Coll659

Members-

Posts

45 -

Joined

-

Last visited

Personal Information

-

Location

Slovakia

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Coll659's Achievements

Member (3/5)

24

Reputation

-

It's done!! Just wanted to say a big thank you to everyone with the advice on this one. After the advice I changed plans and in the end got a sand cement screed laid by a professional company who did an amazing job and finish. Time to move on to the next stage (I'm sure I will gleaming you wisdom again) Thanks again, few pictures before

-

Thanks I'll add a load more staples. And yeah I plan to pressurise them all up to 4 bar (our mains water pressure) to check for leaks before and to monitor during laying

-

Things are progressing and we have some professionals lined up for the concrete (professionals doing a side job for a friend with me and our mutual friend helping). Quick question on the rebar chairs. I have one room almost ready but found the rebar might be an issue. It's 4mm composite on 50mm chairs. However the chairs I got will just pierce the foil and insulation if you step on or close to them. Stepping between is fine as the composite rebar is very flexible so just bends but this might be an issue when they are laying the concrete. It's not easy stuff to walk on. Do you think the rebar chairs with the wide circular buttons would fix the issue or does someone have any tricks for this. Also my concrete guy is quite worried about the the rebar floating but I think tie wrapping it to the chairs and then to the underfloor heating pipes will be fine? Floor build up is: Sand blind 30mm EPS Dpm Insulation (200mm EPS in part of the house, 100mm PIR in the rest) Under floor heating foil 100mm concrete (And round the edges 30mm EPS and foam expansion skirt between Dpm and underfloor heating foil)

-

We have a quote of approx 2700 EUR. That's 100mm concrete throughout the house (approx 110m2) with Labour. That's in central Slovakia.

-

After the advice of pretty much everyone, for once I am going to admit defeat and have some professionals in for this job. We have found a couple of options we are happy with and will readjust the budget a little to accommodate but its not something we can afford to go wrong. I will take some pictures and update you in a couple of weeks when it's done but thank you so for your advice and help and I now know what to watch for when it's poured and what to prepare

-

We are meeting with a professional concrete guy tomorrow so to discuss the job. With a bit of luck we can convince him to take the job on and do it for a reasonable price but we're not sure yet. But at least we will get more info and advice and perhaps some local contacts. A screed mix might be worth considering. Yeah I read through orangebooms experience so I'll definitely be vigilant about that! My underfloor heating will be stapled to the insulation which should hopefully avoid the issue of the pipes and I'll be vigilant about making sure the rebar stays down. Thanks again for everyone's advice, I'm certainly taking it all in and will let you know what we get after meeting with the professional tomorrow

-

Thank you so for the responses. Definetley confirming my thoughts on how difficult it will be. I'm working my way through all the points one by one so will likely be back back with me questions. We have a couple more semi experienced people on board and are in the process of trying to get a professional or two to come as well. And just planning everything to the tiniest detail. I've lost many hours sleep to this recently and really appreciate the advice. We have some phone calls to make next week and see what we can figure out

-

Good idea I'll consider that

-

Thanks all for the advice. Definitely agree that the best advice is to not do it in one pour. Unfortunately for to a variety of factors i love if need to do it in one go. My plan is to cut all the perimeter insulation to the perfect level, plus the insulation in the doorways to level from. Perhaps a laser set up as well.

-

100mm concrete I'm doing the following: Sand blind (only to level) 30mm EPA Dpm Insulation Underfloor heating foil Underfloor heating stapled to insulation and 4mm composite rebar on 50mm chairs 100mm concrete Though please note I'm a joiner and not a professional on this stuff so don't blindly follow me 😅

-

I agree with Mike. I'm in the process of building up my floor (same with insulation below the concrete slab) and in half the house I have only enough space for 100mm PIR and in the other half I more space so used a bigger build up of eps. Got better insulation values and saved a whole bunch of money. Plus building up with eps is much easier and less heavy work than hardcore

-

Thanks for the advice. Currently I have a few people who have no experience but are useful for lugging around hoses where we need them, then there's me and one or hopefully two more people who are not professional builders but pretty good with this stuff and some experience of building work. I will see if I can get someone with experience but not sure if that will be possible yet. I'm thinking to use 100mm eps in all the doorways, set to the level of my concrete and put outer conduit pipe for my underfloor heating pipes to pass through, and tape up the ends. This will then make each room completely separate with it's own slab. I can then just put my flooring straight over the EPS. The water table is pretty high but the foundations come up above the ground quite a lot so my dpc and floor layer is well above water table. But I am also in the process of digging a french drain as well. Looking at local rental shops and see they have the vibrating bull floats and wondering if it's worth hiring one or just using a normal one

-

Just to protect the DPM

-

From what I understood the underfloor heating foil does this job? But I will look more into this thanks. And yeah the walls have an old dpc (the hard tar like one, forgot the name of it right now?) it's old but doesn't seem to be letting any damp up through the walls and it has been empty and in heated for quite a few years. You can just about make it out in the picture below

-

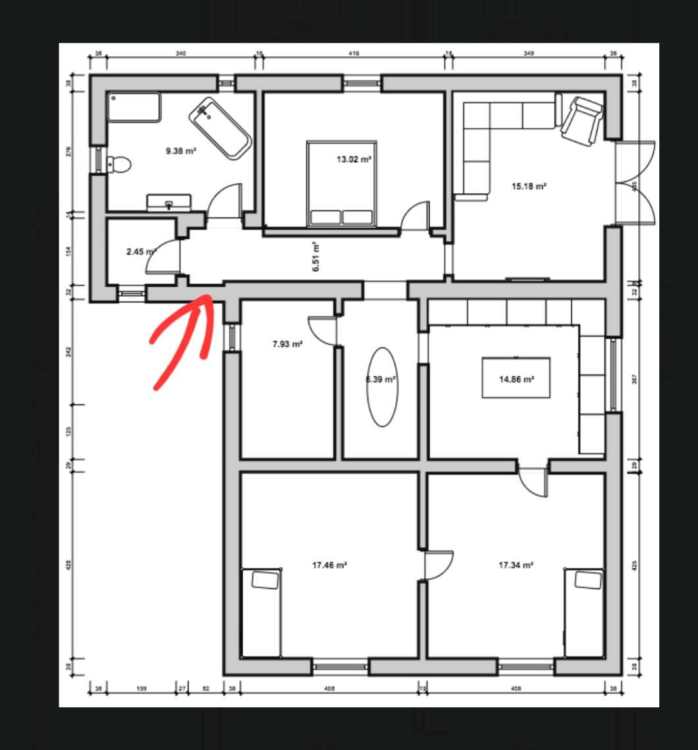

Hopefully the last time I bother you all with my floor. Next week I will be pouring the concrete floor in the house in renovating and looking for advice and tips. It's an old house with stone foundations, I dug out the old rubble that the old wood floor was sat on until I got to compacted ground and now have the following: -sand blinding -30mm eps -Dpm -Insulation (200mm EPS in some places and 100mm PIR in others) -underfloor heating foil -underfloor heating pipes stapled to insulation -4mm composite rebar 150x150 on 50mm chairs -30mm EPS insulation around edges and an expansion foam skirt I'll be getting the concrete delivered with a pump truck and hoses in one go. The main entrance is marked with the red arrow in the picture before, I'll start in the back room and work my way towards the entrance. It's approx 110m2 in total. My questions are: How do I make joints between the rooms taking into account there will be underfloor heating pipes going through doorways. Should the slabs be completely separate for each room to avoid cracking and allow expansion? What advice and tips do you have to successfully pour it all. It will be the finish floor (just tiles and laminate going on top) so I need it smooth and level. I guess I need long straight pieces of wood or something for screeding. Should I make one for each room the full width of the room for screeding? but what do you normally use to screed from (like rails) Then a bull float and keep working back through the house to the entrance. And then I believe after it starts to dry a little you trowel it up? How long after pouring is this normally? Any advice or tips would be great.