fandyman

Members-

Posts

30 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

fandyman's Achievements

Member (3/5)

3

Reputation

-

Layout advice on a first-floor side extension

fandyman replied to fandyman's topic in New House & Self Build Design

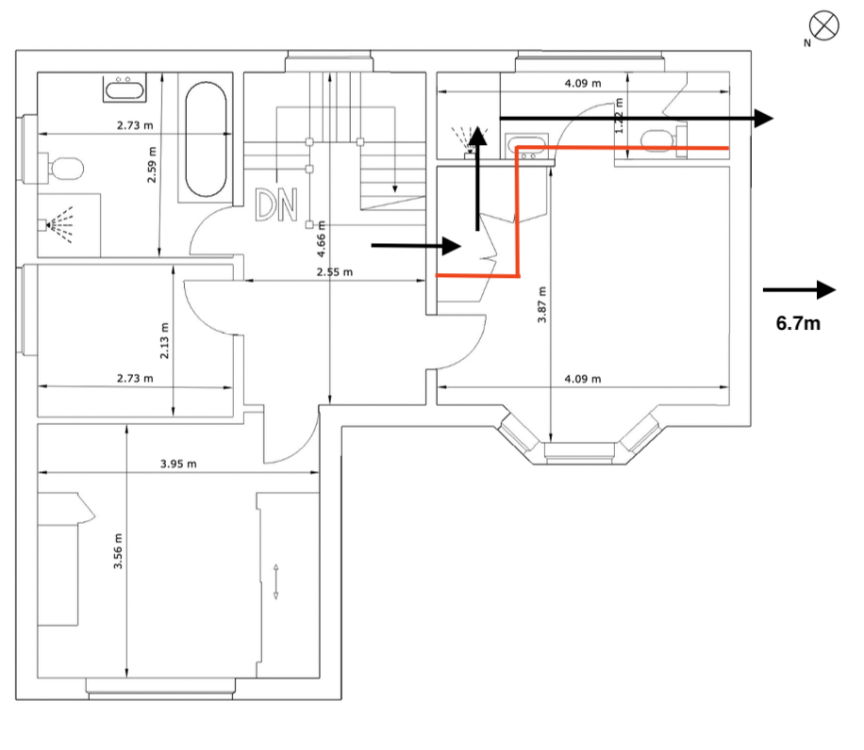

I guess you must have been thinking about a detail like the below @garrymartin: In terms of the en suite @G and J I have actually made it even less intrusive with the above and also downstairs will have a relocated kitchen (new drainage through the front garden connecting to the existing as a new branch inside the existing chamber on the drive) so it should work all fine. -

Layout advice on a first-floor side extension

fandyman replied to fandyman's topic in New House & Self Build Design

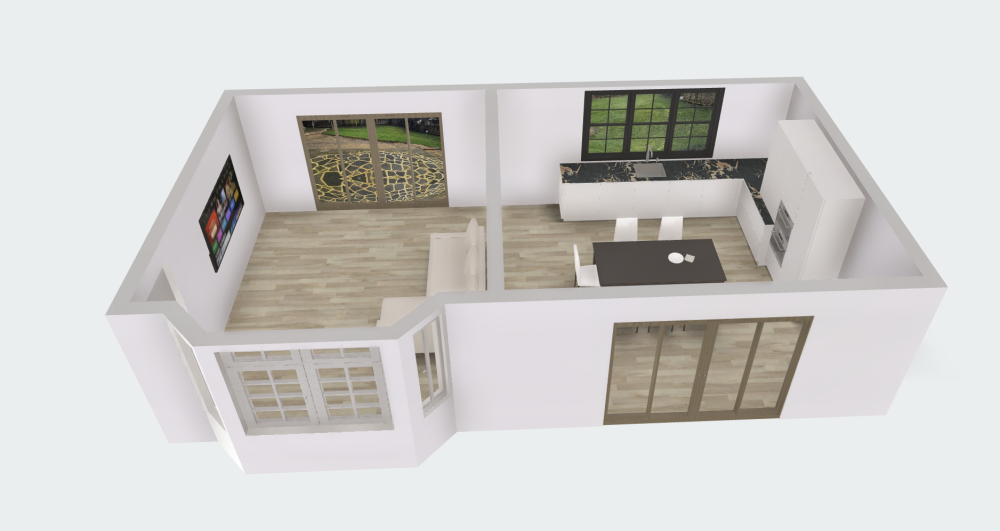

Thanks for all the great ideas - I think this could work. Will now be checking other aspects of it including the lower floor as well. -

Layout advice on a first-floor side extension

fandyman replied to fandyman's topic in New House & Self Build Design

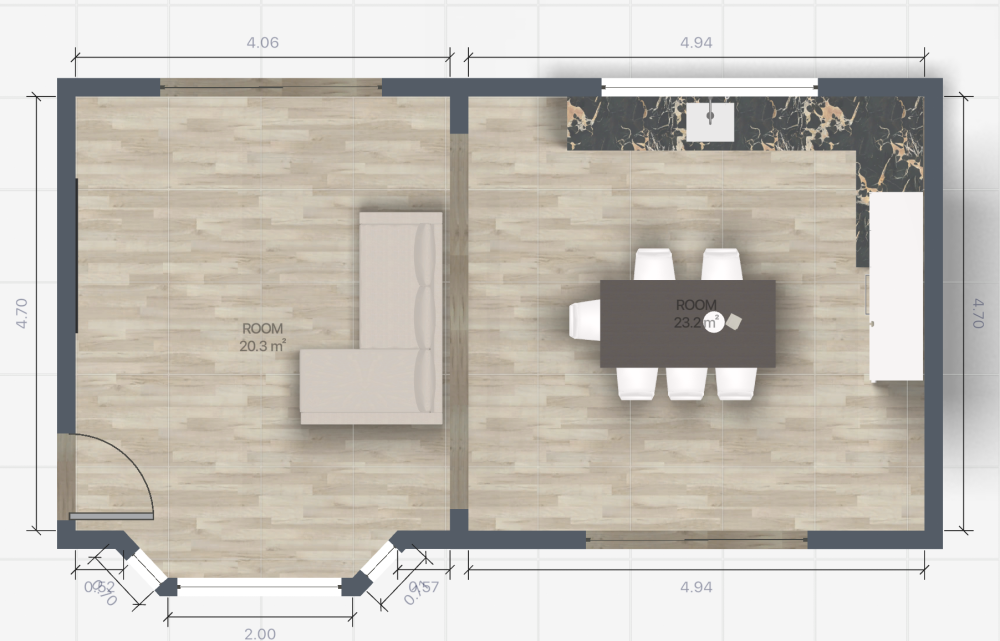

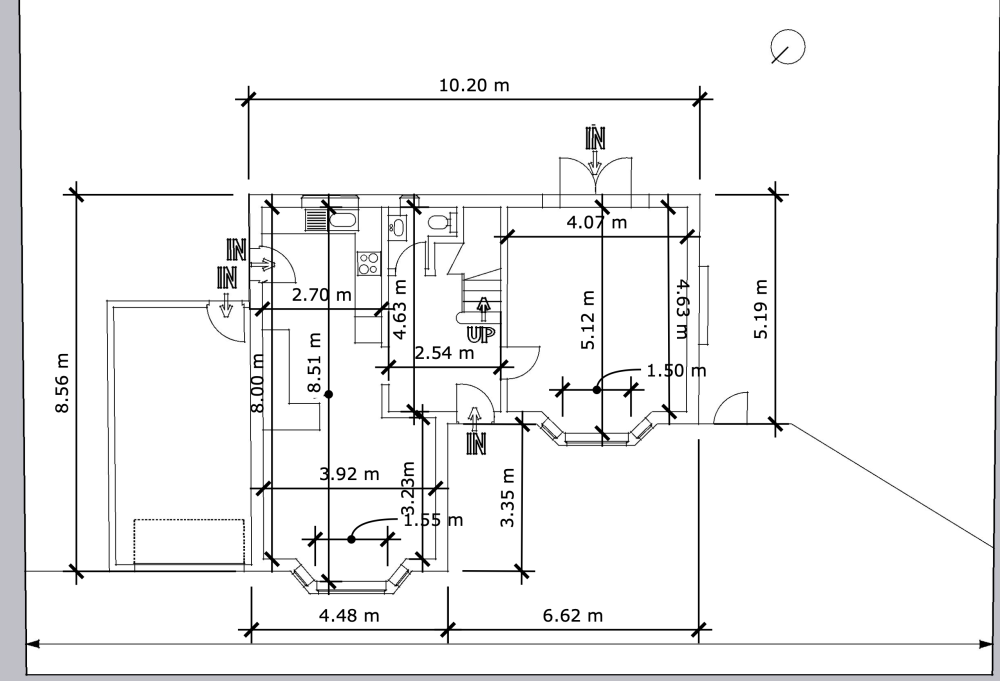

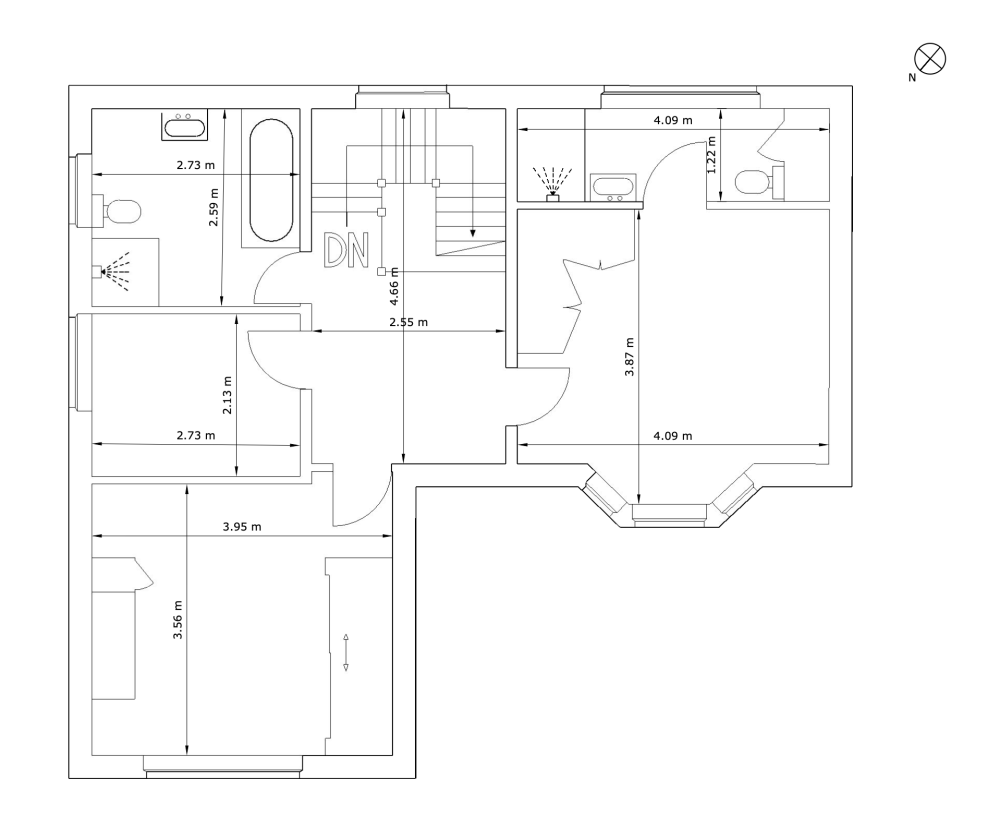

@ConorSee the house floor plan as is currently. @G and J Good point with 'part of the main bedroom' suggestion. I like this approach a lot. All in all, if well executed, do you think it wouldn't kill the value? I know think that as long as the new wide bay hallway serve a purpose eg. drawers/ dressing table/window seat it could make the plan work. WDYT? -

Layout advice on a first-floor side extension

fandyman replied to fandyman's topic in New House & Self Build Design

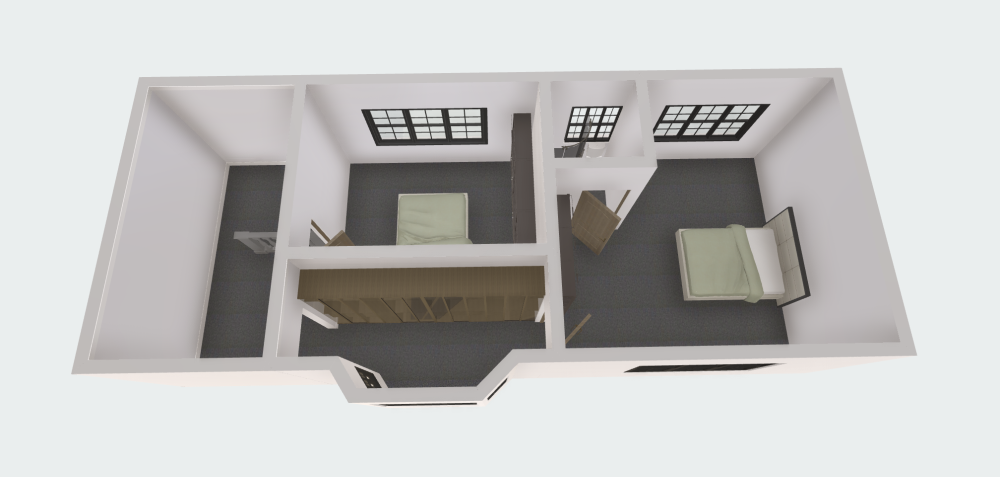

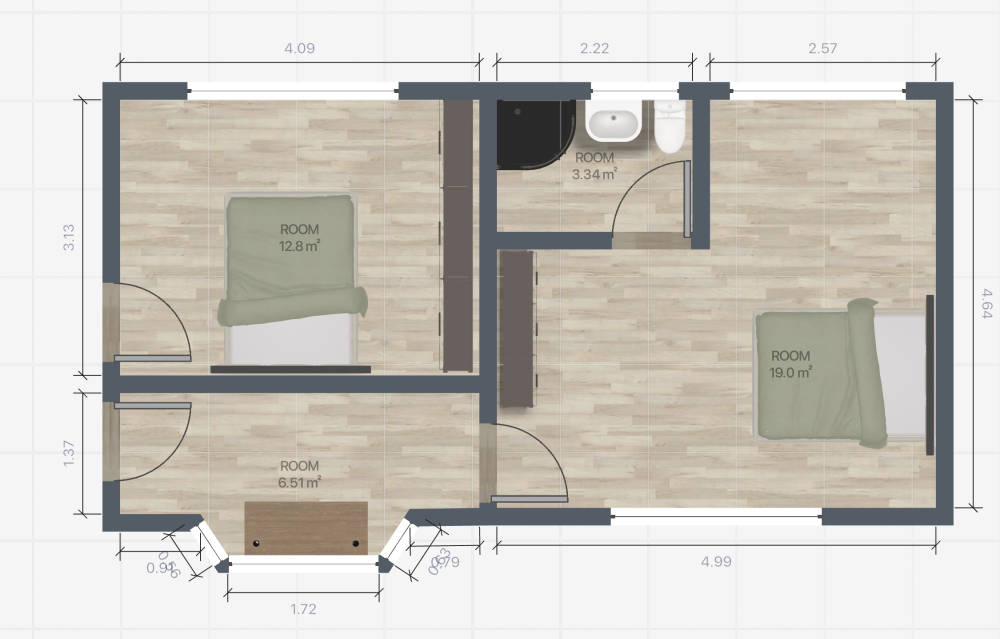

This is what it would look like @G and J I would have to move the ensuite out of that bedroom and create a new one in a new master bedroom Would it be acceptable or look odd? -

Layout advice on a first-floor side extension

fandyman replied to fandyman's topic in New House & Self Build Design

It will be a secondary bedroom and the new room added to the right will become a master bedroom with ensuite. The window in the bathroom is a standard wide non-opaque window. Are you suggesting the bay window may be presented as a functional desk space or bench, desk, reading nook? That might be one option that I have not considered yes. -

Hi all, looking for opinions on a first-floor side extension layout (UK). I’m considering adding one additional room on the first floor to the side of the house (not rear). I’ve attached the existing first-floor plan with the new hallway marked in red and black. Because of the existing stair position and structure, one option involves forming a short internal corridor that is carved out of the current main bedroom (through existing wardrobe space and en suite), rather than walking directly through the bedroom itself. Important clarification: This would not be a walk-through bedroom The new room would be accessed via a dedicated corridor The corridor would have a full-height window for daylight The sleeping area would remain separated by a door So practically it would be closer to a small internal hallway arrangement, not circulation through the bed space. My questions: Is this type of solution generally considered acceptable in UK extensions if proportioned well? Are there any resale or usability red flags you’d immediately see? Would planners / Building Control typically object to this, assuming room sizes and light are compliant? Happy to hear both professional and homeowner perspectives - especially if you’ve seen similar layouts work (or fail). Thanks in advance.

-

I don’t actually disagree with any of that. Identifying causation rigorously is exactly why I’ve moved away from forum debate and toward independent inspection. At this point we’re well past exchanging hypotheses - the issue is persistent, localised, and observable, and the next step is to establish the mechanism formally rather than speculate further. I also agree that trades too often dismiss customer observations until someone “with letters after their name” repeats the same thing. That’s unfortunate, but it’s precisely why independent assessment exists. Whatever the outcome - whether responsibility ultimately sits with the installation detail or the underlying fabric - understanding what’s actually happening is essential before any proper remediation or replacement can be considered. Thanks for taking the time to set that out, and happy new year to you too.

-

Thanks for taking the time to think this through in detail. Some of the scenarios you describe - frame-to-frame alignment tolerances, bedding of the cill, or concealed gaps masked by sealant - are interesting. However, they all ultimately point back to the same issue: the assembly and detailing of a multi-part door system at the threshold. If any of those conditions exist, they wouldn’t be characteristics of the existing building fabric but of the way the system has been installed and integrated. Small tolerances, hidden voids or misalignment at the base may be common, but they are precisely the kinds of details that affect internal surface temperatures and condensation risk. I also note the suggestion that the glazing units themselves may be allowing air passage around the frame. If that were the case, it would raise a much more fundamental issue with the assembly and sealing of the system rather than with the surrounding structure. Ultimately, the challenge here isn’t identifying ever more hypothetical mechanisms in isolation, but assessing whether the installation, taken as a whole, has resulted in an internal threshold detail that performs acceptably under normal occupied conditions. That’s why I’m seeking an independent assessment rather than relying on conjecture or what might typically be tolerated in practice. I appreciate the input, but at this stage the question isn’t what might possibly explain it, it’s what is actually happening — and whether the installation outcome reflects reasonable care and skill.

-

I think we’re actually closer in position than it might appear - though perhaps drawing different conclusions from it. You’re right that Section 75 isn’t a forum for debating where industry responsibility ought to sit. That’s precisely why I’m not relying on what is customary, typical, or widely tolerated in the trade, but instead on independent assessment of whether the actual outcome of the service supplied meets the standard of reasonable care and skill. Where I part company is the suggestion that persistent condensation and mould are merely “subjectively unacceptable”. These are objectively observable outcomes, not matters of taste, and they are exactly the kinds of issues that reasonable care and skill are meant to prevent - regardless of how common a particular installation detail may be. You’re also right that an expert will examine whether a competent installer should have identified the sub-threshold detail and either mitigated it or flagged it before installation. That question sits at the heart of the dispute, which is why speculation about how often this is overlooked in practice doesn’t really resolve it. I appreciate the confidence expressed about how an expert might conclude. I’m comfortable letting evidence rather than expectation decide that point. If the conclusion is that the underlying fabric alone is responsible, I’ll accept it. If not, responsibility will follow accordingly. Either way, I agree - it will be interesting to see the outcome, and I’m happy to report back once it’s determined.

-

That’s fair - we’re clearly coming at this from different perspectives. Where I disagree is that reasonable care is limited only to what a trade chooses to concern itself with. It’s judged on the service actually provided and the outcome it creates, not on whether the installer considers certain aspects “out of scope”. I’m not expecting encyclopaedic knowledge of building regulations or retrofit design - I’m questioning whether an installation outcome that produces persistent condensation and mould under normal conditions is an acceptable result of the service supplied. You’re right that the credit card provider may apply its own logic - which is precisely why I’m comfortable letting an independent process assess it rather than relying on forum consensus. At that point it becomes an evidence-based decision, not a matter of sympathy either way. I appreciate the discussion - I think we’ve probably taken it as far as it can usefully go here.

-

Reasonable care isn’t limited to what a trade normally chooses to think about - it’s judged on the outcome of the service. If the installation creates a new internal surface that predictably falls below dew point under normal conditions, it’s fair to at least question whether that outcome is acceptable. I didn’t engage a general contractor or an architect, but I also didn’t instruct a detail that would knowingly create condensation and mould. The installer surveyed the opening, specified the product, and executed the threshold detail. Whether that outcome is ultimately deemed acceptable or not is exactly why I’m seeking independent review - not because I expect installers to be “more than a window company”, but because outcomes matter regardless of marketing labels.

-

Not exactly. There was a conservatory attached, but it wasn’t part of the main thermal envelope and wasn’t heated to house temperatures. More importantly, the junction itself wasn’t exposed internally. Before the doors were installed, there was a continuous screed/floor build-up across that threshold area, so no cold internal sill/frame surface existed and there was no condensation or mould there. The change introduced by the installation is a new internal sill/frame junction directly coupled to ground-connected masonry. That exposed surface is now cold enough to condense under normal conditions

-

That’s a fair hypothesis to explore, but there’s an important factual point to clarify. Before the doors were installed, there was a continuous screed and floor build-up running from the living space into the conservatory area. The ground-level brickwork at the opening was not exposed internally, and there was no visible condensation or mould at that junction. As part of the works, the conservatory base was removed and the screed was cut back to just behind the brick line. The installer then positioned the sill/frame forward and created a new internal junction, including a small expanding-foam upstand between the sill/frame stack and the remaining screed/finished floor. That foam is incomplete in places and has visible gaps. So while I don’t rule out the ground-contact masonry contributing to cooling, the key change is that the installation has introduced a new cold internal surface and junction detail that did not previously exist, and that surface is now where condensation and mould are forming. That’s why I’ve been focusing on the threshold detail itself - not because I think the building fabric was perfect before, but because the installation altered how that fabric is thermally coupled to the internal environment. I’m not asserting a single cause; I’m trying to understand whether the way the sill and frame were positioned and detailed has unnecessarily amplified what was previously a non-manifesting condition.

-

I don’t think that follows, and it’s not what I’m asserting. I’m not saying silicone or packers create a thermal bridge in isolation. I’m saying the resulting installation detail has coupled the internal frame directly to cold, ground-connected masonry, producing an internal surface temperature low enough to repeatedly condense and grow mould. That outcome is observable and isn’t in dispute. Replacing the lower course of bricks with Marmox / Compacfoam would certainly be one way of mitigating that - but that doesn’t automatically mean the only way, nor does it mean the installer bears no responsibility for the detail they chose and executed. They surveyed the opening, specified the product, and installed the threshold. I didn’t instruct a brick-to-brick sill or prevent any form of thermal mitigation. Saying “this is how any installer would do it” describes industry normality, not whether the outcome is acceptable when it results in persistent condensation under normal internal conditions. Those two things aren’t the same. I’m not arguing that the installer should redesign the house or retrofit insulation into the floor. I’m questioning whether the threshold detail they implemented has unnecessarily amplified heat loss at that junction, and whether the resulting internal surface conditions are a reasonable outcome of the service provided. That’s why I’ve been careful to frame this as an outcome-based question, not a blanket criticism of standard practice.

-

I don’t disagree that many firms would install it this way - that’s kind of the point. “Common practice” and “acceptable outcome” aren’t always the same thing, particularly when the outcome is a persistent cold internal surface that repeatedly condenses and grows mould under normal conditions. I didn’t alter or newly create the opening - it existed as-is when I purchased the property. The installer surveyed it, specified the door, and executed the threshold detail. I didn’t instruct a brick-to-brick sill or prevent any form of thermal mitigation. I also accept that many installers focus on airtightness, water ingress, and operation rather than thermal junction performance. But the question I’m asking isn’t whether this is unusual - it’s whether the resulting internal surface conditions are an acceptable outcome of reasonable care and skill. To answer your questions: there’s no comparable condensation elsewhere in the house, the room is heated in line with the rest of the property, and RH is typical for an occupied dwelling. That’s why the issue being confined to the sill/frame junction matters. I’m not expecting perfection or passive-house detailing - I’m trying to establish whether this outcome is unavoidable, or whether the threshold detail has unnecessarily coupled the internal frame to cold masonry in a way that could reasonably have been mitigated.