels that in hit weather the boiler will essentially have another 100L of water to keep warm alongside the unvented cylinder, is this right? What do we gain with this instead of a large heatstore that hotwater and ufh all come out from? Which one of these set ups is more straightforward for setting up/service and wiring. Which is going to offer me more tweaking for efficency? Thanks again

-

Thank you @JohnMo can you point me to a resource on how to do this properly: "I would start by looking at the longer loop and all pipes to and from that loop and look at pressure drop. Once you have that, it will set pressure drop for system, then add all the flows you need together all loops). Now you have a pump duty point. You can now make a sensible choice of system or heat only." Do you mean I calculate the distance from boiler to manifold 28/22mm and then add the longest loop which I think is 98m at 16mm. Somehow calculate the pressure drop? Then find the overall flow I would need through each zone based on my heat loss and heat output from each floor? One more thing I cant get my head around...on DHW priority, when cylinder calls for heat, boiler diverts to dhwp, then do the pumps on each manifold keep circulating water around each manifold....but what happens if the mixing valve opens to draw heat and dhwp is running. - do the manifolds not fight each other trying to draw from each other? Then do i need a directional flow control - or heatmeisers are smart enough to turn the pump off when cylinder calls for heat? - I know you said no to Low loss header, but this was why I thought it would let the pumps on each manifold to circulate at their leisure without fighting Thanks again,

-

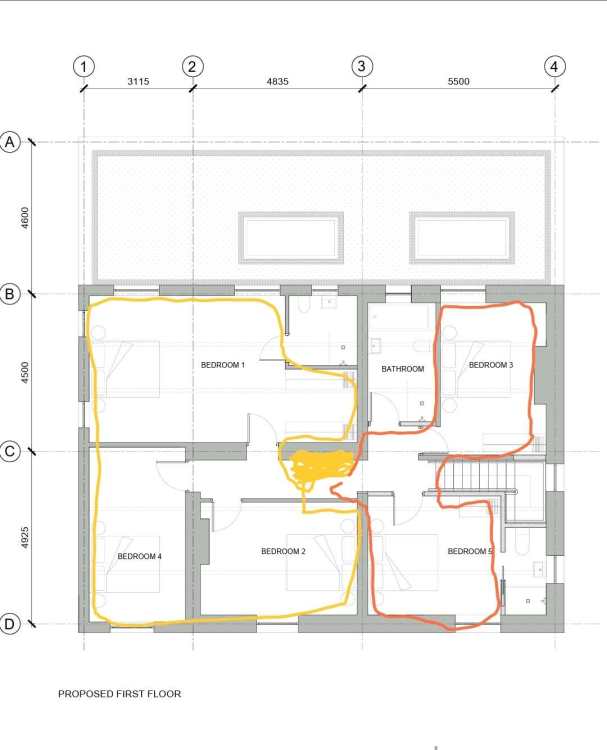

Thank you @marshian and @JohnMo. I have been doing some more reading and your posts in the ufh section. That video is maths heavy, but I am working through things back to front. In that I am doing my heat loss, then using the formulas from heat geek and urban plumbers to calculate what flow I would need and use that as a starting point for each loop (work in progress). Old boiler is Worcester 430/i unknown age but on last service it was not looking good. I think at least 12 years old. New boiler: will go in loft with new cylinder (heat pump coil) to be both decided on compatability of current ufh kit i have (specifically the heatmeisers and how to get weather comp working) I will be doing my best to run each manifold as a single zone, only using actuators on the loops as on/off or very high/ low set back temperatures. The manifolds and it's pump (Grundfos upm3 auto)/mixer is from Thermrite. X2 will be downstairs in garage, supplying the downstairs area. One upstairs for bedrooms. I am assuming if I was to do the above, I would still need to change my mixer valves to ESBE electronic valves for proper weather compensation? Do they work with the heatmeisers? As each of the 3 manifolds have it's own pump on different flows, do I need to do anything special? Can I get a boiler that deals with this set up without special kit? Im confused about LLH/kimbo/closed coupled Tee... Right now I want to make sure I've pulled up all cables needed from each manifold as we are due to start plastering. Currently have 6mm and 2.5mm going up to loft for boiler and cylinder, and 5core from each manifold to future boiler position. Do I need more for ESBE? Do I need temperature monitors on each inflow for the manifolds? Thanks again for the help and education! PS the upstairs orange coloured rooms will be guest rooms which I wanted to zone off, but from what I gather it is better to continue to keep warm even when not being used?!