EinTopaz

Members-

Posts

163 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

EinTopaz's Achievements

Regular Member (4/5)

27

Reputation

-

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

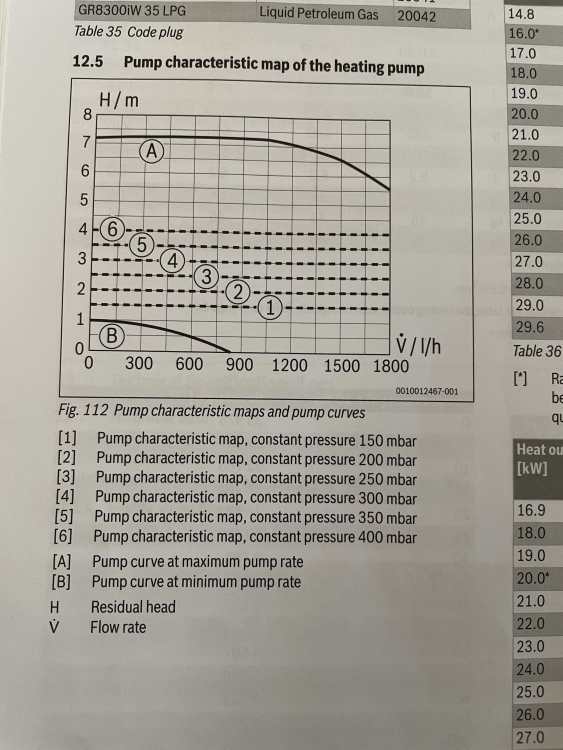

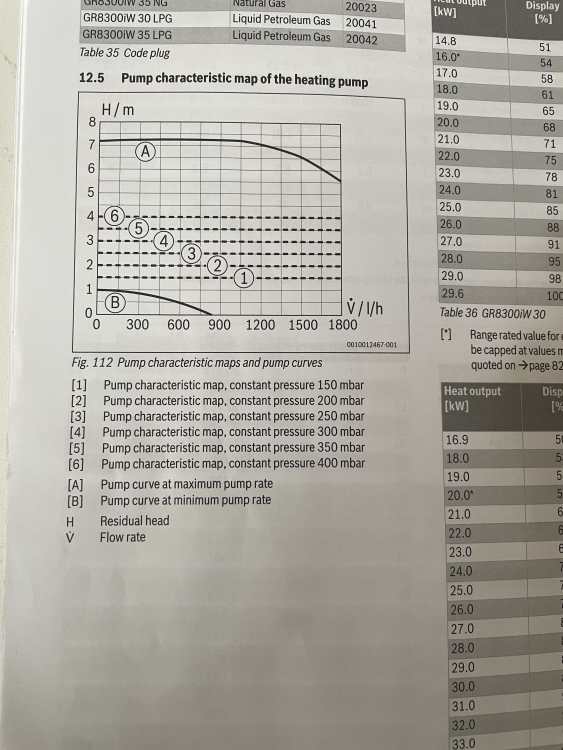

Picking up on a slightly earlier topic in this thread that I want to revisit. As well as the boiler in question here that's having the problems... im using a separate boiler upstairs for CH on the top floors, I may've mentioned already, but it is a 40kw CDI conventional CH only. (it's that large because it used to do the entire property before we extended etc). That powers 10 x type 22 rads/ circa 18kw, and is set to setting 4 (8max) on the potentiometer on the front, this means it gets to 65c. All the rads on this circuit get warm within 5mins, and hot within 10minutes. It's 22mm piping for the first 3meters, then drops to 15mm, then down to 10mm down the wall cavities to each of the rads for the last 2meters or so, so id assume way more resistance in this system than the boiler downstairs (the one i'm having all the problems with in this thread). Also worth mentioning The pump on this is external and a grundfos 25-55. On the boiler downstairs, the one i'm constantly having problems with. I have wondered now that the HEX is fixed and the temps are atleast displaying correctly, if I wanted to speed up the heating time to get it closer to the boiler upstairs, what can I do to improve it? I've looked inside this system boiler now and can see it has a 15-70 pump in there. Which does make me wonder, does that essentially make it a stronger pump with more head than the one I have upstairs? and if its 15-70, why is setting 6 (400mbar) show as pump output 100% on the boiler LCD display? Does that essentially mean its got way more head than it's able to use? i.e it's capable of 700mbar, but can only run 400mbar max? I find the manual quite confusing here and it'd be great to understand this so I can work out the viability of adding a second external pump to this setup, or running an LLH and an external pump too. The goal would be hopefully significantly shorter heat up times. Images attached of the pump and the manual again, for ref. -

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

I have, they're coming back out on the 16th Jan. I've got a 100% repro case waiting for them. And have confirmed; no matter what I set the target to, it's exceeding it by either 5c and cutting off, or very nearly exceeding by 5c, then settling at around 2-3c above target. And can also show it continually climbing at 100% output, 10s of minutes after target is reached. So in summary, not settling at target, overly slow to modulate post achieving target, far exceeding target and tripping. -

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

It has some of the 25mm stuff on already but struggled to get it that thick in many places as the pipes are tied directly to the underside of the floor joists. So a good portion of it is only 13mm thickness too in tighter spaces I was thinking of getting a plumber round to unpin them and run them along the concrete slab floor instead, well not directly on the floor I’d put 100mm PIR board on the floor and run them along that. Then I could go as thick as I like with the insulation. Or put even more insulation ontop of it too then. Or box all the pipes in in using more PIR. I also saw there’s a pipe insulation called phelonic which has a much better insulation rating than the foam stuff. Though it’s about £6 per meter. Wondering how far is too far. But it is -4 here today and that subfloor is very well ventilated. Probably best to treat them as external pipes, or as good as. -

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

Just to update this… It won’t even drop to 60 anymore. For the past 4/5 times it’s been on it settles at 62.5c now despite that being 2.5c over target. The only thing I’ve changed is I’ve rated the boiler down to 95% as this didn’t seem to have a huge affect on how long things took to get hot. -

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

It’s a fair point, it’s not the most egregious thing now everything is getting warm enough. To be honest the overshooting in and of itself isn’t bugging me, I’m fine with everything getting a littler hotter then I’ve set… though what is bugging me is more the fact it’s staying at 100% of its rated output long after it’s reached target. It’s working way harder than I’ve asked it to and the bottom line is that’s costing me unnecessarily everytime I run it. For every hour it’s running at 35kw it costs around £2. So that will add up a lot through the year if it’s not modulating down when it could/should. as a slight aside. Do you know the best insulation method for pipework that runs in a ventilated, unheated subfloor. The pipes are already lagged but wondering what else I can do to keep them as optimally warm as possible. -

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

I’ll give that a try. But I know already from testing that the 90% range rated test I tried yesterday took 5 mins longer to get To target. Still overshot but only by 3.6c this time. But then weirdly never did make its way down to 60. It settled at 62.5 with a modulated output of 54% I assume the higher modulated % was because it was a colder day and the pipes are in the subfloor with the ventilated air bricks etc. so assume it was just working a little harder to keep them at temp. Or above! EDT ^ this was all on pump setting 5, which was essentially locking it at 87% pump speed -

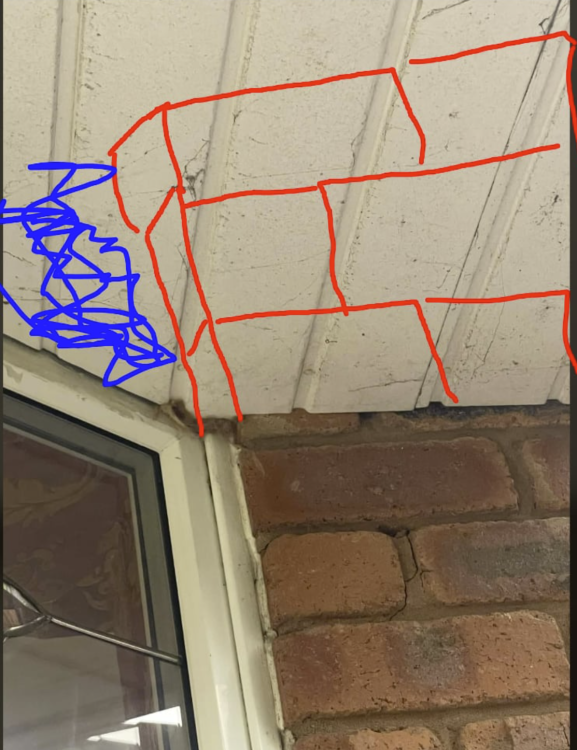

The whole house does have an insulated 75mm cavity. When you say resting on the bay window do you mean ontop of the window frames? Or is it likely to have a flat roof built into the bay window? Trying to work out how invasive this will be to replace. Looking at the floor heights internally I doubt it’s cantilevered to them either. I know from when they converted it from a bungalow to what it is now they kept the original downstairs ceilings in place and built another cavity above that, so every bedroom in the upstairs has a step up by maybe 120mm to the “higher” floor height. That’d be way higher than where the bay roof would be cantilevered from though.

-

I’d assume so yes. But from eyeballing it looks like where the masonry the frame would be bolted to would be. Is a void for some reason.

-

It’s not no, renovated in the past 15 years but it’s originally a 1955 bungalow. So these bays would’ve originally run into the roof / eaves. When it’s been extended upward I wonder what they decided to do with the bays to convert them. I guess we will find out when the soffits and fascia’s are removed but I’m still a bit confused/concerned as to why I’m seeing a void above the bay. is it likely the bay window here won’t have its own flat roof built in? As in when we swap it out for a new window, it’ll be a straight forward swap of the vertical units?

-

Thanks Nick, that's exactly what i'd expect to see, a continuous external brick surface with brick gaps where the timber framework for the roof is fixed to the floor joists. I guess more will be revealed when I remove the soffits and fascias but it definitely looks like a big void where i've marked on blue in the above image. Certainly more than a brick's worth. Though thats just from eye balling it through the gaps between the brick and soffits. Re: The bay forming some structural strength. Do the bay windows like this one come with a flat portion on top that's built into the window when it's fitted? I forgot to add an interior image in the original post but attached it below here. In our case will each of the panes be directly fixed to the circular section above it on that interior image? Or will the bay have a flat roof section built into it? And will that circular section above it have to be removed when we replace the bay window? It looks to my eye like each pane is just fixed directly to it, but i really am not familiar with the construction of the bay windows.

-

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

Yep, I’m trying it on pump 5 for today’s tests and have rated the boiler down to 90% just to see if it helps the over shooting / taking ages to modulate down…. will do pump 0 “proportional” tomorrow. though looking at the manual again I wonder if there’s an error here. In the diagram it clearly shows that the “max” pump rate (A) is far higher than pump setting 6. Though when I ran it on 6 last time. The pump % output constantly read at 100%. So it’s just another thing I’m confused by honestly. 400mbar and 700mbar is a huuuge difference if we’re to believe this diagram. -

Hi all, Noticed something I thought was odd on our bay windows, and wanted to check for sanity. Wasn't sure if this was best in the roofing or Window sub category so will delete and re-post if this is in the wrong place, apologies if so. Anyway, Two of our ground floor bay windows are this sort of setup, where the brickwork beneath them projects out from the property with the window, but the brickwork above the bay window does not. I was looking at having the Windows,fascias and soffits replaced and on inspection earlier today I noticed the area directly above the window appears to be a recess, where the brickwork just stops. Its hard to see clearly without ripping off the soffits etc. But my question is, if I was to remove the soffits and fascias and all the little 'roof' section above the bay window here, if it was 'built' properly should I expect to see a lintel on the inner skin and the rest just solid brick work? Or is it correct to have a big recessed void between the brickwork above where the baywindow is? Tried to draw what I'm describing on my phone on the image below. Red is where the bricks carry on, blue void. Cheers Ged

-

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

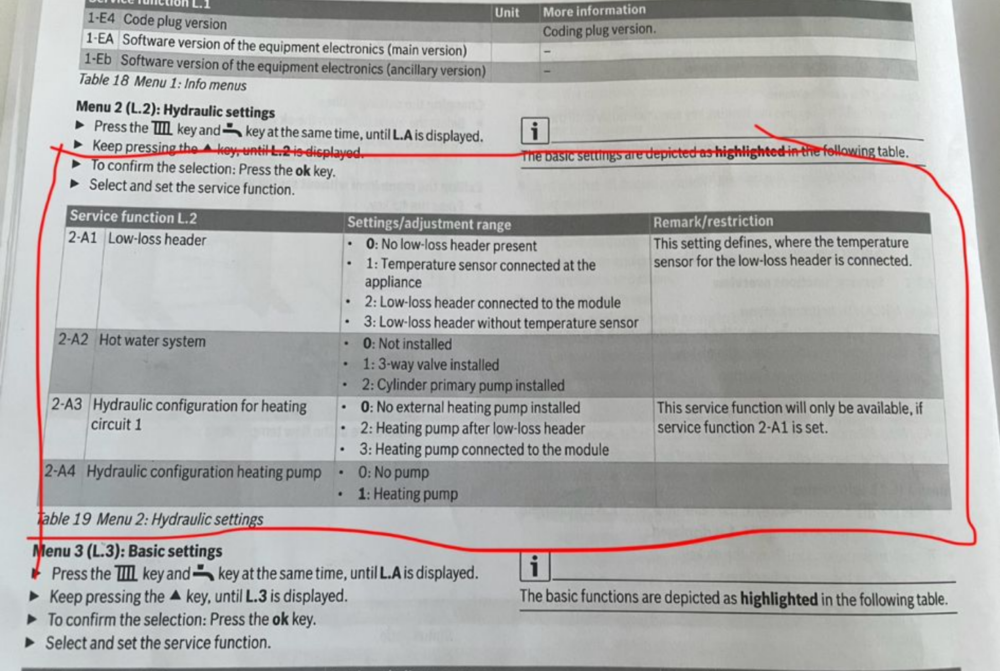

Ok, so First things first, when The boiler is set back to factory defaults, my defaults are not the same as what's in the manual. My defaults are 2-A1 = 0 2-A2 = 1 In this configuration I don't get the option for 2-A3 or 2-A4. 2-A1 makes sense, I don't have a LLH. But 2-A2 have manually set to 0 because i dont have any hot water linked up to this boiler, no cylinder, no DHW, just central heating. When I set 2-A2 to 0, Magically I get the option then of 2-A3 being available. But it only gives me the options 0 and 1 in there. Which is completely inconsistent with the manual. in the manual there isnt even an option for setting "1" in 2-A3 Also, in 2-A2, i get the options of 0, 1 or 3..... which again is inconsistent with the manual, no idea what option 3 is in 2-A2 2-A4, no matter what I set in 2-A1, A2 or A3.... I can never get 2-A4 to appear, so I simply ignore it. SO yes, its a complete and utter mess. WB have told me to just try different configurations with it. And I have. But its never made any sense to me any of this. I've tried these configs below A1 - 0 A2 - 1 ------ A1- 0 A2 - 0 A3 - 0 ------ A1-0 A2-0 A3-1 None seemed to make a massive difference. -

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

Hey guys, sorry ive been away for a few days. Yes one more update, i've been running it at different pump speeds to see which I like best. First set of data logging I tried was pump speed 6 (400mbar constant pressure). This was the setting it tripped on on Xmas day. I since tried pump speed 4 (300mbar constant pressure) it didn't trip out on this setting and didn't seem to take much longer to heat the rads up. Though the dt was 5c greater for most of the operation compared to pump speed 6. Yesterday I tried pump speed 3 (250mbar constant pressure), the flow still got to 60c in 25mins, but the radiators did take notably longer to get hot. Like a good 10-15mins longer, and even more so for the triple column ones. It did not trip out on this setting either, got to 65.5c, and modulated down at a slightly quicker rate than the tests previous. So it is still overshooting target massively, and sometimes tripping out, but mostly taking 30-45mins of time to get from its overshot of target, back to target. With regards to the L2 settings, it's a bit of a saga. I'll make a separate post of it, because its a head scratcher. Though TLDR is i've tried all the obvious configurations in there and it hasnt appeared to make too much of a difference. Will post below. -

Worcester Bosch Greenstar 8000 System Boiler Issues

EinTopaz replied to EinTopaz's topic in Boilers & Hot Water Tanks

What would be reasonable next steps then guys? get WB out again and show them that it's going way beyond target and fingers crossed I can get it to trip out on the day? As it stands they have swapped out the pump, sensors, Hex, and they did the board last Monday too. Not sure what else to do other than keep running it with slower pump speeds and seeing if that fixes anything. I have noticed a whole bunch of weird inconsistencies in the manual, particularly in the L2 hydraulic settings, the settings on my boiler are not consistent with the ones in the manual. But WB told me because i simply have flow/return/Gas and no cylinder or diverter etc, then it doesnt really matter about L2.... again not sure if im being palmed off there again or they're right on that one.